FMC Technologies Smith Meter Ultra Series Instruction manual

Bulletin MNLS007 ║ Issue/Rev 0.0 (7/14)

Liquid Ultrasonic Flowmeters

Smith Meter®

Ultra™Series C Remote Display

Installation / Operation / Maintenance Manual

Rom

Page 2 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Important

All information and technical specications in this documentation have been carefully checked and compiled by the

author. However, we cannot completely exclude the possibility of errors. FMC Technologies is always grateful to be

informed of any errors.

Smith Meter® is a registered trademark of FMC Technologies.

Customer Support

Contact Information:

Customer Service

FMC Technologies Measurement Solutions, Inc.

1602 Wagner Avenue

Erie, Pennsylvania 16510 USA

P: +1 814 898-5000

F: +1 814 899-8927

www.fmctechnologies.com

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 3

Ultra Series Remote Display I/O/M Manual Table of Contents

Table of Contents

1 – Overview....................................................................... 5

1.1. – Features .................................................................... 5

1.2. – Specifications ............................................................ 5

1.3. – Receipt of Equipment ................................................5

1.4. – Specifications ............................................................ 6

1.5. – Ultra 6c and Ultra 4c Architecture .............................. 6

1.6. – Receipt of Equipment ................................................6

1.7. – Pre-Installation Inspection ......................................... 6

2 – Installation.................................................................... 7

2.1. – Mechanical Installation ..............................................7

2.1.1. – General ...................................................................7

2.1.2. – For ATEX and IEC Installations .............................. 7

2.1.3. – For North American Installations ............................ 8

2.1.4. – All Installations - Notes ........................................... 9

2.1.5. – Installation of Cables .............................................. 9

3 – Display Control Board............................................... 11

3.1. – Wiring Examples/Information................................... 11

3.1.1. – Power Supply ....................................................... 11

3.1.2. – Network Ethernet Connection............................... 11

3.1.3. – Direct Connection to the Ultrasonic Meter ............12

4 – Powering Up the Remote Display ............................ 13

4.1. – Start-Up ...................................................................13

5 – User Display Interface............................................... 15

5.1. – Main Menu ...............................................................15

5.2. – Configuration ...........................................................15

5.2.1. – Configuration - General ........................................ 16

5.2.2. – Network Settings .................................................. 16

5.2.3. – Connections..........................................................17

5.2.4. – Modes ...................................................................19

5.3. – Maintenance Settings .............................................. 20

5.3.1. – Touch Screen Calibration ..................................... 21

5.4. – Information...............................................................21

5.5. – Reconnect ............................................................... 22

5.6. – Weights & Sealing Procedures ................................22

6 – Maintenance............................................................... 23

6.1. – Display HMI Electronics........................................... 23

6.1.1. – Board Replacement ..............................................23

6.2. – Returned Goods Policy............................................23

7 – Related Publications ................................................. 25

Page 4 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 5

Ultra Series C Remote Display I/O/M Manual Overview

1 – Overview

The Ultra Series Ultrasonic Flowmeter Remote Display Unit is a touch screen display designed

to be used as an HMI for FMC Technologies equipment with a web based operator interface.

The display is enclosed in an explosion proof housing and is designed to be located outdoors

and in hazardous environments. The Remote Display Unit includes all software for configuring

connections to the desired equipment and includes security functions for compliance with WELMEC

standards for weights and measures. Once configured, the display will automatically connect to

the desired Ultra Series flowmeter upon start up.

1.1 Features

• Touch Screen Display – The touch screen display is pressure sensitive and can

be activated with gloved hands.

• Security – The display includes built in security features for compatibility with

WELMEC standards for custody transfer.

• Configurable – The display can be configured to search for any FMC Technologies Ultra

Series meter on the network. Once configured the display will automatically connect to the

configured device.

• Automatic Connection – Once configured the display will automatically connect

to the configured device upon reboot.

1.2 Specifications

See specification sheet SSLS008, 5.7" Remote Display.

