Fortress Technologies FGTG15 User manual

This manual suits for next models

4

Table of contents

Popular Griddle manuals by other brands

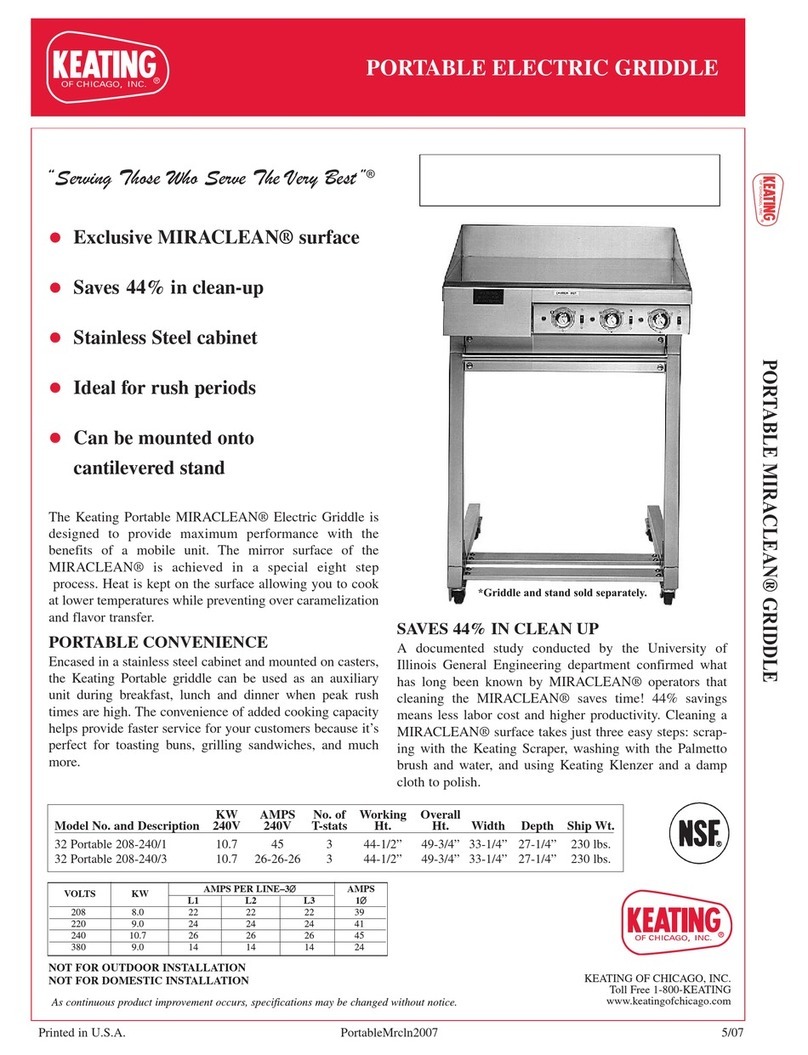

Keating Of Chicago

Keating Of Chicago Miraclean 208-240/1 Specification sheet

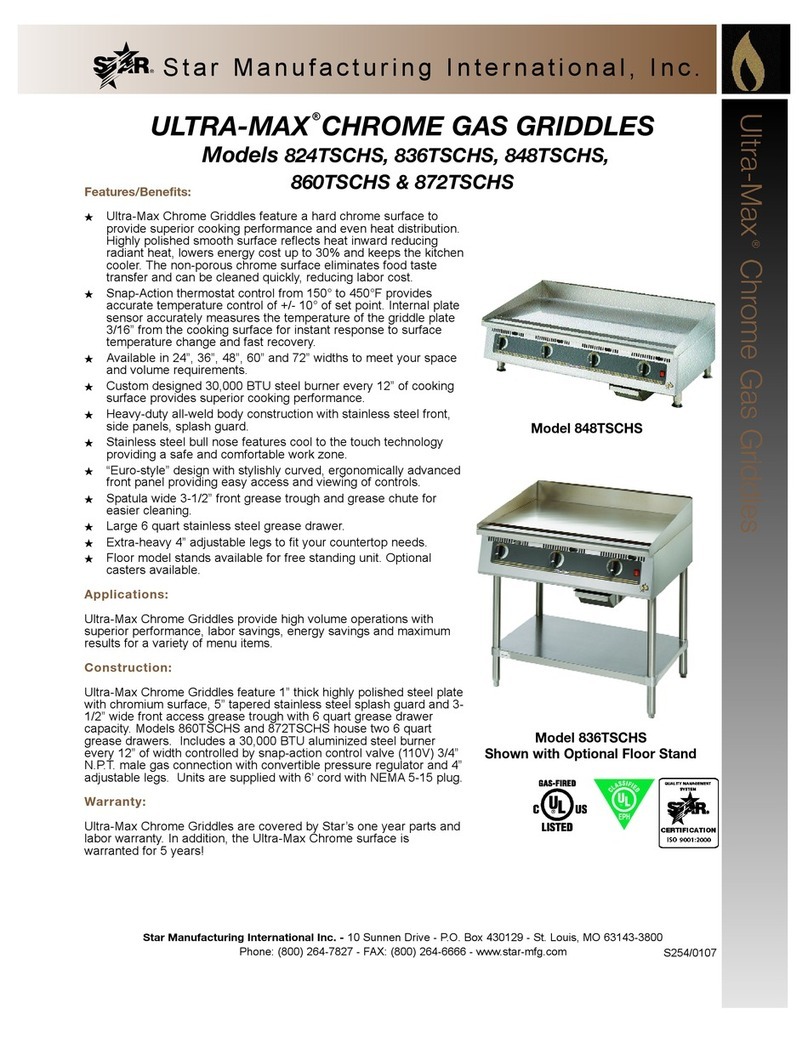

Star Manufacturing

Star Manufacturing ULTRA-MAX 824TSCHS Specification sheet

Pit Boss

Pit Boss PB2BGD2, PB3BGD2, PB4BGD2, PB5BGD2 owner's manual

Black Stone

