Fluke Calibration 5322A-LOAD User manual

PN 5006848

July 2018

©2018 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies. Specifications are subject to change without notice.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

ООО «Флюк СИА

Й

ЭС»

125167, г. Москва,

Ленинградский проспект дом 37,

корпус 9, подъезд 4, 1 этаж

1

5322A-LOAD

High Voltage Load Adapter

Instructions

Introduction

The 5322A-LOAD High Voltage Load Adapter (the

Product) loads a hipot tester to create leakage current

during hipot tester calibration with the 5322A

Multifunction Electrical Tester Calibrator (hereafter the

Calibrator). As shown in Figure 1, the Product consists

of nine power-rated resistors configured to provide

nine resistance taps from 10 kΩto 10 MΩ. Each of the

nine resistors in the Product can be put in parallel with

any other resistor. To do this, use the supplied high-

voltage jumper leads to short the resistor's red terminal

to the resistor’s corresponding black terminal.The

Product withstands a maximum voltage of 1.2 kV to

5.5 kV, depending upon the selected resistor.

HI

LO

10k 25k 50k 100k 250k 500k 1M 5M 10M

Output

Ieu004.eps

Figure 1. Load Schematic

XW Warning

To avoid possible electric shock or

personal injury, use this Product only as

specified in this Instruction Sheet or the

5322A Operators Manual.

How to Contact Fluke Calibration

To contact Fluke Calibration, call one of the following

telephone numbers:

•Technical Support USA: 1-877-355-3225

•Calibration/Repair USA: 1-877-355-3225

•Canada: 1-800-36-FLUKE (1-800-363-5853)

•Europe: +31-40-2675-200

•Japan: +81-3-6714-3114

•Singapore: +65-6799-5566

•China: +86-400-810-3435

•Brazil: +55-11-3759-7600

•Anywhere in the world: +1-425-446-6110

To see product information and download the latest

manual supplements, visit Fluke Calibration’s website

at www.flukecal.com.

To register your product, visit

http://flukecal.com/register-product.

5322A-LOAD

Instructions

2

Symbols

The symbols used in these instructions and on

the Product are shown in Table 1.

Table 1. Symbols

Symbol Description

XWARNING. HAZARDOUS VOLTAGE. Risk

of electric shock.

WWARNING.RISK OF DANGER. Risk of

electric shock.

Consult user documentation.

)Certified by CSA Group to North American

safety standards.

PConforms to European Union directives.

Conforms to relevant Australian Safety and

EMC standards.

AC (Alternating Current)

.Protective conductor terminal

Earth

Fuse

Conforms to relevant South Korean EMC

Standards.

~

This product complies with the WEEE

Directive marking requirements. The affixed

label indicates that you must not discard this

electrical/electronic product in domestic

household waste. Product Category: With

reference to the equipment types in the

WEEE Directive Annex I, this product is

classed as category 9 "Monitoring and

Control Instrumentation" product. Do not

dispose of this product as unsorted

municipal waste.

Preparing for Operation

The Product (see Figure 2) comes with a power line

adapter (to run the cooling fans), a ground cable, three

shorting cables, and these instructions.

The power line adapter comes with five mains plug

adapters that are compatible with different power plug

configurations.

Prior to use:

1. Select the appropriate plug adapter that matches

the local power mains outlet.

2. Attach the plug to the power line adapter. The

power line adapter is now ready for use with the

Product.

3. Once you place the Product on top of the

Calibrator, connect the grounding cable between

the Product’s rear-panel ground terminal and the

rear-panel ground terminal of the Calibrator. See

the grounding cable connection in Figure 3 where

the rear of the Product is shown.

XW Warning

To prevent possible electrical shock, fire,

or personal injury:

•Make sure that the ground terminal on

the rear of the Product is connected to

the ground (GND) terminal on the rear

of the Calibrator. Any application with

non-grounded housing is strictly

prohibited.

•Use only the shrouded high-voltage

banana plug jumpers that are supplied

with this Product to connect resistor

values. Connect the black terminal first

and disconnect the black terminal last

when you connect resistors.

