Forma Scientific 8500 Series User manual

Forma Scientific, Inc.

P.O. Box 649

Marietta, Ohio 45750

Telephone: (740) 373-4763

Telefax: (740) 373-2382

________________________________________

Models:

8516, 8517, 8523, 8525,

8526, and 8560

8500 Series Non-CFC

Ultra-Low Temperature Upright Freezers

Manual No. 7028516 Rev. 2

Read this Instruction Manual.

Failure to read, understand and follow the instructions in this manual may result

in damage to the unit, injury to operating personnel and poor equipment performance.

Caution: All internal adjustments and maintenance must be performed by

qualified service personnel.

Refer to the serial tag on the

rear cover of this manual

Forma Scientific, Inc.___________________________________________________Service

ii

The material in this manual is for information purposes only. The contents and the product it

describes are subject to change without notice. Forma Scientific Inc. makes no representations or

warranties with respect to this manual. In no event shall Forma Scientific Inc. be held liable for

any damages, direct or incidental, arising out of or related to the use of this manual.

This product is not intended for any use(s) other than the use(s) in the labeling or this user’s

manual.

MANUAL NO. 7028516

-- 18249/SI-7545 7/7/99 Added P/N 195517 air filter kit to parts list ccp

-- -- 10/30/98 Added battery replacement time to Section 3.3/ Ed Dutton ccp

-- 16484 9/1/98 Add caution to section 6.7 re: rechargeable type batteries deg

-- FR-1203 5/26/98 Added metric units to ref. drawing for IEC-1010 deg

-- -- 1//20/98 Added “Climatic Class T” to Section 2.2 deg

-- SI-6703 1/5/98 Revised electrical schematics heg

2 see description 11/21/97 Revised per FR-1145, FR-1146, FR-1160 and SI-6706 heg

REV ECR/ECN DATE DESCRIPTION

Forma Scientific, Inc.___________________________________________________Service

iii

Do You Need Inform ation orAssistance on Form a Scientific

Products?

do,please contactus 8:00 a.m .to 7 :0 0 p .m.(E a s tern Time)at:

1-740-373-4763 D ire c t

1-888-213-1790 TollFree,U.S.and C anada

1-740-373-4189 FAX

http ://www.form a.com InternetWorldw ide WebH om e Page

fservice@ form a.com Service E-M ailAddress

If you

Forma's can provide information on pricing and give you quotations. We

can take your order and provide delivery information on major equipment items or make

arrangements to have your local sales representative contact you. Our products are listed on the

Internet and we can be contacted through our Internet home page.

The Forma can supply technical information about proper

setup, operation or troubleshooting of your equipment. We can fill your needs for spare or

replacement parts or provide you with on-site service. We can also provide you with a quotation

on our Extended Warranty for your Forma products.

Whatever Forma products you need or use, we will be happy to discuss your applications.

If you are experiencing technical problems, working together, we will help you locate the

problem and, chances are, correct it yourself...over the telephone without a service call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is

covered by the Forma warranty, we will arrange for the unit to be repaired at our expense and to

your satisfaction.

Regardless of your needs, Forma's professional telephone technicians are available to

assist you Monday through Friday from 8:00 a.m. to 7:00 p.m. Eastern Time. Please contact us

by telephone or fax. If you wish to write, our mailing address is:

Forma Scientific, Inc.

PO Box 649

Marietta, OH 45750

International customers please contact your local Forma Scientific distributor.

Sales Support

Product Service Support

Forma Scientific, Inc.____________________________________________________Safety

iv

General Safety Notes used in this Manual

Important operating and/or maintenance instructions. Read the accompanying text

carefully.

Ce symbole attire l’attention de l’utilisateur sur des instructions importantes de

fonctionnement et/ou d’entretien. Il peut être utilisé seul ou avec d’autres symboles

de sécurité. Lire attentivement le texte d’accompagnement.