Black Stone 1863 owner's manual

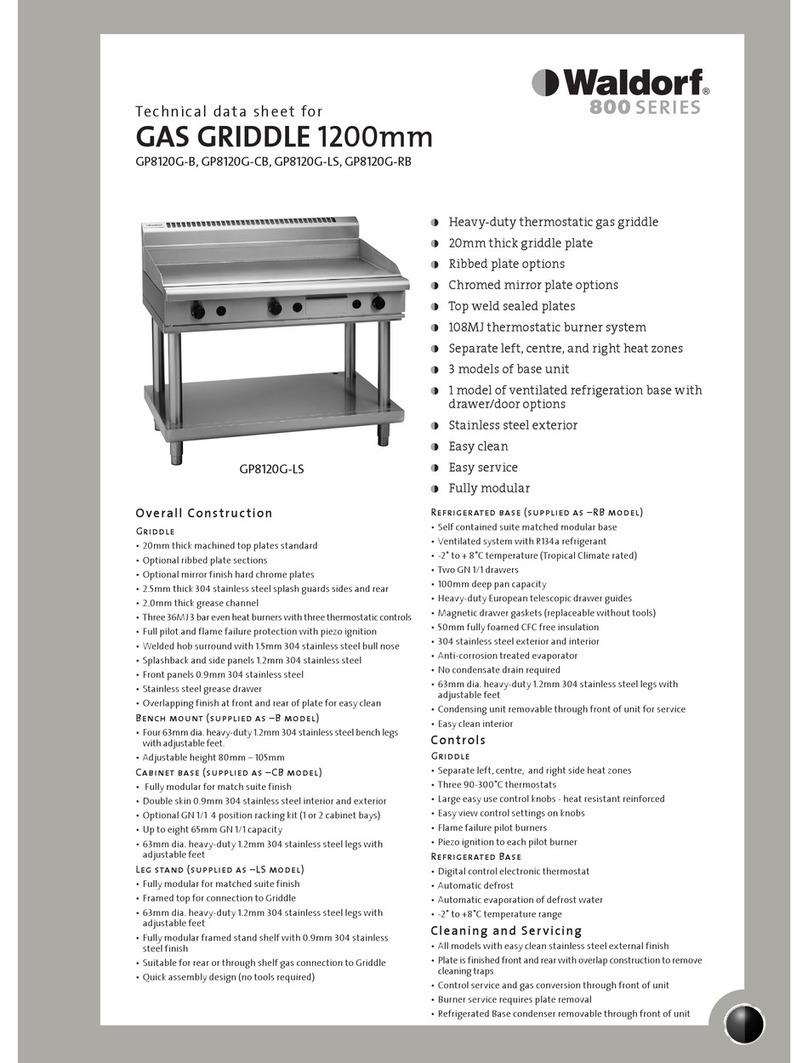

Waldorf

Waldorf GP8120G-CB Technical data sheet

croydon

croydon GR2E instruction manual

Toastmaster

Toastmaster TMGM24 - Installation and operation instructions

Black Stone

Black Stone 1833 Parts & Assembly

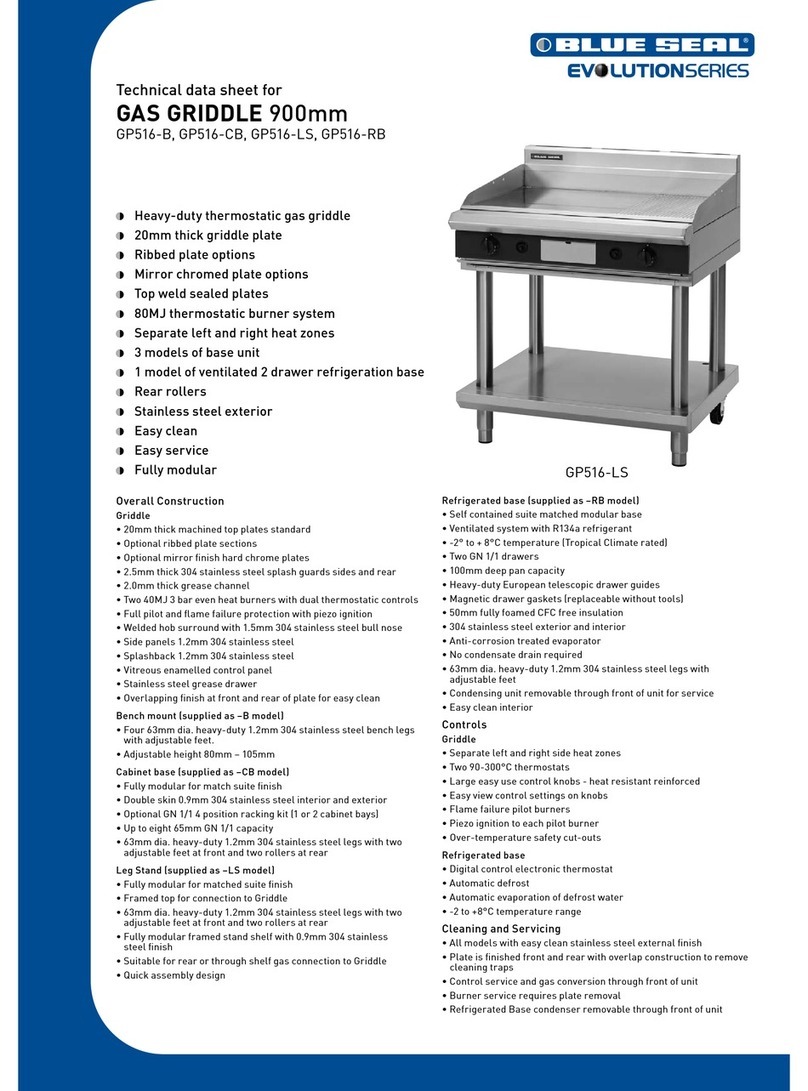

Moffat

Moffat Blue Seal Evolution Series GP516-B Technical data sheet

Pit Boss

Pit Boss 336GS Assembly and operation

