flying Thinz Mad 3D Taco User manual

Mad 3D Taco

An All Out 3D Fun Fly Plane

The FlyingThingZ Mad 3D Taco is a fun 3D aerobatic park flyer’s dream. This is a high performance

electric R/C airplane designed for all out 3D aerobatics using inexpensive power systems such as the

GWS EPS350D motor/gearbox combos.

Utilizing space age materials such as depron and carbon fiber, simple construction methods, and

adding small but powerful electric drive systems, you'll get a spectacular performing electric R/C park

flyer airplane capable of performing 3D maneuvers previously only expected from much larger and

more expensive glow or gas models. Torque rolls with easy; knife edge and harrier right on the deck;

upright or inverted flat spins; If you can dream it up, the FlyingThingZ Mad3D Taco can do it.

All parts are laser cut with the utmost precision which makes assembly a snap. No special tools are

required for alignment, all the parts fall together effortlessly. The Mad 3D Taco could easily be assem-

bled within 3 to 5 hours.

Copyright © 2005Kit# FTZ3D003

Specifications

Wingspan: 37”

Weight: 14 to 16 oz

Radio: 4 Channel with Micro Servos

Motor: GWS 350D to HiMax 2025

2

Table of Contents

Warranty Information...................................................3

Warnings and Safety Precautions............................................. 3

Before Starting the Assembly Process........................................... 3

Using This Manual.................................................... 4

Kit Contents........................................................4

Required Tools and Adhesives...............................................4

Wing Assembly...................................................... 5

Preparing Control Surfaces................................................ 5

Elevator Assembly.....................................................5

Finalized Assembly.................................................... 6

Painting Tips....................................................... 6

Install Control Surfaces..................................................7

Radio & Control Preparation............................................... 8

Radio Installation.....................................................8

Finalize Radio Setup................................................... 10

Throws & Center of Gravity................................................10

Pre-Flight Checklist....................................................11

AMA Safety Code.....................................................11

3

Warranty Information

FlyingThingZ, Inc. guarantees this model to be free from defects in material and workmanship at the date of purchase. This warranty

does not cover any parts damaged by use or modifications. In no way shall FlyingThingZ, Inc. liability exceed the original cost of the

purchased model. Further, FlyingThingZ, Inc. reserves the right to modify this warranty without prior notice.

In that FlyingThingZ, Inc. has no control over the final stages of assembly or material used for the final assembly, no liability shall be

assumed nor accepted for any damage of the final user-assembled product. By the act of using the final product, the user accepts all

resulting liability.

We, as a kit manufacture, provide you with a top quality kit and manual, but the quality and flying characteristics of your finished

model depend on how you build it; therefore, we cannot in any way guarantee the performance of your completed model and no rep-

resentations are expressed or implied as to the performance or safety of your completed model.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this kit

immediately, in new and unused condition, to the place of purchase.

Warnings and Safety Precautions

READ THROUGH THIS MANUAL BEFORE STARTING ASSEMBLY. IT CONTAINS IMPORTANT WARNINGS AND

INSTRUCTIONS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

AN RC AIRCRAFT IS NOT A TOY! IF MISUSED, IT CAN CAUSE SERIOUS BODILY HARM AND DAMAGE TO PROPERTY.

FLY ONLY IN OPEN AREAS, PREFERABLY AT AMA (www.modelaviation.com) APPROVED SITES. FOLLOW ALL INSTRUC-

TIONS INCLUDED WITH YOUR RADIO AND ENGINE.

You must assemble the model according to the instructions. Do not alter or modify the model, as doing so may result in an

unsafe or unstable aircraft. In a few cases the instructions may differ slightly from the images provided. In these cases, the written

instructions should take precedence.

Take your time to build straight, true and strong.

You must use an R/C radio system that is specifically designed for aircraft frequencies, properly tuned and in first class working

condition. The correctly sized engine displacements and miscellaneous components should be used throughout the building process

as specified on this manual.

Check the operation of your model before each flight and insure that all equipment is fully operational and all hardware is secure.

Be sure to check all linkage connections and parts that may become dislodged during flight.

This kit is not intended as a trainer. If you are not an experienced pilot, you should fly the model only with the help and supervi-

sion of a competent, experienced R/C pilot.

Before Starting the Assembly Process

Before beginning assembly of the Mad 3D Taco, remove all parts from their packages for inspection. Inspect all hardware, fuselage

parts, wing components and foam for damage. If you find any damaged or missing parts, please contact us directly.

FlyingThingZ, Inc.

34 Chatham Hill Road

Stroudsburg, PA 18360

www.flyingthingz.com

4

Using This Manual

This manual is divided into sections to aid in the assembly process. It provides an easier more concise layout allowing for breaks

between each major section. Additionally, check boxes have been provided next to each step to help keep track of the completed

assembly process. Steps with two check boxes indicate that the step is repeated, such as for a right and left wing panel, control link-

ages or fuselage side. Remember to take your time and follow the directions carefully.