1.3 Receipt of Equipment

When the equipment is received, the outside packing case should be checked

immediately for any shipping damage. If the packing case has been damaged, the local

carrier should be notified at once regarding their liability. Carefully remove the unit from

its packing case and inspect for damage.

If damage has occurred during shipment or parts are missing, a written report should

be submitted to the Customer Service department by using the contact information at

the beginning of this manual.

Prior to installation, the unit should be stored in its original packing case and protected

from adverse weather conditions and abuse. Throughout the installation process, the

electronics should be protected from adverse weather conditions.

Page 6 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Overview

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 7

Ultra Series C Remote Display I/O/M Manual Installation

2 – Installation

2.1. Mechanical Installation

2.1.1. General

The display is designed to be mounted to a plate through the holes tapped in to the rear

of the housing using size M6 x 1.8 screws.

The display unit must be supplied with an Ethernet RJ45 connection and 24 VDC power.

The cable, conduit and conduit fittings for these connections must meet installation

requirements, such as hazardous area classifications, humidity, temperature, voltage,

current and others. All conduit connections must be installed with approved conduit seals

within the required distance according to the applicable electrical code(s).

The touch screen is protected by an intrinsic safe barrier. The enclosure must be

grounded as per national electrical code regulations, for example NEC/CEC etc.

2.1.2. For ATEX and IEC Ex Installations

The following installation instructions apply for the certified equipment listed in

the equipment covered portion of the table below as per section 1.06 of Annex II of

Directive 94/9/EC (ATEX Directive):

Standards used:

IEC 60079-0 6th Edition, EN 60079-0: 2012, UL 60079-0 4th Edition

IEC 60079-1 6th Edition, EN 60079-1: 2007, UL 1203 4th Edition

IEC 60079-11 6th Edition, EN 60079-11: 2012, UL 60079-ll 5th Edition, UL 913 7 Edi-

tion UL 1203 4th Edition

Cable entries must be in accordance to EN/IEC 60079-1 section 13.

For wiring systems utilizing cable glands, the gland and/or thread adaptor must be

Page 8 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Installation

Ex d certified. The cable end must be securely installed and, depending on the cable

type, be properly protected from mechanical damage.

For wiring systems utilizing conduit, an Ex d certified sealing device must be used

immediately at the entrance of the enclosure. Any unused entry must be suitably blocked

with an Ex d certified plug.

The maximum ambient temperature for the enclosure is 60°C; if the enclosure is directly

mounted to a process piping system that exceeds this value then the enclosure shall

be remotely mounted to guarantee the 60°C ambient is not exceeded.

Equipment bonding shall be provided at the external grounding facility terminal.

External connection is not required when using metallic conduit or armored cable.

CAUTION: To prevent ignition of hazardous atmospheres and to prevent electrical

shock, disconnect from supply circuits before opening, keep tightly closed when circuits

are in operation.

WARNING: Contains internal battery-powered circuit to prevent ignition of hazardous

atmospheres, do not open enclosure unless area is known to be non-hazardous. To

reduce the risk of ignition of hazardous atmospheres, conduit runs must have a sealing

fitting connected within 18 inches of the enclosure. Substitution of components may

impair intrinsic safety.

Special conditions for safe use:

• Select wiring and cable glands suitable for 90°C operation.

• Contact manufacturer at address listed for information on the dimensions of the

flameproof joints.

FMC Technologies Measurement Solutions, Inc.

1602 Wagner Avenue

Erie, Pennsylvania 16510

USA

2.1.3. For North American Installations:

Conduit connections must be in accordance to: USA – National Electric Code (NFPA

70), Canada – Canadian Electric Code (CSA C22.1).

A listed seal-off box must be used immediately at the entrance of the enclosure. (i.e.:

within 3 inches). Any unused entry must be suitably blocked with a suitable listed plug.

Marking Equipment Covered Certicate

Ex d ib IIB T5 Gb

IP66

Tamb = -40°C to +60°C

Remote Mounted

Display

DEMKO 13 ATEX

1204991X

IEC Ex UL 13.0019X

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 9

Ultra Series C Remote Display I/O/M Manual Installation

2.1.4. All Installations – Notes

CAUTION: To prevent ignition of hazardous atmospheres, disconnect from supply cir-

cuit before opening any enclosure. Keep tightly closed when circuits are in operation.