High Voltage Load Adapter

Preparing for Operation

3

WCaution

To prevent damage to the Product, make

sure that the vents on the bottom of the

Product and the fan exhaust vents are

clear of obstructions for proper cooling.

Connect one end of the power line adapter to the

mating power input connector socket on the rear panel

of the Product and the other end to the mains power

outlet.

WCaution

Failure to have the fans operating may

lead to over heating and component

failure.

Push the rear-panel switch to the “I” side of the switch

to turn on the cooling fans. A light on the front panel

illuminates and indicates that power is on. Turn off the

power switch when the Product is no longer being

used.

Ieu001.eps

Figure 2. 5322A-LOAD Front Panel

PROTECTIVE

EARTH (GROUND)

POWER INPUT

12V

10 VA MAX.

NO USER SERVICEABLE PARTS CONTAINED WITHIN.

HAZARDOUS VOLTAGES PRESENT. DO NOT REMOVE COVERS.

SAFETY WARNING

DISCONNECT POWER AND SIGNAL LEADS

BEFORE SERVICING.

READ MANUAL BEFORE USE.

REFER SERVICETO QUALIFIED PERSONNEL.

FLUKE CORPORATION

www.fluke.com

DURING USE,

TERMINAL MUST BE

CONNECTED TO THE

PROTECTIVE EARTH

OF THE 5320A

Rear

Ground Cable

USB

ehq101.eps

Figure 3. Grounding Cable Connection

5322A-LOAD

Instructions

4

Use the Load for Leakage Current

Tests

Select the load resistor based on the appropriate

voltage amplitude for the test or the value

recommended in the hipot tester’s calibration

procedure. A load resistor is connected to the Output

terminals when a resistor's red and black terminals

are shorted together using a high-voltage shrouded

banana jumper lead.

See Paralleling Resistors for making additional

resistance values. See the 5322A Operators Manual

for more detailed application information.

WCaution

To avoid damage, never exceed the

maximum rated voltage, power, and

current limit of the Product.

Usage Limits for Safe Operation for Each

Load Resistor

Safe operation of the Product depends on the amount

of voltage and the length of time it is applied to the

Product. For the 10 kΩ, 35 kΩ, 50 kΩ, 100 kΩ, and

250 kΩresistors, there are time limits where the

higher-voltage levels can be safely applied. This is

graphically shown in Figure 4 for the 10k, 25k, 50k,

100k, and 250k resistors.The maximum voltages can

be applied for up to 3 minutes for these resistors. Due

to self heating, exceeding the 3-minute limit for high

voltages can cause both degradation of performance

and a permanent shift in the resistor value. However,

reduced-voltage levels can be safely applied for

increasing longer times. At specific levels, sustained

voltages can be applied indefinitely. The other

resistors (500k, 1M, 5M and 10M) do not have a time

limit for the maximum voltage (5500V). See Figure 4.

Safe Area

0

1000

2000

3000

4000

5000

6000

110100

Time (min)

Voltage (V)

250 k

100 k

35k/50k

10k

ehq101.eps

Figure 4. Safe Area Chart

Example

The 100 kΩresistor can withstand 5500 V for

3 minutes while it can withstand 4000 V for

60 minutes or longer.

Paralleling Resistors

The Product can output additional values by placing

combinations of the nine resistors in parallel as shown

in Table 2.

To place resistors in parallel, short together

combinations of the given resistors’ red and black

terminals using the supplied high-voltage shrouded

banana jumper leads. For example, to parallel the

10 kΩand 25 kΩresistors, short the 10 kΩred and

black terminals, and the 25 kΩred and black

terminals. This places these two resistors in parallel at

the Product Output terminals. The resultant output is

7.14 kΩ, for a 70 mA leakage current at 500 V, as

shown in Table 2.

In Figure 5, the 10k Ohm, 25k Ohm, and 50k Ohm

resistors are in parallel, giving an output of 6.25 kΩ.

HiPot

Tes te r

Ieu003.eps

Figure 5. Leakage Current Test Connection

The maximum applicable working voltage for parallel

combinations is the maximum voltage of the resistor

with the lowest voltage rating.

WCaution

Do not exceed the specified

voltage limits of any given

resistor.

