Forma Scientific 707 User manual

Forma Scientific, Inc.

Millcreek Road, P.O. Box 649

Marietta, Ohio 45750

U.S.A. Telephone: (740) 373-4763

Telefax: (740) 373-4189

________________________________________

Models:

707, 771, 733 and 754

Non-CFC, Ultra-Low Temperature

Chest Freezers

3.0 and 6.7 cu. ft. capacity

Manual No. 7000707 Rev. 3

Read this Instruction Manual

Failure to read, understand and follow the instructions in this manual may result in

damage to the unit, injury to operating personnel and poor equipment performance.

CAUTION: All internal adjustments and maintenance must be performed

by qualified service personnel.

Refer to the serial tag on the

back cover of this manual

FormaModel 700 Series ____________________________________________________

ii

*Refer to listing of all model numbers on page ii.

*700 Series Freezers

707 6.7 cu ft 120V

771 6.7 cu ft 230V

733 3.0 cu ft 120V

754 3.0 cu ft 230V

The material in this manual is for information purposes only. The contents and the product it

describes are subject to change without notice. Forma Scientific, Inc. makes no representations or

warranties with respect to this manual. In no event shall Forma Scientific, Inc. be held liable for any

damages, direct or incidental, arising out of or related to the use of this manual.

MANUAL NO. 7000707

319279/FR-1402 6/21/00 Revised electrical schematics aks

2FR-1357 12/1/99 Updated per A. Thomas for IEC 1010 (CE listing) ccs

-- 18249/SI-7545 7/7/99 Added P/N 195518 & 195519 air filter kits to parts list ccp

118286/FR-1296 5/11/99 Updated schematics for 771/5477 ccp

-- -- 11/17/98 Added battery change note to Section 3.6 deg

--- FR-1223 6/8/98 Changed temp board heg

-- FR-1203 5/26/98 Added metric units to ref. drawing for IEC-1010

02/98 Original Manual deg

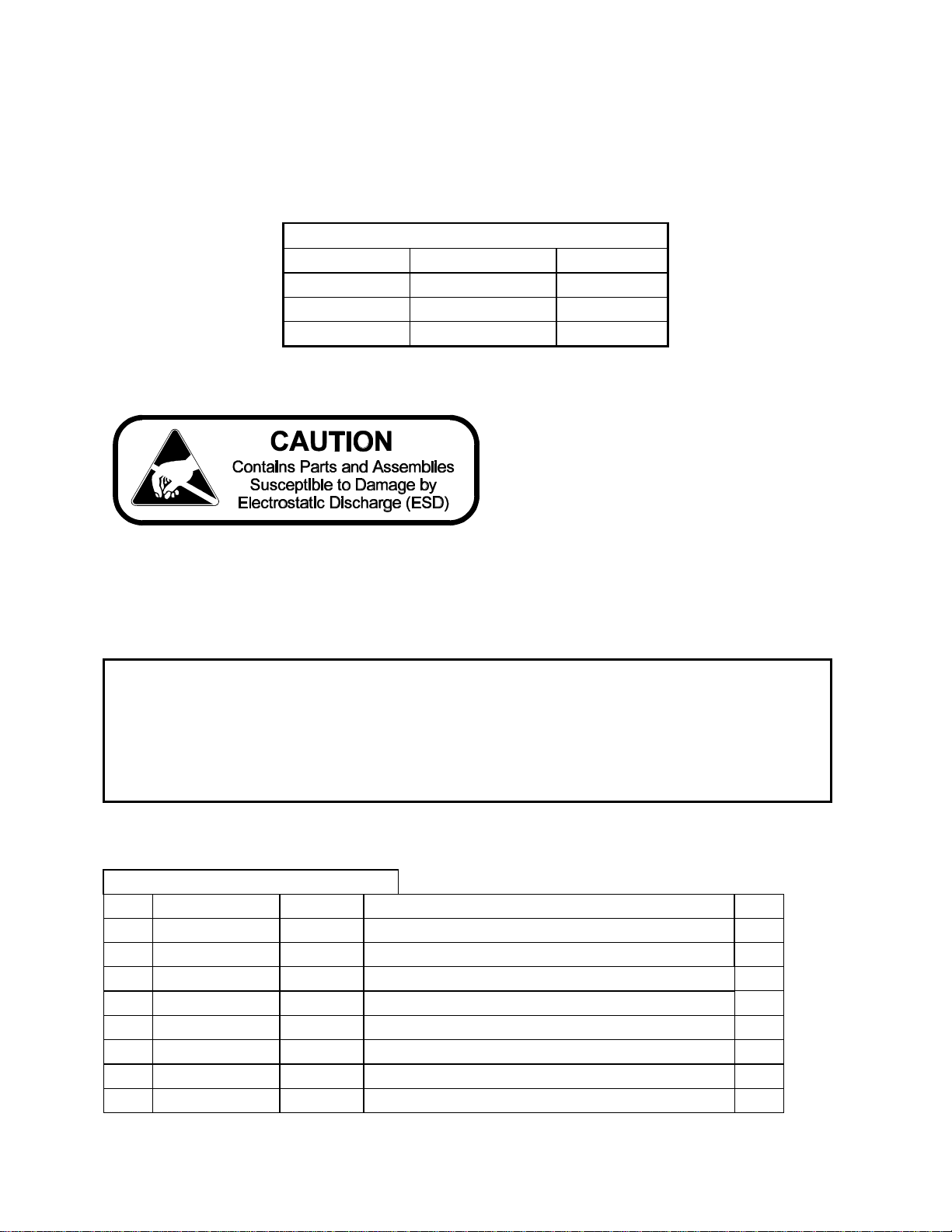

REV ECR/ECN DATE DESCRIPTION By

FormaModel 700 Series ______________________________________________Service

iv

Do You Need Information or Assistance on Forma

Products?

do, please contact us 8:00 a.m. to 7:00 p.m. (Eastern Time) at:

1-740-373-4763Direct

1-888-213-1790Toll Free, U.S. and Canada

1-740-373-4189FAX

http://www.forma.comInternet Worldwide Web Home Page

[email protected]mService E-Mail Address

If you

Our staff can provide information on pricing and giveyou quotations. We

can take your order and provide delivery information on major equipment items or make

arrangements to have your local sales representative contact you. Our products are listed on the

Internet and we can be contacted through our Internet home page.

