Flying Penguin RC FPRC Zero User manual

E

Estim

a

W

T

Flyi

F

P

Bramp

t

www.f

l

flyingp

e

Sp

e

WingSpan

Fuselagele

n

mptyWeigh

t

a

tedFlying

W

W

ingArea:1

5

T

ransmitter:

4

ng

P

P

RC

t

on,Ontari

o

l

yingpengui

n

e

nguin@liv

e

e

cification

s

–42.75”(10

n

gth–30.5”(

t

–9.5‐10oz.

W

eight–20‐2

5

5

1sq.Inch(9

4

or5channe

P

eng

u

ZE

R

o

Canada

n

rc.com

e

.ca

s

85mm)

775mm)

(150‐160g)

5

oz.(320‐40

0

75sq.cm)

lwithflaps

u

in

R

R

O

0

g)

R

C

1|Page

INTRODUCTION

Introduction…………………………………………….…...1

Electronics&hardware…………………………..….…2

BuildingMaterials………………………………………...2

Tools……………………………………………………………..2

Assemblyinstructions

1.PowerCoreBaseAssembly…………………….….2

2.RearFuselageFrame………………..……….………7

3.CompleteFuselageFrame………….…..…..……..8

4.Hardwareinstallation………………………….…..11

5.FuselageCover………………………………………..13

6.FrontAccessCover...………………………….…….19

7.CanopyCover.………………….………………….…..21

8.Wings………………………………………………..…….25

9.Rudder/TailWing………………………………..…33

10.WingReinforcement………………………..……35

11.FitRudder/TailWing……………………..…….36

12.AirScoop/Rearpanels………………………….36

13.LandingGearOption……………..…..…………..38

14.FinalConnections………..…………………………39

PartsIndex………………….……………………………….40

1.YourFPRCZeroshouldnotbeconsidereda

toy,butratherasophisticated,workingmodel

thatfunctionsverymuchlikeafull‐sizeairplane.

AlthoughtheFPRCZEROisalight‐weight

model,justthesameasanyR/Cplane,itshould

stillbeflownwithcare.Evenwhileglidingat

slowspeeds,theFPRCZEROcouldpossibly

causeinjurytoyourselforspectatorsand

damageproperty.Ultimately,itisthe

modeller’sresponsibilitytoselectasuitable,

safeflyingarea.

2.YoumustassembletheFPRCZEROaccording

totheinstructions.Donotalterormodifythe

model,asdoingsomayresultinanunsafeor

unflyablemodel.

3.Bepatient.Youmusttakethetimetobuild

straight,trueandstrong.

4.YoumustuseanR/Cradiosystemthatisin

excellentcondition.

5.YoumustcorrectlyinstallallR/Candother

componentssothatthemodeloperates

correctlyonthegroundandintheair.

6.Youmustchecktheoperationofthemodel

beforeeveryflighttoinsurethatallequipment

isoperatingandthatthemodelhasremained

structurallysound.Besuretocheckconnections

oftenandreplacethemiftheyshowsignsof

wearorfatigue.

7.IfyouarenotalreadyanexperiencedR/C

pilot,youshouldflythemodelonlywiththe

helpofacompetent,experiencedR/Cpilot.

Remember:Takeyourtimeandfollowthe

instructionstoendupwithawell‐builtmodel

Thatisstraightandtrue.

Ifyouhavenotflownthistypeofmodelbefore,

werecommendthatyougettheassistanceof

anexperiencedpilotinyourR/Cclubforyour

firstflights.Ifyou’renotamemberofanR/C

club,yourlocalhobbyshophasinformation

aboutclubsinyourareawhosemembership

Includesexperiencedpilots.

CONTENTS

NOTE:

We, as the model designer, provide you

with top quality plans and detailed

instructions, but ultimately the quality of

your finished model depends on how you

build it; therefore, we cannot in any way

guarantee the performance of your

completed model, and no representations

are expressed or implied as to the

performance or safety of your completed

model.