WARNING: Contains internal battery-powered circuit. To prevent ignition of hazardous

atmospheres, do not open enclosure unless area is known to be non-hazardous.

DO NOT SWITCH POWER ON until all questions pertaining to installation wiring are

resolved. Any damage caused by unauthorized operation will void the warranty.

CAUTION: The cable installation must be performed according to the relevant cabling

lists and/or connection diagrams.

2.1.5. Installation of Cables

Due to customer or location specific requirements, the cables for communication and

power supply lines are not a part of the delivery. However, the technical specifications

for the cables MUST be followed. Prior to installation, these requirements must be

checked. The number of and types of cables are dependent on options utilized by the

end customer. A set of wiring diagrams are available covering the different options later

in this manual.

Cables must be protected against mechanical damage.

Be aware of the minimum bending radius of the cable. The bending radius for multi-

core cable is normally 6 times the diameter. However, the minimum bending radius for

a fiber optic cable may vary from this and must be checked with the cable manufacturer

in each case.

Page 10 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Installation

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 11

Ultra Series C Remote Display I/O/M Manual Installation

3 – Display Control Board

3.1. Wiring Examples / Information

3.1.1. Power Supply

The electronics are designed to be powered by 24 VDC, +20% / -15%, 7W.

The shield of the cable should be connected only at the electronic enclosure,

via the cable gland.

