Fortune Culture Technology L6 User manual

Contents

1. Packing List…………………………………………………………………………………….……1

2. Safety Introductions……………………………………………………………………….……2

3. Printer Parameters………………………………………………………………………….……3

4. Printer Overview…………………………………………………………………………….……4

5. Menu Directory…………………………………………………………………………….……..5

6. Platform Leveling………………………………………………………………………..……….6

7. Slicer Software………………………………………………………………………….…………8

8. First Print Introductions…………………………………………………………..…………21

9. FAQ and Machine Maintenance…………………………………………………………23

1. Packing List

Paper Funnel * 2 Allen Wrench * 1 Scrapers * 2

Print Platform * 1 Resin Vat * 1

Quick Guide * 1

User Manual * 1

3D Printer * 1

Power Adapter * 1

1

2. Safety Instructions

Always follow the safety instructions during assembly and usage, to avoid any

unnecessary damage to the 3d printer or individual injury.

●After receiving the printer, please check the packing accessories first. If any accessories

are missing or damaged (non-human), please contact after-sales service within 3 days to

reissue. (If you do not contact after-sales service within the specified time, the possible costs

will be borne by the customer.)

●Wear gloves and mask to avoid direct skin contact when using. If resin splashes into the

eyes or mouth accidentally, rinse with plenty of water.

●Always use the LCD 3D printer in an open and well ventilated area. It is recommended t

o use the printer indoors and avoid direct sunlight and dusty environment.

●Recommended ambient temperature is 15-40 degrees, and the ambient humidity is 20%-

80%. Use outside of this range may bring poor printing results.

●In case of emergency, please immediately shut down the power of the 3D printer and co-

ntact the technical support.

●It is recommended to use protection glasses when cleaning/sanding the printed models

to avoid small particles contacting eyes.

●Please keep the 3D Printer and its accessories out of the reach of children.

●Please don't disassemble the 3D Printer by yourself, which will cause your warranty to ex-

pire. Please contact the after-sales service if you have any questions.

●If you do not use the machine for a long time, please pay attention to rain and moisture

protection for the 3D printer.

2

3. Printer Parameters

Model L6

Operation 3.5 Inch Touch Screen

Slicer Software CHITUBOX

Connectivity WIFI, USB

Technology UV Photocuring LCD

Light Source 405nm UV Matrix Parallel Light Source

XY Resolution 0.047mm(2560*1620)