Ourstaff can supply technical information about proper setup,

operation or troubleshooting of your equipment. We can fill your needs for spare or replacement

parts or provide you with on-site service. We can also provide you with a quotation on our

Extended Warranty for your Forma products.

Whatever Forma products you need or use, we will be happy to discuss your

applications. If you are experiencing technical problems, working together, we will help you

locate the problem and, chances are, correct it yourself...over the telephone without a service

call.

When more extensive service is necessary, we will assist you with direct factory trained

technicians or a qualified service organization for on-the-spot repair. If your service need is

covered by the warranty, we will arrange for the unit to be repaired at our expense and to your

satisfaction.

Regardless of your needs, our professional telephone technicians are available to assist

you Monday through Friday from 8:00 a.m. to 7:00 p.m. Eastern Time. Please contact us by

telephone or fax. If you wish to write, our mailing address is:

ThermoQuest

Forma Scientific Division

Millcreek Road, PO Box 649

Marietta, OH 45750

International customers please contact your local ThermoQuest, Forma Scientific

Division distributor.

Sales Support

Service Support

FormaModel 700 Series _______________________________________________Safety

v

General Safety Notes used in this Manual

Important operating and/or maintenance instructions. Read the accompanying text

carefully.

Ce symbole attire l’attention de l’utilisateur sur des instructions importantes de

fonctionnement et/ou d’entretien. Il peut être utilisé seul ou avec d’autres symboles de

sécurité. Lire attentivement le texte d’accompagnement.

Wichtige Betriebs- und/oder Wartungshinweise. Lesen Sie den nachfolgenden Text

sorgfältig.

Importante instruccions de operacion y/o mantenimiento. Lea el texto acompanante

cuidadosamente.

Potential electrical hazards. Only qualified persons should perform procedures

associated with this symbol.

Ce symbole attire l’attention de l’utilisateur sur des risques électriques potentiels.

Seules des personnes qualifiées doivent appliquer les instructions et les procédures

associées à ce symbole.

Gefahr von Stromschlägen. Nur qualifizierte Personen sollten die Tätigkeiten

ausführen, die mit diesem Symbol bezeichnet sind.

Potencial de riesgos electricos. Solo personas das capacitadadas deben ejecutar los

procedimientos asociadas con este simbulo.

FormaModel 700 Series _______________________________________________Safety

vi

Equipment being maintained or serviced must be turned off and locked off to prevent

possible injury.

Risques potentiels liés à l’énergie. L’équipement en entretien ou en maintenance doit

être éteint et mis sous clé pour éviter des blessures possibles.

Geräte, an denen Wartungs- oder Servicearbeiten durchgeführt werden, müssen

abgeschaltet und abgeschlossen werden, um Verletzungen zu vermeiden.

El equipo recibiendo servicio o mantenimiento debe ser apagado y segurado para

prevenir danos.

Hot surface(s) present which may cause burns to unprotected skin or to materials

which may be damaged by elevated temperatures

Présence de surface(s) chaude(s) pouvant causer des brûlures sur la peau non

protégée, ou sur des matières pouvant être endommagées par des températures

élevées.

Heiße Oberfläche(n) können ungeschützter Haut Verbrennungen zufügen oder

Schäden an Materialien verursachen, die nicht hitzebeständig sind.

Superficias calientes que pueden causar quemaduras a piel sin proteccion o a

materiales que pueden estar danados por elevadas temperaturas.

√√ Always use the proper protective equipment (clothing, gloves, goggles etc.).

√√ Always dissipate extreme cold or heat and wear protective clothing.

√√ Always follow good hygiene practices.

√√ Each individual is responsible for his or her own safety.

FormaModel 700 Series _____________________________________________Contents

vii

Table of Contents

Section 1 - Installation and Start-Up

1.1 Unloading and Moving the Freezer.......................................................1-1

1.2 Getting to Know Your Freezer .............................................................1-2

1.3 Environmental Conditions....................................................................1-5

1.4 Installing the Wall Bumpers.................................................................1-5

1.5 Location ...............................................................................................1-6

1.6 Connecting the Alarm Battery..............................................................1-6

1.7 Remote Alarm Contacts........................................................................1-7

1.8 Optional Recorder ................................................................................1-7

a. Connecting recorder battery...........................................................1-7

b. Installing the chart paper...............................................................1-7

1.9 Attaching the Power Cord ....................................................................1-8

1.10 Power Switch (mains disconnect).......................................................1-8

1.11 Electrical Requirements and Connection .............................................1-9

1.12 Factory Settings...................................................................................1-9

1.13 Start Up and Loading...........................................................................1-9

Section 2 - Operation

2.1 Changing the Control Temperature Set Point........................................2-1

2.2 Changing the Over Temperature Alarm Set Point.................................2-1

2.3 Alarms..................................................................................................2-2

2.4 Silencing the Over Temperature Alarm ................................................2-3

Section 3 - Calibration

3.1 Temperature Display Calibration..........................................................3-1

3.2 Optional Recorder Calibration..............................................................3-2

a. Changing the recorder range............................................................3-2

b. Calibrating the chart recorder..........................................................3-3

FormaModel 700 Series _____________________________________________Contents

viii

Section 4 - Routine Maintenance

4.1 Cleaning the Cabinet Exterior ..............................................................4-1

4.2 Cleaning the Air Filter..........................................................................4-1

4.3 Cleaning the Condenser........................................................................4-1

4.4 Defrosting the Chamber........................................................................4-2

4.5 Cleaning the Lid Gasket .......................................................................4-2

4.6 Replacing the Battery............................................................................4-3

4.7 Preparing the Unit for Storage...............................................................4-3

Section 5 - Service

5.1 Servicing the Refrigeration System ......................................................5-1

Section 6 - Specifications

Section 7 - Parts List

Section 8 - Refrigeration Drawings

Section 9 - Electrical Schematics

Section 10 - Warranty Information

FormaModel 700 Series ___________________________________Installation/Start-Up

1-1

Section 1 - Installation and Start-Up

1.1 Unloading and Moving the Freezer

To remove the freezer from the pallet, use the 7/16” wrench to remove all the bolts

securing the shipping bracket to the pallet. Remove the shipping bracket. Remove the ramp

boards from the pallet and place the slotted end over the ramp brackets on the pallet. The support

blocks on the ramps will be facing down. Before moving the freezer, make sure the casters are

unlocked and moving freely. Align the caster with the ramp boards. Use adequate personnel to

roll the freezer off the pallet.