Kit Contents

Part # Description Qty.

AHorizontal Fuse 2

BVertical Fuse 1

CWing 1

DElevator 2

EHorizontal Stab 1

FRudder 1

GCarbon Fiber Rod 4

HSkid Plate 1

IMotor Mount 1

JControl Rod Wire 1

KVelcro Strap 1

LHeat Shrink Tubing 1

MEZ Connector 4

Not Shown Elevator Joiner 1

Required to Complete Kit

4 Channel Radio with 4 Micro Servos (eg. Hitech HS-55)

Electric Motor (GWS 350D, HiMax 2015 or 2025)

Speed Controller (eg. Phoenix 25)

Battery Pack (7.4v or 11.1v Li-Po or NiMH)

Gear Box

Propeller

Avoid Using CA to bond parts on foam. Regular CA will eat

the foam and ruin it. FlyingThingZ recommends epoxy, foam

safe CA or Gorilla Glue

5 or 30 Minute Epoxy

#120 Sand Paper

Sanding Block

Hobby Knife

Pen or Pencil

Assorted Screw Drivers

Building T-Pins

Razor Saw

Wire Cutters

Needle Nose Pliers

Paper Towels

Ruler

Mixing Sticks

Alcohol

Rotary Tool / Dremel

Router Attachment

Hot Glue Gun

Hinges or Hinge Tape

Drill

1/16” Drill Bit

Double Sided Tape

Double Sided Velcro Tape

Paint

Foam Safe CA or Gorilla Glue

Required Tools and Adhesives

5

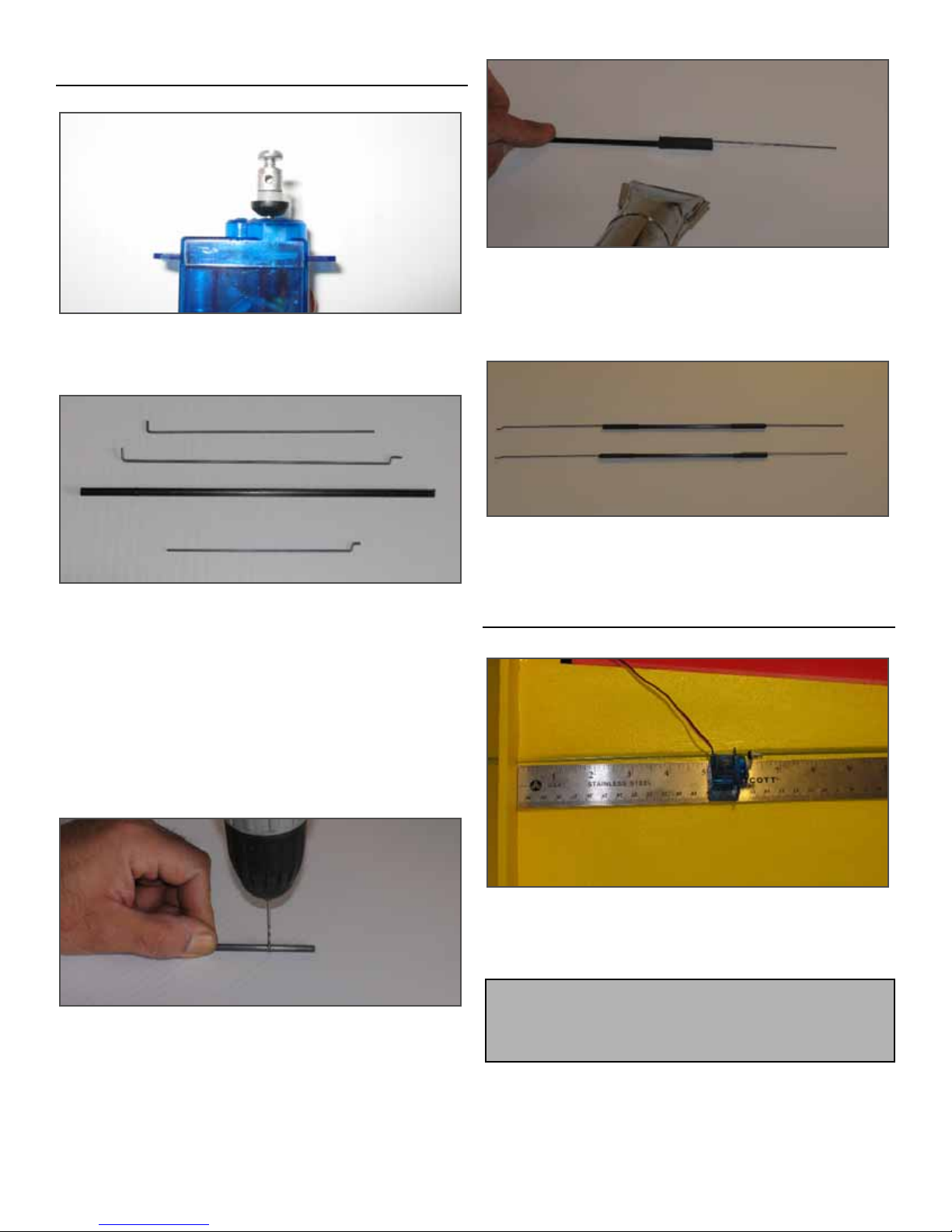

Wing Assembly

Glue the two carbon fiber rods into the precut slots on the

back of the wing. Make sure to lay the wing on a flat level sur-

face before allowing the glue to set. Wipe off any excess glue

with alcohol and paper towels.