Wichtige Betriebs- und/oder Wartungshinweise. Lesen Sie den nachfolgenden

Text sorgfältig.

Importante instruccions de operacion y/o mantenimiento. Lea el texto

acompanante cuidadosamente.

Potential electrical hazards. Only qualified persons should perform procedures

associated with this symbol.

Ce symbole attire l’attention de l’utilisateur sur des risques électriques potentiels.

Seules des personnes qualifiées doivent appliquer les instructions et les procédures

associées à ce symbole.

Gefahr von Stromschlägen. Nur qualifizierte Personen sollten die Tätigkeiten

ausführen, die mit diesem Symbol bezeichnet sind.

Potencial de riesgos electricos. Solo personas das capacitadadas deben ejecutar

los procedimientos asociadas con este simbulo.

Forma Scientific, Inc.____________________________________________________Safety

v

Equipment being maintained or serviced must be turned off and locked off to

prevent possible injury.

Risques potentiels liés à l’énergie. L’équipement en entretien ou en maintenance

doit être éteint et mis sous clé pour éviter des blessures possibles.

Geräte, an denen Wartungs- oder Servicearbeiten durchgeführt werden, müssen

abgeschaltet und abgeschlossen werden, um Verletzungen zu vermeiden.

El equipo recibiendo servicio o mantenimiento debe ser apagado y segurado para

prevenir danos.

Hot surface(s) present which may cause burns to unprotected skin or to materials

which may be damaged by elevated temperatures

Présence de surface(s) chaude(s) pouvant causer des brûlures sur la peau non

protégée, ou sur des matières pouvant être endommagées par des températures

élevées.

Heiße Oberfläche(n) können ungeschützter Haut Verbrennungen zufügen oder

Schäden an Materialien verursachen, die nicht hitzebeständig sind.

Superficias calientes que pueden causar quemaduras a piel sin proteccion o a

materiales que pueden estar danados por elevadas temperaturas.

√

√√

√Always use the proper protective equipment (clothing, gloves, goggles etc.).

√

√√

√Always dissipate extreme cold or heat and wear protective clothing.

√

√√

√Always follow good hygiene practices.

√

√√

√Each individual is responsible for his or her own safety.

Forma Scientific, Inc.__________________________________________________Contents

vi

Table of Contents

Section 1 - Receiving

1.1 Preliminary Inspection..........................................................................1-1

1.2 Visible Loss or Damage........................................................................1-1

1.3 Responsibility for Shipping Damage.....................................................1-1

Section 2 - installation

2.1 Introduction .........................................................................................2-1

a. Enviro-Scan Microprocessor Monitoring System.........................2-1

b. Non-CFC, non-HCFC and Non-flammable Refrigerants..............2-1

c. Peak Control System....................................................................2-1

d. "Smart" Condenser Fans..............................................................2-2

e. Built-In Automatic Voltage Compensation ..................................2-2

2.2 Environmental Conditions ....................................................................2-2

2.3 Installing the Wall Bumpers..................................................................2-3

2.4 Location................................................................................................2-3

2.5 Connecting the Water Supply to the (optional)

Water Cooled Condenser ...............................................................2-3

2.6 Attaching the Power Cord Set...............................................................2-4

2.7 Connecting Power to the Freezer ..........................................................2-4

2.8 Deactivating the Enviro-Scan Monitor for Storage................................2-4

2.9 RS-232 Output Interface.......................................................................2-5

2.10 Remote Alarm Connector...................................................................2-6

Section 3 - Enviro-Scan Monitor

3.1 The Enviro-Scan Monitor ....................................................................3-1

3.2 Main Power Switch (Mains Disconnect)..............................................3-2

3.3 Key Functions Requiring No Access Code...........................................3-2

a. Access Keys...................................................................................3-3

Forma Scientific, Inc.__________________________________________________Contents

vii

3.4 Key Functions Requiring Access Code ................................................3-3

a. Set Point Adjustment Screw..........................................................3-4

