Foshan Genux Metal Products OVE G2S111S User manual

Manufacturer: Foshan Genux Metal Products Co.,Ltd.

Add: No.11 Beiwei Rd, Xihai Industrial Zone, Beijiao Town,

Shunde District, Foshan City, Guangdong, China

Figure 236, Page 1

ITM. / ART. G2S111S

Owner’s Manual

Outdoor Gas Fire Pit

IMPORTANT, RETAIN FOR FUTURE REFERENCE:

READ CAREFULLY

MADE IN CHINA

Questions, problems, missing parts?

Before returning to your retailer, call our customer service

department at

1-866-839-2888

8 a.m. - 5 p.m., EST, Monday - Friday

(Canada and United States only)

English and French speaking representatives available

HEAD OFFICE

2800, rue Étienne-Lenoir, Laval

Québec H7R 0A3 Canada

This item is intended for outdoor domestic use only. Not for commercial use.

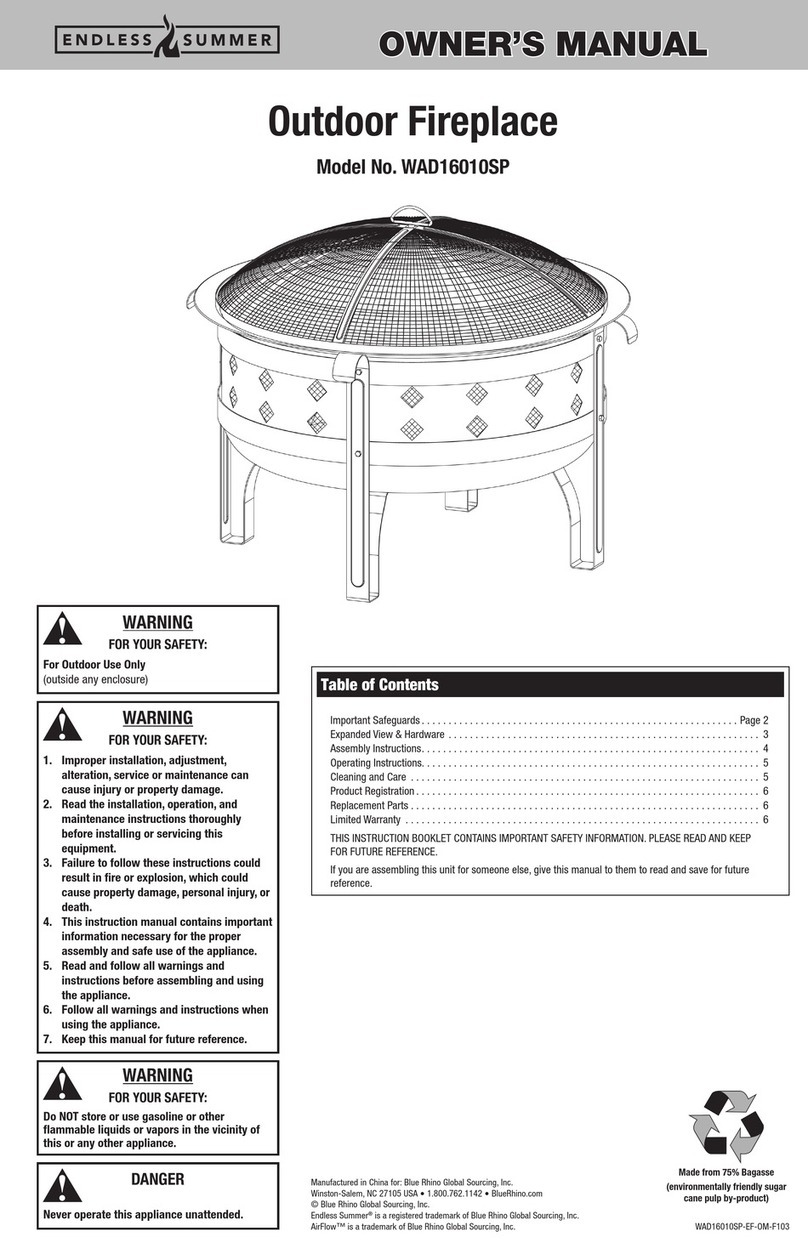

Figure 236, Page 2

106.7 cm

42 in / po

62.5 cm

24.6 in / po

106.7 cm

42 in / po

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install the

product. This appliance has been tested to and complies with the ANSI Z21.97-2017, Outdoor

