FOGO FH 9000 User manual

Manufacturer:

FOGO Sp. z o.o.

ul. Święciechowska 36,

Wilkowice

Święciechowa 64-115, Poland

portable

For models:

HONDA

FH3001, F3001R, FH3541, FH4001, FH4001R, FH4541,

FH6000, FH6000R, FH6540, FH6001, FH6001CRA,

FH6001R, FH6001T, FH6001TE, FH6001TR,

FH6001TRA, FH6001TRE, FH6541, FH8000,

FH8000CRA, FH8000R, FH8000T, FH8000TE,

FH8000TR, FH8000TRA, FH8000TRE, FH8220TW,

FH8220TWE,

FH8220W, FH9000, FH9000CRA, FH9000R, FH9000T,

FH9000TE, FH9000TR, FH9000TRA, FH9000TRE,

FH9220TW, FH9220TWE, FH9220W, FH9540TR,

FH9540TRA, FH9540TRE, FH9540

BRIGGS

FV10001CRA, FV10001TE, FV10001TRA,

FV10001TRE, FV10300TWE, FV10300WE,

FV11300TWE, FV11001CRA, FV11001TE,

FV11001TRA, FV11001TRE, FV13000CRA,

FV13000TE, FV13000TRA, FV13000TRE,

FV13540TRA,

13540TRE, FV15000CRA, FV15000TE,

FV15000TRA, FV15000TRE, FV15540TRA,

FV15540TRE, FV17001CRA, FV17001TRA,

FV17001TRE, FV20000CRA, FV20000TE,

FV20000TRA, FV20000TRE, FV20540TRA,

FV20540TRE

MISTUBISHI

FM6001, FM6001R, FM6001E, FM6001RE, FM8000,

FM8000R, FM8000E, FM8000RE, FM8220W,

FM8220WE, FM9000, FM9000R, FM9000E,

FM9000RE, FM9220W, FM9220WE, FM6541,

FM6541E, FM9540, FM9540RE

FOGO

F3001, F300R

User manual ORIGINAL MANUAL

Portable power generators

1

Introduction

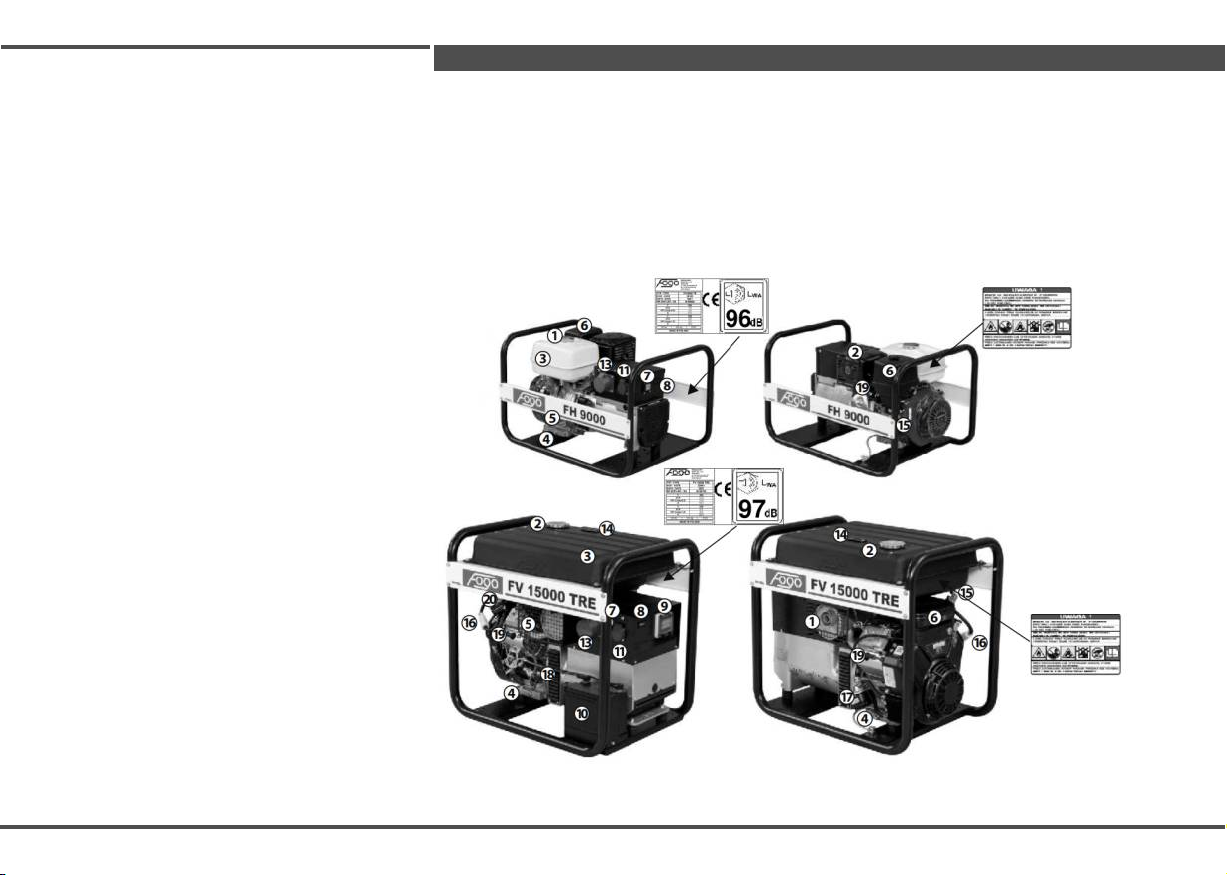

1. Fuel filler cap

2. Silencer

3. Fuel tank

4. Oil drain plug

Location of safety and identification stickers

When using the power generator, remember to observe safety precautions. Therefore, the device is

provided with pictograms reminding about safety during operation. Their meaning is explained

below. Stickers are an integral part of the power generator. If they become illegible or destroyed,

contact your Authorized Dealer of FOGO Sp. z o.o. in order to replace them with new ones. We

strongly recommend carefully reading and understanding the safety rules included in our manual.