3.5 Audible Alarm and Control Panel Indicators........................................3-4

3.6 Double Door Freezer (Factory-Built Option) .......................................3-6

3.7 Set Point Adjustment Screwdriver .......................................................3-6

3.8 Automatic Voltage Compensation System ...........................................3-6

3.9 CoBex Temperature Recorder (optional)..............................................3-7

Section 4 - Start-up

4.1 Setting the Operating Temperature.......................................................4-1

4.2 Setting the Low and High Limit Set Points ..........................................4-1

a. To display or change the Low Limit Set Point...............................4-1

b. To display or change the High Limit Set Point..............................4-2

4.3 General Recommendations ..................................................................4-2

4.4 Preparing the (Optional) CoBex Temperature Recorder.......................4-2

a. Installing the chart recorder battery..............................................4-2

b. Installing the chart paper .............................................................4-3

c. Changing the recorder range ........................................................4-3

d. Calibrating the chart recorder ......................................................4-4

e. Recorder outlet ............................................................................4-4

Section 5 - Calibration

5.1 Calibration...........................................................................................5-1

5.2 Calibrating the Temperature Alarm Monitor Probe..............................5-1

5.3 Calibrating the Control Set Point Temperature Probe ..........................5-2

5.4 Changing the Access Code...................................................................5-3

Section 6 - Routine Maintenance

6.1 Cleaning the Cabinet Exterior...............................................................6-1

6.2 Cleaning the Condenser ........................................................................6-1

6.3 Cleaning the Air Filter..........................................................................6-2

6.4 Defrosting the Chamber........................................................................6-2

6.5 Cleaning the Door Gasket.....................................................................6-3

6.6 Cleaning the Vacuum Relief Port..........................................................6-3

6.7 Replacing the Performance Monitor/Alarm Battery ...............................6-4

Forma Scientific, Inc.__________________________________________________Contents

viii

Section 7 - Service

7.1 Servicing the Refrigeration System.......................................................7-1

7.2 Troubleshooting Guide .........................................................................7-1

7.3 8500 Upright Series Cabinet Hardware.................................................7-1

Section 8 - Specifications

8.1 Models 8516 and 8517..........................................................................8-1

8.2 Model 8523...........................................................................................8-2

8.3 Models 8525 and 8526..........................................................................8-3

8.4 Model 8560...........................................................................................8-4

Section 9 - Spare Parts

Section 10 - Refrigeration Drawings

Section 11 - Electrical Schematics

Section 12 - Supplements and Warranty information

Forma Scientific, Inc._________________________________________________Receiving

1-1

Section 1 - Receiving

1.1 Preliminary Inspection

This item was thoroughly inspected and carefully packed prior to shipment and all

necessary precautions were taken to ensure safe arrival of the merchandise at its destination.

Immediately upon receipt, before the unit is moved from the receiving area, carefully

examine the shipment for loss or damage. Unpack the shipment and inspect both interior and

exterior for any in-transit damage.

1.2 Visible Loss or Damage

If any loss or damage is discovered, note any discrepancies on the delivery receipt.

Failure to adequately describe such evidence of loss or damage may result in the carrier

refusing to honor a damage claim. Immediately call the delivering carrier and request that

their representative perform an inspection. Do not discard any of the packing material and

under no circumstances move the shipment from the receiving area.

1.3 Responsibility for Shipping Damage

For products shipped F.O.B. Marietta, Ohio, the responsibility of Forma Scientific,

Inc. ends when the merchandise is loaded onto the carrier's vehicle.

On F.O.B. Destination shipments, Forma Scientific's and the carrier's responsibility

ends when your Receiving Department personnel sign a free and clear delivery receipt.

Whenever possible, Forma Scientific, Inc. will assist in settling claims for loss or

in-transit damage.