Decorative Gas Appliances. When connecting to a xed piping system, the installation must conform to

local codes or in the absence of local codes, to the National Fuel Gas Code. ANSI Z223.1.NFPA 54;

National Fuel Gas Code; National Gas and Propane Installation Code, CSA B149.1; or Propane

storage and Handing Code, CSA B149.2, as applicable. This manual contains important information about

the assembly, operation and maintenance of this re pit. Keep this manual for future reference and

to educate new users of this product. This manual should be read in conjunction with the labeling on the

product. Safety precautions are essential when any mechanical or propane fueled equipment is involved.

These precautions are necessary when using, storing, and servicing. Using this equipment with the

respect and caution demanded will reduce the possibilities of personal injury or property damage.

The following symbols shown below are used extensively throughout this manual. Always heed these

precautions, as they are essential when using any mechanical or fueled equipment.

DANGER

WARNING

WARNING

WARNING

DANGER

DANGER

If you smell gas:

●Shut o gas to the appliance.

●Extinguish any open ame.

●If odour continues, keep

away from the appliance and

immediately call your gas

supplier or re department.

This appliance can

produce carbon monoxide

which has no odour. Using

it in an enclosed space

can kill you.Never use this

appliance in an enclosed

space such as a camper,

tent or home.

Do not store or use gasoline, or

other flammable vapours and

liquids in the vicinity of this

or any other appliance. An LP-

cylinder not connected for use

shall not be stored in the vicinity

of this or any other appliance.

Improper installation, adjustment,

alteration, service or maintenance can

cause property damage, injury or death.

Read the installation, operation and

maintenance instructions thoroughly

before installing or servicing this

equipment.

For Outdoor Use Only.

CARBON MONOXIDE

HAZARD

Figure 236, Page 3

Figure 236, Page 4

SAFETY INFORMATION

DANGER

DANGER

WARNING

WARNING

Certain materials or items, when stored under the

re pit, will be subjected to radiant heat and could be

seriously damaged.

Alert children and adults to the hazards of high surface

temperatures. Stay away from these surfaces to avoid

burning skin or igniting clothing.

Carefully supervise young children when in the vicinity

of the re pit.

Do not hang clothing or any other ammable materials

from the re pit, or place on or near the re pit.

Replace any guard or protective device removed for

servicing the appliance prior to placing back in service.

Installation and repair should be done by a qualified

service person. The re pit should be inspected before

use and annually by a qualified service person. More

frequent cleaning may be required as necessary. It is

imperative that the control compartment, burners, and

circulating air passageway of the appliance be kept

clean.

• This product is fueled by propane gas. Propane

gas is invisible, odourless, and flammable. An

odourant is normally added to help detect leaks

and can be described as a “rotten egg” smell. The

odourant can fade over time so leaking gas is not

always detectable by smell alone.

• Propane gas is heavier than air and leaking

propane will sink to the lowest level possible. It

can ignite by ignition sources including matches,

lighters, sparks or open ames of any kind many

feet away from the original leak. Use only propane

gas set up for vapor withdrawal.

• Store or use propane gas in compliance with

local ordinances and codes or with ANSI/NFPA 58.

Turn o propane when not in use.

DANGER indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Failure to comply with the

precautions and instructions

provided with this fire pit can

result in death, serious bodily

injury and property loss or damage

from hazards of fire, explosion,

burn, asphyxiation, and/or carbon

monoxide poisoning. Only persons

who can understand and follow the

instructions should use or service

this re pit.

• EXPLOSION - FIRE HAZARD

• Keep solid combustibles,

such as building materials, paper or

cardboard, a safe distance away from

the fire pit as recommended by the

instructions.

• Provide adequate clearances around

air openings into the combustion

chamber.

• Never use the re pit in spaces which

do or may contain volatile or airborne

combustibles, or products such as

gasoline, solvents, paint thinner, dust

particles or unknown chemicals

• During operation, this product can

be a source of ignition. Keep fire pit

area clear and free from combustible

materials, gasoline, paint thinner,

cleaning solvents and other ammable

vapours and liquids. Do not use fire

pit in areas with high dust content.

