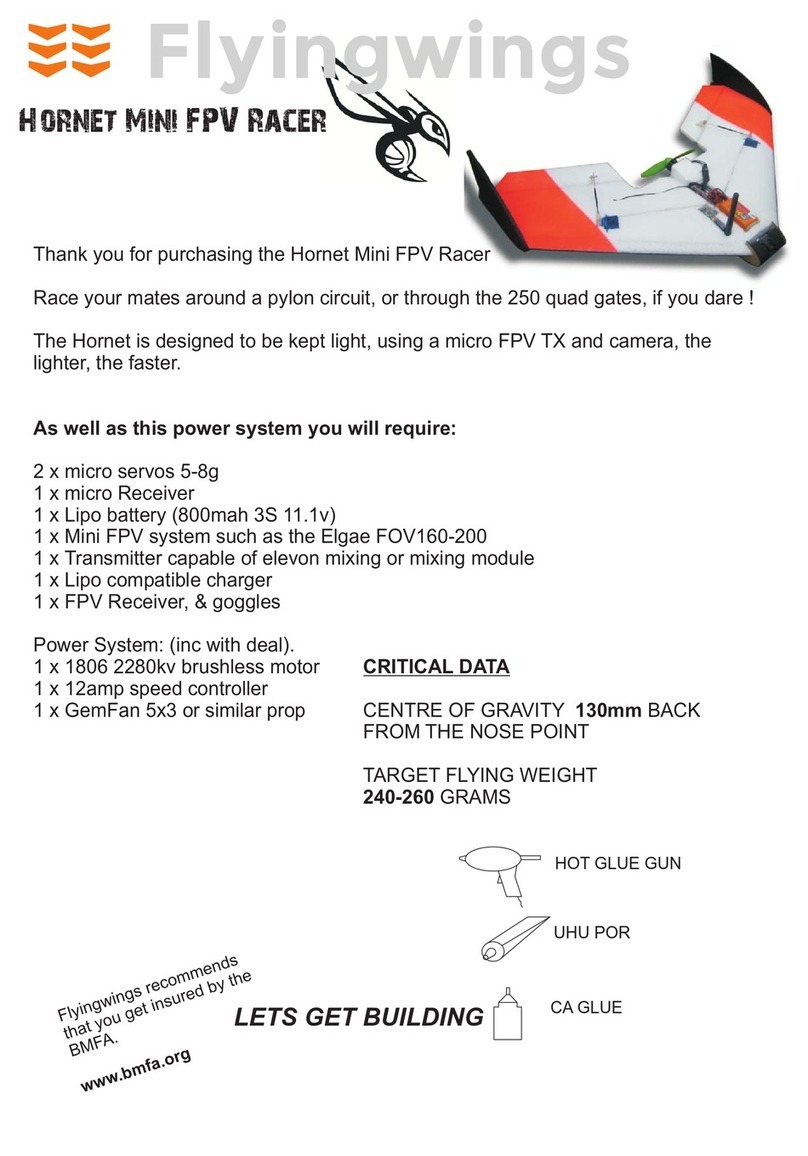

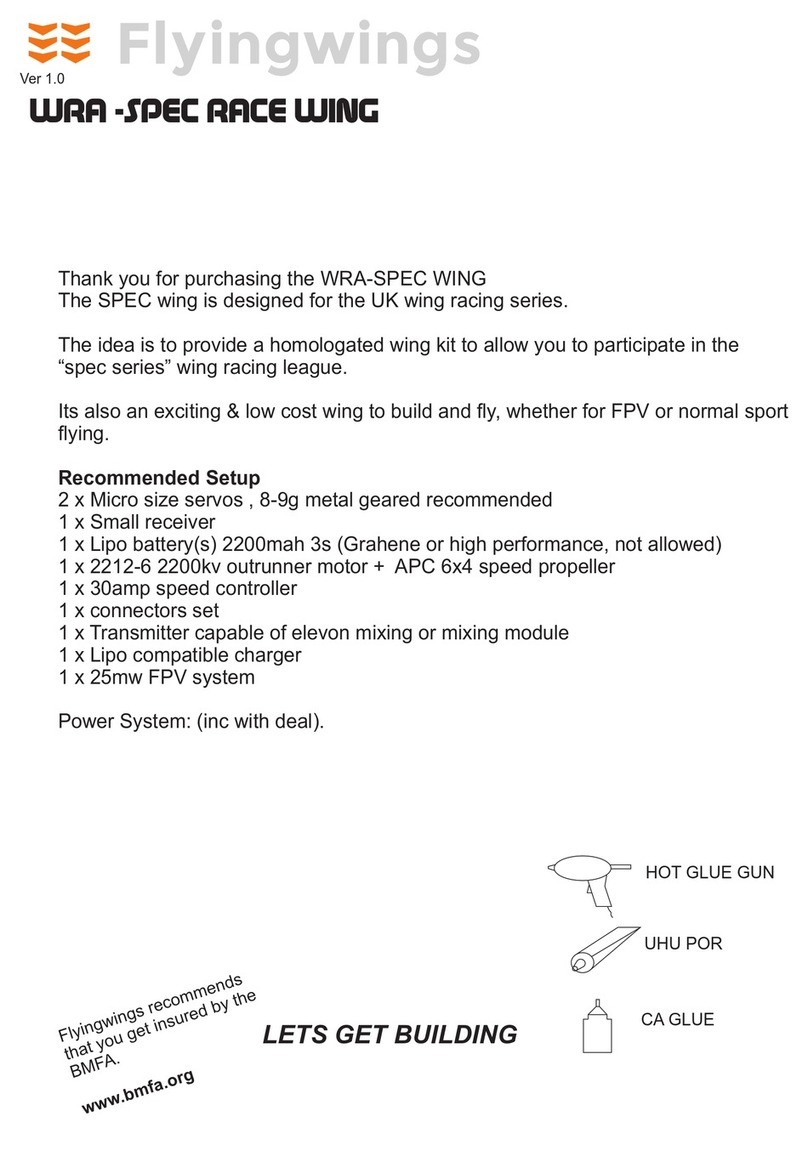

flyingwings Falcon Eco FPV User manual

Other flyingwings Toy manuals

Popular Toy manuals by other brands