Forma Scientific, Inc.________________________________________________Installation

2-1

Section 2 - Installation

2.1 Introduction

The 8500 Series Forma Scientific non-CFC, Ultra-Low Temperature Freezers

feature front-to-back air circulation for cooler compressor temperatures, increased

performance and reliability and longer compressor life. In this unique system, ambient air

enters the front grill of the freezer and passes through the filter, condenser and compressor

housing, exiting out of the rear of the unit.

An enlarged condenser and two cooling fans also contribute to better efficiency and

help extend compressor life. Cleaning the air filter and condenser fins is done from the front

of the unit.

Other important features of the Forma Scientific 8500 Series Freezers are:

a. Enviro-Scan Microprocessor Monitoring System

Enviro-Scan uses a digital display, audible and visual indicators and a touch

sensitive key pad to provide total control of all freezer functions. The module digitally

displays chamber temperature and control setpoint, to the nearest degree C. High and low

alarm set points are easily programmed. A back-up battery system supplies power to the

monitoring system during electrical outages.

An RS-232 port provides a computer interface and monitoring of temperatures and

alarms. A remote alarm connector is also a standard feature.

b. Non-CFC, non-HCFC and non-flammable refrigerants

Committed to a safer, healthier environment, Forma Scientific has phased out the

use of ozone depleting CFC (chlorofluorocarbons) in all of the company's refrigerated

products. Forma also uses non-CFC foamed-in-place urethane insulation and all packaging

materials used in shipping are non-CFC.

c. Peak Control System

Due to the increased demands on today's refrigeration systems, Forma Scientific has

engineered a compressor protection system called PEAK Control. In this system, a pressure

switch senses excessive compressor discharge pressure. When the discharge pressure

exceeds the design limit, a solenoid valve opens allowing refrigerant to enter an expansion

tank. The refrigerant returns to the system through a capillary tube. The PEAK Control

System continues to monitor system pressures, insuring they stay within design limits to

help extend compressor life.

Forma Scientific, Inc.________________________________________________Installation

2-2

d. "Smart" Condenser Fans

For maximum compressor protection, all Forma ULT freezers include two tube

axial fans in the compressor housing. When both compressors are running, both fans operate

to pull ambient air through the condenser and over the compressors. When both compressors

are off, one fan remains ready to cycle on when the thermostat senses a temperature rise

above 32°C.

e. Built-In Automatic Voltage Compensation

A built-in, automatic voltage compensator is built into every Forma 8500 Series

non-CFC, Ultra-Low Temperature Freezer to detect and respond to high or low voltage

situations. Voltage from the incoming power supply is monitored and adjusted by the

automatic voltage compensator, ensuring compressor operation within design parameters. A

light on the front of the control panel indicates when incoming voltage is being corrected.

An enlarged condenser and two temperature controlled cooling fans also contribute

to better efficiency, even in high ambient conditions.

2.2 Environmental Conditions

The Forma 8500 Series ULT Freezers are designed to operate in the following

environmental conditions:

•Indoors

•Altitudes up to 2,000 meters

•Temperature Range of +5°C to +40°C.

•Maximum relative humidity of 80% for temperatures up to 31°C, decreasing linearly

to 50% at 40°C.

•Mains supply voltage fluctuation of ±10% of nominal.

•Installation Category (Overvoltage Category) II, Pollution Degree 2.

•Climatic Class T (Tropical)3

1 Installation category (overvoltage category) defines the level of transient overvoltage which the

instrument is designed to withstand safely. It depends on the nature of the electricity supply and its

overvoltage protection means. For example, in CAT II which is the category used for instruments in

installations supplied from a supply comparable to public mains such as hospital and research

laboratories and most industrial laboratories, the expected transient overvoltage is 2500 V for a 230

V supply and 1500 V for a 120 V supply.

2 Pollution degree describes the amount of conductive pollution present in the operating

evironment. Pollution degree 2 assumes that normally only non-conductive pollution such as dust

occurs with the exception of accasional conductivy caused by condensation.