Minimum fire pit clearances from

combustible materials: 90 cm (3 ft)

from the sides and 90 cm (3 ft) from

the rear, 1.8 m (6 ft) feet from ceiling.

Figure 236, Page 5

SAFETY INFORMATION

WARNING

DANGER

WARNING

We cannot foresee every use which may be made of

our re pit.

Check with your local re safety authority if you have

questions about re pit use.

Other standards govern the use of fuel gases and

heat producing products for specic uses. Your local

authorities can advise you about these.

If no local codes exist, follow National Fuel Gas Code,

ANSI Z223.1. In Canada, installation must conform to

local codes. If no local codes exist, follow the current

National standards of CANADA CAN/CGA-B 149.2.

Do not store or use gasoline or other ammable

vapours and liquids in the vicinity of this or any other

appliance. An LP-cylinder not connected for use

shall not be stored in the vicinity of this or any other

appliance.

Never leave re pit unattended when hot or in use.

Keep out of reach of children.

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury or

death. Read the installation, operation

and maintenance instructions

thoroughly before installing or

servicing this equipment.

DANGER

CARBON MONOXIDE HAZARD

This re pit is a combustion appliance.

All combustion appliances produce

carbon monoxide (CO) during the

combustion process. This product

is designed to produce extremely

minute, non-hazardous amounts of CO

if used and maintained in accordance

with all warnings and instructions. Do

not block air ow into or out of the re

pit. Carbon Monoxide (CO) poisoning

produces flu-like symptoms, watery

eyes, headaches, dizziness, fatigue

and possibly death. You can't see it

and you can't smell it. It's an invisible

killer. If these symptoms are present

during operation of this product get

fresh air immediately!

For outdoor use only.

Never use inside house, or other

unventilated or enclosed areas.

This fire pit consumes air (oxygen).

Do not use in unventilated or enclosed

areas to avoid endangering your life.

WARNING

Don’t burn solid fuels in this

appliance

Figure 236, Page 6

OPERATION CHECKLIST

Operation Checklist

Before Operating:

After Operation

For a safe and pleasurable heating experience, perform this check before each use.

1. Gas control is in OFF position.

2. Gas tank valve is OFF.

3. LP/NG is disconnected.

4. After each use, cap on tank is replaced.

1. I am familiar with the entire owner’s manual and understand all precautions noted.

2. All components are properly assembled, intact and operable.

3. No alterations have been made.

4. All gas connections are secure and do not leak.

5. Wind velocity is below 16 km/h (10 mph).

6. Unit will operate at reduced eciency below 4.44°C /40°F

7. Fire pit is outdoors (outside any enclosure).

8. There is adequate fresh air ventilation.

9. Fire pit is away from gasoline or other ammable liquids or vapours.

10.Fire pit is away from windows, air intake openings, sprinklers and other water sources.

11.Fire pit is at least 90 cm (36 in) on rear and at least 90 cm (36 in) on sides from combustible materials.

12.Fire pit is on a hard and level surface.

13.There are no signs of spider or insect nests.

14.All burner passages are clear.

15.All air circulation passages are clear.

16.Children and adults should be alerted to the hazards of high surface temperatures and should keep

away to avoid burns or clothing ignition.

17.Young children should be carefully supervised when they are in the area of the re pit.

18.Clothing or other protective material should not be hung from the re pit, or placed on or near re pit.

19.Any guard or other protective device removed for servicing the fire pit must be replaced prior to

operating the re pit.

20.Installation and repair should be done by a qualified service person. The fire pit should be

inspected before use and at least annually by a qualied service person.

21.More frequent cleaning may be required as necessary. It is imperative that control burner and

circulating air passageways of the re pit be kept clean.

22.Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the appliance and to replace any part of the control system and any gas control

that has been under water.

