Operating Manual BMGZ710 and BMGZ710.PNET

20.04.2021 2

1Table of contents

1TABLE OF CONTENTS............................................................................................................................. 2

2SAFETY INSTRUCTIONS.......................................................................................................................... 4

2.1 Representations of safety instructions............................................................................................... 4

2.1.1 Risk that may result in minor or moderate injury........................................................................... 4

2.1.2 Instructions to ensure proper functionality..................................................................................... 4

2.2 General safety instructions................................................................................................................. 4

3PRODUCT INFORMATION........................................................................................................................ 5

3.1 System configuration.......................................................................................................................... 5

3.2 Product description ............................................................................................................................ 5

3.3 Functional description........................................................................................................................ 5

3.4 Scope of delivery................................................................................................................................ 5

3.5 Order code for evaluation unit............................................................................................................ 6

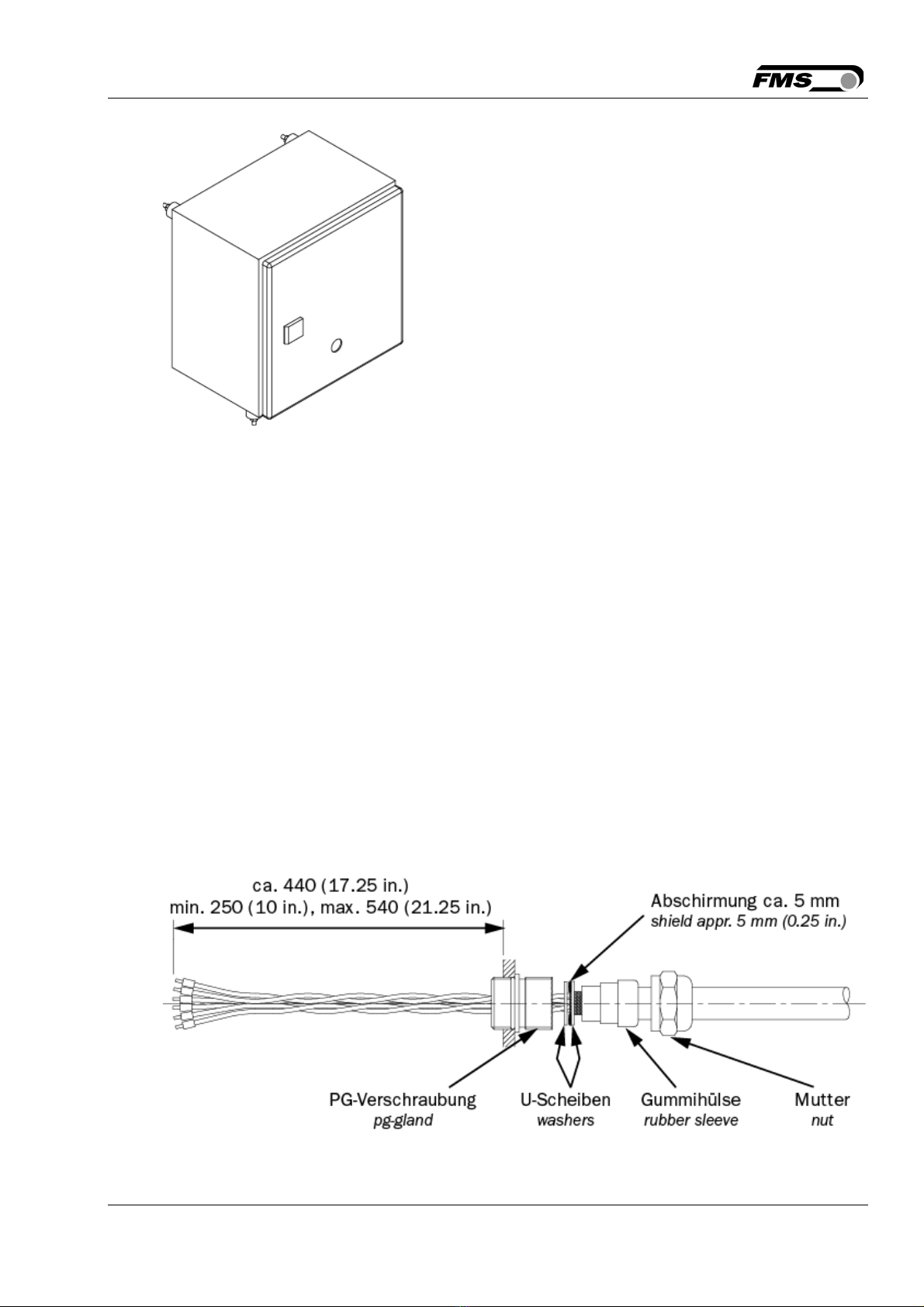

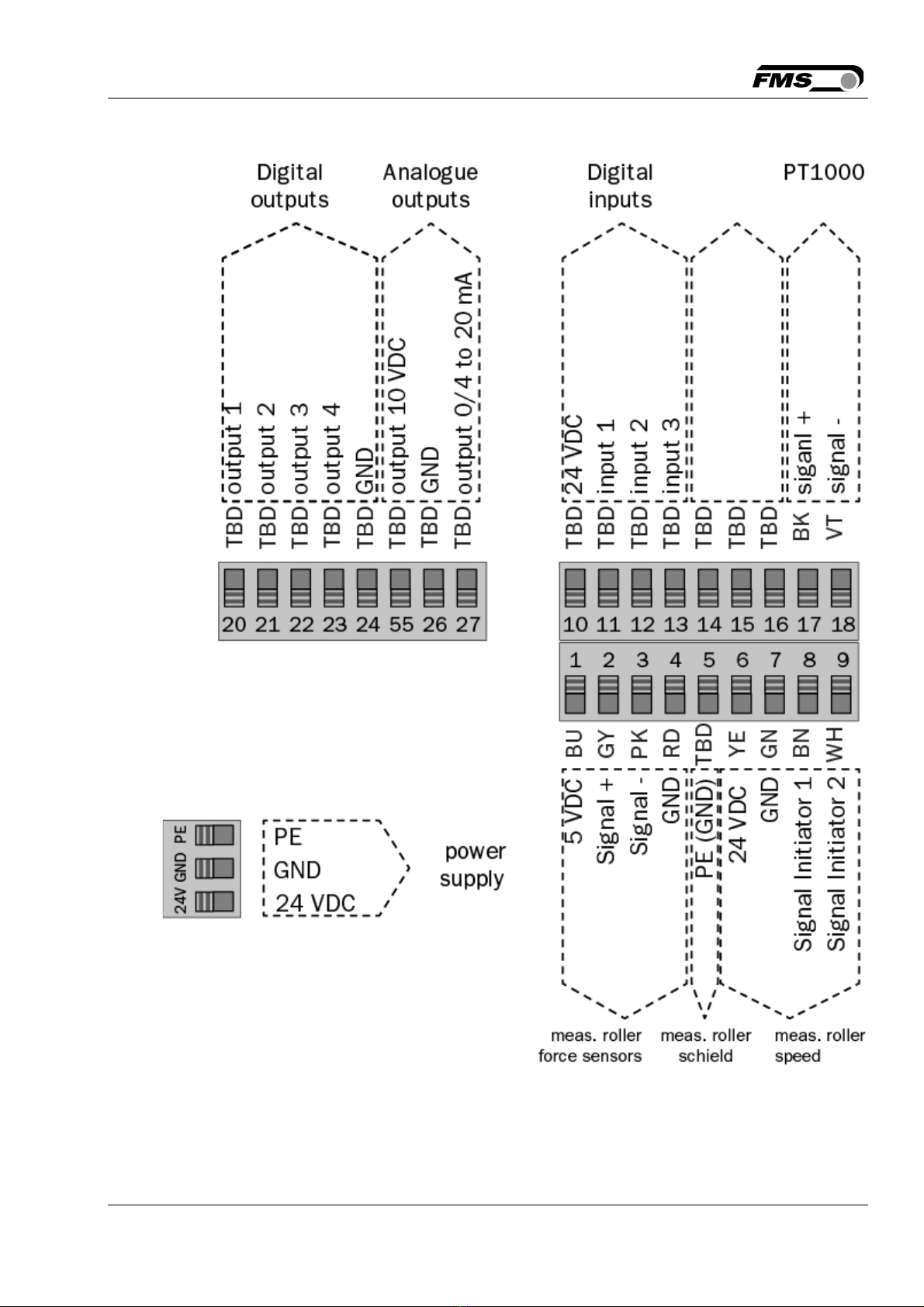

4INSTALLATION.......................................................................................................................................... 7

4.1 Electrical connection (see installation instructions for the FMS measuring roller)............................. 8

5OPERATION AND SURFACE................................................................................................................. 11

5.1 Navigation, quick start...................................................................................................................... 11

6CONFIGURATION.................................................................................................................................... 14

6.1 Plant parameters.............................................................................................................................. 14

6.1.1 Description of plant parameters................................................................................................... 14

6.2 Operating parameters...................................................................................................................... 16

6.2.1 Description of operating parameters ........................................................................................... 17

6.3 System parameters.......................................................................................................................... 19

6.3.1 Description of system parameters............................................................................................... 19

6.4 Service ............................................................................................................................................. 21