3 Class T (Tropical) means that the freezers are electrically safe in a 43°C ambient.

Forma Scientific, Inc.________________________________________________Installation

2-3

2.3 Installing the Wall Bumpers

The parts bag contains two (2) 1/4-20 x 5-1/2" bumper bolts and two (2) neoprene

caps. Install the bolts (the holes are pre-tapped) on the back side of the compressor section.

Install a neoprene cap on each bolt.

For proper ventilation and air flow, a minimum of 5" of clear space

is required behind the freezer. An additional 5" (minimum) of clear

space is also required on both sides of the freezer. When locating the

back of the freezer toward a wall or obstacle(s), make sure that the wall

bumpers are installed.

2.4 Location

Locate the freezer on a firm, level surface in an area of minimum ambient

temperature fluctuation.

2.5 Connecting the Water Supply to the (optional) Water Cooled Condenser

1. Insert a 1/2” OD copper

water line into the cold

water inlet (top) and tighten

the compression fitting.

2. Insert a 1/2”OD drain line

into the water outlet

(bottom) and tighten the

compression fitting. Direct

the drain line to a suitable

drain.

Note: The condensing units must be provided with enough water for adequate cooling. The

units require approximately 1 GPM of 65°F (18.3°C) of tap water per horsepower, or 3 GPM

of 85°F (29.4°C) water per horsepower.

Figure 2-1

Forma Scientific, Inc.________________________________________________Installation

2-4

2.6 Attaching the Power Cord

Plug the cord set (item C in the

illustration at the right) into the back of the

unit below the power switch. Secure it with

the screw provided and identified by the

circle. The line cord retainer (B) is secured

to receptacle (A) by the factory with the

two screws shown.

2.7 Connecting Power to the Freezer

Forma Scientific, Inc. recommends that the freezer be operated on a

dedicated electrical circuit to avoid circuit overload .

Before connecting the freezer to an adequate power source, refer to the

electrical data plate mounted on the back of the unit, the schematics located in Section 11, or

to the electrical specifications listed in Section 8.

2.8 Deactivating the Enviro-Scan Monitor for Storage

The Enviro-Scan Monitor has been deactivated (placed in a sleep mode) prior to

shipment. The monitor re-activates when power is applied to the freezer. If electrical power

is lost or the freezer is disconnected, the monitor will be sustained by the battery back-up.

Whenever the freezer is unplugged for storage, the "Enviro-Scan" must be de-activated

to preserve the life of the battery and preserve the warranty.

•Turn off or unplug the freezer.

•Obtain the access code prompt by pressing the UP ARROW key and the BATTERY

% CHARGE key simultaneously. A "1" must appear in the display window. If a "1"

does not appear in the window, repeat step 2.

•Enter the four digit access code. The Access Code set at the factory = 1,2,3,4. For

Access Code information, refer to Section 3.2 and Section 4.1. To change the

Access Code refer to Section 5.3.

Forma Scientific, Inc.________________________________________________Installation

2-5

•After entering the four digit Access Code, press the ENTER key and "CAL" will

appear in the window.

•Press the DOWN ARROW key.

The Enviro-Scan monitor is now deactivated (placed in a sleep mode) until

electrical power is restored.

2.9 RS-232 Output Interface

The 8500 series freezers are equipped with an RS-232 Serial Communication

Interface for the remote transmission of sensor data. A standard DB-25S connector is located

on the rear of the compressor housing. The data is "dumb printer" formatted, which permits

interfacing with either a computer or a serial printer.

Three wires are used for the RS-232 interface:

1) TX Data = Pin 2

2) RX Data = Pin 3

3) Signal Ground = Pin 7

The data format is seven-bit ASCII with a leading zero (8th bit). Each character is

transmitted with one start-bit, eight data-bits, and two stop-bits, totaling eleven bits. NO

parity-bit is included. Baud rate is 1200.