EXPLODED VIEW Figure 236, Page 7

Glass bead (4kg x 2 box)

Burner

Table top

Knob

Control panel

Ignitor

Valve assembly and LP hose

LP Reducer

NG Reducer

NG Hose

Table base

Top cover

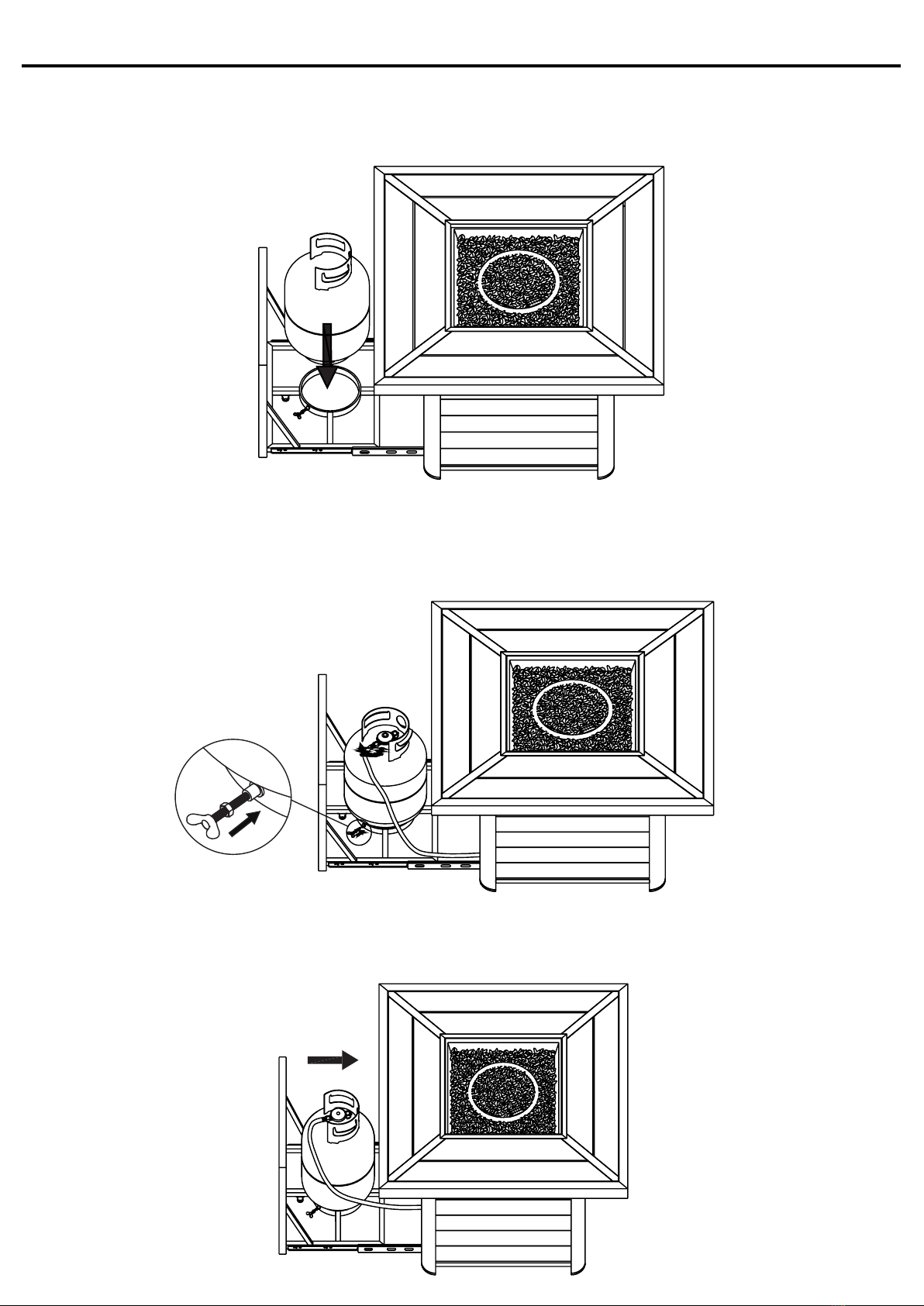

ASSEMBLY INSTRUCTIONS FOR LP

Step 1

Step 2

Figure 236, Page 8

Hang the top cover on the side of the re table.

Put the glass beads onto the burner.

DO NOT COVER THE WINDGUARD WITH THE BEADS.

ASSEMBLY INSTRUCTIONS FOR LP

Step 3

Step 5

Figure 236, Page 9

Secure the gas tank to the re table at the bottom using the bolts.

Connect the gas to the re table using LPG regulator.

Close the re table.

Step 4

Open the re table and

install the gas tank (20 LBS) into the re table.