6

1

3

2

5. Oil dipstick

6. Air filter

7. Thermal switch

8. Operation time counter

9. Magneto-thermal circuit breaker

10. Battery

11. 230V 16A socket

12. 230V 32A socket

13. 400V 16/32A socket

14. Fuel gauge

15. Fuel valve

16. Fuel filter

17. Oil filter

5

4

2

20

16 5

19

11 17 3 6

8 19

15

14 14

3 2

15

7 8 9 1 6

13 11 19 16

18. Electric starter

19. Spark plug

20. Fuel pump

18

4

17

10

4

1

Introduction

Dear Customer

Thank you for your trust in our equipment and purchase of high-quality FOGO® power generator. We

are convinced that cooperation with world-leading manufacturers of components and application of innovative

technological solutions, we have created a product that sets standards in terms of quality, safety and reliability.

We hope that our product will meet your requirements in everyday use, ensuring long-lasting, trouble-free

operation.

FOGO Sp. z o.o.

Before the first start of the device, it is

absolutely necessary to read the manual !!

Safety of the user and all persons staying near to the device is very important. Therefore, before using

the power generator, it is essential to read these instructions. The buyer of the power generator must ensure

that this manual is always available for its operator and that every user reads the manual before starting any

activities related to device operation.

Fogo power generators are designed and manufactured in accordance with current European

directives, which we confirm by the declaration of conformity. In order to confirm that our generators meet EU

safety requirements, we submit them to additional conformity assessment procedure, performed by a third

party Notified Body.

FOGO® devices comply with the relevant European standards and other specific requirements in

terms of the construction, operational safety and environmental protection. Each power generator is provided

with CE declaration of conformity with the measuring sheet and technical specification of the unit.

2

1

Content

1. Construction of power generator................................................................................................. 4

Engine ................................................................................................................................ 4

Alternator ........................................................................................................................... 5

2. Safety rules .................................................................................................................................. 7

3. Selecting proper power generator for the receiver ................................................................... 10

4. Delivery, unloading, storage ....................................................................................................... 11

5. Disposal ....................................................................................................................................... 11

6. Operation .................................................................................................................................... 13

Starting ..................................................................................................................... 13

Stopping ................................................................................................................................... 17

7. Repair, maintenance..................................................................................................................... 19

List of maintenance operations ............................................................................................ 19

Maintenance methods ............................................................................................................ 19

Faults ................................................................................................................................. 22

8. Maintenance .............................................................................................................................. 23

List of spare parts and consumables .................................................................................... 23

Transport and storage ................................................................................................................ 24

9. General commercial terms. ........................................................................................................ 25

10. Repair log-book.......................................................................................................................... 26

11. Complaint notification card ....................................................................................................... 27

3

1

1. Construction of power generator

Power generator is a device generating

electricity by converting mechanical energy

produced by the combustion engine into

electricity produced in the alternator

connected to the engine. Power generators

are used as a source of power in case of

power failure in the network or as an

alternate power source in a building site, plot,

workshop or at home.

When operating with automatic start-up,

power generator is an excellent back-up

device for private and public buildings to

prevent uncontrolled power outages.

Technical specifications of power

generators are defined for the altitude of 0

m ASL, ambient temperature of 20°C and

60% RH. When operating in other

conditions, their performance is reduced:

for altitude - the performance decreases by

1% each 100m, for temperature - the

decrease is 2% per each 5°C. The power

generator may be adapted for permanent

use at high altitudes (above 1830 m above

sea level) by necessary modifications in

the engine introduced by an authorized

workshop.

CONSTRUCTION OF POWER GENERATOR

The power generator, in its basic version,

consists of a combustion engine

and a three- or single-phase alternator,

fixed together and installed on dampeners

in a metal frame. As a standard solution,

the power generator is equipped with

necessary protection to enable its correct

functioning, e.g. a sensor for pressure or

engine oil, two- or four-pole over-current

circuit breaker, electric starter and the

battery. The optional accessories include

working hour meter, grounding set,

transport kit, a hose for the exhaust

system, welding wires (units with a welding

module), automatic start panel with ATS

(for units with electric starter).

ENGINE

FOGO® portable generators are equipped

with four-stroke, overhead valve engines

fuelled by gasoline.

Mechanical stabilization of the engine

speed is maintained at 3000 rpm and it

operates independently of the load,

ensuring optimal parameters for

alternators. All the engines are air-cooled

and can effectively work outdoors in

ambient temperatures up to 40°C.

The engine operating indoors should be

provided with fresh air inflow of at least

100 m3/h (variable value depending on the

type of unit - for correct selection of device

and ventilation, please contact the

customer service of Agregaty S.A.).

Engines are equipped with own exhaust

systems ended with a silencer and with

compatible exhaust hoses.

The user may use one of two types of start-

up: manual with a retractable cord and

electric starter (may operate with automation

accessories). Engines with electric starter are

equipped with a system that ensures proper

charging of the battery.

SINGLE-CYLINDER (HONDA, MITSUBISHI,

RATO)

Depending on the design of the motor,

lubrication is carried out in different ways.

For single-cylinder engines it is splash

lubrication. Engines are protected against

low oil level.

Single-cylinder engines are equipped

with own fuel tanks, where fuel flows by

gravitation into the combustion chamber.

(optionally, fuel tanks may be replaced

with tanks of larger capacity).

4

1

1. Construction of power generator

Two-cylinder (BRIGGS & STRATTON-

COMMERCIAL POWER line)

In two-cylinder engines (fork-shaped), the

lubrication is carried out using pressure. The

engine has an oil pump that forces oil circulation -

when engine is stopped may cause the oil

pressure drop.

Two-cylinder engines are equipped with a

vacuum pumps for drawing fuel from external

tanks. FOGO® power generators are equipped

with two-cylinder engines are provided with tanks

of 45 litres, mounted on the frame above the

motor. All fuel tanks used in FOGO® generators

are equipped with fuel mesh filters to protect

against ingress of dust particles or other

contaminants into the carburettor.