If tipped more than 45°, allow the unit to set upright for

24 hours before start up.

The freezer can be easily pushed to the desired approved location that is described in

Section 1.5. When the freezer is in position, set the front caster brakes.

The freezer must not be moved with the product load inside.

FormaModel 700 Series____________________________________Installation/Start-Up

1-2

1.2 Getting to Know Your Freezer

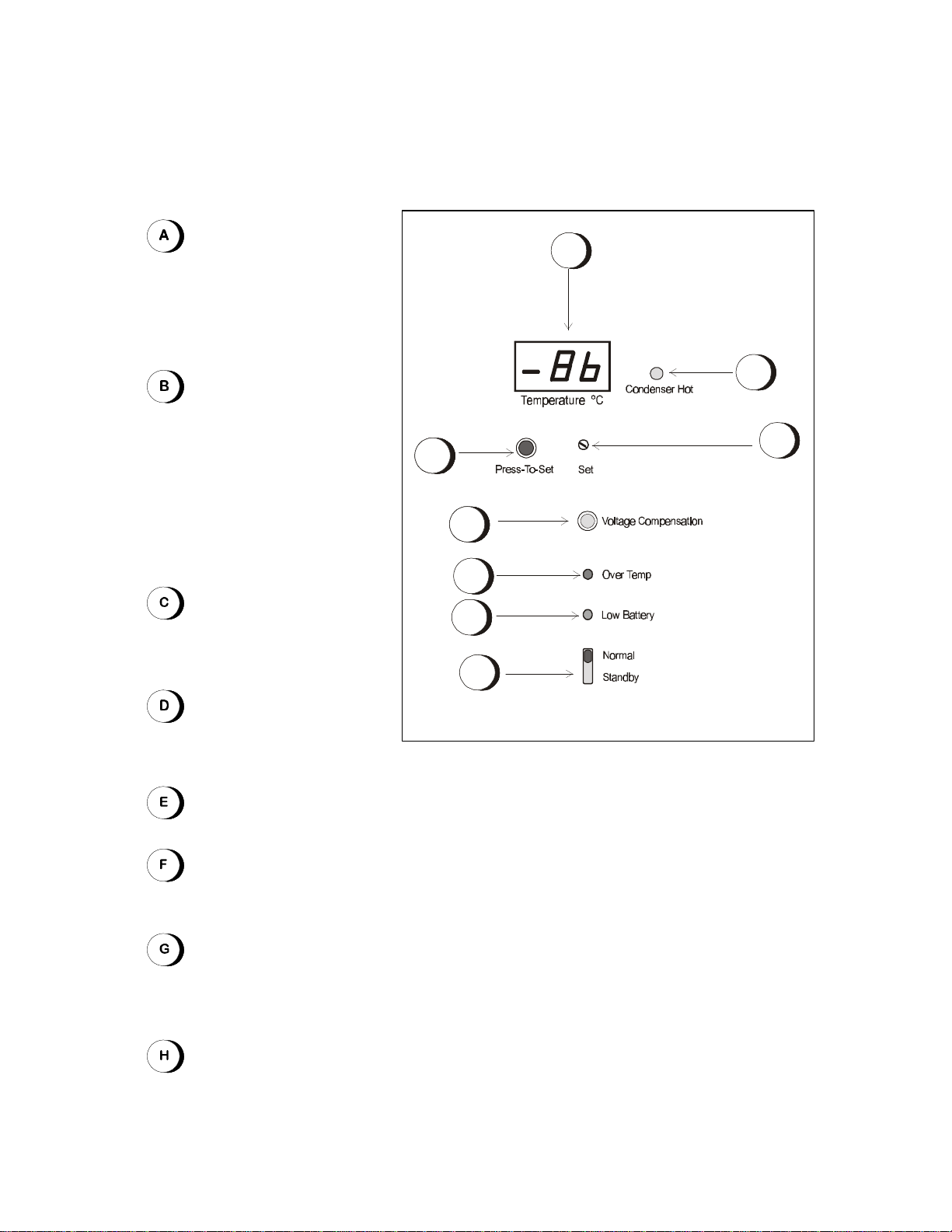

LED display - Shows

actual chamber temperature

and indicates the control

temperature set point when the

Press-To-Set button is pressed.

Condenser Hot

indicator - Lights when the

thermostat on the condenser

reaches 40°C, indicating

typically a dirty air filter, a

clogged condenser, a fan

failure or high ambient

temperature.

Set Point Adjustment

Screw - Sets the control

temperature set point.

Normal/Standby

switch - Silences the audible alarm.

Low Battery indicator - Flashes when the battery needs to be replaced.

Over Temp indicator - Flashes when the chamber temperature rises above the

Over Temperature Alarm setting.

Voltage Compensation indicator - Indicates when the in-coming electrical

power is being automatically adjusted to ensure that the compressor operates within

specification.

Press-to-Set button - Press to display control temperature set point.