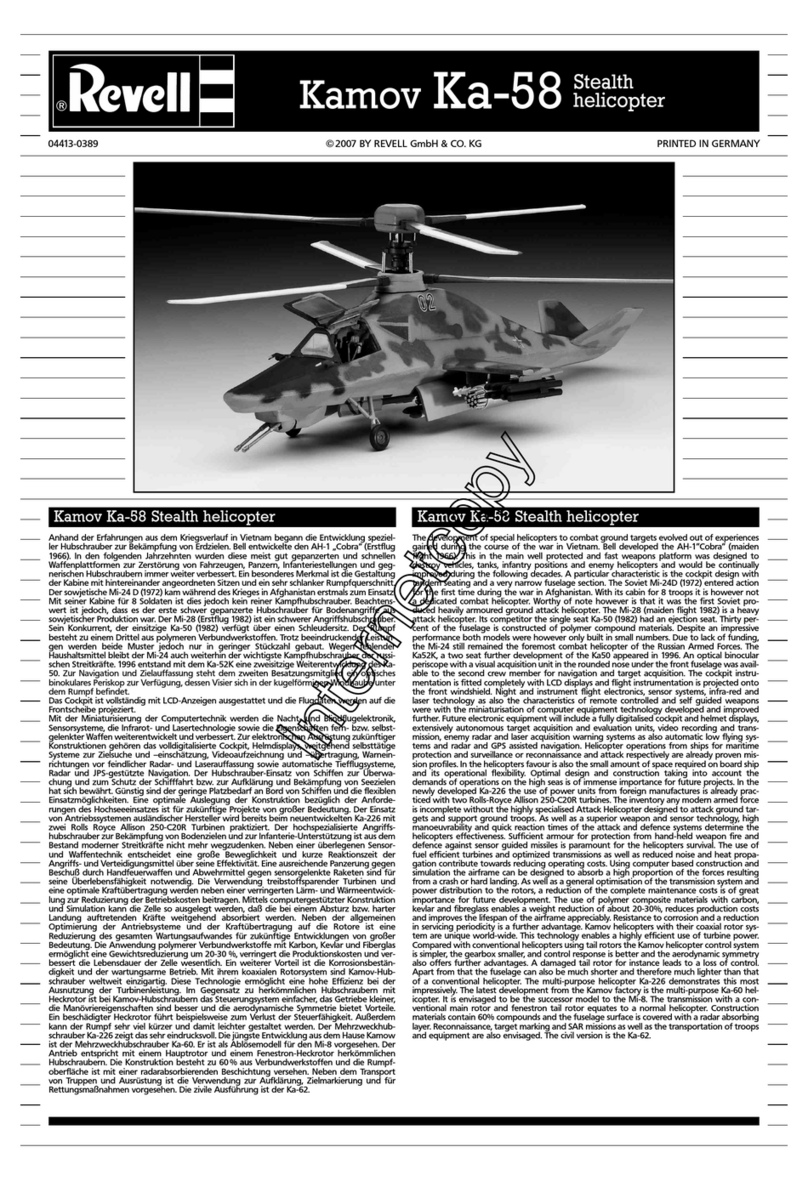

REVELL

REVELL Fairey Gannet A.S.1./4 Assembly manual

Mattel

Mattel Monster High BJR25 instructions

Startright

Startright Bilingual Super Notebook manual