Install the wing into the vertical fuselage. Use t-pins and the

provided squares to attach the wing to the fuselage. Run a bead of

glue alone the top and bottom edges of the wing. Quickly move to

the next step before the glue sets.

Insert the motor mount into it’s slot in the fuselage and into

the notch on the wing. Glue it in place making sure that motor

mount is centered with the fuselage. The motor mount should

help straighten the wing.

Put the Taco aside as the glue sets and move on to the next steps.

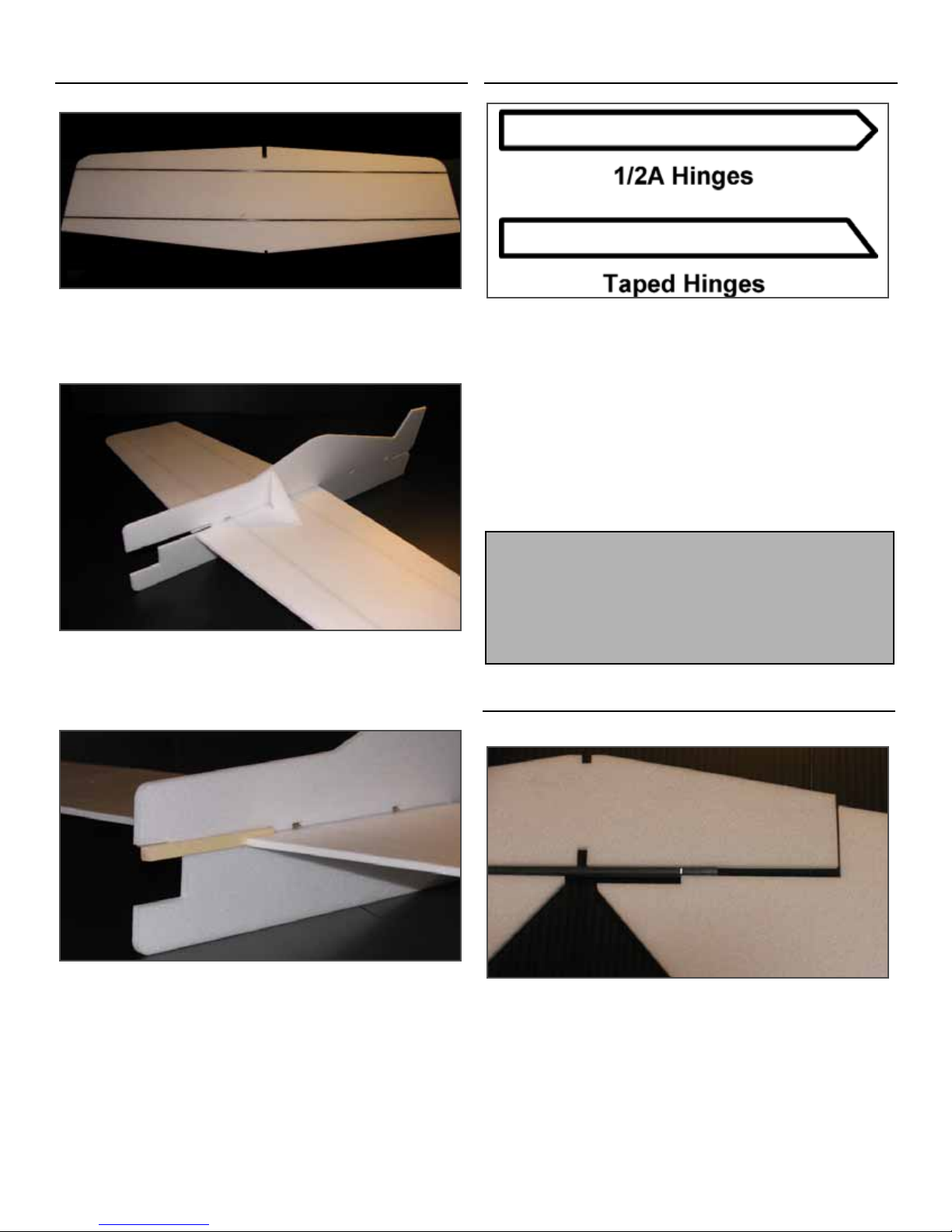

Preparing Control Surfaces

To prepare the control surfaces, you have to make a decision. If

you are going to hinge your control surfaces with regular hinges,

then the surface must be shaped as shown above for the 1/2A

Hinges.