Figure 1-1, Control Panel

AA

B

C

D

E

F

H

G

FormaModel 700 Series____________________________________Installation/Start-Up

1-3

1 2

3

1 2

3

Figure 1-2 Figure 1-3

3.0 cu. ft. Chest Freezer 6.7 cu. ft. Chest Freezer

Figure 1-4

Chest Freezer Base, back view

Figure 1-5

Chamber Probe Assembly

Recorder

Probe

Probe

Cover

Performance Alarm

Monitor and

Temperature Probe

FormaModel 700 Series____________________________________Installation/Start-Up

1-4

1.3 Environmental Conditions

The ULT Freezers are designed to be electrically safe in the following environmental

conditions:

•Indoors

•Altitude: Up to 2,000 meters

•Temperature: 5°C to 43°C

•Humidity: 80% RH at or below 31°C, decreasing linearly to 50% RH at 40°C

•Mains Supply Fluctuations: ±10% of nominal.

•Installation Category II 1

•Pollution Degree 2 2

•Class of Equipment I

•Climatic Class T (Tropical)3

1 Installation category (overvoltage category) defines the level of transient overvoltage which the

instrument is designed to withstand safely. It depends on the nature of the electricity supply and its

overvoltage protection means. For example, in CAT II which is the category used for instruments in

installations supplied from a supply comparable to public mains such as hospital and research

laboratories and most industrial laboratories, the expected transient overvoltage is 2500V for a 230V

supply and 1500V for a 120V supply.

2 Pollution degree describes the amount of conductive pollution present in the operating environment.

Pollution degree 2 assumes that normally only non-conductive pollution such as dust occurs with the

exception of occasional conductivity caused by condensation.

3 Class T (Tropical) means that the freezers are electrically safe in a 43°C ambient.

1.4 Installing the Wall Bumpers (Refer to Figure 1-4)

The parts bag, located inside the cabinet, contains the following parts.

Qty. Stock # Description Purpose

2 224 510016 1/4-20 x 5-1/2" Bolt Wall Bumper

2 311 380520 Neoprene Cap Cap Protector

Install the bolts into the pre-tapped holes on the back of the compressor section.

Install a neoprene cap on each bolt. Refer to Figure 1-4 for the locations of the pre-

tapped holes.

FormaModel 700 Series____________________________________Installation/Start-Up

1-5

1.5 Location

Locate the freezer on a firm, level surface in an area with an ambient temperature

between 18°C and 32°C. Provide ample room to reach the mains disconnect switch

(power switch) located on the rear of the freezer.

For proper ventilation and airflow, a minimum of 5" of clear space

is required around the freezer.

1.6 Connecting the Alarm Battery

NOTE: The battery must be connected upon start-up so that the alarm will activate

during an Overtemperature condition.

1. To gain access to the battery, remove the grill on the front of the freezer. The grill is

attached to the freezer by friction plugs on each of the four corners and is readily

pulled off. The battery is the rectangle fastened by Velcro to the compressor

compartment frame and has a connector with red and black wires. Another red and

black wire set with connector is secured to the wiring harness passing through the

area of the freezer. Join the two wire connectors and replace the grill.

2. When the battery is connected, the OVERTEMP light will flash and the alarm will

sound. Turn the NORMAL/STANDBY switch to the STANDBY position. This will

silence the alarm. The alarm will remain silent until the unit is below alarm

setpoint. The alarm setpoint is factory set for -65°C. If another setpoint is required,

see Section 2.2.