6.5 Digital inputs..................................................................................................................................... 22

6.5.1 Digital input 1 (zero setting)......................................................................................................... 22

6.5.2 Digital input 2 (batch active) ........................................................................................................ 22

6.5.3 Digital input 3 (belt running)......................................................................................................... 22

6.5.4 Digital input 4 (impulse)............................................................................................................... 22

6.6 Digital outputs .................................................................................................................................. 23

6.6.1 Digital output 1 (BMGZ OK)......................................................................................................... 23

6.6.2 Digital output 2 (taring active)...................................................................................................... 23

6.6.3 Digital output 3 (remote impulse)................................................................................................. 23

6.6.4 Digital output 4 (remote reset)..................................................................................................... 23

7STANDARD PROCEDURES................................................................................................................... 24

7.1 Taring (zero setting)......................................................................................................................... 24

7.2 Calibrating........................................................................................................................................ 25

7.3 Manual batch weighing .................................................................................................................... 26

7.4 Manual batch weighing – with storage in the alibi protocol.............................................................. 26

8CONFIGURATION VIA WEB INTERFACE ............................................................................................. 27

8.1 Peer-to-peer connection................................................................................................................... 27

8.2 Home screen.................................................................................................................................... 30

8.3 Current reading................................................................................................................................ 30

8.4 Parameters....................................................................................................................................... 30

8.5 Alibi protocol..................................................................................................................................... 31

8.6 Ethernet settings.............................................................................................................................. 32

8.7 System settings................................................................................................................................ 32

9DIMENSIONS........................................................................................................................................... 33