If you prefer to use tape to hinge your control surfaces, then the

surfaces must be shaped as shown above for Taped Hinges.

Using #120 grit sandpaper on a sanding block, shape the edges

of your control surfaces as shown above for your preferred hing-

ing method. Make sure the correct edge on the control surface is

shaped by checking them against the wing or stab.

Elevator Assembly

Dry fit the elevators onto the horizontal stab with the elevator

joiner between the two elevator halves. Make a mark on the

elevator joiner where it meets the second elevator. Cut the eleva-

tor joiner on the mark. Make sure to compensate for the outside

edges of the elevator that butt up against the horizontal stab.

FlyingThingZ recommends taking the extra time and steps to

hinge your control surfaces with Dubro 1/2A Hinges (part# 118

or 119)

If you’d prefer to use the tape method, we recommend using

Dubro’s Electric Flyer Hinge Tape (part#916)

6

Test fit the elevators with the joiner installed. Sand down the

joiner as necessary to get a good fit. Make sure the elevators are

not rubbing against the stab.

Using your preferred gluing method, join the two elevator

halves with the elevator joiner in place. Make sure to lay them on

a flat surface to assure they are perfectly level.

Put the elevator assembly aside as the glue sets and move on to the

next steps.

Finalized Assembly

Slide the horizontal stab through the back of the Taco. The fit

is extremely tight so be careful when inserting it. Once inserted,

make sure that the stab is fully seated in position before gluing.

Use the provided squares with t-pins to hold the assembly in place

as the glue sets.

Dry fit the horizontal fuselage on top of the wing. From the

bottom of the Taco, make a mark onto the horizontal fuselage

where the wing’s leading edge and trailing edge meet. Do the

same for the horizontal stab. This is to assure you don’t put glue

outside the wing area. Apply a liberal amount of glue to the hor-

izontal stab between your marks and glue into place. Use t-pins

to hold the assembly together as the glue sets.

Glue the skid plate onto the Taco’s belly. Once the glue has set,

the Mad 3D Taco is ready to be painted.

Painting Tips

It’s finally time to paint your Mad 3D Taco.

Before painting the model, make sure it it free of dust and oil. Use

alcohol and a lint free rag to rub off any oils or dust on the model.

Alternatively, you can use a tack cloth to remove dust.

FlyingThingZ recommends standard spray paint that can be

picked up at most hardware stores. There is one thing that you

should avoid when using spray paints. Make sure it does not con-

tain any rust inhibitors. Rust-O-leum and other paints with these

inhibitors will deteriorate the foam.

When applying the paint, use multiple light coats. Painting it on

too thick will add weight and create runs. Use the foam triangles

to test your paint before applying it on the Taco.

Other painting methods you can use are:

Permanent Colored Magic Markers

Latex Based Paint

Acrylic Based Paint

Airbrushing

7

Install Control Surfaces

1/2A Hinges

Use a hinge as a guide to mark both the wing and the aileron

where the hinge locations will be. The wing half should have 4

hinges evenly spaced apart from each other.

Repeat this step for the rudder and elevators. The rudder uses

3 hinges and the elevator uses 2 hinges per side.

Using a hinge slotting tool, make a slit in the foam at the

locations marked in the previous step. With a small amount of

glue, install the hinges into the wing. If a hinge tool is not avail-

able, use your best judgement for centering the slits where the

hinges will install.

Repeat this step for the rudder and elevators.

Install the aileron using a small amount of epoxy. Move the

ailerons up and down so that the hinge pins don’t get stuck.

Finally, repeat the same process for the rudder and elevator.

Keep moving the control surfaces to assure they don’t get stuck.

Tape Hinges (Optional Method)

Optional: Apply the first strip of tape to the wing or stab. Place

the control surface at the angle that was created on the control sur-

face and attach tape to the control surface.

Optional: Move the control surface to the opposite side and add

an additional strip of tape to the other side.

Optional: The finished taped hinge control surface.

Tip: Applying a small amount of vaseline or oil to the hinge

pin will help prevent it from getting gummed up with glue.