FormaModel 700 Series____________________________________Installation/Start-Up

1-6

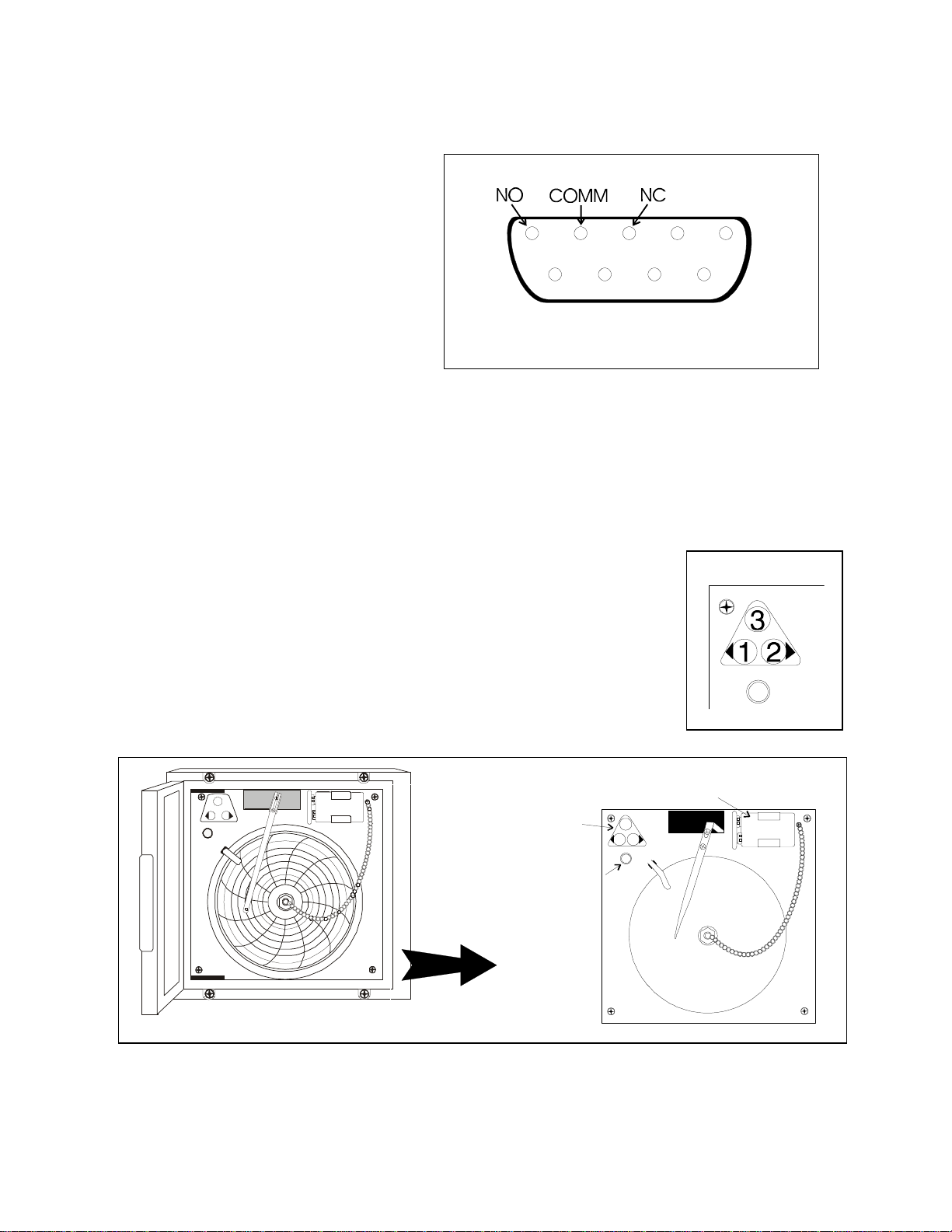

1.7 Remote Alarm Contacts

Remote alarm contacts are

located on the rear of the unit.

See Figure 1-6 for pin

description, shown in the alarm

state. The Formapart number

for the plug required is 195482.

Maximum rating for this plug

is 1.0A @ 30VAC.

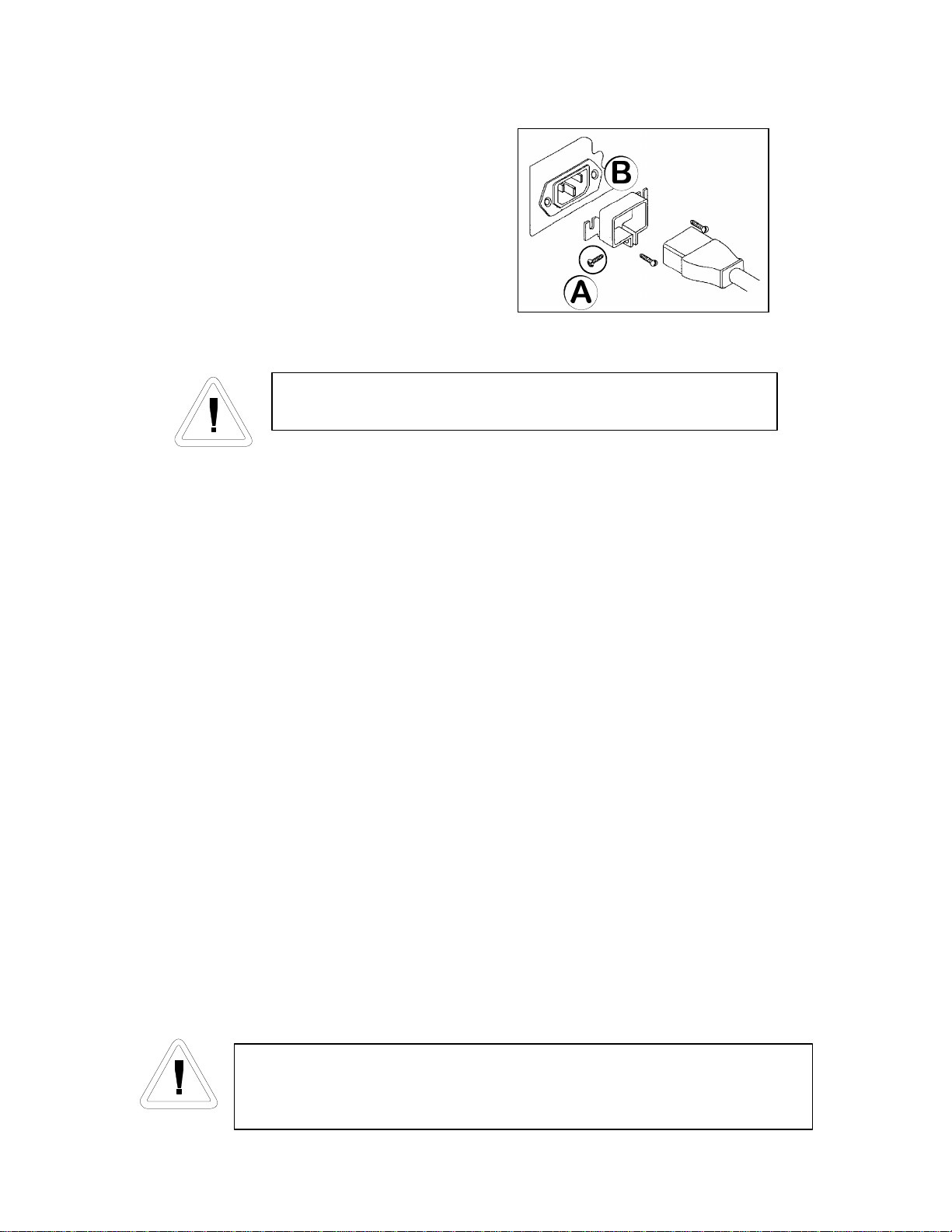

1.8 (Optional) Temperature Recorder

a. Connecting recorder battery

Open the glass door of the recorder and connect the 9-volt battery. The green

light on the recorder will come on.

b. Installing the chart paper

1. Open the glass door of the recorder and press button #3 until the

pen begins to move outward.

2. Unscrew the knob at the center of the chart and remove the

paper.

3. Install the new chart paper, position the paper to the correct

time line and replace the knob.