APW Wyott

APW Wyott EG-24S owner's manual

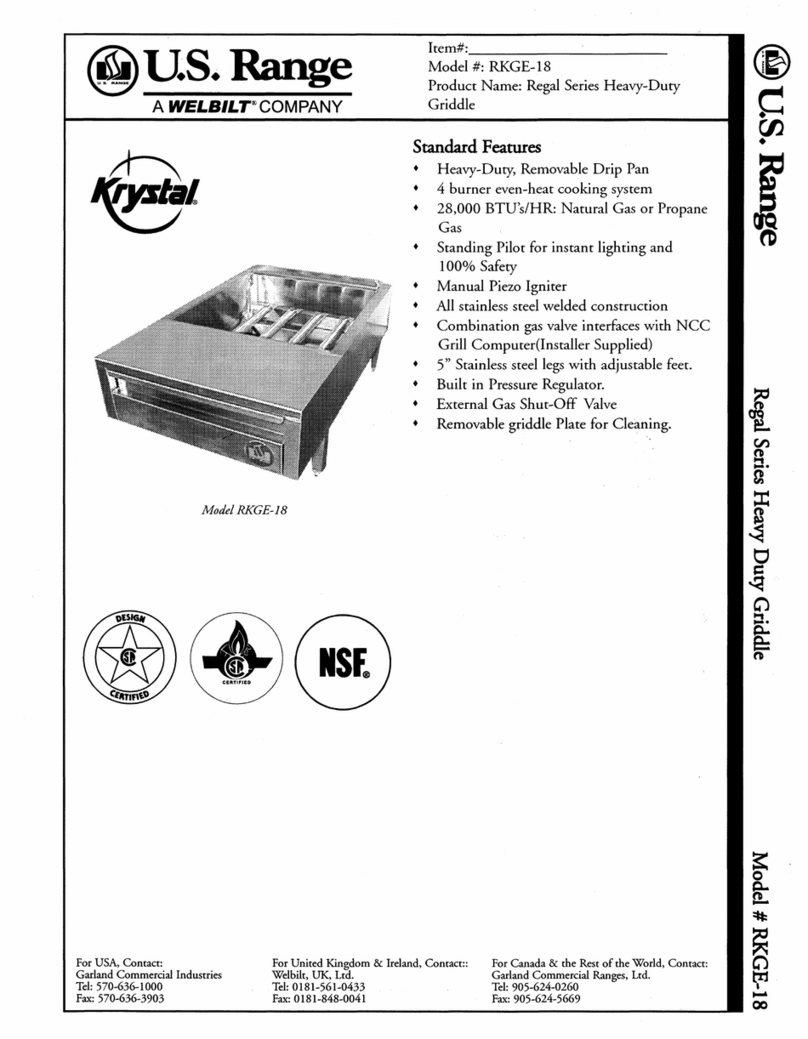

U.S. Range

U.S. Range RKGE-18 Information

Vulcan-Hart

Vulcan-Hart 924RX Specification sheet

Royal Catering

Royal Catering RCKG-2200-GY user manual

Lang

Lang 124ZT Installation and operation instructions

Lang

Lang SELECTRONIC Installation, operation and maintenance instructions

LE MARQUIER

LE MARQUIER PLOG260D user manual

Presto

Presto Liddle Griddle instructions