8

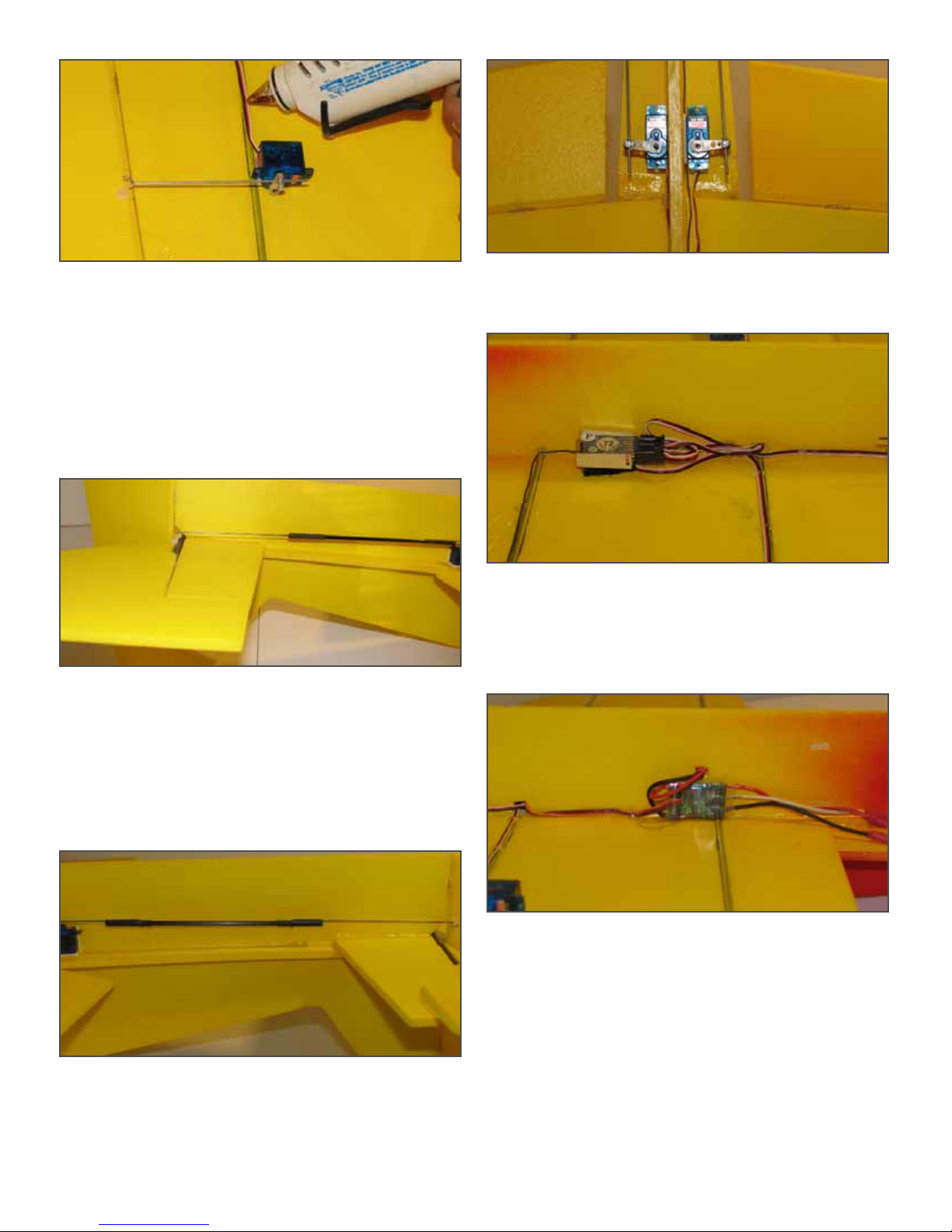

Radio & Control Preparation

Attach the control horns to your servos and attach the

included Mini EZ Connectors to the outer most hold on the control

horn as shown above.

Cut down the carbon fiber rods to 8”.

Create two wires with a 90 degree bend at 5 1/2”. The wire

should run 5 1/2” then turn 90 degrees. Make sure the bend is no

more than a 1/4” long.

Create two wires with a 90 degree bend and a Z bend on the

other side that is 4 1/2”. The length of the wire before any bend

should be 4 1/2”.

Finally create two wires with a Z bend bend at 4”. The wire

should run 4” then turn into a Z bend.

Drill a 1/16” hole, 1” from each end of the carbon rod. Make

sure the holes line up as much as possible with each other.

Cut down the heat shrink tubing to 1 1/2” pieces. Place

the tubing over the carbon fiber rod and insert the 90 degree bend

into the drilled hole. Using a hot air gun or lighter, heat the tub-

ing until it wraps tightly around the rod and wire. Add a few

drops of CA into the opening of the rod for added strength.

One side should use the wire that has the Z bend, while the other

end, should just have the straight wire as shown in the image

above.