Z Axis Accuracy 0.00125mm

Layer Thickness 0.025-0.1mm

Print Speed 20~60mm/h

Rated Power 48W

Offline Printing Support

Operate System Windows

Build Volume 130.56(L)x82.62(W)x150(H)mm

Print Materials 405nm Photopolymer Resin

Net Weight 4.7kg

Gross Weight 6.6kg

Printer Dimensions 270(L)x275(W)x405(H)mm

Package Size 340(L)x340(W)x490(H)mm

3

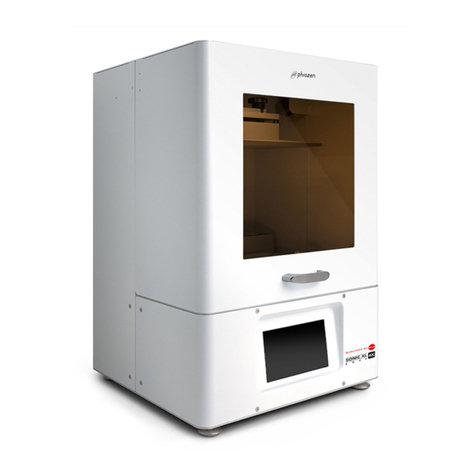

4. Printer Overview

Air Vent

Z Leadscrew

UV-blocking Cover

Linear Guidway

Printer Shell

Platform Arm

USB Port Power Switch

Screws

4

Build Platform

Resin Vat

Touch Screen

Platform Securing Knob

Leveling Pad

Power Interface

5. Screen Functions

Menu

Print

Choose files

Exposure test

Start

Settings 1 Settings 2

WIFI

Clean the vat

Move Z

Z=0

Language

Info

0.1mm 1mm 10mm

5

100%

L6

V1.0.1

6. Assembly and Leveling Instructions

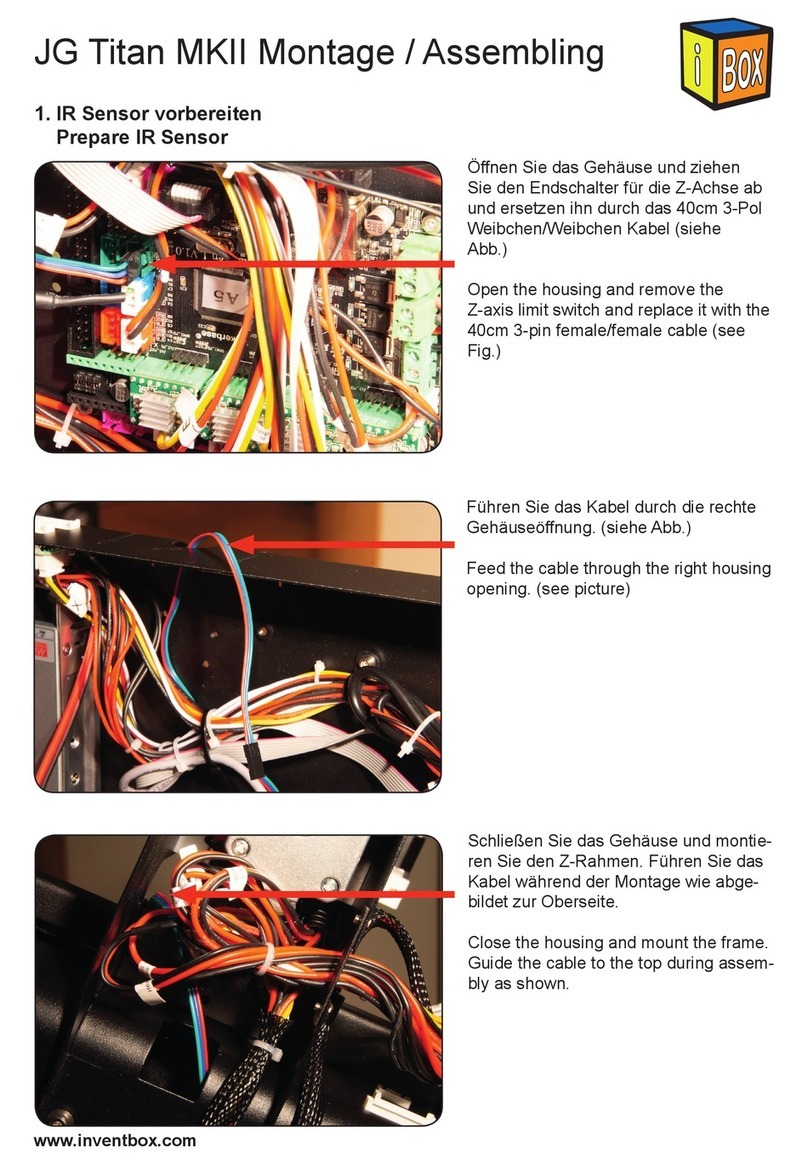

6.1 Connect power cable to printer and power supply; as shown in picture (6.1)

6.2 Click on the operation screen <Settings>-<Move Z>, select <10mm> travel and

click to rise the Z axis. Check and keep the LCD screen and the platform clean and free

of debris; as shown in picture (6.2)

6.3 Loosen the set screw on the printing platform with an Allen wrench so the platform

can be rotated freely. Install the platform onto the platform bracket and push it to the

end. Lastly tighten the platform securing knob on the top; as shown in picture (6.3)

6.4 Click“HOME”, wait for the Z axis to descend and then it will stop automatically; as

shown in picture (6.4&6.5)

Picture (6.1)

Picture (6.2)

Picture (6.3)

Power interface

Power switch

Picture (6.4) 6

10mm

:

:10mm

Platform Securing Knob Fastening screw

②

①

Picture (6.5)

6.5 After the Z-axis descends and stops, gently press on top of the platform with your

hand, to let it fit evenly on the 2K LCD screen and ensure that the printing platform is

parallel to the LCD screen. Then fix the set screw as tight as possible; as shown in

picture (6.6)

6.6 The platform rises about 120mm, click on the operation screen <Return>-<Next>-

<Exposure>-<Next> to check whether the light source is working normally, as shown

in picture (6.7); The 2K screen should display the same as the picture below the image

indicates that the UV lights work perfectly; as shown in picture (6.8)

6.7 Before putting it in the resin vat, please make sure the release film is tight. If the

release film is not tight, please tighten the screw on the bottom of the resin vat to fix

the release film; then follow the steps in the figure below to install it. Put the resin vat

back and fasten the press buckles on both sides to complete the leveling. (as shown in

picture 6.9&6.10)

Picture (6.7) Picture (6.8)

Click here to

change the

detection

exposure time

Picture (6.10)Picture (6.9) 7

Picture (6.6)

7.Use of Slicing Software

The 3D printer reads the slice file and cascades out three-dimensional objects.There-

fore,users need to convert 3D format files (such as stl format or obj format) into

machinereadable slice files (such as ZIP format). This process is commonly known as

"slicing", that is, "cutting" the 3D model into many Floor.Software that can convert 3D

format files into slice files is called slice software.