ALTERNATOR

FOGO® generators operate with one- and

three-phase synchronous and asynchronous AC

alternators with different degrees of protection

rating (IP).

Single-phase alternators have a system of

voltage self-regulation provided by the inner

winding coupled in circuit with the capacitor. It

maintains voltage at the level of 10% with

uniform load distribution. Three-phase

alternators have a system of voltage self-

regulation at the level of 6%, and those with AVR

at the level of +/-2% at uniform load. The three-

phase alternators may operate at uneven phase

load, reaching 10 % of rated power, while the

single-phase sockets of three-phase alternators

provide up to 40% of the generator rated power.

5

For some models, it is allowed to receive power

from single-phase sockets above 40% (see

technical data). When these values are

exceeded, the electrical parameters (mainly

voltage) of the alternator may deteriorate and

windings may overheat resulting in their

burning. For single- one and three-phase

alternators, momentary overloads exceeding

10% of rated power are allowed, but they

cannot be longer than 5 minutes in every 3

hours of device operation.

Single-bearing design and the flange

connection to the engine ensure quiet and safe

operation. The drive from the engine is

transmitted through a tapered connection and

threaded rod. Alternator housing is made of

light aluminium alloys. Winding of the rotor and

stator is insulated with a special epoxy varnish

and is rated in insulation class H.

Alternators used in FOGO power generators

have the protection degree of IP 23 or IP 54.

Applying the protection degree of IP 54 extends

the life of the alternator, as the bearings and

winding are perfectly protected against harmful

impact of external factors. IP 54 increases the

range of applications in high humidity and dusty

conditions.

Synchronous alternator (IP23) - used for

inductive receivers, power tools and

construction equipment with engines of high

starting current. This alternator has windings

on the rotor and is self-excited by capacitor

that collects the remaining energy from

residual magnetization or from additional

excitation system consisting of the magnetic or

electronic regulator. Cooling of these alternators

is carried out mostly by forced air circulation in

their interior (direct cooling of windings).

Synchronous alternator IP54

Synchronous alternators in special versions are

equipped with electronic voltage regulators (AVR)

with controlled voltage and current of all three

phases. In these alternators the impact of heavily

loaded phases on the stability of a phase with a low

load is very small. AVRs ensure voltage stability of

(+/- 2%) for SDI alternator (+/- 1%). These

generators may operate at uneven phase load,

reaching 10% of rated power, while cooling is

carried out by forced air circulation in the slots

outside of the generator.

Asynchronous alternator IP54

This alternator is highly durable and transfers

no current to the moving parts through contacts,

which eliminates arcing and wearing of

brushes. The rotor has no visible windings, it

uses a cage made of steel laminations isolated

from each other with the addition of silicon.

For single- one and three-phase

alternators, momentary overloads

exceeding 10% of rated power are

allowed, but they cannot be longer

than 5 minutes in every 3 hours of

device operation.

1. Construction of power generator

The electrical circuit of the rotor is made of non-

insulated aluminium rods,

3

Ingress protection rating of IP23 or IP54

joined on both sides of the rotor with shorting

rings. Asynchronous alternator provides active

power, but consumes reactive power necessary

for magnetizing the machine. To compensate the

consumed inductive reactive power, the output of

the power generator is equipped with capacitors.

Constant speed of the alternator rotor is

maintained by the combustion engine.

First digit

Protection against foreign

objects and touch

0- without protection

1 - foreign bodies > 50 mm

2 - foreign bodies > 12 mm

3 - foreign bodies > 2.5 mm

4 - foreign bodies > 1 mm

Second digit

5 4

Protection against 6

water ingress 7

8

0 - no protection 9 11 1 2

1 - vertically falling water drops 10

2 - water dripping up to 5°

from the vertical

3 - water splashing obliquely up to6 0 °from vertical 12

4 - water spouting from all directions

Figure 1. Description of ingress protection IP symbols 3

When load changes, the speed varies only in

the range of the machine slip. It has relatively

high voltage instability at terminals of the

alternator. Some alternators have additional

windings (connected with a capacitor) to support

excitation of the generator. Cooling in these

alternators is carried out by forced air circulation

in slots outside the alternator.

4

6

safe

8

9

10.

11

12

MARKING OF THE POWER GENERATOR

2

1

13 14

DESCRIPTION OF THE NAMEPLATE

Alternator with welding module IP23

Alternators in some models are equipped with

welding modules for working with electrodes of

each type, having a diameter of max. 5 mm (FH

8220 W (TW, TWE) and 6 mm ((FV 11300

TWE, FV 11400 TWE) in the cycle of 35%, i.e.

3.5 minutes in every 10 minutes of operation.

PROTECTION CLASS IP 23 and IP 54

First digit: protection against foreign objects.

Second digit: protection against the ingress of

water.

F -

FOGO generator

Engine t ype s

H

- HONDA

V

- VANGUARD B&S

M

-

MITSUBISHI

n one

-

RATO

Engin e powe r

(~kVA)

FH 9540TRA

Protection rating

00

- IP 23

54

- IP 54

Numbe r o f pha se s

1 - single-phase (220V)

0 - three-phase (400V)

Additional options

X

- special

C

- silenced

E

- electric start

A-

prepared to connect automation

R

- AVR - Automatic Voltage Regulation

T

- enlarged tank

W

- welding module

MARKING OF THE POWER GENERATOR

NAMEPLATE

1 - CE mark confirming compliance with the

requirements of the European Directives

2 - Noise level emitted to the environment, acc. to

Directive 2000/14/EC,

3 - Name and address of the manufacturer,

4 - Model / Type,

5 - Manufacturer's code

6 - Year of production,

7 - Serial number,

8 - Nominal power [kVA],

9 - Nominal power [kW],

10 - Voltage [V],

11 - Current [A],

12 - Frequency [Hz],

13 - Weight of power generator [kg],

14 - Protection class IP 6

2. Safety rules

Safety of the user and all persons staying near to the

device is very important. Important information is

included in the manual and on the power generator set -

it must be read carefully. The information indicates and

warns of potential danger for user and third parties.