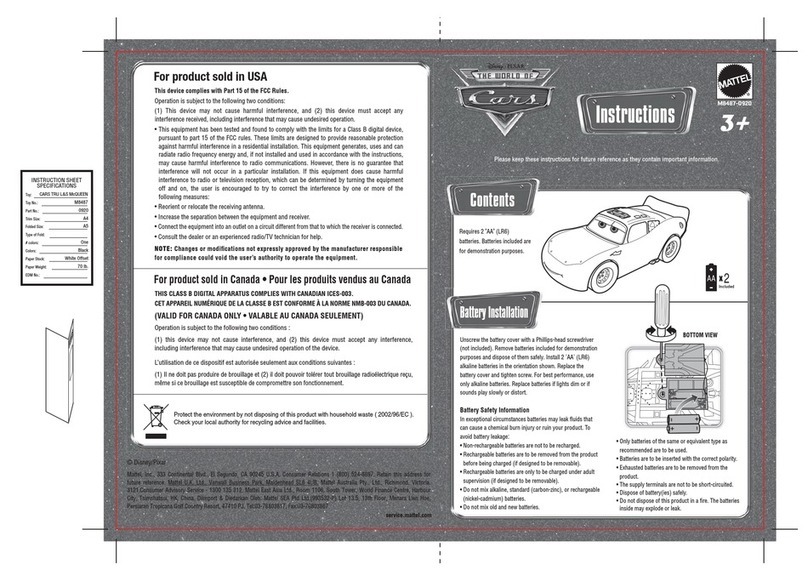

Mattel

Mattel CARS M8487-0920 instructions

Carson

Carson Tyrann Sport 180 operating instructions

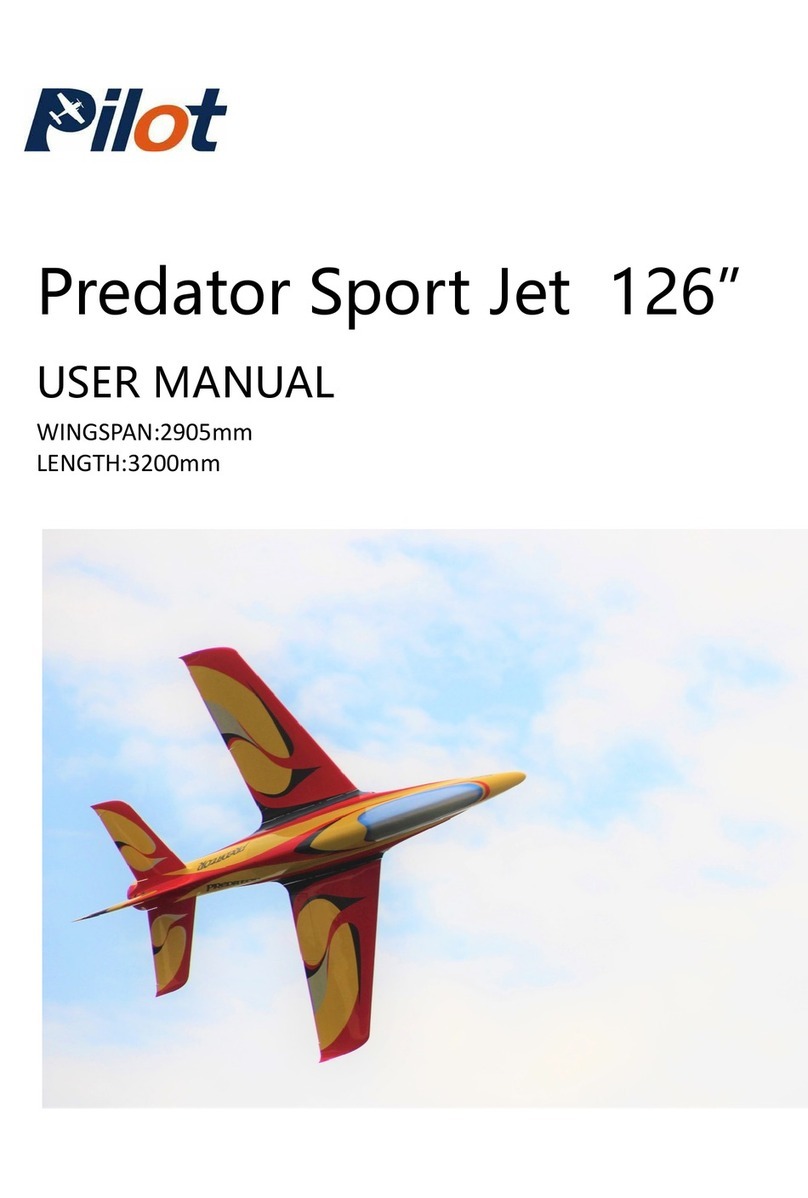

Pilot Communications