A data transfer sequence is transmitted according to the following format. X refers

to the variable numerical temperature data.

(NUL) (-) XXX (SP) C (SP) (OVERTEMP) (SP) (LF) (CR) (EOT) (SP) (UNDER TEMP )

The words "OVERTEMP" or "UNDER TEMP" are transmitted with the temperature

if one of those conditions exists at the time the data is transmitted. When there is no alarm

condition, spaces will be sent instead so that there is always a total of 20 characters sent.

SP - space

LF - line feed

CR - carriage return

EOT - end of text

NUL - null character (00)

The Enviro-Scan Monitor transmits temperature and alarm condition data when

power is first applied to the Monitor and then once every hour.

The Enviro-Scan Monitor responds to two ASCII commands from the remote:

Forma Scientific, Inc.________________________________________________Installation

2-6

DC1 (XON) and DC3 (XOFF)

DC1 (11H): The Enviro-Scan Monitor will transmit temperature and alarm

condition data upon receipt of DC1 and resume 60 minute interval transmissions if they had

been inhibited by a DC3.

DC3 (13H): Receiving a DC3 from the remote inhibits the Enviro-Scan Monitor

from sending serial data indefinitely until a DC1 is received or Monitor power is removed

and then reapplied.

Figure 2-2

Figure 2-1 identifies the location of the RS-232 output connector.

2.10 Remote Alarm Connector

For installations requiring remote temperature monitoring or high/low temperature

alarm systems, a remote connector is provided on all Forma 8500 Series Upright Freezers.

Figure 2-1 identifies the location of the remote alarm connector, Figure 2-2 identifies the pin

output. (A label on the back of the freezer cabinet also contains this information.)

The alarm contacts are rated: .5A at 30 VDC, 15 watts maximum

.6A at 24 VAC, 14 watts maximum

Forma Scientific, Inc.________________________________________________Installation

2-7

Key Pin # Description

1

2

3

4

5

6

7

8

9

10

Over temperature Common

Over temperature N.C.

Over temperature N.O.

Millivolt Out (Positive +)

Under temperature N.C.

Millivolt Out (Negative -)

Under temperature Common

Under temperature N.O.

(Not Used)

(Not Used)

Figure 2-3

Forma Scientific, Inc.________________________________________Enviro-Scan Monitor

3-1

Section 3 - Enviro-Scan Monitor

3.1 The Enviro-Scan Monitor

Figure 3-1

Enviro-Scan Monitor

The Enviro-Scan Monitor provides constant monitoring of the freezer's operation.

The numerical LCD display provides a readout of the freezer chamber temperature in

increments of one degree Celsius.

Some functions of the Enviro-Scan Monitor require the entry of a four digit security

code to access, display or change them. Access code 1,2,3,4 is programmed into each unit at

the factory. This code may be changed to any four digit combination of the numbers 1,2,3,

and 4. (Section 5.3 describes the procedures to change the Access Code.)

Functions requiring no access code are:

Alarm Silence Power Line Voltage

Enter Low Alarm Test

Standby High Alarm Test

Battery Charge Battery Test

Other features include:

Over Temp light Under Temp light

Standby light Low Battery light

Door Ajar light Power light

Power Failure light Condenser Hot light (hidden)

Forma Scientific, Inc.________________________________________Enviro-Scan Monitor

3-2

3.2 Main Power Switch (mains disconnect)

The main power switch is located on the back of the refrigeration unit, directly

above the line cord. Off = (o) On = (|)

3.3 Key Functions Requiring No Access Code (Refer to Figure 3-1)

Battery

% Charge Displays the Enviro-Scan Monitor backup battery's percent of charge. The

reading gives some indication of how long the monitor will operate on battery backup. The

Backup system is designed to maintain monitor operation for at least 72 hours. A reading of

50%, when on battery power, indicates that the monitor will run for approximately 36 hours.