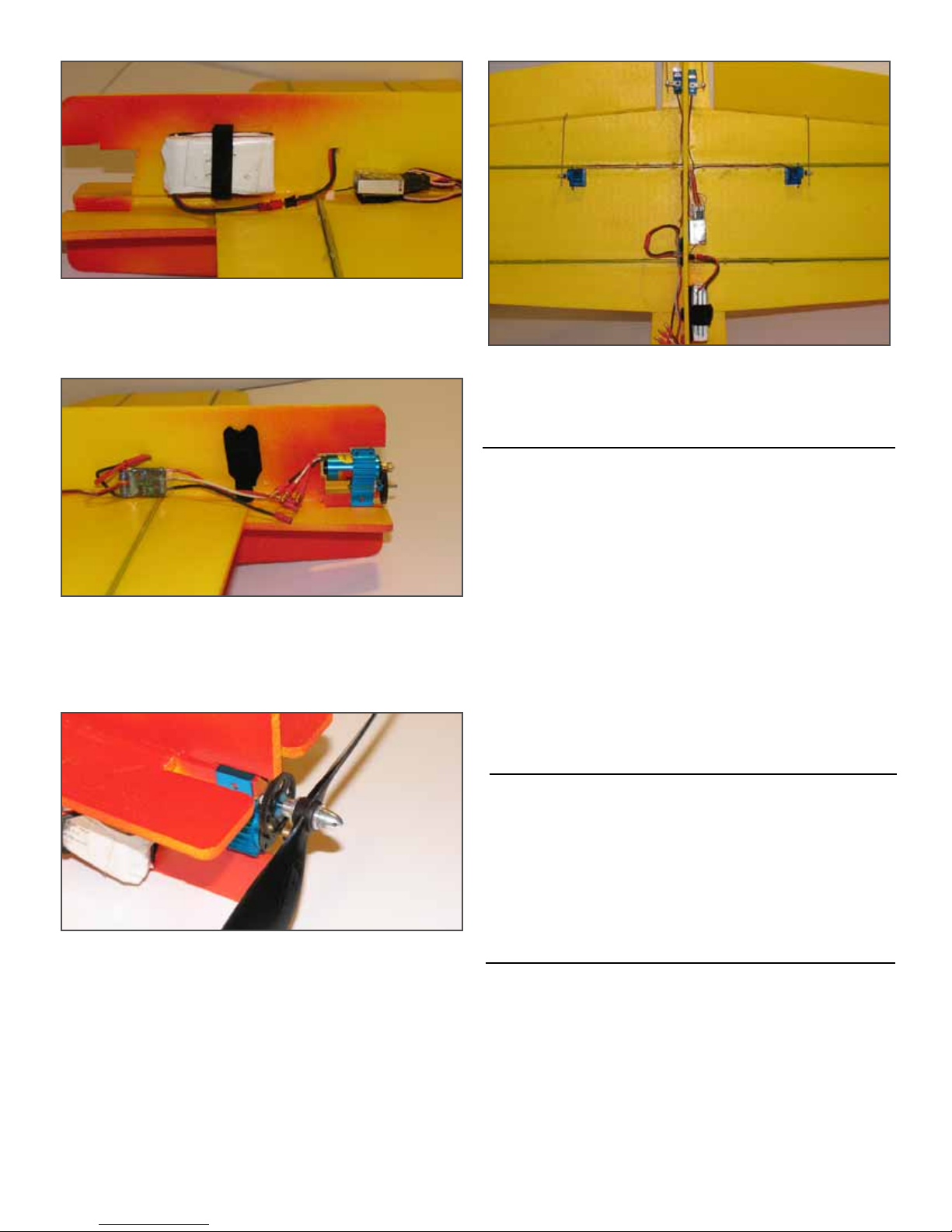

Radio Installation

Install the aileron servos on the bottom of the wing 5” from

the side of the fuselage. Use double sided tape or hot glue to hold

the servo in place. Repeat on the other side. Make sure to clean

all surfaces with alcohol before applying your double sided tape.

Tip: FlyingThingZ recommends using double sided tape over

hot glue. During extremely hot days, we have experience ser-

vos coming loose during flight.

9

Attach the aileron control rod wire through the control horn.

You may have to use a drill bit or X-acto knife to make the hole a

little bigger for the rod. Slip the wire through the hole in the EZ

connector and punch the control horn into the foam on the aileron.

Make sure the holes on the control horn are as close to the center

of the wing / aileron joint as possible.

Glue the horns in place. Add a small dot of glue on the

opposite side that protrudes from the control horn.

Use a few beads of hot glue to hold the wire in place.

Attach a control horn to one of the assembled carbon fiber rod

control arms. Run the other end through the EZ Connector on the

elevator servo. Line up the rod with the vertical fuselage and

punch the control horn through the foam as close to the joint

between the stab and elevators.

Glue the horns in place and place a small dot of glue on the

opposite side that protrudes from the control horn. Do not attach

the servo at this time.

Install the rudder control horn in the same manner as previ-

ous steps.

The elevator and the rudder servos should be lined up as

shown above. Use double sided tape or hot glue to hold the ser-

vos in place. Use beads of hot glue to hold the wires in place.

Install the receiver as far forward as the shortest servo wire

will allow. You’ll have to make a hole in the vertical fuselage to

pass the wires from the other side to the receiver. When you route

your receiver antenna, try to keep it away from your servo leads.

Use double sided velcro tape to hold the receiver in place. Use

beads of hot glue to hold the wires in place.