4. Remove the cap from the felt pen and press button #3.

Figure 1-8 Chart Recorder, detail view

1 2

3

1 2

3

9-volt battery

Green LED

Program selectionand

calibration buttons

Figure 1-6

Remote Alarm Contact

FormaModel 700 Series____________________________________Installation/Start-Up

1-7

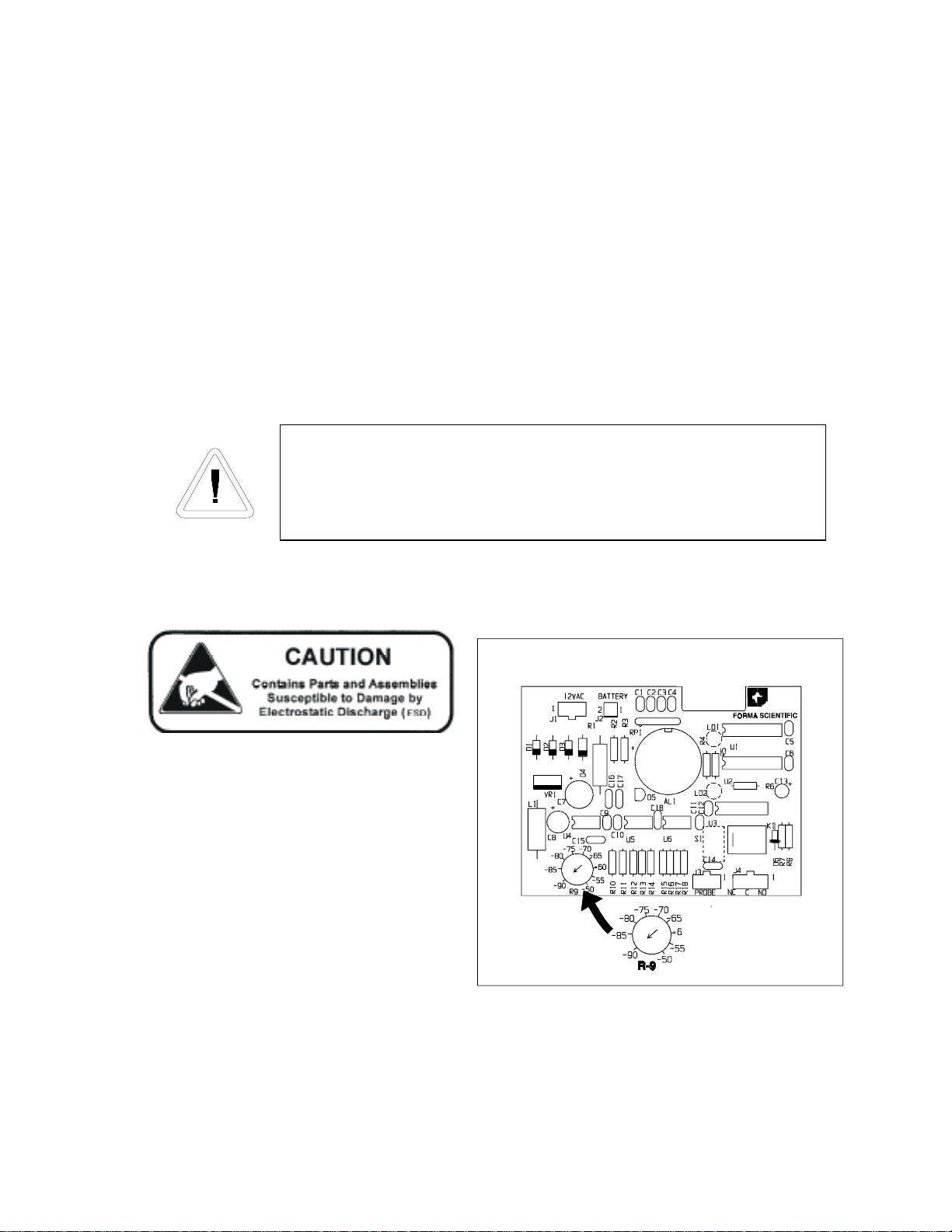

1.9 Attaching the Power Cord

1. Loosen screw (A) located on the power

cord retainer.

2. Spread the power cord retainer.

3. Insert the power cord into the power outlet

module (B).

4. Tighten screw (A) on the power cord

retainer.

1.10 Power Switch (mains disconnect)

The power switch is located on the rear of the unit, directly above the power cord.

The power switch is also a circuit breaker that protects the entire unit.

1.11 Electrical Requirement and Connection

•The freezer should be operated on a dedicated grounded service.

•Check voltage rating on the serial tag of the unit and compare it with the outlet voltage.

•With the power switch turned off, plug the line cord into the wall outlet.

1.12 Factory Settings

•Control Temperature – 707 & 771: -80°C

– 733 & 754: -75°C

•Over Temperature Alarm: -65°C

If you wish to change any of these settings, see the appropriate section(s) in Section 2.

1.13 Start Up and Loading

•Turn the freezer on and allow it to run empty overnight.

•When the empty freezer has stabilized overnight at the control temperature set point, load

the chamber with pre-frozen product.

Figure 1-9

Power Cord Assembly

Make sure the power cord connection is completely seated.

The freezer was designed for the storage of pre-frozen product

only. The addition of warm product may cause a temporary rise in

the cabinet temperature.

FormaModel 700 Series____________________________________________Operation

2-1

Section 2 – Operation

2.1 Changing the Control Temperature Set Point

1. Remove the screwdriver on the front left corner of the control panel.

2. Press and hold in the PRESS-TO-SET key on the control panel.

3. Using the screwdriver, turn the SETscrew until the desired temperature is displayed.

Clockwise lowers the temperature and counter clockwise raises the temperature. The

approved operating temperature range for the 707 & 771 is -50°C to -86°C and the

range for the 733 & 754 is –50°C to –77°C.

The unit should NEVER be set to operate below the approved

operating range. Setting the unit below this range will cause the

compressors to operate continuously and reduce compressor life.