High Voltage Load Adapter

Paralleling Resistors

5

Example

To set up a leakage current of 3 mA at a test voltage

of 1000 V, find the row in Table 2 for 3 mA and then

select the desired test voltage. For 1000 V, parallel

the 500 kΩand 1 MΩresistors to make a 333.33 kΩ

output.

Table 2. Parallel Combination of Resistors Versus Voltage Versus Current

Current

(mA) 500 V 1000 V 2000 V 5000 V

0.05 10M - - -

0.1 5M 10M - -

0.2 - 5M 10M -

0.3 - 5M, 10M - -

0.4 - - 5M -

0.5 1M - - 10M

0.6 1M,5M - 5M, 10M -

1 500k 1M - 5M

1.5 500k, 1M - - 5M, 10M

2 250k 500k 1M -

2.5 250k, 1M - - -

3 250k, 500k 500k, 1M - -

4 - 250k 500k -

5 100k 250k, 1M - 1M

6 100k,500k 250k, 500k 500k, 1M 1M, 5M

7 100k, 250k 250k, 500k, 1M - -

8 100k, 250k, 500k - 250k -

10 50k 100k 250k, 1M 500k

12 - 100k,500k 250k, 500k -

14 - - 250k, 500k, 1M -

15 50k, 100k - - 500k, 1M

16 - 100k, 250k, 500k - -

20 25k 50k - -

30 25k, 50k 50k, 100k - -

50 10k - - -

70 10k, 25k - - -

80 10k, 25k, 50k - - -

5322A-LOAD

Instructions

6

Performance and Verification Test

With normal operation, verify the resistance values of

the Product at least once per year. Also, verify the

load resistor if there is a possibility of the resistance

values changing due to excessive heating or power

dissipation.

To verify the electrical performance of the Product,

use one of these test methods to ensure the load

resistors are within specification:

•Voltage Test Method - Use voltage and current

levels that ensure that the resistors dissipate a

reasonable power as they are verified.

•Mutlimeter Test Method - Use a multimeter to

measure the load resistance.

Both methods check to see if it is within 10 % of the

nominal value. The multimeter test uses minimal

voltage and current levels, dissipating negligible

power when measuring the resistance values of the

load resistance.

Either test method can be used, but Fluke Calibration

recommends the voltage method as it verifies the

resistance value while the resistor disipates actual

power – similar to the normal usage of the Product.

The voltage method signal levels are based on

capabilities of the recommended voltage calibrators.

These levels use voltages up to 1 kV. It is possible

and acceptable to test using other sources to test at

higher voltages, but staying within the limits of the

Product’s safe area of operation.

Table 3 lists the load resistance nominal value for

each load resistor terminal.

To use the voltage test method, apply a test voltage

across each resistance, between the respective input

and COM terminals. The resulting current through the

resistor is measured, and the value of the resistance

is calculated. Use a calibrator as the precision-voltage

source. Use a multimeter to measure the current.

Figure 6 shows the test equipment setup. Refer to

Table 3 for the respective sourced voltage level

settings and the nominal currents to be measured.

Note

Fluke Calibration recommends a Fluke

5520A or 5500A Calibrator as a source

for the voltage method due to its output

voltage/current capabilities. Fluke

Calibration recommends a Fluke

8845A Digital Multimeter (or

equivalent) for measurements with

either test method.

For the voltage test method, test each resistor as

follows:

1. Apply the recommended voltage (Vs) at power

mains frequency (either 50 Hz or 60 Hz) between

the terminal for the resistor being measured and

the COM terminal.

2. Measure the current (Im) flowing through the load.

3. Calculate the resistance (RL) by dividing the

sourced voltage by the measured current

(RL=Vs/Im).

The calculated resistance should be within 10 % of

the nominal resistance value found in Table 3.

Repeat steps 1 through 3 for each load resistor

terminal and adjust the applied voltage per Table 3.

For the alternative multimeter test method, measure

each resistor as follows:

1. Place the probes of a multimeter between the

selected resistor input (red) terminal and the COM

terminal.

2. Read the measured resistor using the resistance

mode of the multimeter, and note the value.

