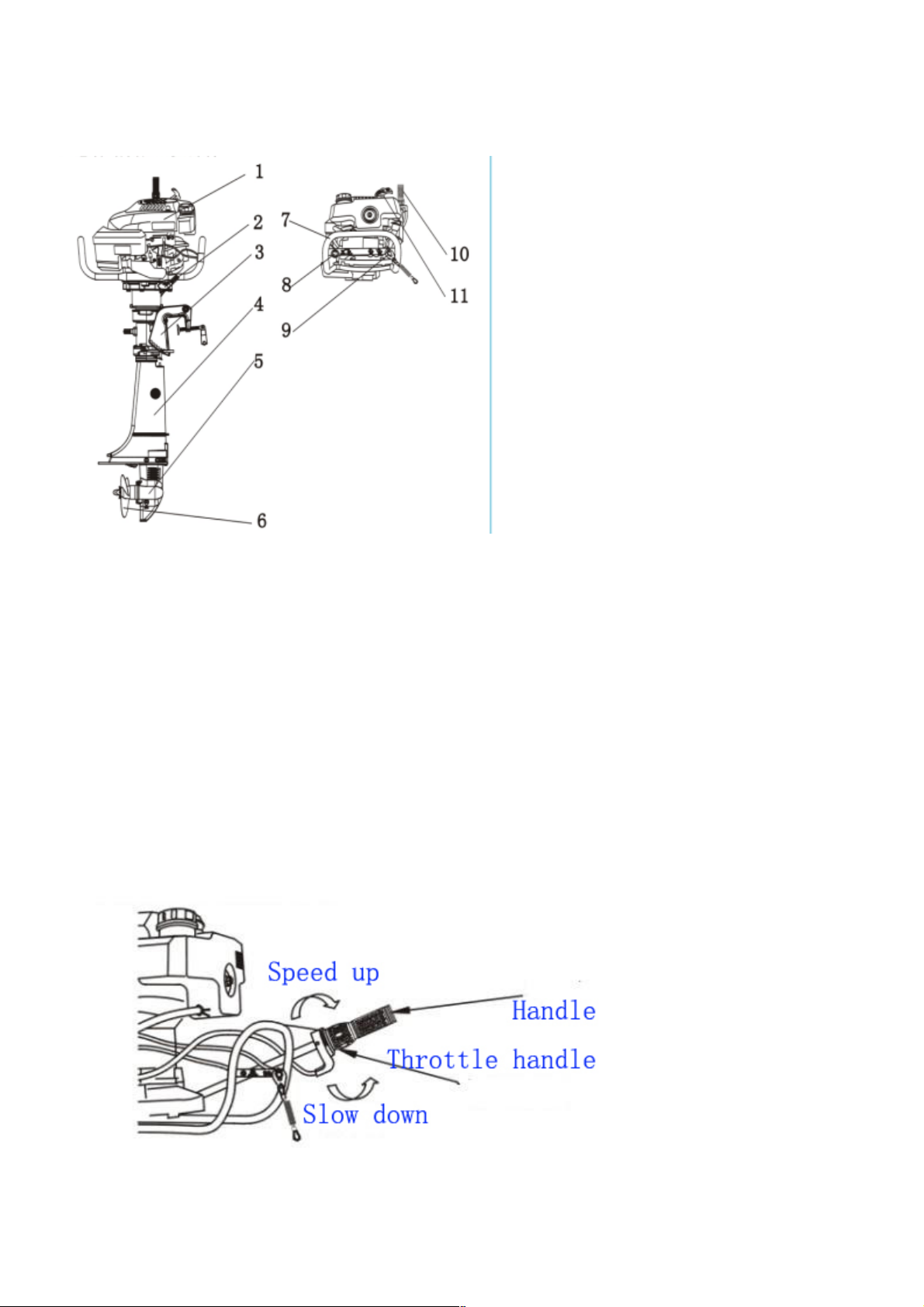

(5)Starting handle

If you want to start the engine, first pull the handle gently until you feel resistance.

Then you may pull the handle quickly to start the engine. see Figure3.1.

