flyingwings Hornet Mini FPV Racer User manual

Thank you for purchasing the Hornet Mini FPV Racer

Race your mates around a pylon circuit, or through the 250 quad gates, if you dare !

The Hornet is designed to be kept light, using a micro FPV TX and camera, the

lighter, the faster.

As well as this power system you will require:

2 x micro servos 5-8g

1 x micro Receiver

1 x Lipo battery (800mah 3S 11.1v)

1 x Mini FPV system such as the Elgae FOV160-200

1 x Transmitter capable of elevon mixing or mixing module

1 x Lipo compatible charger

1 x FPV Receiver, & goggles

Power System: (inc with deal).

1 x 1806 2280kv brushless motor

1 x 12amp speed controller

1 x GemFan 5x3 or similar prop

LETS GET BUILDING

Hornet Mini FPV Racer

Flyingwings recommends

that you get insured by the

BMFA.

www.bmfa.org

CRITICAL DATA

CENTRE OF GRAVITY 130mm BACK

FROM THE NOSE POINT

TARGET FLYING WEIGHT

240-260 GRAMS

UHU POR

HOT GLUE GUN

CA GLUE

STEP

STEP

1

2

1. Turn the wing over and insert the

carbon strip spar.

Cut the battery & radio

compartment out to lines drawn on

the wing. Then join the wing.

Use the full size template on

the template sheet

STEP

STEP

3

4

STEP 4

Glue the ply side panels to the

fuselage,

Glue motor mount as shown and then

the ply plate.

Glue the fuselage to the underneath of the wing centrally, note that this leaves a

gap, allowing the installation of a standard board camera

gap

Installation of servo adaptors:

Open up the top hole on each ply horn so that the threaded part of

the metal servo adaptors are snug but can turn in the horn. Put the

washer and nut on (not easy when you have fingers like sausages

!). Tighten the nut so the adaptor is firm but can still turn. A blob of

CA glue on the end of the nut will stop it from coming loose.

blob of CA

Glue

washer

nut

STEP 4

Hinging elevon,

Method , UHU Por hinge. Run a small bead of glue along the rear top edge of

thetrailing edge of the wing and the same on the leading edge (LE) of the elevon.

Allow glue to set for 5 minutes. On a flat surface bring the two edges together, the

glue fuses together giving a strong flexible hinge, magic.

STEP 3a

Attaching the elevon horn.

The push rod should run parallel to the centre line of the wing.

Using a ruller draw a line on the elevon where the horn should be

situated. Press one of the horns into the foam to leave an

impression, cut this with a knife so that the horn sits in the elevon

around half depth, glue in with plenty of CA glue.

Horn location

STEP 6

Radio Installation:

Set up your servos as shown in the Radio Setup section and

double check everything is working in the correct manner outside

of the model before installing it into the model.

Two pre-cut holes have been made into the wing, these give you

a guide to fit your servos. All micro servos vary in size a little,

so you may have to cut around the servo to sit them into a

snug fitting hole, take your time with this.

1. Place your servo over the hole, draw around it to show

where more foam needs to be removed.

2. cut carefully around, the line draw and prize out the

foam, keep checking for fit with servo.

3. Cut a line around 2mm deep (no deeper) from the servo

cable wire output to the receiver location, push the cable into the

slot.

STEP 5

USE SERVO TEMPLATE

SHEET

Installing the horns & pushrods.

SWITCH ON YOUR RADIO AND CANCEL ALL SUB TRIM

SET TRIMS TO NEUTRAL

Screw the screws into the horns so that the points of the

screws are just proud, Line up the horns as shown in FIG

5C, press down the horns, then screw them right down, get

the bottom part of the horn, align screws and screw down

until the horns grip the elevon, but not too tight.

Screw the clevises onto the pushrods halfway, attach the

clevis to the servo horn, Set the elevon position slightly

upwards as shown, mark the pushrod with a felt tip and

make your z-bend at this point. Note the horn holes may

need to be enlarged slightly,

Use a ruler to set neutral position

STEP 8

Attach wing tips with glue

Push rod assembly:

Glue the plastic clevises onto the end of each carbon push rod,

with CA glue. Attach the piano wire a 20mm overlap to the carbon

rod. Use a generous blob of CA glue to coat this area. Slide the

heatshrink tube over and shrink using a heat source.