Connect input power cable to connector CN4

DC Input Wire Terminal

24 VDC (+) CN4-1

24 VDC (common) CN4-2

Ground CN4-3

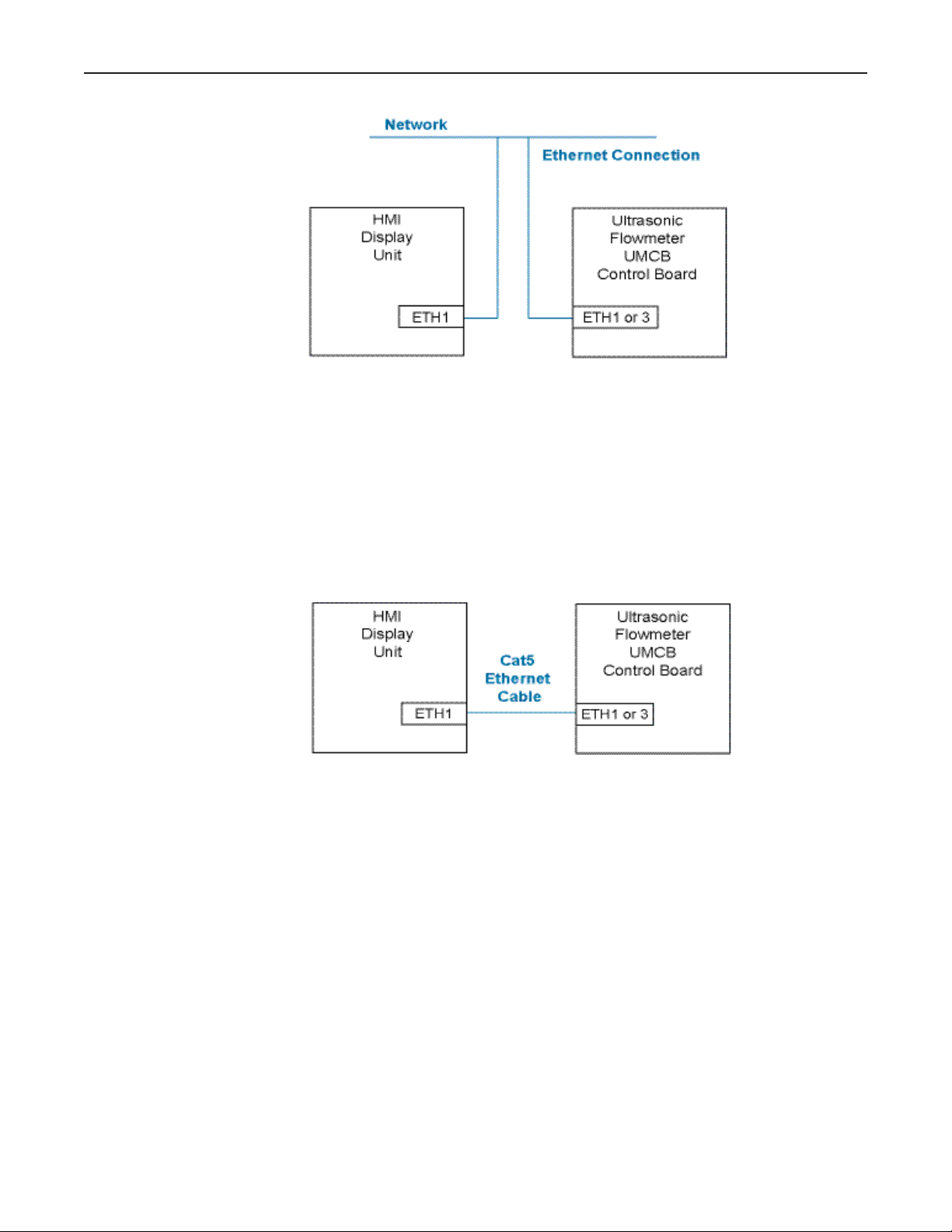

3.1.2. Network Ethernet Connection

The display utilizes ANSI/IEEE 802.3 Ethernet operating at 10/100 Mbps. The 10/100

Base-TX connection is made to the RJ45 connector at ETH1. The display unit will need

to be able to see the IP address of the ultrasonic meter from this network connection in

order to function. Refer to Configuration (Section 5.2) of this manual for details on

connecting to the ultrasonic meter.

Comm. Port Connection Port

10/100 Base-TX ETH1

Page 12 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Display Control Board