The power generator produces enough power to cause a

serious electrical shock in case of improper use. Make

sure that the power generator is grounded when

connected receivers are grounded. For grounding the

power generator, use a copper conductor with cross

section equal or larger than the conductor used to

connect receivers. If you connect the receivers having

the grounding, a grounding cable must be used.

Grounding rod is present in every Fogo generator - on

the crossbar of the frame under the engine and marked.

•

- Before starting the power generator, read its manual and make

sure that you understand all its recommendations. Every person

using the power generator must read its manual.

CAUTION ! During operation of the device,

the silencer reaches high temperatures and

remains hot for some time after stopping.

Allow the engine to cool before storing it

indoors.

•

- Do not operate the generator in an enclosed

space without sufficient ventilation. Exhaust gases

are toxic (contain large amounts of odourless

carbon monoxide [CO]) -

RISK OF POISONING OR EVEN DEATH!!!

7

During the operation, the engine should be provided

with fresh air inflow of at least 100 m³/h (variable value

depending on the type of the device - for the correct

selection of ventilation, please contact the customer

service of AGREGATY S.A.). When using the power

generator unit with additional ventilation indoors,

observe the additional requirements for explosion

protection.

- Do not fill the fuel tank while the engine is

working - RISK OF EXPLOSION!!!

- Do not start the power generator in case of

fuel spillage. Restarting is permitted after

removing of the spilled fuel - FIRE RISK!!!

- Do not run the generator in an environment with

escaping gas, paint vapours, solvents or other

combustible materials - RISK OF EXPLOSION!!!

- Do not smoke and do not use open flames near the fuel

canisters or containers RISK OF EXPLOSION!!!

- Do not operate the generator in forest areas or similar

without a spark arrester

- RISK OF FIRE!!!

- Do not operate the generator, when it is wet or damp

- RISK OF ELECTRIC SHOCK OR EVEN DEATH!!!

- Before starting the operation, check the technical

condition of the device, especially guard covers the

cable insulation.

- Do not touch the rotating parts during operation

RISK OF INJURIES OR HEALTH DAMAGE!!!

- During operation of the power generator, pay attention to

children and animals present in its vicinity

- Do not transport and do not leave the power generator

in closed rooms immediately after the operation

- RISK OF FIRE!!!

- Do not place any objects on the operating

generator. Pay attention to any objects near

the generator - its parts heat up to high

temperatures during operation - RISK OF

IGNITION!!!

- During operation, and a long time after its inactivation,

do not touch the exhaust system and silencer shields -

RISK OF BURNS!!!

- Do not operate or stop the generator under load -

RISK OF DAMAGE!!! (of the generator and the connected

receivers)

- Do not adjust the engine speed by yourself - RISK OF

ELECTRIC SHOCK OR ALTERNATOR DAMAGE!!!(failure

of alternator's winding or generating a high voltage).

- Do not fill the generator with non-compatible fluids, fuel

or with oil of inadequate quantity and quality (check oil

level daily or every 8 hours of operation, in case of oil loss -

refill with oil of the same parameters)

- RISK OF DAMAGE AND GUARANTEE LOSS!!!

2. Safety rules

- Ensure that the device is not tilted by more than 20

degrees during transport or operation. Larger tilt may

cause fuel leakage or poor engine lubrication - RISK OF

DAMAGE!!!

- Do not use non-original spare parts and fuel of unknown

origin - RISK OF DAMAGE AND GUARANTEE LOSS!!!

- After ending the operation, close the fuel tap. When the

tap is left open it may cause fuel to enter the oil pan,

reducing lubricating properties of the oil - RISK OF ENGINE

DAMAGE OR SEIZURE!!!

Do not fill the fuel during operation of the power

generator! Refuel only in well-ventilated areas. Never

unscrew the fuel cap when the engine is running or when it

is hot. If you spill fuel, move the power generator to

another place and wait before starting the engine. Fuel

must evaporate.

Read the manual.

Use safety goggles.

Use hearing protection

Any work on electrical system may only be

carried out by qualified electricians who have

the appropriate permissions SEP (Association

of Polish Electrical Engineers).

It is strictly forbidden for unauthorized

persons to work on the distribution box.

. After ending the operation, always close the fuel

valve. Avoid repeated or prolonged contact of fuel with

the skin, as well as inhalation of vapours.

DO NOT CONNECT THE POWER GENERATOR TO ANY

SOURCES OF ELECTRICITY

Connecting the power generator as a source of

emergency power supply may be made only by a

qualified licensed electrician. When connecting,

consider operational requirements of the generator in

conditions for supplying domestic networks in

accordance with applicable standards.

- Do not overload the power generator and its power

cord. Protect the power cord from heat, oil, sharp

edges and moving parts. Damage to the power cord

increases the RISK OF ELECTRIC SHOCK.

- If you work outside enclosed rooms, use extension

cords intended for use outdoors. Using suitable

extension cords reduces the RISK OF ELECTRIC SHOCK.

Using plugs and cables must not be damaged even in

the slightest degree

- RISK OF ELECTRIC SHOCK

OPERATING THE POWER GENERATOR.

The power generator is a reliable device, designed

to ensure safety. It facilitates the work and rest,

but note that there is a risk of electric shock if basic

instructions contained in the manual are not

observed.

-

Never connect the generator to the outlets in the

building.

-

Do not connect any receivers to the power

generator before starting it.

-

Do not change the internal wiring in the power

generator.

-

Never connect the three-phase sockets of the

generator to a single-phase distribution box

-

Do not adjust the rotation of the engine: current

voltage and frequency are directly dependent on

the engine speed - the adjustment is made by the

manufacturer.

-

Supply only those devices, where the voltage on the

rating plate is identical with the voltage of the

generator.