2|Page

‐Motor:1200kv/250wbrushlesselectric

‐ESC:25ampbrushlessspeedcontroller

‐Battery:2200mAh3S11.1VLipoPack

‐Servos:(4x)9‐10gramdigitalmicroservos

‐Propeller:8x6Eor9x6E

‐ControlHorns(x4)

‐PushRods:1mmpianowire.(2x16”&2x3.5”)

‐Four(4x)sheetsfoamboard/foamcoreboard

3/16”x20”x30”(5x510x760mm)

‐One(1x)sheetposterboard

‐1/8”hobbyplywood

‐Two(2x)wooddowels.1/8”diameter,5”long.

‐PopsicleSticks

‐Velcroorrareearthmagnets

‐3/16”dia.orsquarecarbontube(optional)

‐X‐Actoknife&replacementblades

‐Utilityknife&replacementblades

‐Metalrulerorstraightedge

‐HotgluegunorCAAdhesive

‐Penorpencil

‐Drillandsmallwoodbits

‐ClearPackingTape

‐SmallScrewdrivers

Partsrequired:1‐5

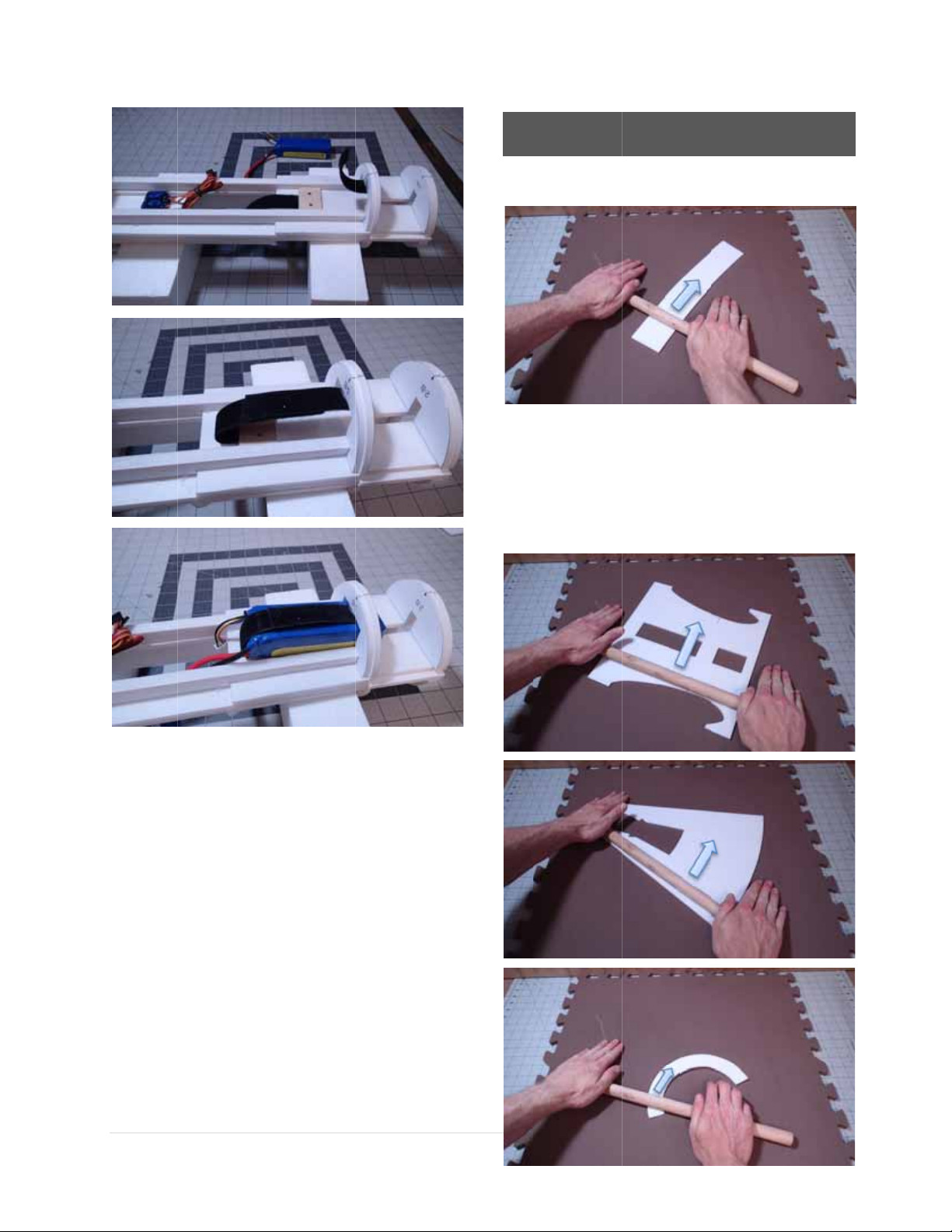

1.Startwithpowercorebase(1)flatontable.

2.Applyathinlayerofwhiteschoolglueor

multi‐purposecraftgluetoshadedsurfaceas

shownabove.

3.Foldtopsurfaceover.Applingevenpressure,

holddownuntildry.

ElectronicsandHardware

BuildingMaterials

Tools

ASSEMBLYINSTRUCTIONS

1.POWERCOREBASE

ASSEMBLY

ADDITIONALREQUIREDITEMS

3|Page

4.Repeatsteps2and3forbottomsurface.

5.Nextwecancombineparts(2A‐2A)and

(2B‐2B).First,useapenorpenciltomarkthe

centerontheedgeasshownabove.Thiswill

helpustoalignthefuselagecoverlater.

6.Applyathinlayerofwhiteschoolglueor

multi‐purposecraftgluetoshadedsurfaceas

shownabove.Combineparts(2A),asthetwo

partsareidenticalalledgeswillalign.

7.Repeatsteps5and6for(2B).

4|Page

8.Repeatsteps5and6for(4A‐5A)and(4B‐5B).

Applygluetoframesection(5)firstthen

combinewith(4).

9.Framesections(5)areslightlysmallerthan

framesections(4)soalignthepartswiththe

squareopeningandbottomedge.