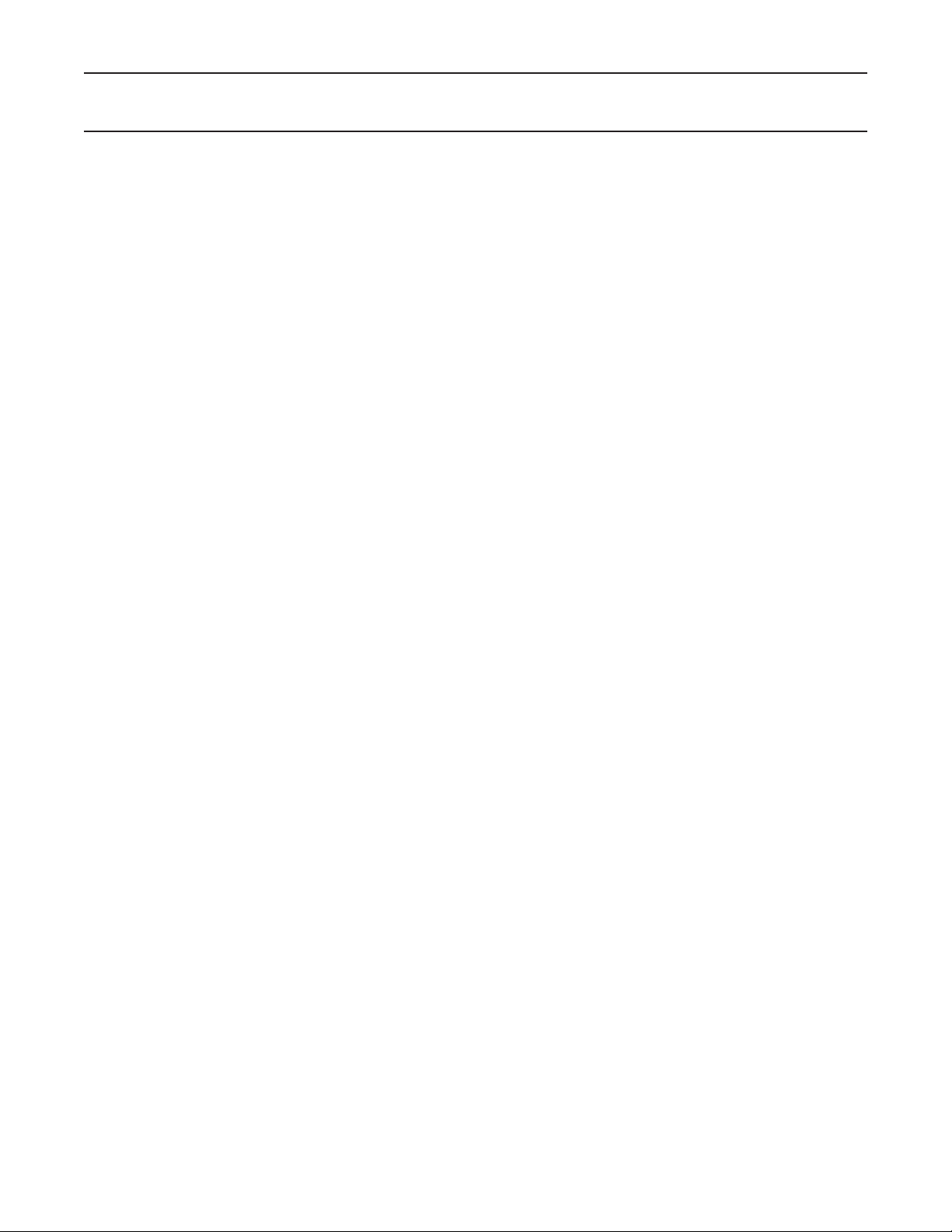

3.1.3. Direct Connection to the Ultrasonic Meter

The display unit can also be connected directly to the Ultrasonic meter using a CAT5

Ethernet cable (or better). Note that the Remote Display will still need to be configured

with the Serial Number or IP Address of the ultrasonic meter to function. Refer to

Configuration (Section 6.2) of this manual for details on connecting to the ultrasonic

meter.

Maximum cable distance: 100m (328ft)

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 13

Ultra Series C Remote Display I/O/M Manual Powering Up the Remote Display

4 – Powering Up the Remote Display

Before powering on the display unit, verify that the following items are completed:

• Display unit has been installed securely to a fixed mounting location.

• Power and network connections have been checked for proper wiring and

connection integrity.

• All conduit and/or gland connections are in adherence to applicable electrical codes.

When power is applied to the unit it will go through a boot sequence and the unit will

attempt to connect to the configured device. If the display has not been configured or if

it fails to connect to the desired device, the display will return to the Main Menu.

4.1. Start-Up

Upon power up the unit will proceed through the following boot sequence:

1. FMC Technologies logo screen with boot progress bar.

2. For a short period, a configuration icon is shown (gears graphic); if this button is

pressed, the connection sequence in the next item is skipped and the display

connects immediately to the Display main menu.

3. If the display is configured, it will attempt to connect with the host device:

a. If the Primary URL is configured, the display will attempt to connect to this

host. If the Primary URL fails it will try to connect to the device with the

specified "Device Serial Number".

b. If a host serial number is configured, the display will search the network for

an FMC Technologies device with the specified serial number, obtain an IP

address, and attempt to connect with that host. If it fails with the device serial

number it will attempt to connect to the secondary URL.

c. If a fallback URL is configured the Display will attempt to connect to that host.

4. If step 2 is unsuccessful in connecting to any configured device or if the

Remote Display has not been configured, the Remote Display main menu will

be shown. From the Main Menu the connection settings can be configured and

the connection sequence repeated.