-

Protection against electric shock depends on the

fuse, which rating must be properly selected for the

model of the power generator. If the fuse needs to

be replaced, it must be replaced with a fuse having

identical rating/specifications.

-

Due to its increased resistance to mechanical

damage, a multicore cable in rubber sheathing

should be used.

-

Connect only devices in good working condition;

most of the portable electrical equipment is rated

in Class II (double insulation). Devices that do not

meet the requirements of this class (tools in a metal

housing) must be connected with a three-wire

cable.

-

Grounding of the neutral conductor of the generator

may be carried out only by a qualified electrician,

who applies an additional shock protection

measures. (PN-EN 60364-4-41).

8

2. Safety rules

-

Where the power generator is used for supplying an

existing network, e.g. at home or workshop, check

the effectiveness of electric protection used in this

network. Additional protection may be necessary

due to the low short-circuit current of the power

generator. Connecting the unit to such a network

may be only performed by a qualified and licensed

electrician.

-

Electrical cables must be carefully selected,

adjusted and serviced. Good technical

condition of t he ins ulation ensures the

safety of the user. Cables must be inspected

periodically and in case of damaging, they

must be replaced (not repaired).

-

Adjust the length and cross-section of the cable

according to the needs:

-

Depending on the cable length, there is a voltage and

current drop. We recommend the use of extension

cords with a core cross-section of 1.5mm2 or

more, and the total length not exceeding 60 m.

Observe the following rules:

-

Do not use the cables of unknown origin,

-

expand the cable completely to avoid kinks in cable

insulation,

-

use cables in accordance with the manufacturer's

instructions,

-

Power generators without AVR (Automatic Voltage

Regulation) are not designed to power sensitive

electronic equipment, e.g. TV, hi-fi equipment,

computers. These devices may not be compatible

with the power generator.

9

-

Do not overload the power generator. To ensure

proper operation and long life of the power

generator, observe the following rules:

-

total power of current receivers must not exceed

the power stated on the nameplate.

-

some current receivers (in particular electric

motors, compressors, etc.), during their start-up,

draw power greater than their rated power. For

more detailed information, contact an

authorized dealer of FOGO Sp. z o.o.

-

do not exceed the maximum power of connecting

sockets of the power generator.

-

Do not apply the nominal power to the

power generator in conditions different

than the nominal conditions. Rated power

is specified for specific operational

conditions - (atmospheric pressure of 1

bar, air temp. of 20°C, air humidity of 60%).

Power drop caused by the air temperature

or pressure drop (due to the location

altitude) may in adverse conditions exceed

10%.

-

Information on the construction of the power

generator - electrical connection. Generator

windings are not connected to the ground. As a

result, the device is safe and eliminates the risk

of electric shock. When the power generator is

used to supply power to receiving networks in

TN or TT system, it is necessary to connect the

neutral point of the generator winding to a PE

terminal and to ground

the device in accordance with PN-EN 60364-4-41

standard, as well as to provide additional shock

protection - RCD with tripping current not

exceeding 30 mA. The installation of this

equipment must be carried out by a qualified

electrician. The RCD acts as a protection against

insulation damage. It cuts off the power after

detecting insulation failure (leakage) between the

voltage line and any part of the grounding (casing)

on the output side of the RCD.

-

3-phase power generators (230/400V), single-

phase outputs (230V) are connected in parallel

with the winding in order to withstand the full

load. Power of single-phase output (230V)

indicated on the nameplate and in the technical

data is only available for these outputs under the

condition that other three-phase receivers are

not connected to the socket. Caution!!! Never

connect the three-phase sockets of the

generator to a single-phase distribution box.

When using both: single-phase 230V current and

three-phase 400V current, the current value per

phase must not exceed the value indicated on

the nameplate of the power generator.

-

Thermal or magneto-thermal circuit breaker. Power

generators are equipped with a thermal circuit

breaker, which acts as overload protection. If the

power supply is interrupted during operation, it

may be caused by automatic activation of the

thermal overload switch.

3. Selection of the power generator.

If this happens, wait for a while, eliminate the cause

of the overload, then reconnect the switch by

pressing it.

The switches are selected according to the technical

parameters of the generator; if you need to replace

them in case of damage, use only original parts of with

identical current ratings.

SELECTING PROPER POWER GENERATOR

FOR THE RECEIVER

Devices with electric motors.

Star connection - power of the power generator

may be up to 3 times higher than the rated power

of the receiver.

Delta connection - power of the power

generator may be up to 9 higher than the rated

power of the receiver.

Star / delta connection (softstart)- the power

of the generator, up to 3 times higher than the

rated power of the receiver.

With inverter, the power of the generator - up to

1.5 times higher than the rated power of the

receiver.

Commutator connections (power tools) - the

power of the generator at least 1.2 times higher

than the rated power of the receiver.

Heating equipment

Power of the generator at least 1.2 times higher

than the rated power of the receiver.

Lighting

Incandescent - power of the generator is up to

1.2 times higher than the rated power of the

heaters.

Sodium - power of the generator is up to 5 times

higher than the rated power of the bulb.

UPS

Power of the generator up to 1.7 times larger

than the power rating of connected receivers.

Electronic devices

Power of the generator at least 1.2 times larger

than the rated power of receivers.

NOTE: In order to accurately select the

power generator for the receiver, a

qualified electrician must perform

electrical measurements of the electrical

switchboard, at the start-up of the device.

Voltage of idle gear of generators is max. 253 V.

At the rated load, the voltage should not fall

below 207 V.

NOTE: Receivers sensitive to too

low or too high voltages may be

damaged when powered from

power generating sets.

ENVIRONMENTAL PROTECTION

Symbol indicating the selective

collection of waste electrical and

electronic equipment. Used

electrical appliances are secondary

raw materials

- do not dispose of them with

household waste, as they contain substances

harmful to human health and the environment!

Actively help to responsibly manage natural

resources and protect the environment by

passing the used device to the point dedicated for

used electric appliances. To reduce the waste

amount, it is necessary to reuse, recycle or

recover materials in a different form.

10.