7.1 Installation of CHITUBOX

Open the slicing software installation package in the included U disk, select the

installation program (such as 32-bit or 64-bit) suitable for the current co- mputer

operating system type, and then start the installation; as shown in figure (7.1)

Figure (7.1)

8

7.2 Software startup

Use the icon on the desktop or the shortcut in the start menu to start the software. When you

open the software for the first time, a model selection box will pop up, you can choose the list

model according to your needs. Select the model only for the first login, and do not need to

set again when logging in later. (The software has no corresponding parameters for this mac-

hine, please choose other-default and set the parameters yourself.)

7.3 Introduction to the software interface, as shown in figure (7.2)

3.1 drop-down list, as shown in figure (7.3)

3.1.1 Open project: open the project that needs to be operated;

3.1.2 Save project: store the operated model to the specified

directory path;

3.1.3 Open…: Open the model (the system default value will dir-

ectly save the directory path of the previous model);

3.1.4 Save as...: save to computer;

3.1.5 Recently opened: the recently opened model file record;

3.1.6 Account: login and authorization;

3.1.7 Language: Users can choose the language according to th-

eir needs (English, Simplified Chinese, Traditional Chinese

Chinese, German, French, Russian, Korean, Italian, Portuguese,

Spanish, etc.);

3.1.8 Help: Check for updates: The user can check or uncheck

when starting CHITUBOX

Check the latest version automatically;

3.1.9 Example: A cube model and a cylinder model are given in the system;

3.1.10 Exit: Click to close and exit CHITUBOX.

Figure (7.2)

Figure (7.3)

9

Screenshot

3.2 Introduction to the menu bar, the menu bar interface is shown in figure (7.4)

3.2.1 Open file: open the file that needs to be operated;

3.2.2 Save file: store the operation files that have been carried out;

3.2.3 Screenshot/recording: watermark, screen record, and screenshot of

the screen; as shown in figure (7.5)

(1) Watermark: tick mark date (real-time date), author & others (files can be edited) on

the watermark;

(2) Screen recording: You can set the time (/s) and frame rate (/fps) yourself, and then

click Start;

(3) Screenshot: Click the "Start" button to start the screenshot.

3.2.4 Restore & Redo (Undo forward, undo backward);

3.2.5 Clone and copy the current model (click to copy the model on

the current platform);

3.2.6 Automatic layout: center, X side, Y side placed on the platform;

as shown in figure (7.6)

Figure (7.4)

Watermark Screen recording

Figure (7.5)

Center X side Y side

Figure (7.6)

10

3.2.7 hollowing: internal hollowing or external hollowing, the wall thickness

and accuracy need to be set; as shown in figure (7.7)

3.2.8 Tug hole: need to set shape and size, choose whether to keep the hole,

add a hole; as shown in figure (7.8)

3.3 Editing the model

3.3.1 Mobile model operation, as shown in figure (7.9)

(1) Move on the X, Y, and Z axes: place the cursor directly in the number box and roll

the mouse;

(2) The model can be directly placed on the bottom plate, centered, and reset;

Figure (7.7)

Figure (7.8)

Figure (7.9)

11

3.3.2 Rotating model operation, as shown in figure (7.10)

(1) Rotate on the X, Y, and Z axes:

Click to rotate 15°in the positive direction of X/Y/Z;

Click to rotate 15°in the negative direction of X/Y/Z;

The cursor rolls the mouse on the number box, and rotates every +5°/ -5°;

(2) Place the cursor directly on the color bar on the model and hold down the left

mouse button to move (red-X, green-Y, blue-Z);

3.3.3 Zoom model operation, as shown in figure (7.11)

Zoom on the X, Y, and Z axes respectively:

(1) The cursor can be zoomed by rolling the mouse on the number box;

(2) When the scale is locked, no matter which axis is placed on the scale, the other two

axes will become larger and smaller in proportion;

(3) Reset: clear the previous zoom operation and re-zoom again;

Figure (7.10)

Figure (7.11)