Page 14 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Powering Up the Remote Display

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 15

Ultra Series C Remote Display I/O/M Manual Display User Interface

5 – User Display Interface

5.1. Main Menu

The main menu will be displayed if the display does not connect to a device after pow-

ering up. The main menu can also be accessed by interrupting the startup process by

tapping the configuration icon during startup. The following information and configuration

options are presented in the display main menu:

• Configuration – settings for a connection to a device

• Maintenance – adjustment of display setting

• Information – key identification and settings data

• Reconnect – initiate a reconnection to the configured device

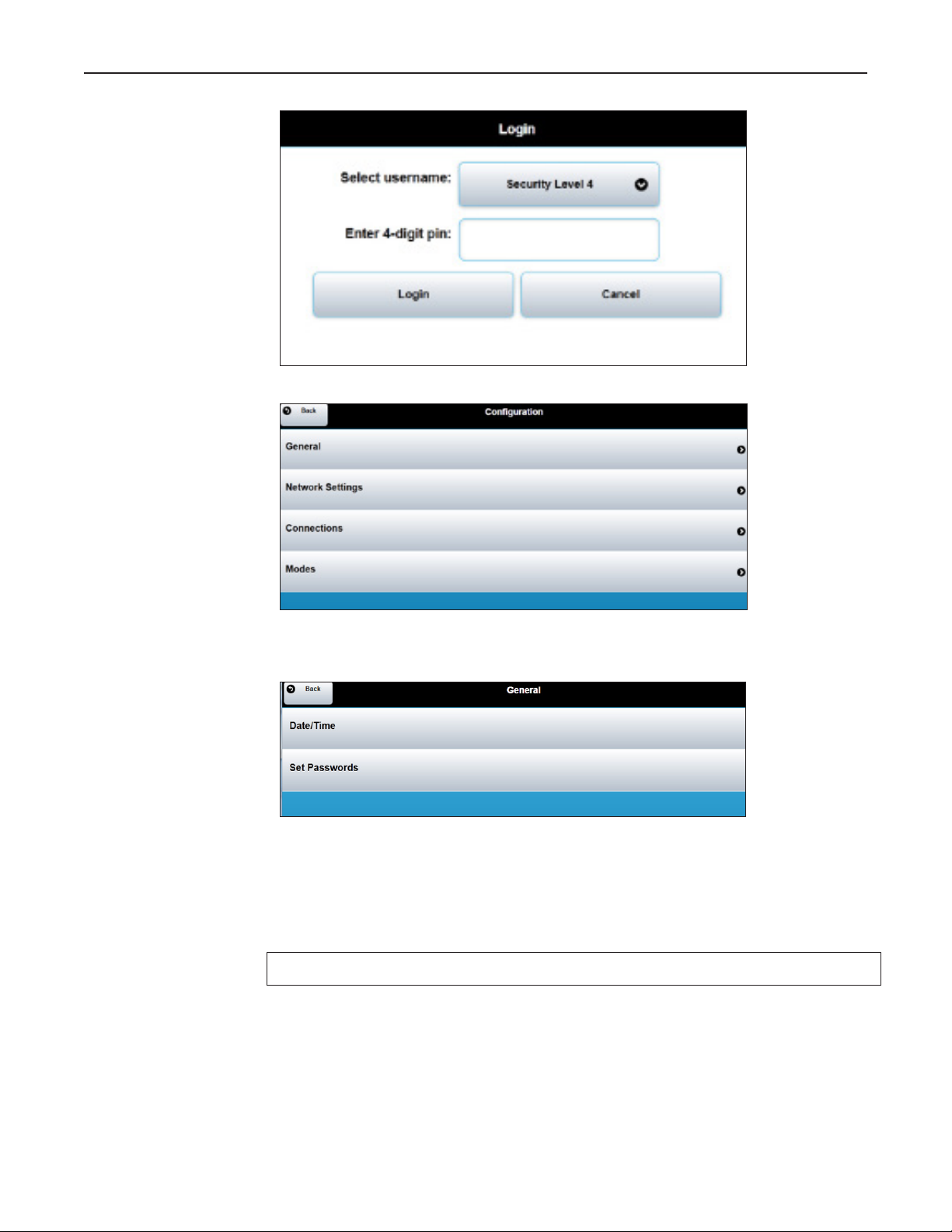

5.2. Configuration

The configuration tab is used .to set up the display to communicate with the desired

device and to set the password to control access of the display settings. A password

is required to access the configuration settings. When the Configuration Button Icon is

selected, a Login Screen will appear. There are two different levels of security access

for the Display with the following default passwords:

• Level 4 Password – 4444 Network configuration level

• Level 5 Password – 5555 Weights & Measures access level

It is recommended to change the passwords from the default value to a more secure

setting. Refer to Section 5.2.1 for password setting instructions.

