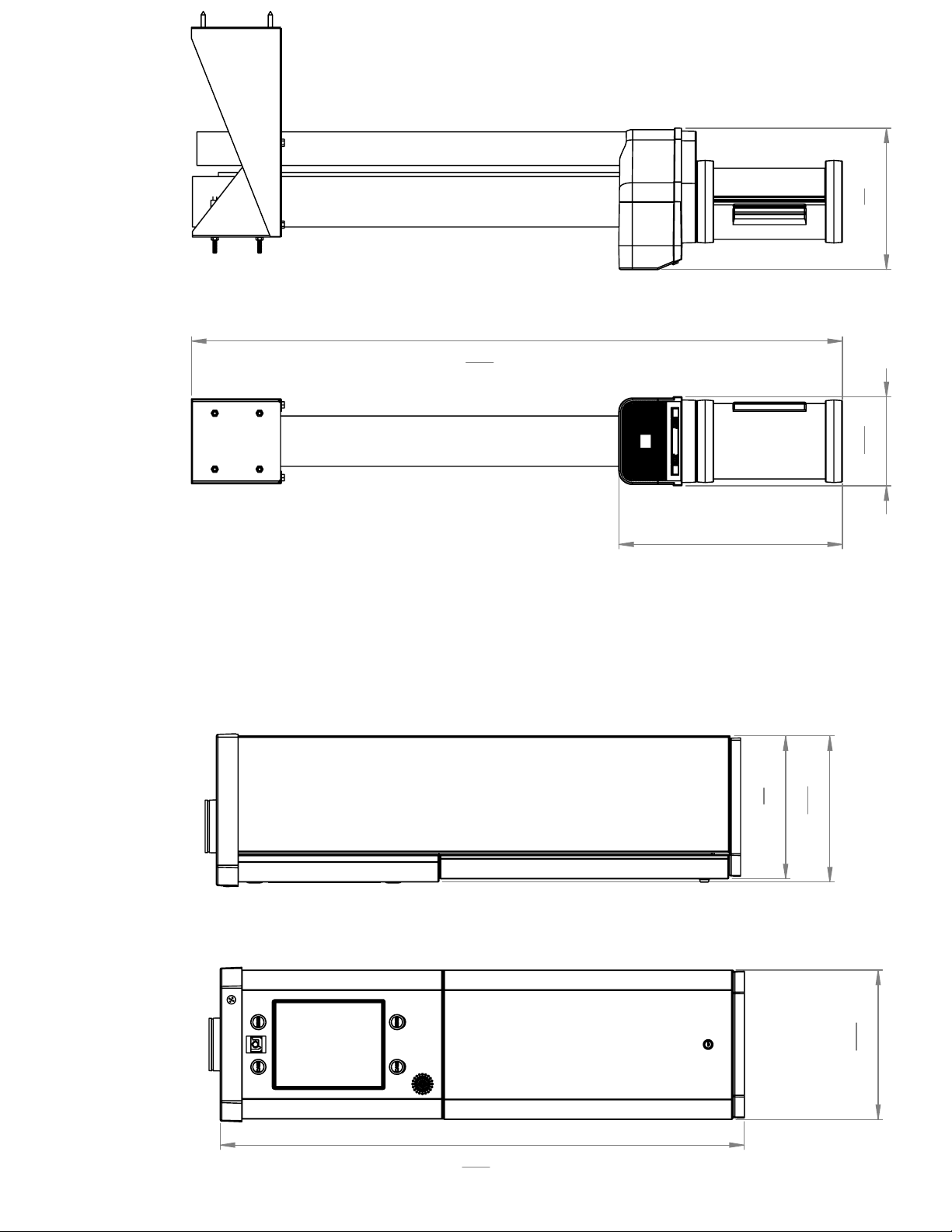

Mounting the Customer Unit

Locate Customer Unit on Island per detailed drawing. The front of the

unit should be five inches from the front of the curb. Remove the turbine

box by removing the flex hoses and lift out of unit. Mark the location of

the four mounting holes. Using four 3/8 “ dia concrete anchors secure

customer unit to island. Before final tightening of base anchors check

level of unit front to back and left to right. Make sure unit is not twisted

once fully tighten down to island

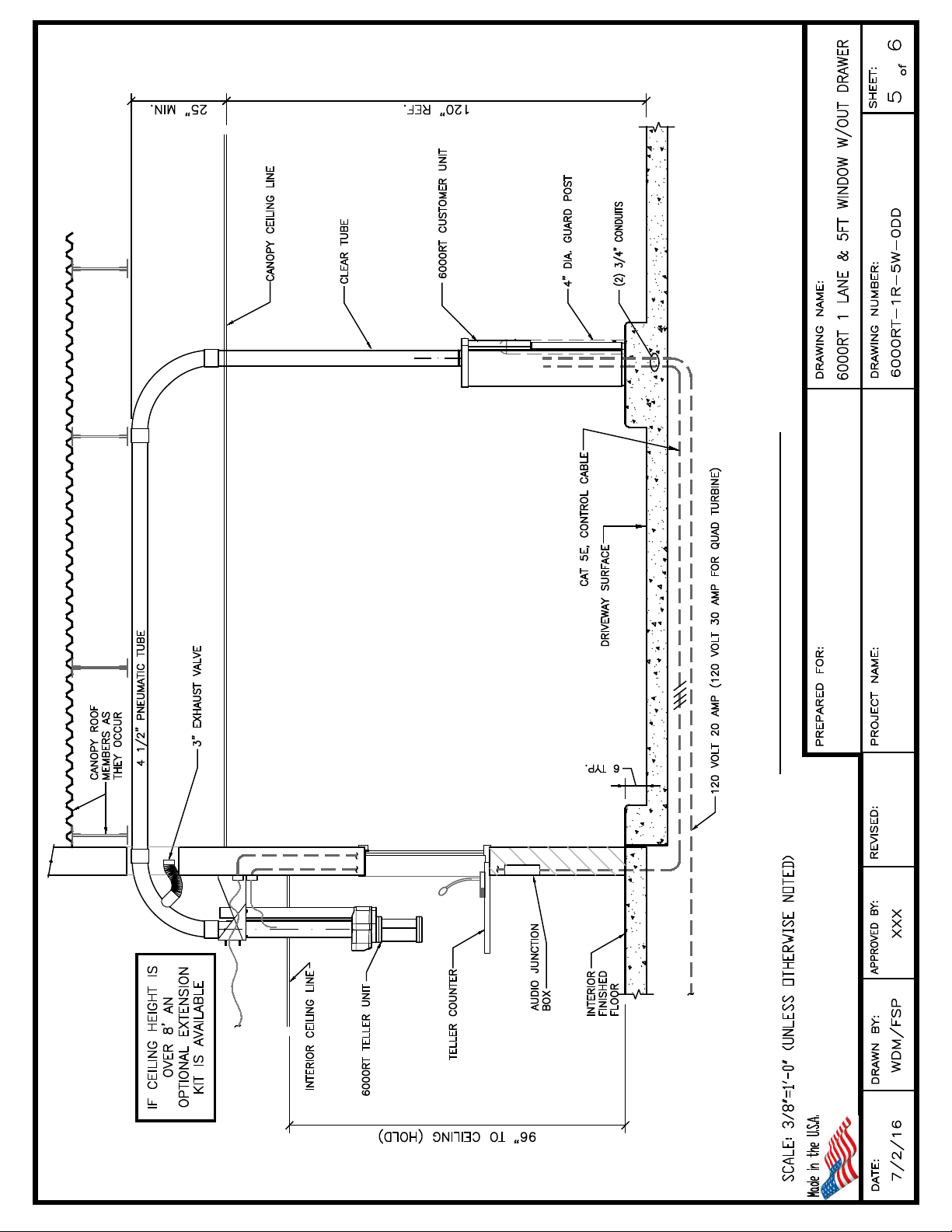

Electrical Connections

The main power connection is a 120V 20A circuit using a Nema L5-20P

cord end. The electrician should install an outlet for this style cord end

in a junction box that is mounted to the inside of the right side of the

cabinet. Make sure that this junction box and outlet do not interfere with

the removal and installation of the Turbine Assembly.

Note – If you are connecting conduits to the top of the unit.

DO NOT CUT ANY HOLES IN THE TOP. REMOVE THE TWO PLUGS IN

THE TOP. THESE HOLES ARE TAPPED SO THAT A ½” CONDUIT

CONNECTOR CAN BE THREADED INTO PLACE.

IT IS IMPORTANT THAT YOU ONLY USE THESE HOLES. THE

UNDERNEATH OF THE TOP IS CONSTRUCTED WITH A HAS A AIR

MANIFOLD MADE INTO IT. CUUTING INTO THE TOP WILL MAKE

THE UNIT UN-USABLE!

Each unit is shipped with a field wiring harness. The harness has eight

color coded wires which are to be connected to the field wiring cable that

runs between each station.

Connect these wires color for color.