4. Delivery, unloading, storage

For transport purposes, the power generator is

protected against the influence of weather. After

unpacking, remove the packing materials in a

way safe for the environment. Detailed

information on waste handling is defined in the

Regulation of the Minister of Economy and

Labour of 14 December 2013 - Dz.U. of 2013,

item 21.

UNLOADING

The recipient of the power generator is responsible

for its unloading and safety. To unload the power

generator, observe the general safety rules and H&S

regulations.

In particular, observe the following:

-

for unloading always use equipment dedicated for

this purpose (crane, forklift) with a suitable lifting

capacity

-

all hooks must be safely attached to dedicated

lugs - carry out unloading on a properly

hardened surface, which is suitable to withstand

the weight of the power generator and

unloading equipment.

STORAGE

When the power generator is to be stored for a

longer period, follow the basic rules:

-

store it in properly prepared room (dry and

ventilated)

-

adequately secure power generator against

dust and corrosion

-

clean the power generator from any dirt

Detailed recommendations are presented in

manuals provided by manufacturers of the engine,

alternator and other essential components.

The generator should be handled using dedicated

lugs, which form also the frame of the device.

Observe H&S regulations when handling the

power generator. In case of handling heavy loads,

it is necessary to use suitable equipment.

DISPOSAL

The purpose of disposal / recycling

is

reduced use of natural

resources and minimizing amount of

waste. According to the Waste Act of

11 September 2015 on

electrical and electronic equipment waste, term

"recycling" means a recovery, which involves re-

processing of substances or materials contained in

the waste to maximize re-use of these materials,

including minimizing of expenditures for their

processing, which protects natural resources used

for their manufacture and further processing.

CAUTION! Both the generator

and

materials used for its

construction and operation may

cause considerable damage to

the environment when

improperly disposed of. By re-

using of materials or other forms

of using old appliances, you make

an important contribution to

protecting our environment.

11

5. Disposal

CAUTION! Do not dispose the

generator and consumables at the

end of their operational life as

household waste! All waste is a

potential source of danger and

environmental pollution.

It is categorically forbidden to cause

environmental pollution by used materials or

devices. All materials must be collected, sorted,

recycled and used in accordance with the applicable

national regulations. Information on the appropriate

disposal of used devices is available from local

authorities.

After the end of the operational life of the power

generator or any of its parts, dispose them in

accordance with regulations. The following

materials must be provided to the official disposal

sites, as they may be hazardous waste. Hazardous

waste includes used objects, solids and liquids other

than wastewater, generated in households,

commercial facilities, unsuitable for the place and

time in which they have been generated and

burdensome for the environment.

It applies in particular to:

-

fluids (engine oil, coolant, etc.)

- filters

- starter batteries

- a mixture of water and antifreeze agents

-

any material soaked with operational fluids or

diesel oil

-

materials used for cleaning (e.g.

greasy, fuel-soaked or contaminated with

chemicals cleaning cloth).

-

These materials must be provided to

organisations authorised to purchase, collect

and dispose them. Do not pollute the

environment, or store the materials together

with normal household waste.

If the generator is no longer used, it must be

delivered to the organization officially involved

in disposal of industrial machinery.

The used power generator may be delivered to

the manufacturer of power generators - FOGO

company.

12

6. Operation

STARTING OF THE POWER GENERATOR

1 Fill the tank with "fresh" fuel (unleaded petrol PB

95 / 98). Refuelling must be carried out in well-

ventilated areas with the engine switched off. Do

not to smoke and do not use devices with open

flame or generating sparks in the location of

refuelling and in fuel storage areas. Do not

overfill the tank - the fuel surface must be lower

than 2 cm from the upper edge of the tank. After

each refuelling check if the container is properly

closed

2 Pour oil into the power generator, optionally - check

the oil level and refill. The oil level must be checked

when the generator stands on a level surface. To

check the condition of the oil, unscrew the filler cap

or take out the oil dipstick, wipe it, reinsert and take

out again to check the oil level on the dipstick. In the

case of a screw-cap, insert it into the hole without

screwing and check the oil level. If the level is too

low, add oil to reach the maximum level. Do not fill

oil above the maximum level mark. Use oils provided

by engine manufacturers.

Fuel level indicator (for the

aggregates with enlarged fuel tank "T"

)

Fig.2 Checking the oil level in HONDA, MITSUBISHI, RATO

engine (single-cylinder)

For power generators with Honda, Mitsubishi, Rato

engine acc. to API as SG, SF, CC or CD (SAE10W30)

Tab. 1.

Oils shown in Table may be used if the average ambient

temperature is within the indicated range.

For Briggs & Stratton "Vanguard" SE, SF, SG (SAE30)

oils may be used Tab. 2.

Depending on the temperature, for Vanguard engines

we recommend oils specified in Table 2. SAE 30 oil

used below 4°C may impact starting-up of the engine

and may cause damage to the cylinder due to

insufficient lubrication. Air cooled engines heat-up

more than liquid-cooled automotive engines. Using

synthetic multigrade oils (5W-30, 10W-30, etc.) at

temperatures above 4°C will lead to increased oil

consumption and may cause engine damage. If you use

this type of oil, it is advisable to check oil level more

frequently.

For Honda, Mitsubishi, Rato engines – use

SAE 10W30 or SAE10W40 oil, which is recommended

for general in the widest range of temperatures.

The amount of oil for each engine is indicated

in technical specifications. Do not use oils for two-

stroke engines and insoluble oils, as they affect the

life of the engine and may lead to damage.

When the amount of oil in the oil pan

MIN

MAX is insufficient or excessive, oil level or oil pressure

sensors may be activated, consequently stopping of

the engine, or preventing its start.

Fig.1 Checking oil level in a single-cylinder engine

13

Honda, Mitsubishi, Rato

Fig. 3 Checking the oil level - B&S engines (two-cylinder) Providing the engine with oil sensor

absolutely does not relieve the user from

checking the oil level every day.

