ENGLISH

19. Disengage all control levers and stop engine before you

leave the operating position (behind the handles). Wait until

the auger/impeller comes to a complete stop before unclogging

the chute assembly, making any adjustments, or inspections.

20. Never put your hand in the discharge or collector

openings. Always use the clean-out tool provided to unclog the

discharge opening. Do not unclog chute assembly while engine

is running. Shut off engine and remain behind handles until all

moving parts have stopped before unclogging.

21. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

22. When starting engine, pull cord slowly until resistance is

felt,then pull rapidly. Rapid retraction of starter cord (kickback)

will pull hand and arm toward engine faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

23. if situations occur which are not covered in this manual,

use care and good judgment. Contact Customer Support for

assistance and the name of your nearest servicing dealer.

24. Never leave a running unit unattended. Always disengage

the auger and traction controls, stop engine and remove keys.

25. Snow can hide obstacles. Make sure to remove all obstacles

from the area to be cleared.

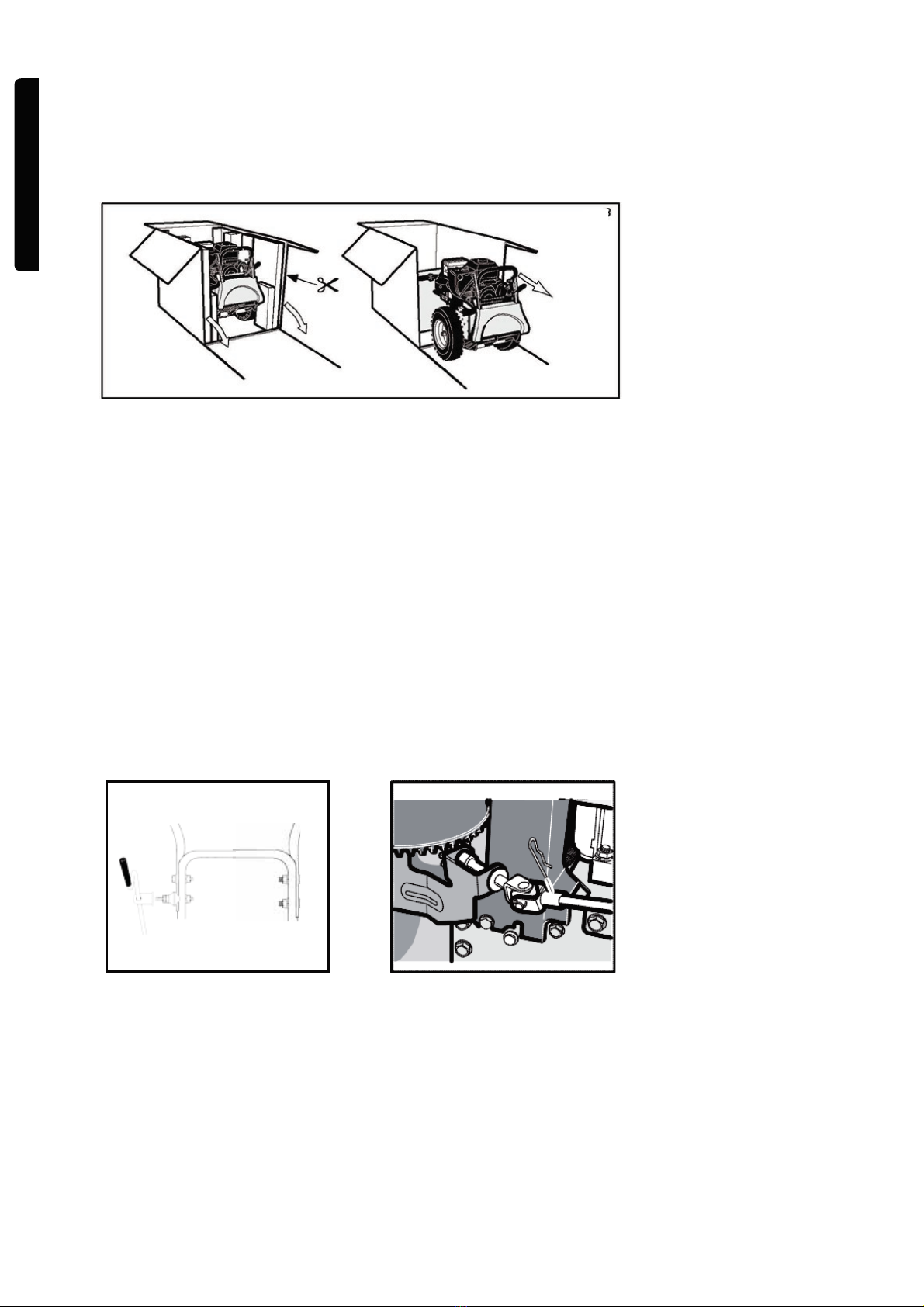

26.Clearing a clogged discharge chute

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injure associated with snow

throwers.Never use your hand to clean out the discharge chute.

To clear the chute

1.

Shut the engine off!

2.

Wait 10 seconds to be sure the impeller blades have stopped

rotating.

3.

Always use a clean-out tool,not your hands.

Maintenance & Storage

1.

Never tamper with safety devices. Check their proper operation

regularly. Refer to the maintenance and adjustment sections of this

manual.

2.

Before cleaning, repairing, or inspecting machine disengage

all control levers and stop the engine. Wait until the auger/

impeller come to a complete stop. Disconnect the spark plug wire

and ground against the engine to prevent unintended starting.

3.

Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition. Also,

visually inspect machine for any damage.

4.

Do not change the engine governor setting or over-speed the

engine. The governor controls the maximum safe operating speed

of the engine.

5.

Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently check all

components and replace with original equipment manufacturer’s

(OEM) parts only. Use of parts which do not meet the original

equipment specifications may lead to improper performance and

compromise safety!

6.

Check control levers periodically to verify they engage and

6