ASSEMBLY INSTRUCTIONS FOR NG

NG and LP conversion:

A.Change the orice

B.Connect the natural gas gray pipe

Orice size: NG=3.66mm, LPG=2.12 mm

LP TRANSFORMATION PART LIST

LP reducer with

2.12 mm orice

NG reducer with

3.66 mm orice

LP hose assembly NG hose assembly

NG TRANSFORMATION PART LIST

① ①

② ②

Step 1

Figure 236, Page 10

Turn over the re table.

ASSEMBLY INSTRUCTIONS FOR NG

Step 2

Step 3

Figure 236, Page 11

Remove the LP hose using wrench.

Keep the LPG reducer steady using a wrench and loose the pipe using another wrench.

ASSEMBLY INSTRUCTIONS FOR NG

Step 4

Step 5

Figure 236, Page 12

Disconnect the pipe and the LPG reducer.

Uninstall the LP reducer.

LP reducer

Φ 2.12

ASSEMBLY INSTRUCTIONS FOR NG

Step 6

Step 7

Figure 236, Page 13

Install the NG reducer to the pipe.

Reinstall the pipe to the reducer using wrench.

NG reducer

Φ 3.66

ASSEMBLY INSTRUCTIONS FOR NG

Step 8

Step 9

Figure 236, Page 14

Turn over the re table.

Fix the NG hose to the re table.

ASSEMBLY INSTRUCTIONS FOR NG

Step 10

Figure 236, Page 15

Install the NG hose to the NG inlet of re table using wrench.

Natural Gas Inlet

ASSEMBLY INSTRUCTIONS FOR NG

WARNING

This conversion kit shall be installed by a qualied

service agency in accordance with the manufacturer's

instructions and all applicable codes and requirements

of the Authority Having Jurisdiction. If the information

in these instructions are not followed exactly, a re,

explosion or production of carbon monoxide may result,

causing property damage, personal injury or loss of life.

The qualied service agency is responsible for the proper

installation of this kit. The installation is not proper and

complete until the operation of the converted appliance is

checked as specied in the manufacturer's instructions

supplied with the kit.