The Battery % Charge display may not indicate the full number of hours of

monitor backup power. The % of charge can vary depending on the age, usage and

condition of the battery. For a consistent and dependable charge, replace the battery every

2-3 years.

Silence

Alarm

Silences all alarms for approximately 30 minutes and changes the display to

cabinet temperature.

Enter Displays cabinet temperature.

This key is also used for functions requiring the access code.

Power

Line

Voltage Displays the operating voltage of the freezer when both compressors are

running. A zero will be displayed on the LCD when the line voltage reading drops below

100 volts on a 208/220 volt circuit (50 volts on a 115 volt circuit).

Standby

The standby key silences the audible alarm after an alarm condition or a power

failure. The standby key will silence the audible alarm only. The alarm light will stay on

until the alarm condition has been corrected. A built-in ring-back feature audibly signals that

the unit has returned to normal setpoint limits. Press the STANDBY key to remove the

audible tone.

Forma Scientific, Inc.________________________________________Enviro-Scan Monitor

3-3

Low

Alarm

Test The alarm limit must be set to within 45°C of actual cabinet temperature to

perform this test. If the alarm limit is not set within this limit, a long tone will sound and no

test will occur. If within limits, the alarm will be activated when the probe temperature

drops below the low alarm limit. The test may be aborted at any time by pressing ENTER.

All other key functions are "locked-out" during this test.

High

Alarm

Test The alarm limit must be set to within 45°C of actual cabinet temperature to

perform this test. If the alarm limit is not set within this limit, a long tone will sound and no

test will occur. If within limits, the probe will be heated until it reaches the alarm limit and

the alarm will be activated. The probe will then gradually cool back to the actual cabinet

temperature. The test may be aborted at any time by pressing ENTER. All other key

functions are "locked-out" during this test.

Test

Battery

Disconnects the main power from the monitor, making it switch and operate on

battery power.

a. Access Keys:

Keys 1,2,3 and 4 are used for the entry of the four digit Access Code.

3.4 Key Functions Requiring the Access Code (refer to Figure 3-1)

σ

σσ

σPressing the up arrow key will increase the display by increments of one

division. If this key is held down for more than two seconds the display will increment

automatically.

Note: The up and down arrow keys are used for setting the high and low limits and

all calibration functions.

τ

ττ

τPressing the down arrow key will decrease the display by increments of one

division. If this key is held down for more than two seconds the display will increment

automatically.

Forma Scientific, Inc.________________________________________Enviro-Scan Monitor

3-4

Limit

Low

The low limit key is used to establish a Low Limit set point. When the chamber

temperature reaches (or exceeds) the Low Limit set point, the audible alarm will sound and

the UNDER TEMP indicating light will come on. The remote alarm contacts, located on the

back of freezer, will also be activated. Refer to Section 4.2 for Low Limit setting

instructions.

Limit

High

The high limit key is used to establish a High Limit set point. When the

chamber temperature reaches, or exceeds, the High Limit set point, the audible alarm will

sound and the OVER TEMP indicating light will come on. The remote alarm contacts,

located on the back of the freezer, will also be activated. Refer to Section 4.2 for High

Limit setting instructions.

Setpoint

Control

After depressing this key and entering the access code, the setting for the

temperature control will appear in the display. The control setting is adjusted by turning the

Set Point Adjusting Screw located on the far right of the monitor panel.

Note: When in a battery backup condition (AC power off), the control set point

value is replaced with "--" to prevent false data from being displayed.

Press ENTER to return to the temperature display.

a. Set Point Adjustment Screw located to the right of the ENTER key is used to

set the operating temperature of the freezer. An adjustment screwdriver is located on the

back panel of the compressor section. (See Figure 3-2 and Figure 2-1).