3. Ensure the measured value is within 10 % of the

nominal resistance.

Repeat steps 1 through 3 for each load resistor

terminal per Table 3.

High Voltage Load Adapter

Performance and Verification Test

7

POWER

I

O

0•

123

456

789

ENTER

M

k

mVHz

FIELD

EDIT

/

+

F

OPR EARTH EXGRD SCOPE MENU

PREV

SHIFT

RESET

CE

SETUP

REF

NEW

TC

MEAS

¡F

µ

n

p

W

dBm sec

¡CA

MULT

x

DIV

÷

MODES

MORE

STBY

HI

LO

TRIG

GUARD

TC

20A

NORMAL AUX

5520A CALIBRATOR

SCOPE

OUT

V, , ,RTD A, -SENSE, AUX V

20V PK MAX

20V PK MAX

5320A-LOAD

1200V MAX

140 W MA X

2000V MAX

110 W M AX

2000V MAX

80W MAX

5500V MAX

300W MAX

5500V MAX

120 W MAX

5500V MAX

60W MAX

5500V MAX

30W MAX

5500V MAX

6 W MAX

COM

10 k 35k 500k 1M50k 100 k 250k 5M

100 m A 40 mA 10 mA 4 mA 1mA

POWER

20 V MAX

8846A

6-1/2 DIGIT PRECISION MULTIMETER

0.20100 mA~

DCV ACV DC I ACI TRIG

FREQ

PERIOD

TEMP ZERO

INSTR

SETUP

MEAS

SETUP

RANGE

F1 F2 F3 F4 F5

BACK

MEMORY

ANALYZE

INPUT SENSE

HI

LO

FRONT

REAR

10 A

1V

400

mA

4

W

HI

LO

2W/4W

V

300V

FUSED

1000V CAT I

600V CAT II

Ieu002.eps

Figure 6. Test Equipment Connections for Voltage Test Method

Table 3. 5322-LOAD Resistance Verification Values

Nominal

Resistance

Value

Voltage Method – Verifying the Load Resistances while under Power Alternative DMM

Verification

Method

Externally

Applied Test

Voltage at

mains

Frequency

Nominally

Required Test

Current

Measured

Current

Calculated

Resistance

RL=Vs/Im

(±10 % of nominal)

Measured

Resistance

(±10 % of nominal)

10 kΩ200 V ac 20 mA

25 kΩ315 V ac 9 mA

50 kΩ300 V ac 6 mA

100 kΩ600 V ac 6 mA

250 kΩ1000 V ac 4 mA

500 kΩ1000 V ac 2 mA

1 MΩ1000 V ac 1 mA

5 MΩ1000 V ac 0.2 mA

10 MΩ1000 V ac 0.1 mA

5322A-LOAD

Instructions

8

Replaceable Parts

Table 4 lists the replaceable parts for the Product.

Table 4. Replaceable Parts

Description Fluke PN

POWER ADAPTER 100-240V AC, 12 V DC, with five plug adapters 3132484

GROUNDING CABLE 3132491

TEST LEAD, HIGH VOLTAGE, BANANA, 25 cm set of 3 (RED) 5006907

General Specifications

Power supply voltage.............................................. AC adapter 100-240 V, output voltage 12 V @ 0.4 amps min.

Warm-up time ......................................................... Not applicable

Specifications confidence level............................... 99 %

Temperature

Operating Temperature .......................................... 5 °C to 40 °C

Recommended Calibration Temperature (Tcal) ..... 23 °C

Storage Temperature.............................................. -20 °C to +70 °C

Altitude, Maximum

Operating................................................................ 3 050 m (10 000 ft)

Storage ................................................................... 12 200 m (40 000 ft)

Dimensions............................................................. 430 mm X 462 mm X 95 mm (16.9 in X 18.2 in X 3.7 in)

Weight (net) ............................................................ 3 kg (8 lb 4.5 oz)

Power Consumption ............................................... 5 W maximum

Safety class ............................................................ I according to EN 61010-1

Electrical Specifications

Total resistance range .................................................. 10 kΩto 10 MΩ