10.Preparepart(3).Removefoambetween

50%cutlinesleavingpaperonoppositeside.A

smallflattopscrewdriverisgoodforthis.

11.Placeabeadofglueinthespaceasshown

above.Foldthesidesothatitrestontopofthe

Adjacentsurface.

12.Repeatstep11fortheotherside.

5|Page

13.Nextwecancombineparts(1‐5)

14.Placeabeadofgluealongthetop/front

edgeofthepowercorebase(1).

15.Attachframesection(2A)topowercore

base(1).Alignwithfrontedgeandcenter.Make

sureframesection(2A)is90°topowercore

base(1),holduntildry.

16.Applygluetofrontedgeandbottomedges

ofpart(3)asshownabove.

17.Attachpart(3)totopofpowercorebase(1)

andtobackofframesection(2A)asshown

above.Aligntheinsidewallsofpart(3)withthe

squareopeninginfrontofframesection(2A).

6|Page

18.Applygluetobottomofframesections

(4A/5A)andtothebackedgesofpart(3)as

shownabove.Attachframesection(4A/5A)to

topofpowercorebase(1)withframesection

(5A)facingback.Alignwithsquareopeningin

part(3)andsidesofpowercorebase(1).

19.Applygluetobottomedgeofframesection

(2B).Attachtobottomofpowercorebase(1)as

shownabove.Alignwithfrontedgeandcenter.

Makesureframesection(2B)is90°topower

corebase(1),holduntildry.

20.Applygluetobottomedgeofframesection

(4B/5B).Attachtobottomofpowercorebase

(1)withframesection(5B)facingbackasshown

above.Viewfromthesideandalignwithframe

section(4A/5A)ontop.Makesureframe

section(4B/5B)is90°topowercorebase(1),

holduntildry.

7|Page

Partsrequired:6‐10

21.Applyathinlayerofwhiteschoolglueor

multi‐purposecraftgluetoonesideofframe

section(6).Combineparts(6),asthetwoparts

areidenticalalledgeswillalign

22.Usearulerandpenorpenciltocreatea

centerlineononesideofframesection(6).