3.5 Audible Alarm and Control Panel Indicators

Audible Alarm:

Provides a pulsing audible tone whenever an alarm condition is present. The DOOR

AJAR audible alarm has a 30 second delay to prevent nuisance alarms when the door is

opened. Pressing the ALARM SILENCE key will silence all alarms for 30 minutes.

Note: When in STANDBY mode, the audible alarm is silent until all alarm

conditions are cleared. Audible alarm conditions include OVER TEMP,

UNDER TEMP, DOOR AJAR and AC power failure.

Over Temp (LED): Flashes when an over temperature condition

exists.

Other manuals for 8500 Series

1

This manual suits for next models

6

Table of contents

Other Forma Scientific Freezer manuals

Popular Freezer manuals by other brands

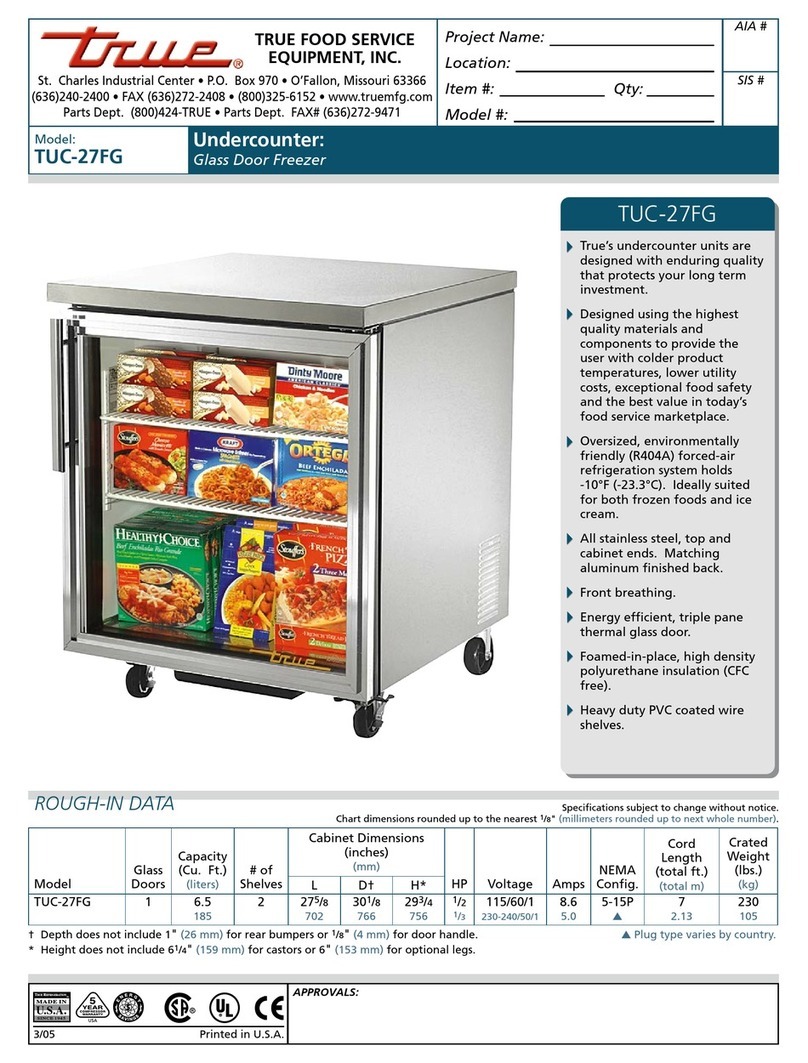

True

True TUC-27FG Specifications

Stevens

Stevens Silver King SKFB27 Technical manual and replacement parts list

Frigidaire

Frigidaire FFC09K0DW Factory parts catalog

Ariston

Ariston RG 2330 operating instructions

CONTINENTAL EDISON

CONTINENTAL EDISON MF-181W user manual

Miele

Miele F 1471 Vi OPERATING AND INSTALLATION Manual