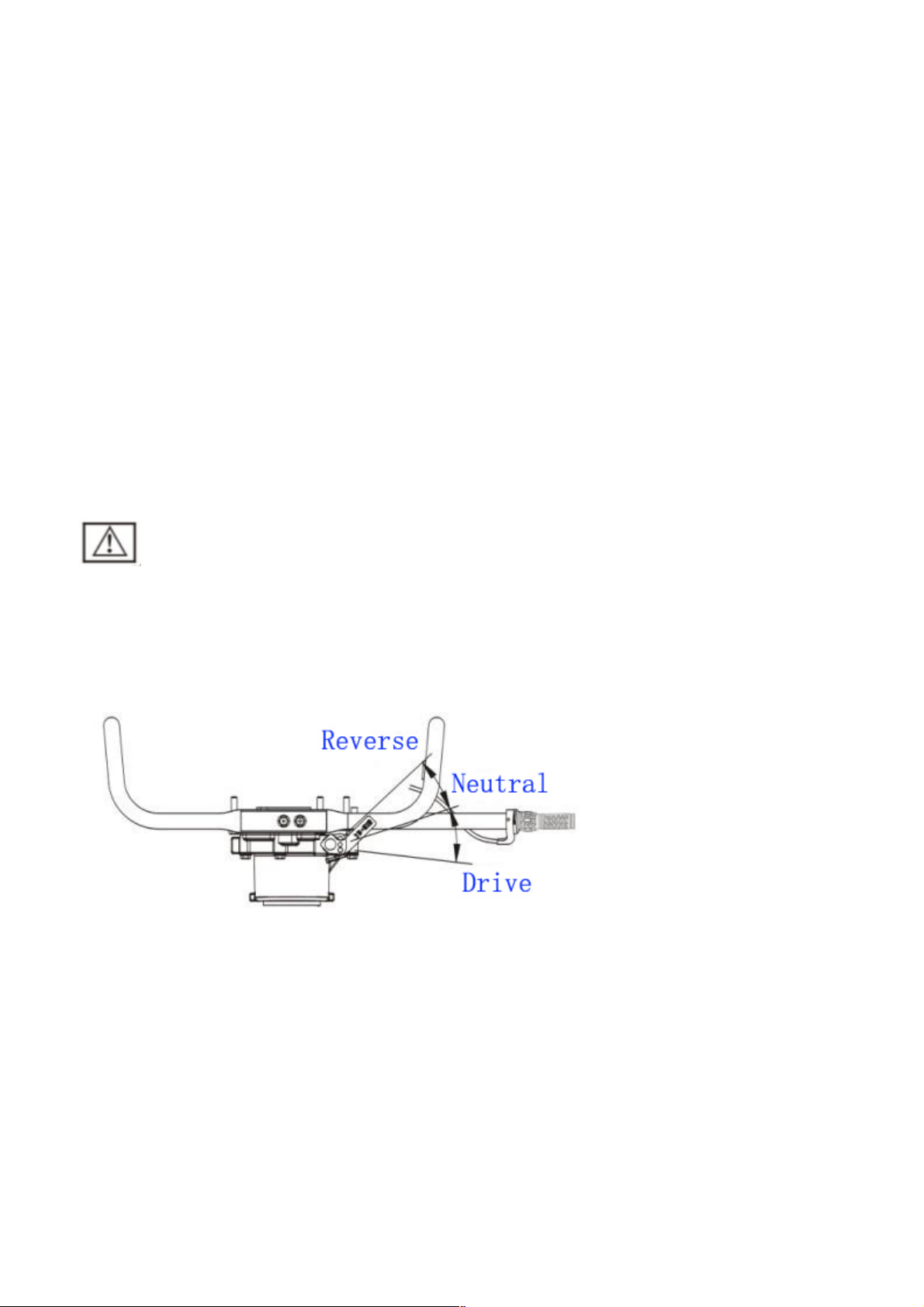

( )Shifting handle

Move the handle down to the low position, Figure 5 , the outboard motor goes

forward, the propeller begins rotating and the boats goes Forward

Move the handle up to the high position,Figure 5, the outboard motor goes back,

and the propeller inverts, the boat goes in Reverse.

Move the handle to the middle,Figure 5, the outboard motor idles, and the

propeller stops, the boat loses driving force(Neutral).

Attention!

1. To ensure safety and easy starting, you need to start the engine on the null.

2. If you want to shift, motor must be at a stable idle and not at high speed.

Figure 5

(7)Handle

There are steel pipe handles on the head of cylinder on the Boss outboard motor.

You can use your hands to carry easily. See Figure .