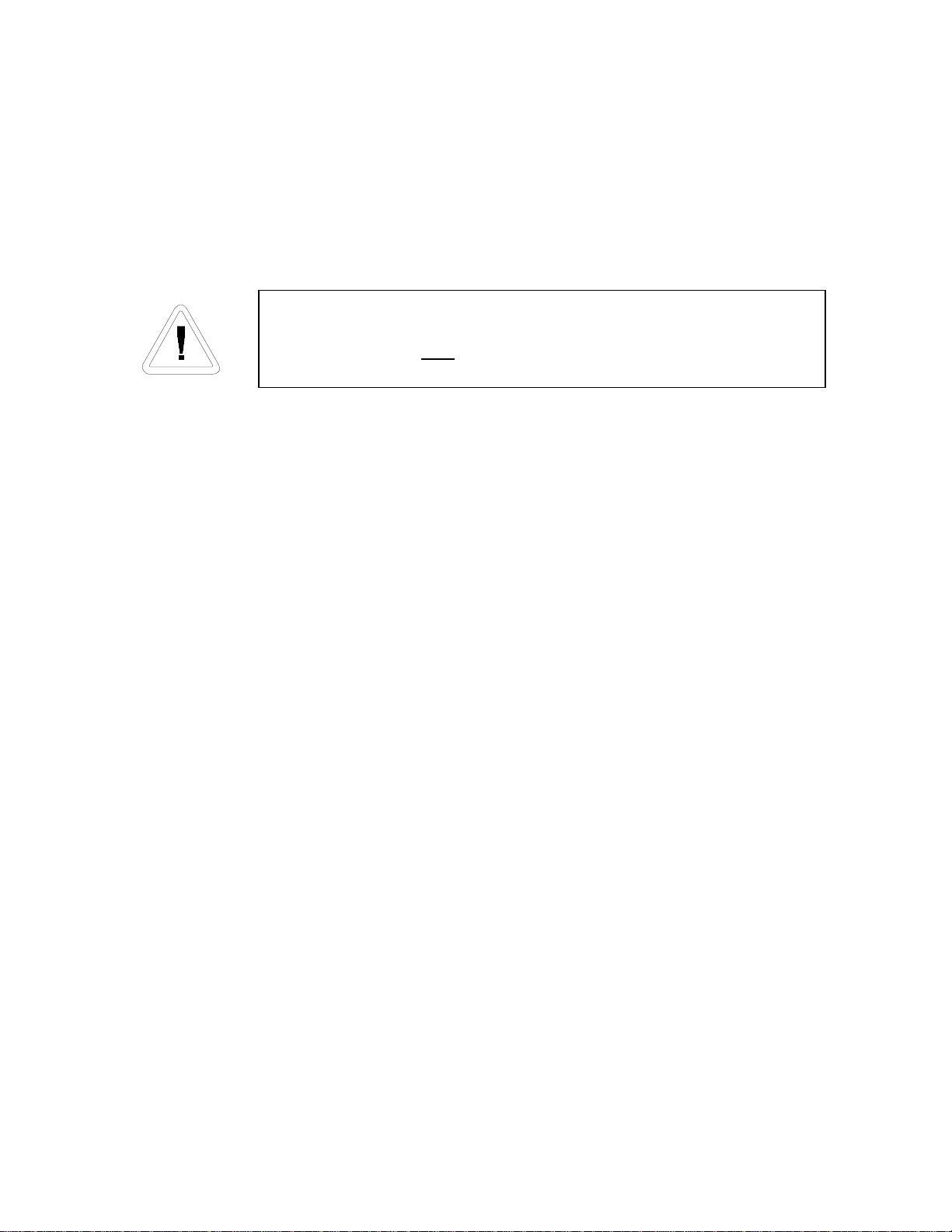

2.2 Changing the Over Temp Alarm Set Point

The following procedure sets the alarm for

a precise temperature during initial set up. If a

precise temperature is not required, set R9 to

the desired temperature.

1. Set the unit to operate at the desired alarm

point (see Section 2.1) and allow the unit

to operate until it reaches the set point.

2. Remove the top two screws securing the

control panel and loosen the bottom two

screws. Carefully remove the control

panel.

3. Remove the six screws securing the cover of the

box attached to the inside of the control panel to

expose the alarm board.

4. Turn the switch on the control panel to the NORMAL position.

Figure 2-1, Temperature

Alarm Circuit Board

showing R-9 Control

FormaModel 700 Series____________________________________________Operation

2-2

5. If the unit alarms, slowly adjust R9 clockwise (warmer) until the alarm turns off. If the unit is

not in alarm, slowly adjust R9 counterclockwise (colder) until the alarm turns on.

6. The alarm is now set for the desired temperature. Reinstall the box cover and secure with

screws. Carefully install the control panel to its proper location and secure with screws.