Pilot Communications Predator Sport Jet 90" user manual

Model Engines

Model Engines Mini Twister Sport instruction manual

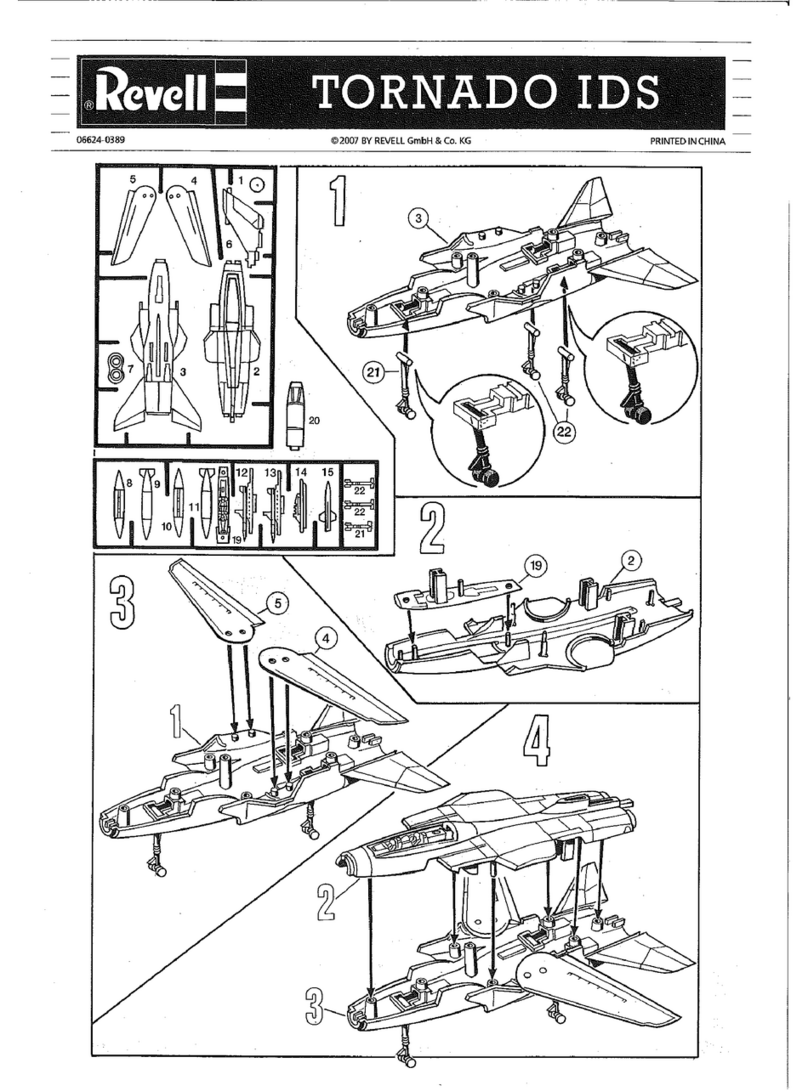

REVELL

REVELL Tornado IDS Assembly instructions