Fuel filter empty full

Upper

level

+

-

6. Operation

Table 1. Selection of engine oil for HONDA, MITSUBISHI RATO

Table 2. Selection of engine oil for BRIGGS & STRATTON

3 Check the air filter for contamination/dirt. Clean,

when dirty/contaminated. Using a dirty air filter,

results in improper air-fuel ratio, causing the engine

to work unevenly, choke or to emit black exhaust gas

and finally its complete stop. This is particularly

dangerous in case of power generators, as a drop of

engine speed changes the frequency of the current

provided in the power outlet socket. Using other

forms of air filtration or using the device without the

air filter may cause device malfunction or even

serious damage (e.g. scratching the cylinder walls,

contaminating the carburettor etc.).

Do not start the engine without the air filter

installed, as it leads to quick engine wear.

4. CONNECTING THE BATTERY

(Only for engines fitted with electric starter)

The battery pack should have a nominal voltage of

12V and a capacity of at least:

- 18Ah (built-in and non-built-in single-cylinder

generators)

- 30Ah (non-built-in two-cylinder generators)

- 35Ah (-built-in two-cylinder generators).

Connecting the battery to the engine may be

performed after ensuring that this action will not

result in uncontrolled starting of the power

generator. To prevent this, the engine fuel valve

should be closed and the ignition key must be in

"STOP / 0 / OFF" position.

The cables must be connected as follows:

First, connect the terminal ("+ " red line) of the

starting device to (+) pole of the battery.

Connect terminal of "ground wire", attached to the

body of the engine or the entire housing of the

power generator, with (-) pole of the battery.

Tighten terminals firmly to prevent their loosening

during engine operation.

Make sure that the cable ends are not corroded.

Any signs of corrosion must be removed and cable

ends must be slightly greased with technical

Vaseline.

WARNING

The battery produces exploding gases,

therefore open flames, cigarettes and

spark-producing devices are prohibited

near the battery.

14

Positive (+)

cable of the

battery

Negative (-) cable of the battery

6. Operation

CAUTION!!! 5

Do not connect a cable

with unknown polarization.

Turn the fuel tap to "OPEN" position in power generators with the tank on the frame

CAUTION!

All engines with electric starter

are equipped with a system that ensures proper

charging of the battery. Short circuit in the

system or in connection of the battery with faulty

(reversed) polarity will automatically switch off the

engine (in Honda engines). The green indicator in

the switch indicates that the switch is turned off.

Remove the cause of switch tripping and then re-

attach it by pushing it down.

1

2

5 Turn the fuel tap to "ON"

1 2

VANGUARD

1 2

VANGUARD

in power generators with tank on the engine Set the ignition switch in ON position

"1"

HONDA / RATO

1 2

1

MIT SUBISHI

HONDA / RATO

1

2

HONDA / RATO

1

2

MIT SUBISHI

2

MIT SUBISHI

1

2

1 2

15

HONDA

2

When the engine is cold, activate choke switch, do

not use the choke when the engine is hot. When the

engine cannot stabilize its speed after start and works

unevenly, this means that the fuel-air mixture is too

rich and the choke function must be switched off.

HONDA 1 2

RATO

VANGUARD

21 HP 1

VANGUARD 1 2

31 HP

After starting the engine, do not release the cord freely,

but control its retraction by gradually releasing it. When

you release cord freely, it will be rapidly retracted by the

return spring and the handle will hit the housing.

NOTE: When the unit warmed up, it is

recommended to apply the minimum load equal

to 30% of the rated load. The power generator

should be loaded evenly in 3 phases.

HONDA 1 2

RATO

HONDA 1 2

RATO

MITSUBISHI 1 2

VANGUARD 1 2

18 HP

6. Operation

Make sure the connected receivers are

turned off or disconnect the receivers for

the start-up period.

6 MANUAL START

Pull the starter cord gently

until a slight resistance (at

this point the starter clutch

engages with the attaching

basket located placed

on the engine flywheel). Vigorously pull the cord. If

the start-up fails, repeat until it is successful. If the

starter cord is pulled by engaging clutch, this will

cause a strong collision of coupling elements with

the engaging basket, which may lead to the rupture

of the starter cord or damage of clutch

components. Pulling the cord to its end may

damage the return spring of the starter.

7 ELECTRICAL START-UP

In models with electric starter

- insert the key into the ignition and turn to (1) or ON

position

- turn the key to START position or

- after engine starts, release the key which automatically

returns to (1) or ON position and remains there during

operation of the power generator.

CAUTION!! The starter should not work for more than 5

seconds. Between consecutive start-up attempts, wait approx.

10 seconds.

NOTE: Never attempt to start the operating or not

fully stopped engine. There is risk of damage to the

starter (breaking teeth of the starter and flywheel).

When the engine is running evenly, return the choke to its

initial position. After stabilizing the engine speed, power

receivers may be activated.

HONDA 1

2

RATO

HONDA 1

2

RATO

16

1

2

6. Operation

MITSUBISHI 1

2

1

2

VANGUARD

8 STOPPING THE POWER GENERATOR

- Unplug the receiver from the socket or turn off the

receiver,

- After removing the receivers, leave the working

power generator at idling speed for 3 minutes to cool

the condenser coils.

- For power generators fuelled by petrol, set the

ignition switch in OFF position ("0"), whereas for

power generators with electric starters, turn the

ignition key to OFF position ("0").

- Close the fuel tap. For single-cylinder engines,

leaving the fuel valve open may cause fuel to

penetrate the carburettor and overflow it. Excessive

amount of fuel flows into the combustion chamber,

and from there it enters the oil sump, mixing with

oil. This mixture loses the lubricating properties,

slowly seizing the engine (connecting rod,

crankshaft, rings and cylinder). As the engine uses

splash lubrication, too high level of the oil-fuel

mixture may overflow the piston and immobilize the

engine. In such cases, remove the spark plug, drain

oil, clean the combustion chamber with compressed

air and change the oil.

VANGUARD

CAUTION! When the piston moves with the

spark plug removed, the oil accumulated

over the piston is ejected with a great force

to a considerable distance.