Install your speed controller on the opposite side of the receiv-

er. Pass the wire to the receiver through the hold crated to pass the

servo leads through. Create another hold above the speed con-

troller to pass the battery connector through. Attach the speed

controller to the model with double sided velcro tape. Use beads

of hot glue to hold the wires in place.

10

Mount the battery onto the vertical fuselage centered with the

leading edge of the wing. Cut slits on the top and bottom of the

battery location to pass the provided velcro strap through. Make

sure the battery leads can plug into the speed controller.

Install the motor and gearbox onto the motor mount. Using a

1/16” drill bit, make a hole to secure the gearbox to the motor

mount. Use a servo mounting screw to secure the gearbox to the

motor mount. DO NOT connect your motor wires to the wires on

the speed controller at this time.

Securely install the propeller onto the gearbox output shaft.

Follow the manufacturers recommendations for securing the prop

and prop nut to the shaft.

The final setup should ultimately look similar to the image above.

Make sure to secure your wires with hot glue or your preferred

method.

Finalize Radio Setup

Turn on your transmitter and connect the battery to the speed

controller. Center all servos using the transmitters trim or sub-

trim. Make any necessary adjustments on the EZ Connectors and

control rods to assure your control surfaces are perfectly lined up.

Make sure all the control surfaces operate in the proper direc-

tion for your control input.

Follow the manufactures instructions on setting up the speed

controller and motor/gearbox combination you have chosen for

your plane.

Attach the motor wires to the speed controller. Make sure

your throttle operates in the proper direction. Be extremely care-

ful with the prop when connecting the battery for the first time.

Throws & Center of Gravity

The throws should be set as high as possible on all control sur-

faces. Set a 50% dual rate on one switch as a bailout if you feel

the controls are too sensitive.

The CG should be 5 1/4” from the leading edge. Adjust the bat-

tery position to obtain a balancing point on or as close to the

location of the center of gravity.

Damage Repair

Repairing a damaged aircraft is easy and very quick. Usually,

you can be up and flying again within minutes of a severe crash.

Use 5 minute epoxy or hot glue to join any broken parts. Make

sure not to melt the foam with the hot glue gun.

If you bend your drive shaft, try straightening it out before

replacing it. We’ve bent a few shaft and have been able to bend

them back close enough to avoid vibrations.

11

Pre-Flight Checklist

Check the CG according to the steps outlined in the balanc-

ing section of this manual

Make sure that battery and receiver are securely mounted.

Make sure your receiver antenna is fully extended. Do not

cut any excess antenna wire.

Use a threadlocking compound on all metal to metal

fasteners such as nuts, bolts and set screws.

Make sure all hinges are secure and in good working

condition.

Reinforce holes for wood screws with CA where

appropriate.

Confirm all controls operate freely and in the correct direc-

tion. Make sure all throws are set as specified in this manual.

Make sure all your wire connections are secure and in good

physical condition.

Make sure the prop nut is fully fastened and secure.

Place your name, address AMA number and telephone

number on or inside your model.

Cycle all battery packs and make sure they are fully charged

before flying.

Range check your radio at the flying field before the first

flight following the radio manufacturer's instructions.

GENERAL

1. A model aircraft shall be defined as a non-human-carrying

device capable of sustained flight in the atmosphere. It shall not

exceed limitations established in this code and is intended to be

used exclusively for recreational or competition activity.

2. The maximum takeoff weight of a model aircraft, including

fuel, is 55 pounds, except for those flown under the AMA

Experimental Aircraft Rules.

3. I will abide by this Safety Code and all rules established for the

flying site I use. I will not willfully fly my model aircraft in a

reckless and/or dangerous manner.

4. I will not fly my model aircraft in sanctioned events, air shows,

or model demonstrations until it has been proven airworthy.

5. I will not fly my model aircraft higher than approximately 400

feet above ground level, when within three (3) miles of an airport

without notifying the airport operator. I will yield the right-of-

way and avoid flying in the proximity of full-scale aircraft, utiliz-

ing a spotter when appropriate.

6. I will not fly my model aircraft unless it is identified with my

name and address, or AMA number, inside or affixed to the out-

side of the model aircraft. This does not apply to model aircraft

flown indoors.

7. I will not operate model aircraft with metal-blade propellers or

with gaseous boosts (other than air), nor will I operate model air-

craft with fuels containing tetranitromethane or hydrazine.

8. I will not operate model aircraft carrying pyrotechnic devices

which explode, burn, or propel a projectile of any kind.

Exceptions include Free Flight fuses or devices that burn produc-

ing smoke and are securely attached to the model aircraft during

flight. Rocket motors up to a G-series size may be used, provided

they remain firmly attached to the model aircraft during flight.

Model rockets may be flown in accordance with the National

Model Rocketry Safety Code; however, they may not be launched

from model aircraft. Officially designated AMA Air Show Teams

(AST) are authorized to use devices and practices as defined

within the Air Show Advisory Committee Document.