12

3.3.4 Model mirror operation, as shown in figure (7.12)

(1) X mirror image: mirror the current model with the X axis as the axis of symmetry;

(2) Y mirror image: mirror the current model with the Y axis as the axis of symmetry;

(3) Z mirror image: mirror the current model with the Z axis as the axis of symmetry;

3.4 Mouse operation (operation in the middle panel); as shown in figure (7.13)

3.4.1 Left-click: Click on the model to select the model for operation, click on the platform or blank

space;

3.4.2 Left key press

(1) Long-press the model with the left button to move the model on the current horizontal plane;

(2) Long press the platform or blank space with the left button to drag the platform and model in all

directions;

3.4.3 Right-click long press: Right-click long press can rotate the platform;

3.4.4 Mouse scroll wheel: zoom the whole platform and model in proportion;

Figure (7.12)

Figure (7.13)

13

3.5 scene interface; as shown in figure (7.14)

3.5.1 Drag scene: long press the left mouse button;

3.5.2 rotation scene: long press the right button

3.5.3 Zoom scene: Roll the mouse wheel;

3.5.4 Front view: click to make the scene and the model front right view facing

the user;

3.5.5 Front view/perspective view: the current model can be switched between

front view and perspective view;

3.5.6 Top view/left view/front view: T-top view; L-left view; F-front view;

3.5.7 Entity/Perspective: Click to allow the model to switch between entity and

perspective;

3.5.8 model bar: take the entire model as a scale to view the correspo-

nding cross-section of the model in real time; there are up and

down, right and right sides of the one-, two-, and three-speed

progress of the slice playback and pause;

3.5.9 Expand/Hide: Click to expand and hide the content on the right, making the scene more

empty;

3.6 Common settings

3.6.1 File list: all the models on the platform will be arranged in the file list, and you can edit or delete

them in the full/single selection model; as shown in figure (7.15)

Figure (7.14)

Figure (7.15)

14

3.6.2 Slice setting; as shown in figure (7.16)

You can add your own machine type, and then set the relevant data;

<Import>: Import the saved machine configuration parameters; (The attached U disk has the

recommended parameter configuration file of the machine. When slicing, directly click "Import

Configuration File" in "Slice Settings" to import the parameters.)

<Export>: Export the configured machine parameters;

(1) Machine setting interface; as shown in figure (7.17)

<Name>: machine name, you can directly enter text for custom naming;

<Resolution>: the resolution of the projector or LCD screen, this parameter directly affects the

dimensional accuracy of printing;

<Locking ratio>: Under normal circumstances, the ratio of the forming size XY = resolution ratio, that is,

the locking ratio; in some cases, such as DLP projectors, due to accuracy or machine design reasons,

the XY size is slightly different, and it may not be maintained Proportion, fill in the actual projection

size;

<Size>: The maximum forming size of the machine;

Figure (7.16)

Figure (7.17)

15

(2) Resin setting interface; as shown in figure (7.18)

<Resin type>: Different resin types have different parameters, some resins recommended by integrated

companies and corresponding parameters;

<Resin density>: Density of resin, used to calculate mass;

<Resin price>: The cost of resin, used to calculate the cost;

(3) Print setting interface; as shown in figure (7.19)

<layer thickness>: The thickness of each layer of the model is generally 0.025/0.05/0.1mm;

<Number of bottom layers>: The number of layers to be solidified at the bottom of the model.

In order to better stick to the platform, the parameters of the bottom layer need to be set

separately;

<exposure time>: exposure time of normal layer;

<Bottom layer exposure time>: the exposure time of the bottom layers, the general time will

be longer than the normal layer exposure time, let the resin cure as completely as possible, to

ensure that it sticks to the molding platform;

<Light-off delay>: Calculated from the end of the exposure of the previous layer, the final

light-off time = maximum (the total time of the Z axis moving up and down, the configured

light-off delay)

Figure (7.18)

Figure (7.19)

16

For example, the period of the Z axis moving up and down is 6 seconds:

If the "light-off delay" is set to 10 seconds, the final turn-off time is 10 seconds;

If the "light-off delay" is set to 1 second, the final light-off time is 6 seconds;

<Bottom light-off delay>: The light-off delay time of the bottom layers is calculated in

the same way as above;

<Bottom layer lifting distance>: the distance the molding platform is lifted when

printing the bottom layers;

<Lifting distance>: the distance the forming platform is lifted during normal layer

printing;

<Bottom lifting speed>: the speed at which the forming platform lifts when printing

the bottom layers;