- If the power generator is to be stopped for

longer than 30 days, its fuel tank should be

completely emptied. Drain the fuel from the

fuel tank (not by turning the device over),

then use the remaining fuel by starting the

device and waiting for its automatic

shutdown due to lack of fuel.

- Wait until the power generator is completely cooled.

- Leave the unit in a dry, well-ventilated and roofed area

- In emergency situations requiring immediate stop of the

engine, set the ignition switch in the OFF position ("0").

- after a long stop, with fuel in the carburettor, weathered fuel

must be drained by removing the screw in the bottom part of the

float chamber (the screw is always installed at an angle)

HONDA

HONDA

MIT SUBISHI

MITSUBISHI

17

=

Table 1 Recommended diameters of welding cables

Welding current

30-100 A

100-200 A

200-300 A

15-30 m

25 mm

2

35 mm

2

50 mm

2

15-30 m

25 mm

2

50 mm

2

70 mm

2

30-60 m

35 mm

2

70 mm

2

90 mm

2

6. Operation

POWER GENERATOR WITH WELDING MODULE

DESCRIPTION OF THE CONTROL PANEL:

1. Selection of welding current

2. Selection of welding current range

3. Negative welding socket

4. Positive welding socket

CAUTION!!! Do not weld

and use the generator at the same time

To use the device as a power generator:

- Set the switch (2) to "GEN"

- Proceed as in "Starting

power generators" section

NOTE: Do not switch the welding

current switches (1 and 1a) during

welding

NOTE: During the welding, voltage is

present on the power outlet sockets, but

its voltage is low and unstable. It is recommended to

unplug the devices connected to the socket for their

safety.

NOTE: The welder may provide the maximum welding

current only for a few minutes, then it should be left to

cool down (see the table on the control panel) -

therefore if the work with high welding currents triggers

the thermal switch (welding stops, the electrode is

'sticking') let the power generator work for a few

minutes without load in order to cool it down.

Recommended diameters of welding cables:

To use the device as a welder:

- Plug the grounding cable to the socket (3)

- Connect the grounding cable to the welded

item,

- Insert the plug of the cable with the electrode

handle to the second positive socket (4).

- Set the range of welding current with switch (1 ),

(2),

- Proceed as in section "Starting the power

generator" without connected receivers.

- Start welding.

examples of welding currents:

TAB.2

Welding current

Electrodes Acidic Rutile

Cellulose

Basic

Semi-basic

1.5 mm

20-50A

20-30A

2.0 mm

40-65A

20-50A

30-60A

2.5 mm 60-110A

60-100A

50-90A

70-100A

50-80A

3.25 mm

90-150A

70-130A

70-130A

90-130A

60-100A

4.0 mm 140-

210A

120-

160A

90-170A

110-

170A

100-

140A

5.0 mm 200-

290A

190-

250A

140-

210A

175-

220A

130-

180A

18

Length

Periodic inspection /Service work

Every day

Every month

or after

first

8

hours

Every 3

months

or every 50

hours

Every 6

months

or every 100

hours

Every 12

months

or every 300

hours

Cleaning the alternator*

Checking the oil level

Oil change

**

Replacing the oil filter **

Checking the air filter *

Cleaning the air filter *

Replacing the air filter

Cleaning the spark plug

Checking and adjusting the

valve clearance ***

Adjustment of engine speed ***

Cleaning the fuel sump

Cleaning the fuel tank ***

Checking the fuel system

Every 2 years

Measuring insulation resistance

Every 6 months

7. Repair, maintenance

LIST OF SERVICE OPERATIONS

The schedule presents a list of operations performed

every day, after the first 8 hours of operation of the

device, and then subsequently every 50, 100 and 300

hours of operation.

MAINTENANCE ACTIVITIES

Cleaning and checking the alternator, each time

before starting the power generator inspect visually

connections of individual elements of the alternator,

check for damage in insulation of wires, poor

contacts, etc. In case of longer storage in

unfavourable climatic conditions, especially at high

humidity, it is recommended to measure the

insulation resistance of the alternator, using a

megohmmeter of 500 V. The insulation resistance

should be not less than 1 M Ω. If it is lower, then the

alternator's winding should be blown with dry and

warm air.

After blowing with dry and warm air, repeat the

insulation resistance measurement.

Checking oil - see section OPERATION and START-UP

Changing the oil - drain the used oil when the

engine is hot –this ensures its quick and complete

drainage. Unscrew the filler cap and the drain plug.

Drain the oil into a vessel prepared earlier.

(*) In dusty conditions the air filter and the alternator should be cleaned every day, and if necessary even at

shorter intervals.

(**) If the power generator is operated under severe conditions and in high temperatures, change oil every 25

working hours, including the oil filter.

(***) The work must be performed by an authorized servicing workshop/apartment.

CAUTION!

Use only original spare parts to ensure good quality of repair and correct operation of the

engine and alternator, enabling full guarantee of the seller. Seller (and the Guarantor)

shall not be responsible for engine damage arising from the use of spare parts that are

not original or not supplied by the Distributor.

19

This manual suits for next models

1

Table of contents

Popular Portable Generator manuals by other brands

Smarter tools

Smarter tools ST-GP6500 owner's manual

Stephill

Stephill SE6000D Handbook

Generac Power Systems

Generac Power Systems 9067-0 owner's manual

Kenwood

Kenwood TEXIO FGX-293 Series quick start guide

Mecc Alte

Mecc Alte ECO43 Series Installation, use and maintenance manual

Keysight Technologies

Keysight Technologies X Series Getting started guide

Northern Lights

Northern Lights Lugger M843NW3 Operator's manual

Pulsar

Pulsar PG4000iSR Operator's manual

Generac Power Systems

Generac Power Systems GH-410 Installation guidelines

Troy-Bilt

Troy-Bilt 1924 owner's manual

Fieldmann

Fieldmann FZI 4018 BI user manual

Briggs & Stratton

Briggs & Stratton 040248A Operator's manual