9. I will not operate my model aircraft while under the influence

of alcohol or within eight (8) hours of having consumed alcohol.

10. I will not operate my model aircraft while using any drug

which could adversely affect my ability to safely control my

model aircraft.

11. Children under six (6) years old are only allowed on a flight-

line or in a flight area as a pilot or while under flight instruction.

12. When and where required by rules, helmets must be properly

worn and fastened. They must be OSHA, DOT, ANSI, SNELL or

NOCSAE approved or comply with comparable standards.

RADIO CONTROL

1. I will have completed a successful radio equipment ground-

range check before the first flight of a new or repaired model

aircraft.

2. I will not fly my model aircraft in the presence of spectators

until I become a proficient flier, unless I am assisted by an experi-

enced pilot.

3. At all flying sites a straight or curved flightline must be estab-

lished, in front of which all flying takes place. Only personnel

associated with flying the model aircraft are allowed at or in

front of the flightline. In the case of airshows, demonstrations, or

competitions, straight lines must be established. An area away

from the flightline must be maintained for spectators. Intentional

flying behind the flightline is prohibited.

4. I will operate my model aircraft using only radio-control fre-

quencies currently allowed by the Federal Communications

Commission (FCC). Only individuals properly licensed by the

FCC are authorized to operate equipment on Amateur Band fre-

quencies.

5. I will not knowingly operate my model aircraft within three (3)

2005 Official AMA National Model Aircraft Safety Code

Effective January 1, 2005

12

miles of any preexisting flying site without a frequency-manage-

ment agreement. A frequency-management agreement may be an

allocation of frequencies for each site, a day-use agreement

between sites, or testing which determines that no interference

exists. A frequency-management agreement may exist between

two or more AMA chartered clubs, AMA clubs and individual

AMA members, or individual AMA members. Frequency-man-

agement agreements, including an interference test report if the

agreement indicates no interference exists, will be signed by all

parties and copies provided to AMA Headquarters.

6. With the exception of events flown under official AMA

Competition Regulations rules, after launch, no powered model

may be flown outdoors closer than 25 feet to any individual,

except for the pilots and helpers located at the flightline.

7. Under no circumstances may a pilot or other person touch a

model aircraft in flight while it is still under power, except to

divert it from striking an individual.

8. Radio-controlled night flying is limited to low-performance

model aircraft (less than 100 mph). The model aircraft must be

equipped with a lighting system which clearly defines the air-

craft's attitude and direction at all times.

9. The operator of a radio-controlled model aircraft shall control

it during the entire flight, maintaining visual contact without

enhancement other than by corrective lenses that are prescribed

for the pilot. No model aircraft shall be equipped with devices

which allow it to be flown to a selected location which is beyond

the visual range of the pilot.

FREE FLIGHT

1. I will not launch my model aircraft unless I am at least 100 feet

downwind of spectators and automobile parking.

2. I will not fly my model aircraft unless the launch area is clear

of all individuals except my mechanic, officials, and other flyers.

3. I will use an effective device to extinguish any fuse on the

model aircraft after the fuse has completed its function.

CONTROL LINE

1. I will subject my complete control system (including the safety

thong where applicable) to an inspection and pull test prior to

flying. The pull test will be in accordance with the current

Competition Regulations for the applicable model aircraft catego-

ry. Model aircraft not fitting a specific category shall use those

pull-test requirements as indicated for Control Line Precision

Aerobatics.

2. I will ensure that my flying area is clear of all utility wires or

poles and I will not fly a model aircraft closer than 50 feet to any

above-ground electric utility lines.

3. I will ensure that my flying area is clear of all nonessential par-

ticipants and spectators before permitting my engine to be

started.

SPECIALIZED SUPPLEMENTAL SAFETY CODES

Specialized supplemental Safety Codes exist for the following:

RADIO CONTROL COMBAT (#525)

GENERAL RADIO CONTROL RACING (#530)

GIANT SCALE RADIO CONTROL RACING (#515-A)

GAS TURBINE OPERATION (Note: Special waiver required)

(#510-A)

These special codes and appropriate documents may be obtained

either from the AMA Web site or by contacting AMA

Headquarters.

13

Unique and Exotic Aircraft from FlyingThingZ

Indy Sport Car M1A1 Flying Tank

Flagship .40 Extra 300 3D

Sky Cutter .40 V2 Witch Wilga

Table of contents

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price BGC55 instructions

ATOMIC MASS GAMES

ATOMIC MASS GAMES STAR WARS LEGION SWL11 Assembly

MTHTrains

MTHTrains RAIL KING SOUTHERN Ps-4 4-6-2 DIE-CAST STEAM... operating instructions

Tomy

Tomy Starlight Dreamshow Instructions for use

HPI Racing

HPI Racing Sprint 2 sport instruction manual

YIBOO

YIBOO Dragon 807 UJ807 user manual