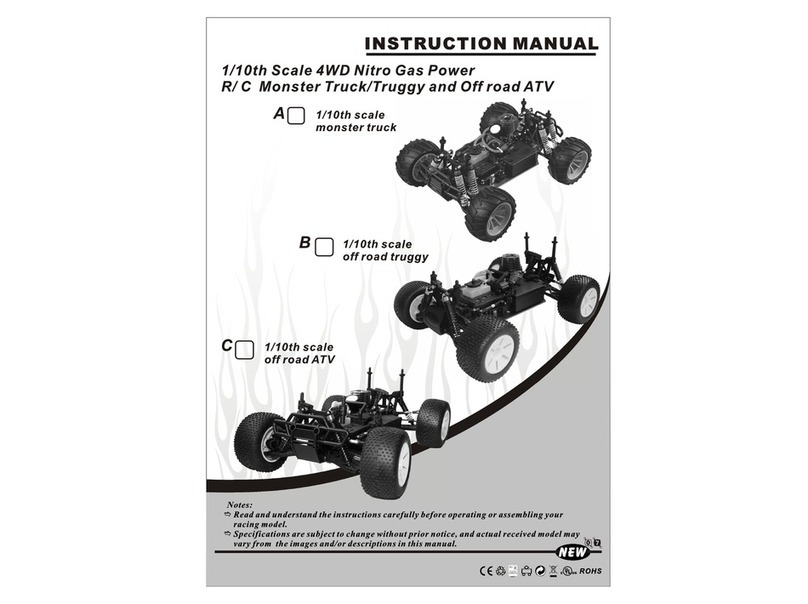

Himoto

Himoto 1/10th scalemonster truck instruction manual

Fisher-Price

Fisher-Price Power Wheels 76920 Owner's manual with assembly instructions