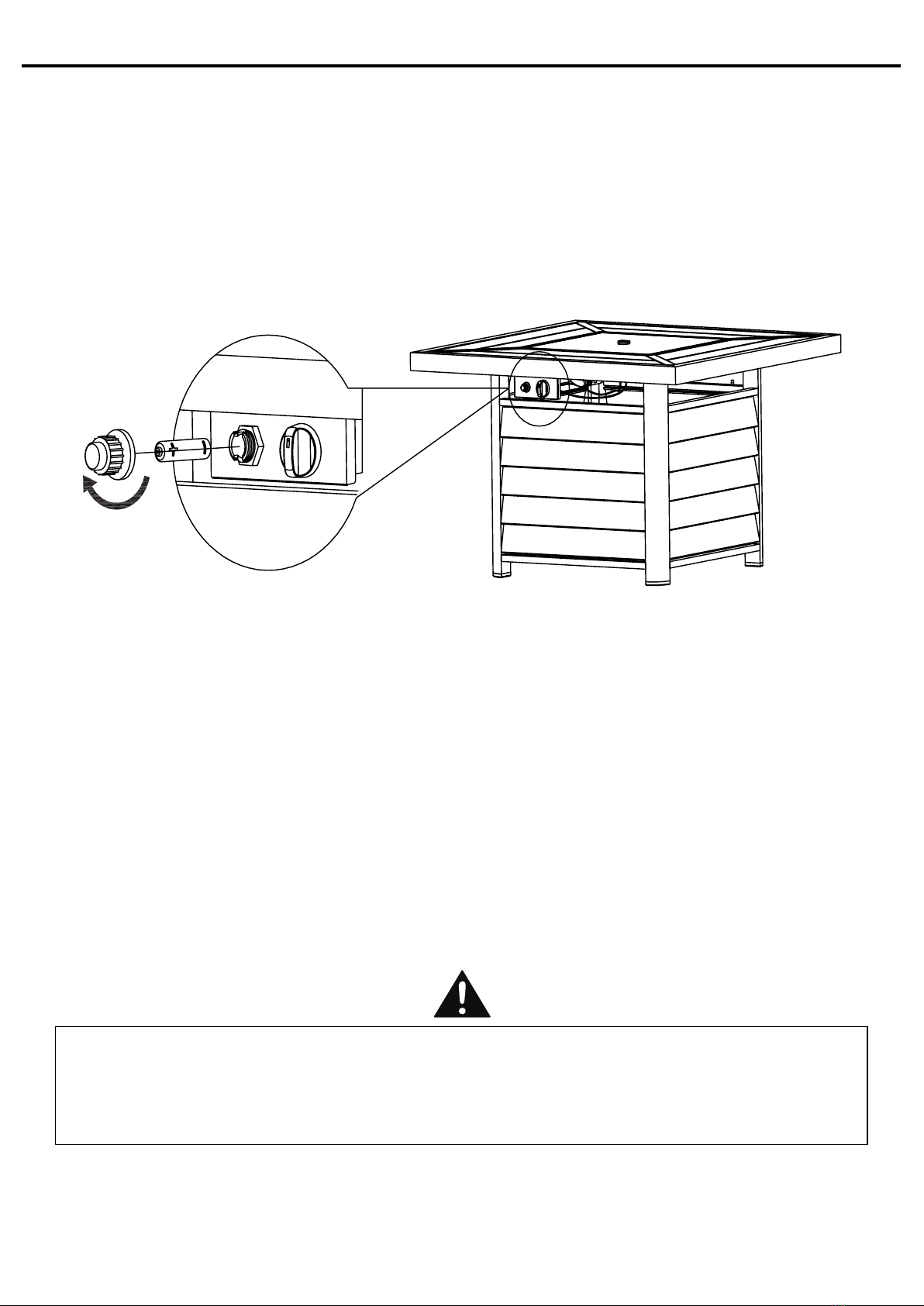

Figure 236, Page 16

• Connecting LP Gas Tank

• Disconnecting LP Gas Tank

• Connecting NG

• Disconnecting NG

This appliance can use two types of fuel/gas: LPG-Propane OR Natural Gas

Suitable LP gas tank size for this appliance is 20 lb (9.1 kg)

Do not ll the LP gas tank with more than 80% liquid gas

The inlet gas supply pressure for the purpose of input adjustment pressure:

LPG-Propane 28 cm (11 in) w.c. (2.74kPa)

Natural Gas 18 cm (7 in) w.c. (1.74kPa)

The appliance must be isolated from the gas supply piping system by closing its individual

manual shut o valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5kPa).

The LP-gas supply cylinder to be used must be:

• Constructed and marked in accordance with the U.S. Department of Transportation (D.O.T.)

Specications for LP-Gas Cylinders;

• Provided with a listed overlling prevention device, and provided with a cylinder connection

device compatible with the connection for the appliance.

• Provided with a cylinder connection device compatible with the connection for the appliance.

WARNING: Make sure LP gas tank valve is closed. Close by turning valve clockwise.

Place the LP gas tank upright into the tank tray and secure the tank by screw.

CONNECTING AND DISCONNECTING LP & NG

Before connecting, be sure that there is no debris

caught in the head of the LP gas tank, head of

the regulator valve or in the head of the burner

and burner ports.

Connect regulator/hose assembly to tank by

turning knob clockwise.

Before disconnecting make sure the LP gas tank valve

is "CLOSED."

Disconnect regulator/hose assembly from LP gas tank

by turning knob counterclockwise until it is loose.

Caution: LP gas tank must be properly disconnected

and removed prior to moving this pit.

1. A professionally-installed shut-o valve between the supply piping and the socket is

recommended, but not required, by the National Fuel Gas Code. Socket connection

must be made outdoors.

2. Coat the gas supply pipe nipple with gas-resistant pipe dope or approved teon tape. Screw socket onto gas

supply pipe (house gas source), and wrench-tighten.

3. Pull back the sleeve on the quick disconnect socket and insert the unattached end of the gas hose into the

socket. Release the sleeve and continue pushing the hose into the socket until the sleeve snaps into the

locked position.

4. When the quick disconnect socket and the gas hose are connected, a valve in the socket opens automatically

to permit full gas ow. When the gas hose is disconnected, the valve in the socket instantly and positively

shuts o the ow of gas, the grill can be disconnected from the gas source by disconnecting the gas hose

from the quick disconnect socket. The socket should be left attached to the gas source (hose piping).