Thissidewillfacethefrontoftheframe.

23.Applyasmallamountofglueoverthetab

slotinsideframe(7)asshownabove.Insert

framesection(6)withcenterlinefacingthe

front.

24.Repeatstep23forframesection(8).

2.REARFUSELAGEFRAME

8|Page

25.Applyasmallamountofglueintabslotsin

framesections(6)and(8)andtobackedgeof

sideframe(7)asshownabove.Insertsecond

sideframe(7)intoframesection(6)and(8).

26.Applyasmallamountofglueonthetop

centerofframesections(6)and(8)asshown

above.Insertframesupport(9)betweenframe

sections(6)and(8).

27.Repeatsteps26forframesupport(10)on

thebottomofframebetweenframesections

(6)and(8)asshownabove.

Partsrequired:powercorebaseassembly(1‐5),

rearfuselageframe(6‐10)andparts11‐14.

`

28.Applygluetoeachsideoftheslotinthe

backofthepowercorebase(1)aboutthewidth

ofthesideframe(7)asshownabove.

3.COMPLETEFUSELAGEFRAME

9|Page

29.Insertendsofsideframes(7)intoslotatthe

backofthepowercorebase(1).Makesurethe

powercorebaseandrearframetop/bottomis

orientedcorrectly.

Tip:Afoamblockcanbeusedtosteadythe

framefortherestofthebuildprocess.

30.Applygluetothebottomedgeofframe

section(11)andtobackedgeofpowercore

base(1)abovesideframes(7)asshownabove.

31.Framesection(11)shouldrestontopofside

frame(7)andbesidebackofpowercorebase

(1)andalignedwithedgeofsideframe(7).

32.Placeabeadofgluealongtheedgesof

servoplate(12)andacrossframesection(6)as

shownabove.Centerservoplate(12)with

framesection(6).

10|Page

33.Placeabeadofgluealongthebottomand

onesideedgeofframesupport(13)andside

frame(11)asshownabove.Inserttheframe

support(13)betweenframesection(11)&(6).

34.Repeatstep33forsecondframesupport

(13)tooppositesideasshownabove.

35.Preparebottomframesupports(14).Fold

partoveratthe50%cutasshownabove.Apply

gluetoinsideofframesupport(14)asshown

above.Placeflatontableandapplyalittle

downpressureuntildry,repeatforsecond

framesupport(14).

36.Testfitbatterybeforemovingtonextstep.

Enlargebatteryopeningifnecessaryandusea

penciltotracethesidesofthebatteryon

bottomofpowercorebase(1)forreference.

11|Page

37.Placeabeadofgluealongthetopofframe

support(14)andonthesideofframesection

(5B)asshownabove.Insertframesupport(14)

betweenframesections(5B)and(6).

38.Repeatstep37forsecondframesupport

(14)onoppositeside.

39.Placeasmallbeadofglueofonesideof

servoandattachsecondservofacingopposite

directionasshownabove.

40.Placeservowiresthroughopeninginservo

plate(12).Applyasmallamountofgluetothe

bottomoftheservotabsoneachsideofservos.

5.HARDWAREINSTALLATION

12|Page

41.Insertservosintoservoplate(12)asshown

above.

42.Gluetwostrawsbetweensmallholesin

framesections(6)and(8)asshownabove.

Thesewillhelpguidethecontrolrodtothe

servoslaterinthebuild.

43.Use1/8”hobbyplywoodoroldplasticgift

cardstocreatereinforcementplatesforthe

powercorelockingholes.

44.Gluethereinforcementplatestothetop

andbottomofthepowercorebase(1)as

shownabove.

45.Testfitbatteryandmarklocationofrearof

batteryonbottomofpowercorebase(1).

13|Pa

g

46.Glue

V

andtoun

section(

5

batteryh

a

duringfli

g

g

e

V

elcrostrips

t

dersideofsq

5

B)asshown

a

rnesstohol

d

g

ht.

t

opowercor

e

uareopenin

g

above.This

w

d

thebattery

e

base(1)

g

inframe

w

illcreatea

inplace

Part

s

47.