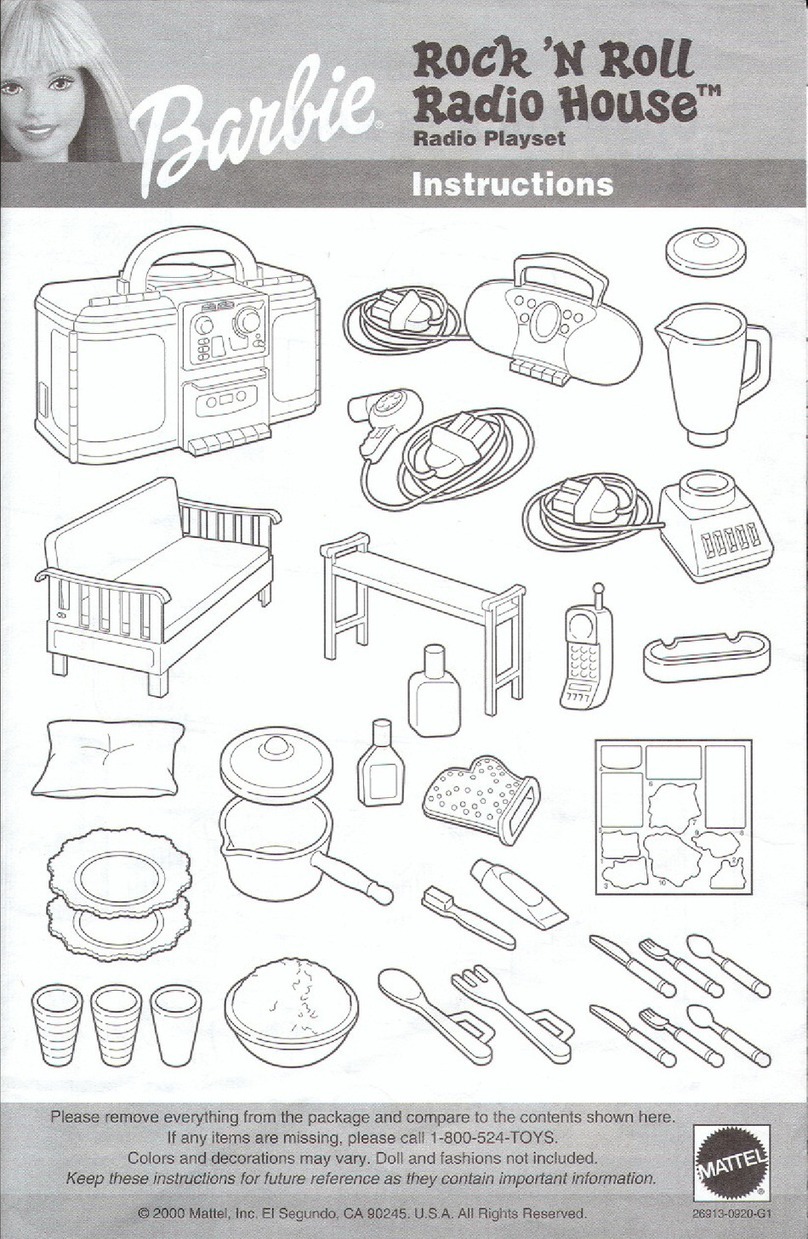

Mattel

Mattel Barbie Rock 'N Roll Radio House instructions

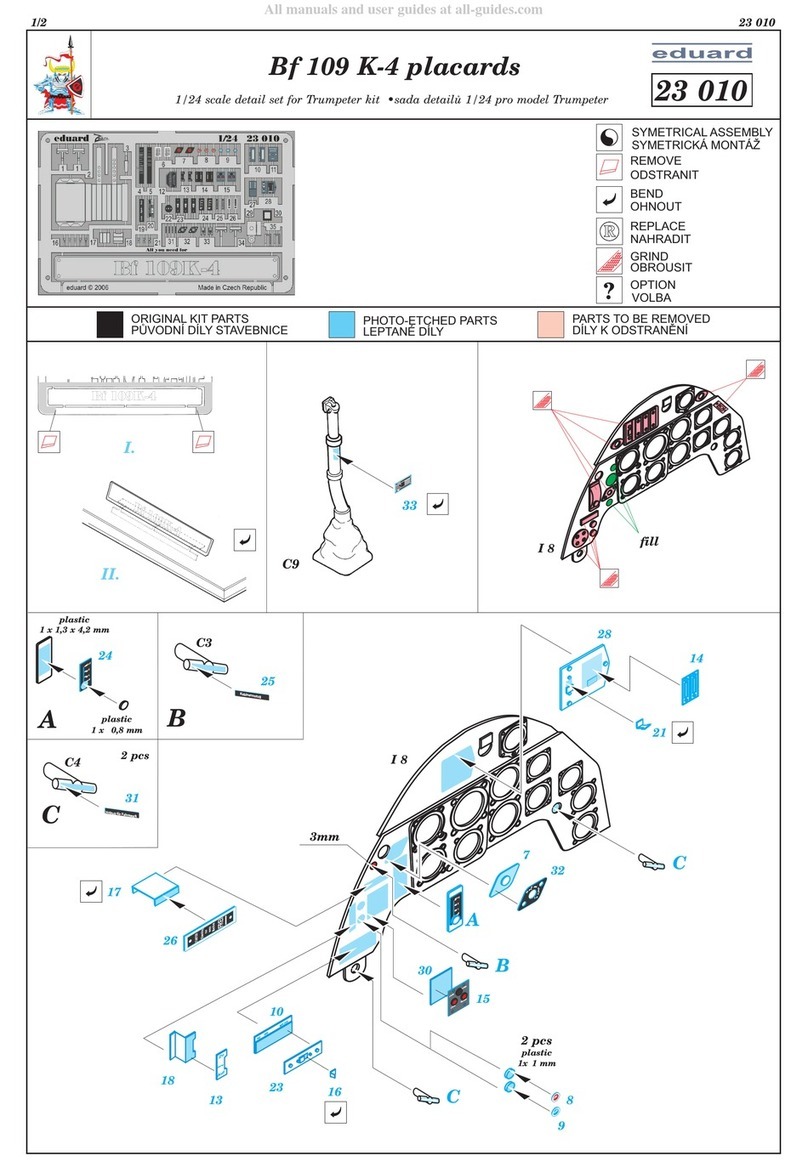

Eduard

Eduard Bf 109 K-4 placards Assembly instructions