7. Set the unit to the desired control temperature. See Section 2.1.

2.3 Alarms

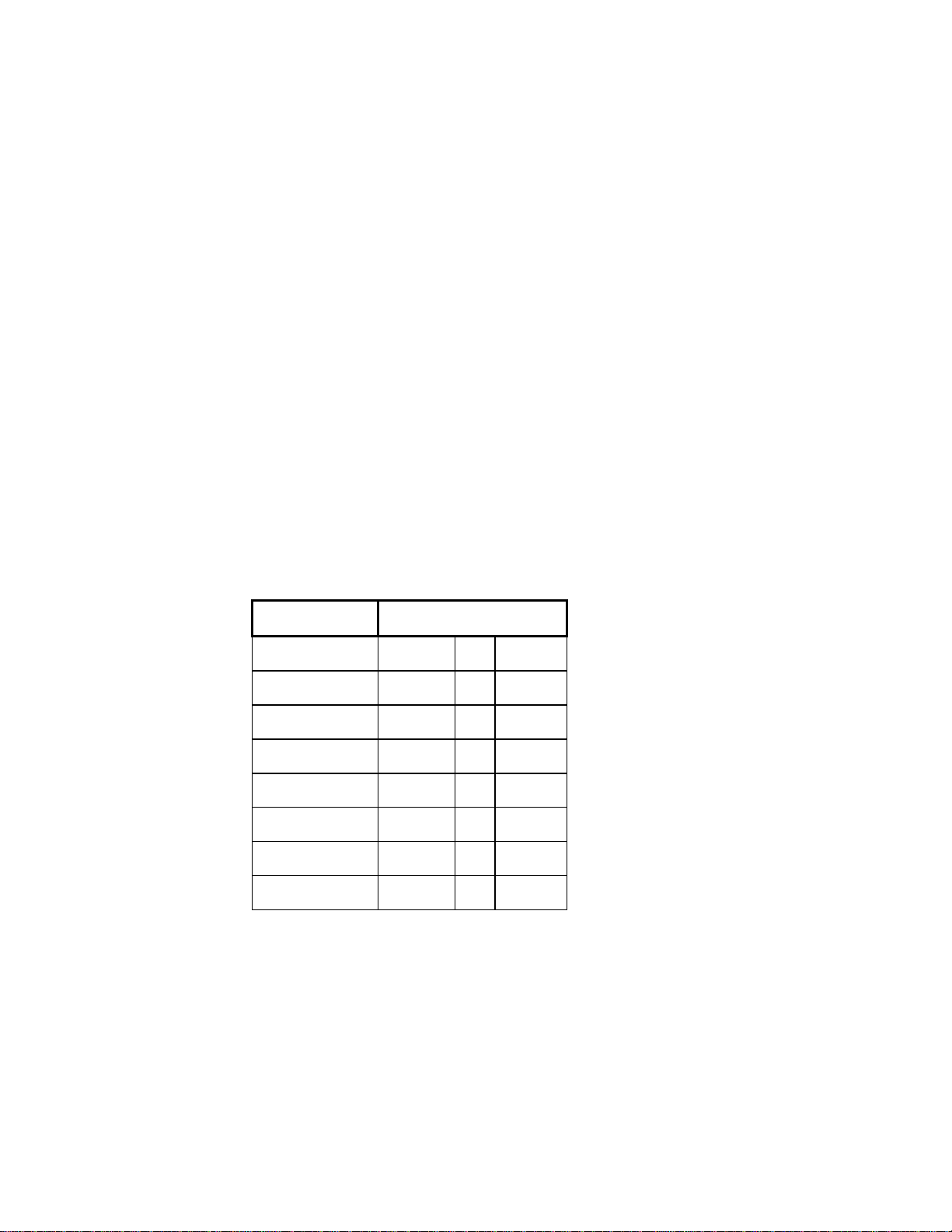

Alarm Description Visual Audible Cause Action Required

Over Temperature Flashing

(red) On •Unit is above

alarm setpoint.

•Addition of

excessive

product load

•Check freezer

operation.

Condenser Hot On (red) --- •Filter and/or

condenser dirty.

•Operating freezer

in greater than

40°C ambient.

•See Section 4.2 and

4.3 for cleaning

filter and

condenser.

Low Battery Flashing

(red) --- •Rechargeable

battery not

connected

•Rechargeable

battery needs

replaced

•See Section 1.6.

•Replace battery.

See Section 4.7 for

battery replacement

instructions. See

spare parts list for

battery part number.

Voltage

Compensation On (green) --- •Incoming voltage

too high or too

low

•Check if line

voltage is within

operating range. See

Section 6. If within

specs, no action is

required.

FormaModel 700 Series____________________________________________Operation

2-3

2.4 Silencing the Over Temperature Alarm

•Move the switch from the NORMAL position to the STANDBY position. When the

alarm condition has been corrected, the alarm will sound. The switch must then be

returned to the NORMAL position to exit STANDBY mode.

If the unit is left in the STANDBY mode, none of the alarms listed will

sound, alarm lights only will turn on.

FormaModel 700 Series ______________________________________________Calibration

3-1

Section 3 - Calibration

Calibration must be performed when the unit is at operating temperature.

Required equipment: Accurate low-temperature remote bulb thermometer or thermocouple of

known accuracy.

3.1 Temperature Display Calibration

Place a measuring device near the

probe cover. See Figure 1-5.

1. Allow the unit to stabilize at the

operating temperature.

2. Remove the top two screws securing

the control panel and loosen the

bottom screws.

3. Carefully remove the control panel.

4. Remove the six screws securing the

cover of box attached to the inside of

the control panel. Remove the cover.

5. Adjust R17 until the control panel

display matches the independent

measuring device. Several turns of

R17 may be required to achieve the

desired temperature.

6. Reinstall cover to the box and secure.

7. Check the control temperature set point. Set

point may have been altered during the

calibration procedure.

Figure 3-1,

Temperature Control Board

showing R-17 Location

FormaModel 700 Series ______________________________________________Calibration

3-2

3.2 Optional Recorder Calibration

a. Changing the recorder range:

The chart recorder contains eight temperature ranges and is factory-programmed for

the freezer.

1. Press and hold button #3 for one second, then let the pen move off of the chart

paper.

2. Press and hold for five seconds either button #1 or button #2.

3. Release the button and the green LED will begin to flash. Count the number of

flashes to determine the present program setting.

4. To change the program setting, press the left or right arrows to increase or decrease

the count.

5. When the desired program number is flashing, press button #3 to bring the pen arm

back onto the chart. Recording will begin in the new program.

NOTE: Changing ranges may require an offset calibration as outlined in Section 3.2.b.

Program No. Range

Program 1 -40°C to 30°C

Program 2 0°C to 60°C

Program 3 -100°C to 38°C

Program 4 -5°C to 50°C

Program 5 0°C to 100°C

Program 6 -100°C to -200°C

Program 7 -115°C to 50°C

Program 8 -10°C to 70°C

Table 3-1

Recorder Range Chart

FormaModel 700 Series ______________________________________________Calibration

3-3

b. Calibrating the chart recorder:

The recorder must be in service for 24 hours before performing the following

calibration procedure.

1. Place an accurate thermometer in the chamber next to the recorder probe.

2. Temperature probes for the recorder are located in the left front corner of the freezer

chamber (Figure 1-5).

3. After about three minutes, compare the thermometer reading with the chart recorder

reading.

4. If an adjustment is necessary, press the #1 button to move the pen to the left or the

#2 to move the pen to the right. The button must be held about five seconds before

the pen begins to move. Release the button when the pen position matches the

thermometer.

NOTE: The felt-tip pen on the recorder requires periodic replacement. Usually the ink

will appear to fade before replacement becomes necessary. Additional pen tips may be

purchased from Forma Scientific. Refer to Parts List, Section 7. o

This manual suits for next models

3

Table of contents

Other Forma Scientific Freezer manuals