With proper assembly, the gas hose cannot be removed without pushing the quick disconnect sleeve back. To

disconnect, push sleeve back and pull plug out of sleeve (this automatically shuts o gas). The appliance and its

individual shut o valve must be disconnected from the gas supply piping system during any pressure testing on

that system at test pressures in excess of 1/2 psi (3.5kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shut o valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5kPa).

LP GAS

NG

Figure 236, Page 17

LEAK TESTING

WARNING: Before using this outdoor re pit, make sure you have read, understand and

are following all information provided in the Dangers and Warnings. Failure to follow

those instructions can cause death, serious injury or property damage.

WARNING

DANGER

CAUTION Strong odours, colds, sinus congestion, etc. may prevent the detection of

propane by smell. Use caution and common sense when testing for leaks.

WHEN TO PERFORM A LEAK TEST:

Never use your re pit without leak testing all gas connections, hoses and propane tank.

To prevent re or explosion hazard:

• DO NOT smoke or permit ignition sources in the area while conducting a leak test.

• Perform test OUTDOORS in a well-ventilated area that is protected from the wind.

• Never perform a leak test with a match or open ame.

• Never perform a leak test while the re pit is in use or while the re pit is still hot.

• After assembling your re pit and before lighting for the rst time, even if purchased fully-assembled.

• Every time the LP gas cylinder is relled, exchanged or if any of the gas components are disconnected

or replaced.

• Any time your re pit has been moved.

• At least once per year or if your re pit has not been used for more than 60 days.

1. Create a mixture of 50% water and 50% liquid dishwashing soap.

2. Ensure all control knobs are set to the OFF position.

3. Turn on the gas at the cylinder valve. Turn the cylinder valve knob counter-clockwise until

fully opened. If you hear a rushing sound or smell gas, turn the gas off. Tighten any leaking

connections. If the leak is detected at connection nut and tightening does not stop leak, re-inspect

propane tank rubber seal.

4. Apply the soapy water mixture to the following:

A) Supply tank (cylinder) welds B) Connection nut to tank valve

C) Back side of connection nut to brass nipple D) Brass nipple connection into regulator

E) Regulator connections to gas supply hoses F) Hose connection to gas manifold

G) The full length of gas supply hose H) Tank valve to cylinder

5. Check each place listed (A-H) for growing bubbles, which indicates a leak. Large leaks may not be

detected by bubbles but should produce a rushing sound or gas smell.

6. Turn o gas supply at cylinder valve.

7. Turn on control knobs to release gas pressure in hose.

8. Turn control knobs to OFF position.

9. Tighten any leaking connections. If leak is detected at connection nut and tightening does not stop

leak, re-inspect propane tank rubber seal.

10.Repeat soapy water test until no leaks are detected.

11. Turn o gas supply at cylinder valve until you are ready to use your re pit.

12.Wash o soapy residue with cold water and towel dry.

Note: The leak test must be performed in an area that has adequate lighting in order to see if bubbles are

developing and not in a windy or noisy area so larger leaks can be detected by smell or sound.

CAUTION Natural Gas leak testing is similar to LP Gas leak testing. The dierence is you

need to apply the soapy water mixture to the gas supply pipe nipple.

Figure 236, Page 18

BATTERY INSTALLATION

1x AAA Battery (included)

Figure 236, Page 19

Always purchase the correct size and grade of battery most suitable for the intended use.

Clean the battery contacts and also those of the device prior to battery installation.

Remove batteries from equipment which is not to be used for an extended period of time.

STORAGE FOR TABLE COVER Figure 236, Page 20

Step 1

Step 2

Step 3

Table of contents

Other Foshan Genux Metal Products Outdoor Fireplace manuals

Popular Outdoor Fireplace manuals by other brands

Sunjoy

Sunjoy HAMPTON A301004901 Assembly instructions

AMD DIrect

AMD DIrect TF-GFRC-FBWGR-30 Installation and operating instructions

Outdoor GreatRoom Company

Outdoor GreatRoom Company Cedar Bluff manual

Bond

Bond HYFP50095-92 owner's manual

Solo Stove

Solo Stove mesa instructions

Vulcan-Hart

Vulcan-Hart Talbot LPG manual