FLOWAIR sp. z o.o. / OMSAC210708EN 1

1. Introduction........................................................................................................................................................................3

Meaning of symbols ...........................................................................................................................................................3

1.1. General equipment specification...............................................................................................................................3

1.2. AURA HCS model line.................................................................................................................................................3

Use of HCS units .................................................................................................................................................................4

Basic description of the standard execution ......................................................................................................................4

Dimensions .........................................................................................................................................................................5

1.3. Used refrigerant.........................................................................................................................................................5

1.4. Legislation and security .............................................................................................................................................6

Specialized operator...........................................................................................................................................................6

Place of installation ............................................................................................................................................................7

1.5. Device identification ..................................................................................................................................................7

2. Handling and storage..........................................................................................................................................................8

2.1. Receipt of equipment ................................................................................................................................................8

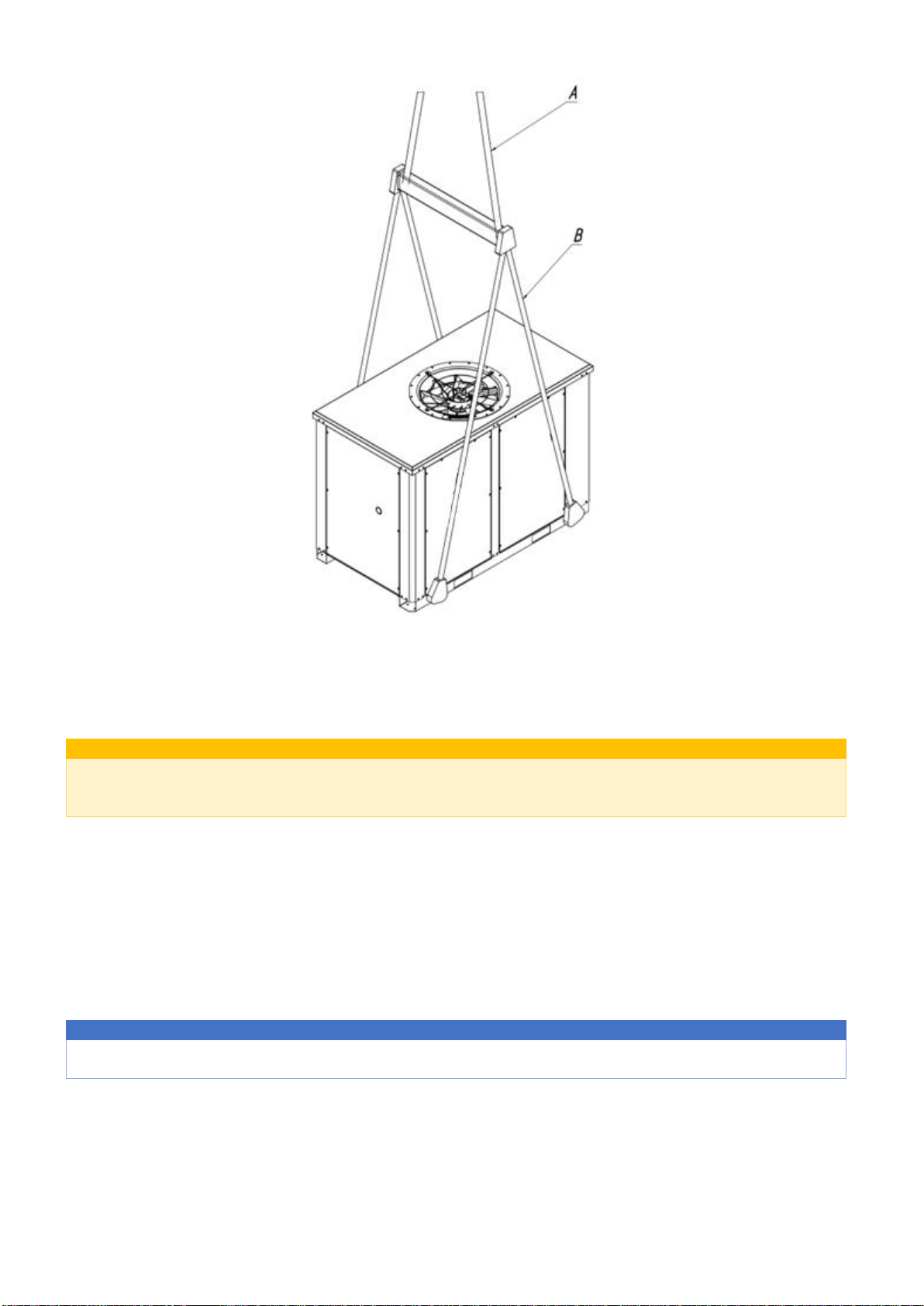

2.2. Manipulation .............................................................................................................................................................8

2.3. Storage.......................................................................................................................................................................9

3. INSTALLATION AND PREPARATION FOR COMMISSIONING..............................................................................................10

3.1. Location ...................................................................................................................................................................10

3.2. Hydraulic part ..........................................................................................................................................................12

Water treatment ..............................................................................................................................................................14

3.3. Electrical part...........................................................................................................................................................15

3.4. Cooling circuit ..........................................................................................................................................................16

4. Commissioning .................................................................................................................................................................18

4.1. Pre-commissioning inspection.................................................................................................................................18

4.2. Commissioning.........................................................................................................................................................18

Commissioning protocol...................................................................................................................................................18

Operator training..............................................................................................................................................................18

5. Operation and maintenance.............................................................................................................................................19

5.1. Principles of traffic safety ........................................................................................................................................19

5.2. Operation.................................................................................................................................................................19

Operator responsibility.....................................................................................................................................................19

5.3. Troubleshooting.......................................................................................................................................................20

5.4. Maintenance............................................................................................................................................................21

Regular service inspections ..............................................................................................................................................21

5.5. Product life cycle and disposal.................................................................................................................................22

Cooling equipment life cycle ............................................................................................................................................22

Disposal ............................................................................................................................................................................22