Part No.23747 Rev. F June 2017 - 4 - Refrigerated Well GN Series

CLEANING........................................................................................................................16

Cautions ......................................................................................................................................................... 16

Power ....................................................................................................................................................... 16

Water........................................................................................................................................................ 16

Exterior ........................................................................................................................................................... 16

Metal Surfaces.......................................................................................................................................... 16

Glass (Optional Hood).............................................................................................................................. 16

Louvers..................................................................................................................................................... 16

Interior............................................................................................................................................................. 17

Cabinet Well Layout ................................................................................................................................. 17

Deck Trays and Dishes ............................................................................................................................ 17

Air Louvers ............................................................................................................................................... 17

Side Grills ................................................................................................................................................. 17

Fan Cover................................................................................................................................................. 17

Stainless Steel Items................................................................................................................................ 18

Well Cleaning ........................................................................................................................................... 18

Cooling Coil .............................................................................................................................................. 18

Removal of Fan Deck............................................................................................................................... 19

Temperature Probes................................................................................................................................. 19

Cleaning Routines ......................................................................................................................................... 20

Schedules................................................................................................................................................. 20

Louvers..................................................................................................................................................... 20

Condenser Radiator ................................................................................................................................. 20

Inspection ................................................................................................................................................. 20

Correction................................................................................................................................................. 20

INSTALLATION ................................................................................................................21

Regulations .................................................................................................................................................... 21

Compliance with Local Requirements...................................................................................................... 21

Setting Up....................................................................................................................................................... 21

Unpacking................................................................................................................................................. 21

Transport .................................................................................................................................................. 21

Site Preparation........................................................................................................................................ 21

Well Assembly Preparation ...................................................................................................................... 21

Grounding................................................................................................................................................. 21

Power Supply ........................................................................................................................................... 22

Isolation .................................................................................................................................................... 22

Protection ................................................................................................................................................. 22

Drains ....................................................................................................................................................... 22

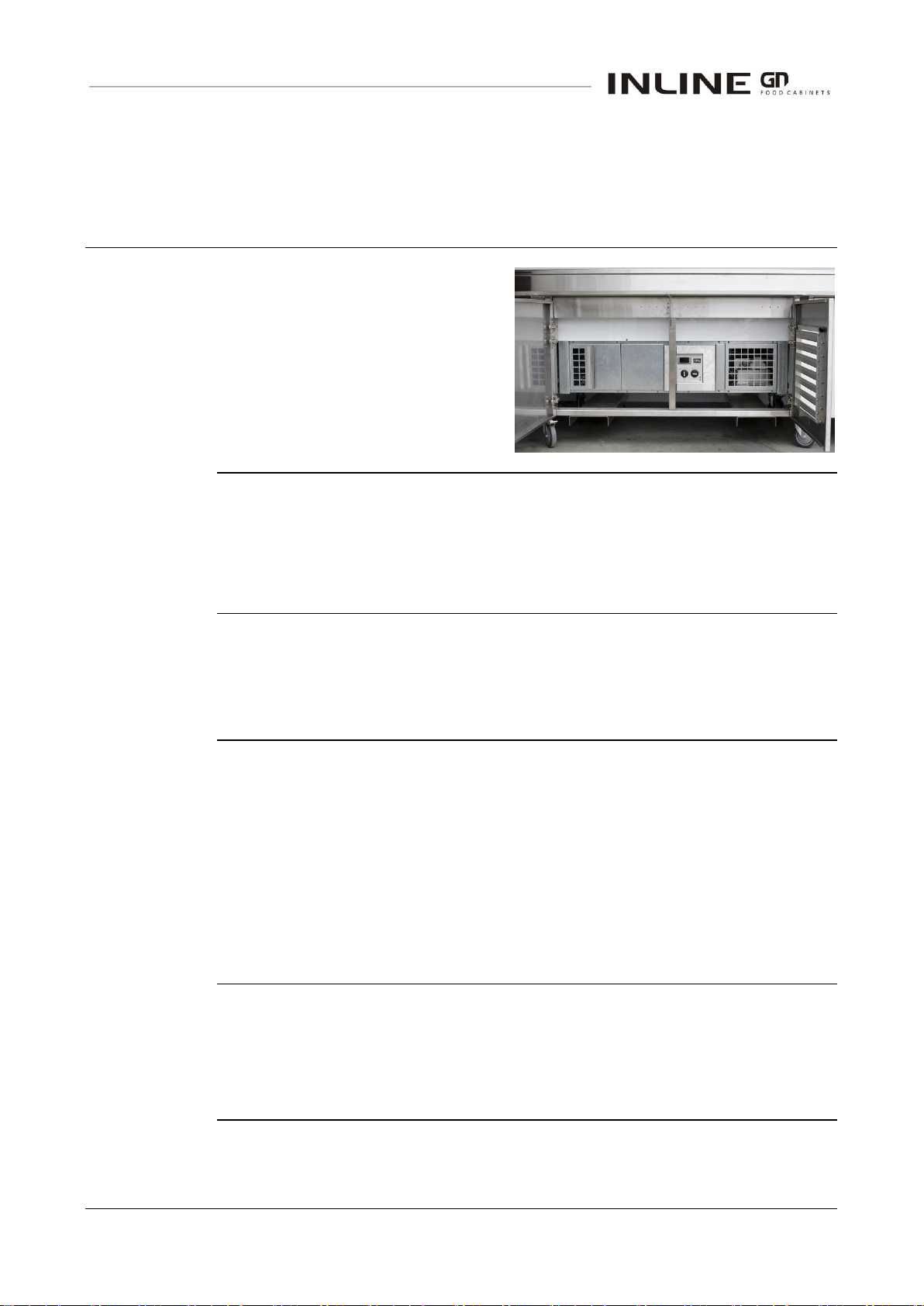

Control Panel............................................................................................................................................ 22

Control Panel Mounting............................................................................................................................ 23

Location.......................................................................................................................................................... 23

Ventilation................................................................................................................................................. 23

Air Louvers ............................................................................................................................................... 23

Access...................................................................................................................................................... 23

Fumes and Odours................................................................................................................................... 23