<Lifting speed>: the speed at which the forming platform is raised during normal layer

printing;

<Return speed>: the speed at which the forming platform descends;

(4) Fill the setting interface; as shown in figure (7.20)

<Filling structure>: Selection of filling type inside the model, such as mesh structure, etc.;

Figure (7.20)

17

(5) Gcode setting interface; as shown in figure (7.21)

<Start>: preprocessing command executed at the start of printing (can be customized);

<Interlayer>: Processing commands executed by each layer during printing (can be customized);

{image} The name of the exposure image generated;

{raise_pos} corresponds to the lifted position, it is an absolute coordinate value, value = exposure

position + lifted height;

{raise_speed} is the lifting speed, lifting speed = bottom lifting speed or lifting speed;

{fall_pos} corresponds to the position of fall, it is an absolute coordinate, value = exposure position;

{fall_speed} is the falling speed, the falling speed = the bottom falling speed or the falling speed;

{exposure_time} corresponds to the bottom exposure time or exposure time, the unit is ms;

<End>: Processing command executed at the end of printing (can be customized);

{machine_height} corresponds to the height of the machine size;

Figure (7.21)

18

Table of contents

Popular 3D Printer manuals by other brands

3D Upfitters

3D Upfitters Taz6 Enclosure Kit installation manual

3D Upfitters

3D Upfitters LulzBot Mini 2 R1 installation manual

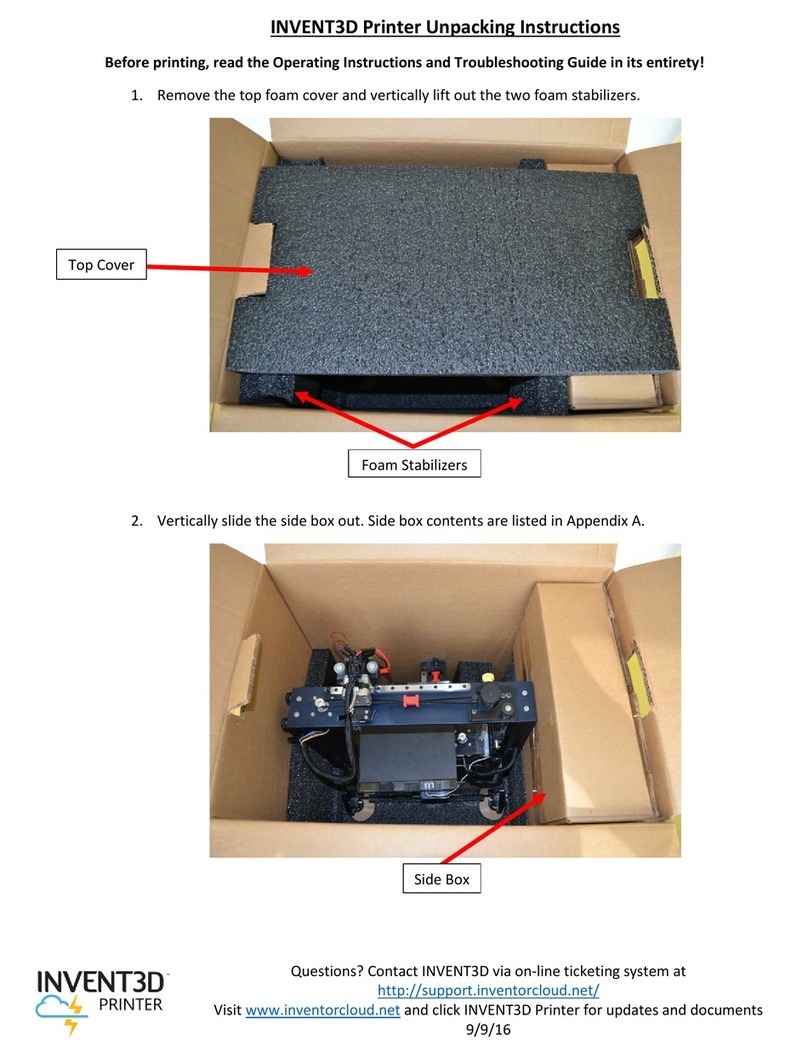

Inventorcloud

Inventorcloud Invent3d Series unpacking instructions

RAISE 3D

RAISE 3D N1 quick start guide

Shining 3D

Shining 3D AccuFab L4D installation guide

3D Upfitters

3D Upfitters Prusa i3 Enclosure Kit installation manual