Page 16 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Display User Interface

5.2.1. Configuration – General

Date/Time – Adjust the date and time of the display unit. Once the display has been

sealed the date and time adjustment will be locked out.

Set Passwords – Update the passwords for either level 4 or level 5 access. The

screen will prompt for the old password and for the new password to be entered twice

for confirmation.

The password is unique to the remote display and is not shared with the ultrasonic meter.

IMPORTANT: Record all password modifications and store in a secure location.

5.2.2. Network Settings

The network settings are to configure the address of the Remote Display on the net-

work. Note that this is not the address of the meter that the display is connecting to. The

display is required to have a unique IP address because it exists as a device on the IP

network. There are two modes to create the display’s network address:

DHCP - The Dynamic Host Configuration Protocol is used to request the IP address from

the network server. With this configuration checked, the DHCP server assigns a local

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 17

Ultra Series C Remote Display I/O/M Manual Display User Interface

IP address to the Remote Display connected to the local network. This is the default

network setting from the factory.

Fixed – If the network administrator prefers to fix the IP address then this configuration

can be used. The network settings for the fixed address must be entered manually on

the display screen.

Note: The unit must be power cycled for the new settings to take effect.

5.2.3. Connections

The connections setting is used to connect to the desired ultrasonic flow meter.

Primary URL – This fixes a target IP/URL address that the display will first attempt to

connect to upon startup of the unit. In order to configure this value the IP address of

the ultrasonic flow meter must be known.

Primary Timeout – Maximum time allowed for the primary URL connection attempt, in

seconds. The URL connection attempt can be skipped by setting a zero timeout.

Device Serial Number – The unique serial number assigned to the ultrasonic meter

control board. The Ultra S eries flow meter will broadcast this Serial Number over the

network in a way that the Remote Display unit can detect. When the Remote Display

matches the configured Serial Number to a device on the network it will form a connec-

tion. The ultrasonic meter Serial Number will be displayed in the meter electronics box.

This is the recommended connection method to the ultrasonic flow meter.

Device Timeout – Maximum time to allow for the device Serial Number connection

attempt.

Secondary URL – An alternate target IP/URL address that the display will attempt to

connect to. In order to configure this value the IP address of the target device must be

known.

Secondary Timeout – Maximum time allowed for the secondary URL connection at-

tempt. The connection attempt can be skipped by setting a zero timeout.

Minimum Up Time – A minimum time since power up to allow before attempting a host

connection. Setting this to a larger value (in seconds) may be needed if the display

attempts to connect to its host before the host is ready to accept connections (for ex-

ample, if all instruments are turned on with the same power source, and the host takes

longer to boot up).

Page 18 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Display User Interface