30mm 40mm

CA Glue

Heatshrink Wire

STEP 7

RECEIVER

centre of gravity

130mm back

from nose

Cut small slots

2mm deep with a

sharp knife, push

servo leads in

ESC

Hold battery in with a small

piece of velcro, run cables

below it

Carefully cut an aperture for

your camera to snugly sit in.

Cut a small hole behind and

feed the cable through

VTX transmitter, cut a small tray

for this to sit in.

Note, on a small wing, keep this

part close to the centre line to

maintain balance

POWER SYSTEM SETUP

Motor assembly and wiring

Speed

Controller

Battery

JST

connectors

Receiver, throttle

channel

Always do the motor setup with no propeller attached for safety.

In some cases the motor will not react to sudden throttle opening or stutters, this is resolved

when the propeller is attached.

Trouble shooting:

The motor will not start

> Always switch on the transmitter, set throttle to zero, then switch on model and wait for start up

sequence (beeps)

> Incorrect wiring, check battery to speed controller and controller to motor polarities

> Check servos are working, if not , there is a problem with the battery to speed controller

connection or a crystal problem. check with a separate battery.

Motor runs the wrong way

> As with all brushless motors there is 3 wires, left, middle & right. The middle connects to the

middle of the speed controller, the two out wires, left & right can connect either way and will dictate

the direction the motor spins.

Insulate

connection

each

Left Aileron: right servo travels back, left travels forward & vice versa

Up Elevator: right servo travels back, left travels back & vice versa

Viewing the model from the

rear, the motor should run

clockwise with propeller put

on backwards.

Recommended control throws measured at trailing edge of elevon.

Up/Down +/- 7mm, Left/Right +/- 7mm

Important : When setting control throws, note that all 4 settings

(up,down,left,right) are the same whatever value. Ie all 75% or all 65%

Radio setup

There is small writing on the

propeller near the hub, this

should face towards the

front of the model

Indented prop size

marking near root of

prop eg 5030 should

face forwards

Setup and flying. Set the elevon neutral position so that it follows the

sweep up from the bottom of the wing as if it were part of the wing, then

add 3mm of up elevator, this is the neutral position.

The Hornet can be flown in medium breezes, but choose a calm day for

your first flight. Hold the leading edge of the wing and give a gentle toss

with full power to launch then reduce throttle.

Help Line 01908 615163

Table of contents

Other flyingwings Toy manuals

Popular Toy manuals by other brands

Bontempi

Bontempi Toy Band Star 12 3109 owner's manual

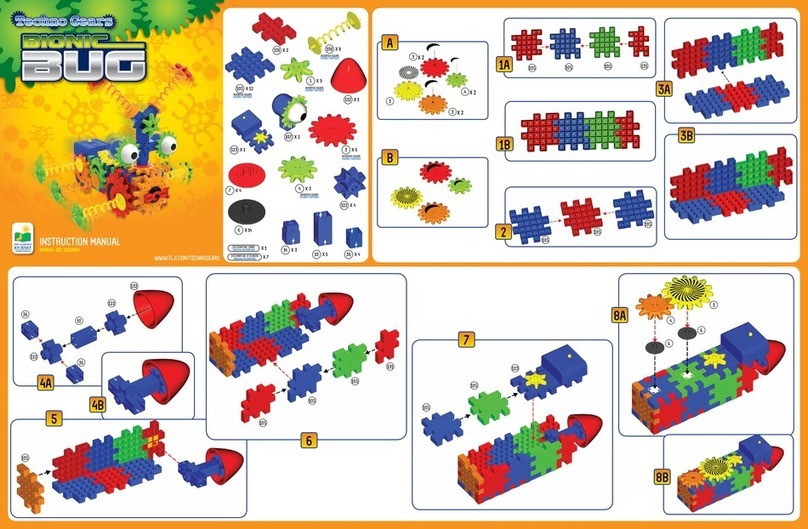

Techno Gears

Techno Gears Bionic Bug instruction manual

Fisher-Price

Fisher-Price Loving Family Musical Surprise Party quick start guide

PLANEPRINT

PLANEPRINT Funbus manual

Eduard

Eduard Mirage F.1B interior S.A. quick start guide

Tabata

Tabata ReefTourer Underwater Viewing Bucket manual