Number of specific resistance values........................... 9

Tolerance to Nominal Value ......................................... 10 % (One year, Tcal ±5 °C)

Maximum Ratings

Nominal Value Max. Voltage Max. Dissipation Power Max. Time at Maximum Power

10 kΩ1200 V 140 W Limited to 3 minutes (see Figure 4)

35 kΩ2000 V 110 W Limited to 3 minutes (see Figure 4)

50 kΩ2000 V 80 W Limited to 3 minutes (see Figure 4)

100 kΩ5500 V 300 W Limited to 3 minutes (see Figure 4)

250 kΩ5500 V 120 W Limited to 3 minutes (see Figure 4)

500 kΩ5500 V 60 W No limit

1 MΩ5500 V 30 W No limit

5 MΩ5500 V 5 W No limit

10 MΩ5500 V 3 W No limit

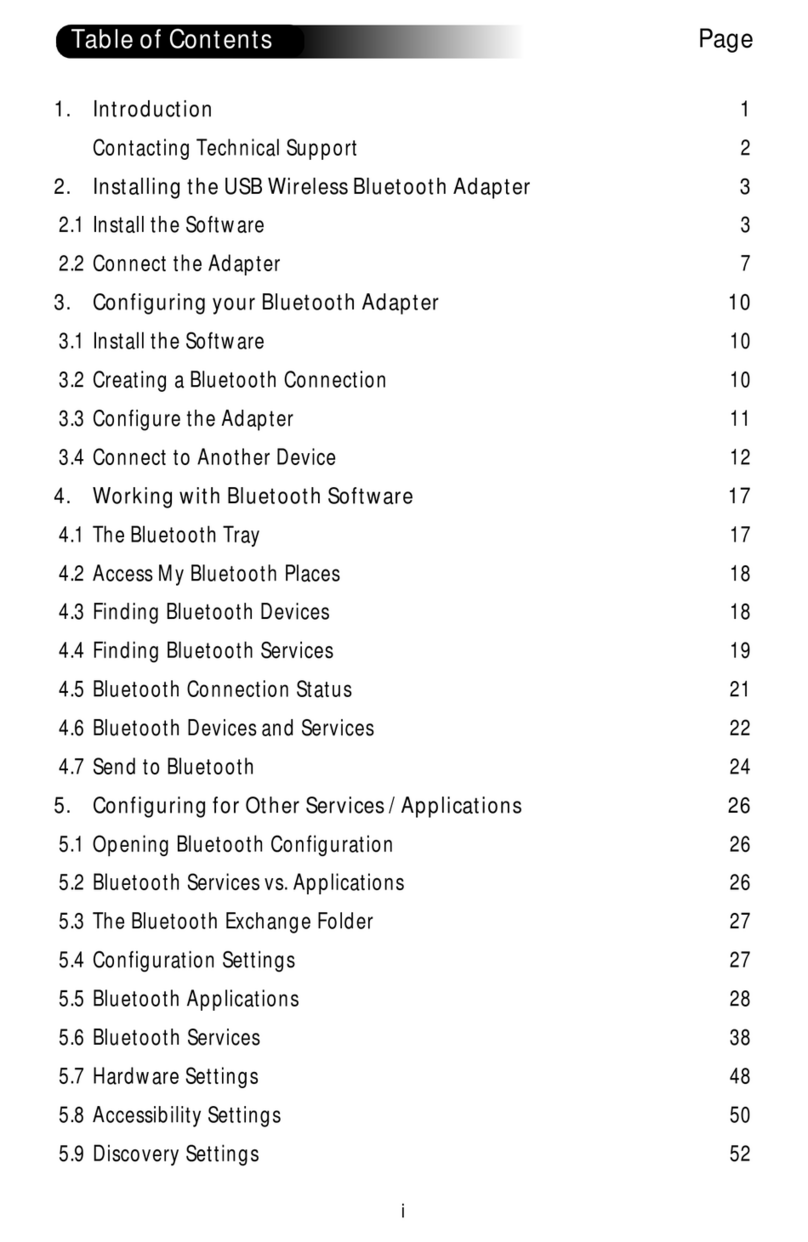

Table of contents