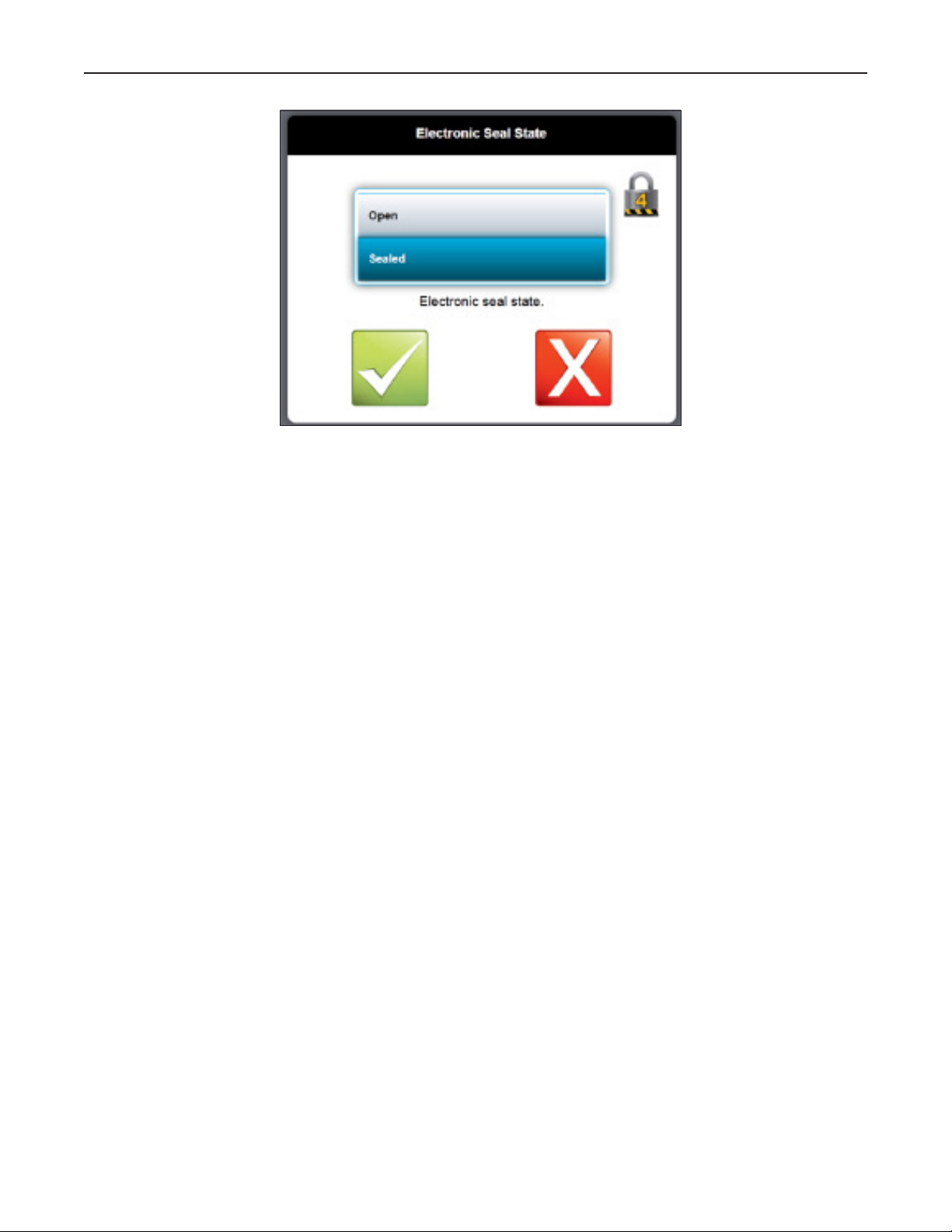

5.2.4. Modes

The Modes setting is used to configure the electronic seal and to configure the back-

lighting sleep mode for the display.

Electronic Seal State

This is used to set the electronic seal onto the display unit. Sealing locks out the ad-

justment of parameters that would be required to be fixed by a weights and measures

official. Sealing can only be opened on Level 4 or 5 access. Sealing can only be set

by Level 5 access.

Issue/Rev. 0.0 (7/14) ║ MNLS007 • Page 19

Ultra Series C Remote Display I/O/M Manual Display User Interface

Backlight Timeout

This sets the amount of time before the LCD backlight switched off for a sleep mode.

The following backlight timer duration options are available from the configuration screen.

• Always On

• 1 Minute

• 5 Minutes

• 20 Minutes

• 1 Hour

Page 20 • MNLS007 ║ Issue/Rev. 0.0 (7/14)

Ultra Series C Remote Display I/O/M Manual Display User Interface

5.3. Maintenance Settings

Allows for the unit to be reset to factory defaults by clearing all new settings.

5.3.1. Touch Screen Calibration

Opens a touch position calibration screen. This will calibrate the screen input by

displaying a series of touch screen targets and matching the input values with the known

location of the targets.

5.3.2. Password Reset

This option allows resetting all passwords to factory defaults. The procedure described

below must be followed to successfully accomplish this task. Please note that if success-

ful, the electronic seal will be broken and the action logged; if the unit is under Weights

and Measures control, it will need inspected and sealed again.

Table of contents