P

Lay

t

cou

c

pin

r

inth

s

required1

5

P

reparethef

u

t

hepartsflat

c

hcushionw

o

r

ollacrossth

e

h

efoamassh

5.F

U

5

‐19

u

selagecove

r

onapieceo

f

o

rksbest)an

d

e

parttocrea

ownabovea

U

SELAGE

r

parts(15‐1

9

f

foam.(Afla

t

d

usingarolli

teanatural

c

ndbelow.

COVER

9

).

t

ng

c

urve

14|Page

48.Allfuselagecoverpartsshouldnowhavea

naturalcurveasshownabove.Thiswillmake

fittingoverthefuselageframemucheasier.

49.Dryfitfuselagecover(15)andmarkthe

endsatthebottomcenterandtrimifrequired.

50.Trimeachedgetocreateasnugfit.

15|Page

51.Applyasmallbeadofglueonthecenter/top

offramesections(2A)and(4A)asshownabove.

52.Centerthefuselagecover(15)between

framesections(2A)and(4A)andalignwith

frontasshownabove.Makesurethelonger

sideoffuselagecover(15)facestheback.

53.Togluetheframecover(15)totheframe

startwithoneside.Applygluetothetopedges

offramesection(2A)and(4A)andalongthe

sideedgeofthepowercorebase(1)asshown

above.Holdthefuselagecover(15)inplaceand

holduntildry.

54.Completethesidebyapplyinggluetothe

bottomsideedgesofframesections(2B)and

(4B)asshownabove.Holdthefuselagecover

(15)inplaceandholduntildry.

55.Nowmovetotheoppositesideandrepeat

theprocess.Startwiththetop,applyingglueto

theframesectionsandalongpowercorebase.

Foldoverandholduntildry.

56.Finishthebottomarea.Applygluetothe

sideframesandfuselagesection(15)edgeas

shownabove.Foldoverandholduntildry.

16|Page

FinishedFrontFuselageCover(15)

57.Nextwecanattachthecenterfuselage

cover(16).Usingthepreviousprocess;dryfit

first,trim(ifrequired),centerandgluetotopof

framesections.

58.Startwithonesideandgluethefronthalfof

thefuselagecoverfirst.Applygluetoedgeof

framesection(5A)andalongthesideframeas

shownabove.Foldoverandholduntildry.

59.Finishthebottomarea.Applygluetothe

sideedgeofframesection(5B)asshownabove.

Foldoverandholduntildry.

60.Repeatsteps58‐59tofinishthefronthalfof

fuselagecover(16).

61.Next,applygluetothesideofframesection

(6)andalongthesideframeasshownabove.

Foldoverandholduntildry.

17|Page

62.Finishthesidebyapplyinggluetotheside

edgeofframesection(6)asshownabove.Fold

overandholduntildry.

63.Repeatsteps61‐62tofinishthebackhalfof

fuselagecover(16).

64.Applygluetoonesideofsupportpart(17)

andinsertinsidefuselageasshownabove.

Centerwithfuselagecover(16)andrepeatfor

theotherside.

Thiswillhelptostrengthentheareawherewe

willinstallawooddowelforsecuringthewing.

65.Repeattheprocessforrearfuselagecover

(18).Dryfitfirst,trim(ifrequired),centerand

gluetotopofframe.

66.Doonesideatatime.Fronthalffirst,

startingwithtoparea.

18|Page

67.Gluethebottomareaofthefronthalffirst.

68.Placeasmallbeadofglueononeedgeof

thebottom/backoffuselagecover(18).Hold

togetheruntildry.Wipeaccessglueawaywitha

pieceofscrapfoam.

69.Applyabeadofgluealongthebackedgeof

thesideframeasshownabove.Holdthe

fuselagecovertotheframeuntildry.Repeatfor

theotherside.

70.Sandtheouteredgeofthenosefuselage

cover(19)toabevelshape.

Thebevelshapewillallowthecovertofitflush

tothefrontedgewhencurved.

71.Startatthetopapplyingasmallamountof

gluetothefrontedgeandusetheprocesswe

usedfortheotherfuselagecovers.Workyour

wayaroundaboutanincheachtime.

19|Page

Completedfrontfuselage

Completedrearfuselage

Completedsideandbottomviewoffuselage.

Partsrequired20‐22

72.Drawacenterlineonthesidesofcover

frame(21)andonthebottomofcover(22).

Measure3/4”or19mmfromthefrontedgeand

makeamarkasshownabove.Rollthecover

(22)aswedidforthefuselagecoverstocreate

anaturalcurve.

6.FRONTACCESSCOVER

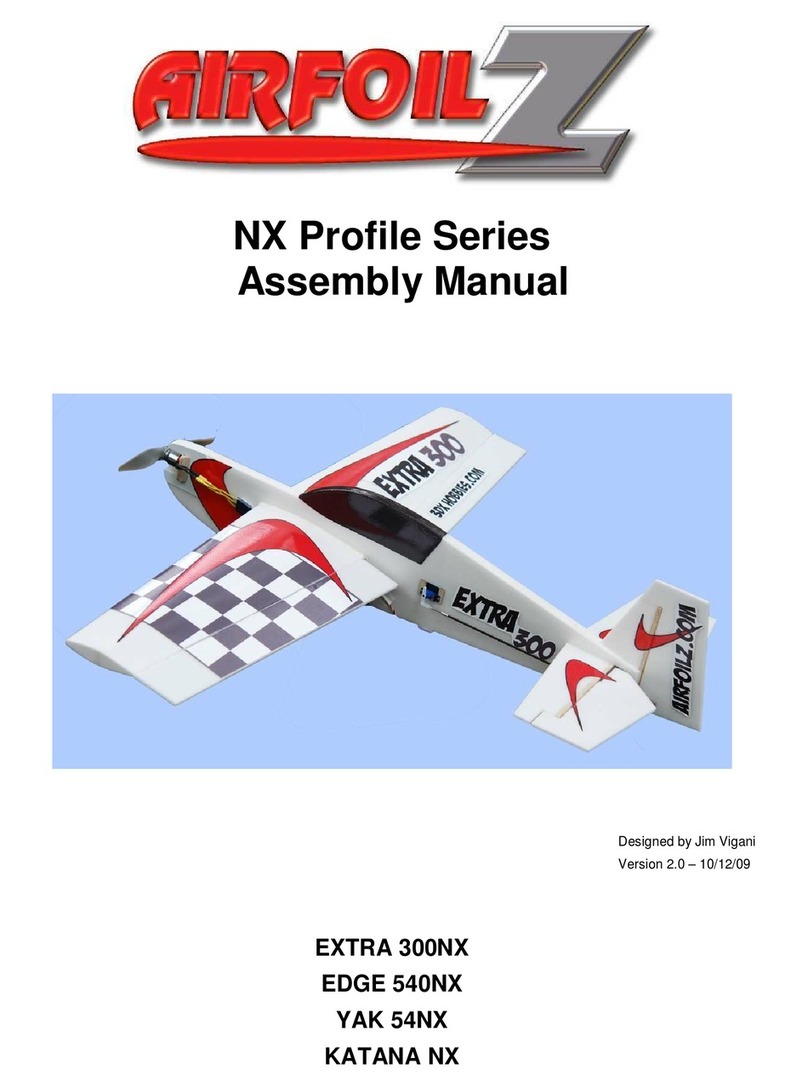

Table of contents

Popular Toy manuals by other brands

MGA Entertainment

MGA Entertainment Little Tikes My First Mighty Blasters POWER... manual

Tamiya

Tamiya Lockheed P-38 F/G Lightning manual

Faller

Faller OCHSENHAUSEN STATION manual

RC Factory

RC Factory Flash 3D aerobatic EPP Building instructions

E-FLITE

E-FLITE Sukhoi SU-26m 480 Assembly manual

Mega Bloks

Mega Bloks Collector Series instructions