2. Parts not manufactured by FPM Agromehanika AD Boljevac (tires, plastics, belts, cardan shafts,

cardan shields, hydraulic cylinders with connection hoses, etc.) are not covered by this warranty, but

by the manufacturer's warranty

3. Parts that are normally consumed in exploitation, such as: wedge belts, discs, cutting blades, tires,

scrapers, cutter blades, sliders underneath the cutting machine, protective guard.

4. This warranty is not valid in case of poor use, improper or negligent use or damage due to an

accident. The warranty ceases to be valid due to the use of non-original parts, and the factory is not

responsible for the damage resulting from the transport.

THE FACTORY IS NOT RESPONSIBLE FOR LOSS OF THE PROFIT DUE TO MALFUNCTION

OF THE MOWER OR THE FAILURE OF THIRD PARTIES, NOR FOR ADDITIONAL COSTS OF

WORK ON REMOVAL AND REPLACEMENT OF PARTS.

The buyer is responsible and bear the costs of the following:

1. Normal maintenance, such as lubrication, oil retention, minor adjustments, and the like.

2. Transport of the mower where the service is performed in the warranty period and return.

3. Time of travel of the authorized service to the owner of the mower and return, or delivery and return

of the mower from the workshop after the repair.

This warranty does not apply to the rear tractor mower with two cutting bars which has been modified

without our explicit permission, or if it was performed by someone else, outside the authorized service.

The warranty is related to strict adherence to the warning:

- all the instructions in this manual must be respected and all shields are regularly reviewed and

replaced,

as needed.

No warranty is given for products that are not new.

The people who just work in our factory are not officially representatives of the factory and do not

have the right to assume any obligation on its behalf.

No warranty covers product equipment that is larger than that given, so the factory is not responsible

for any injuries caused by such use.

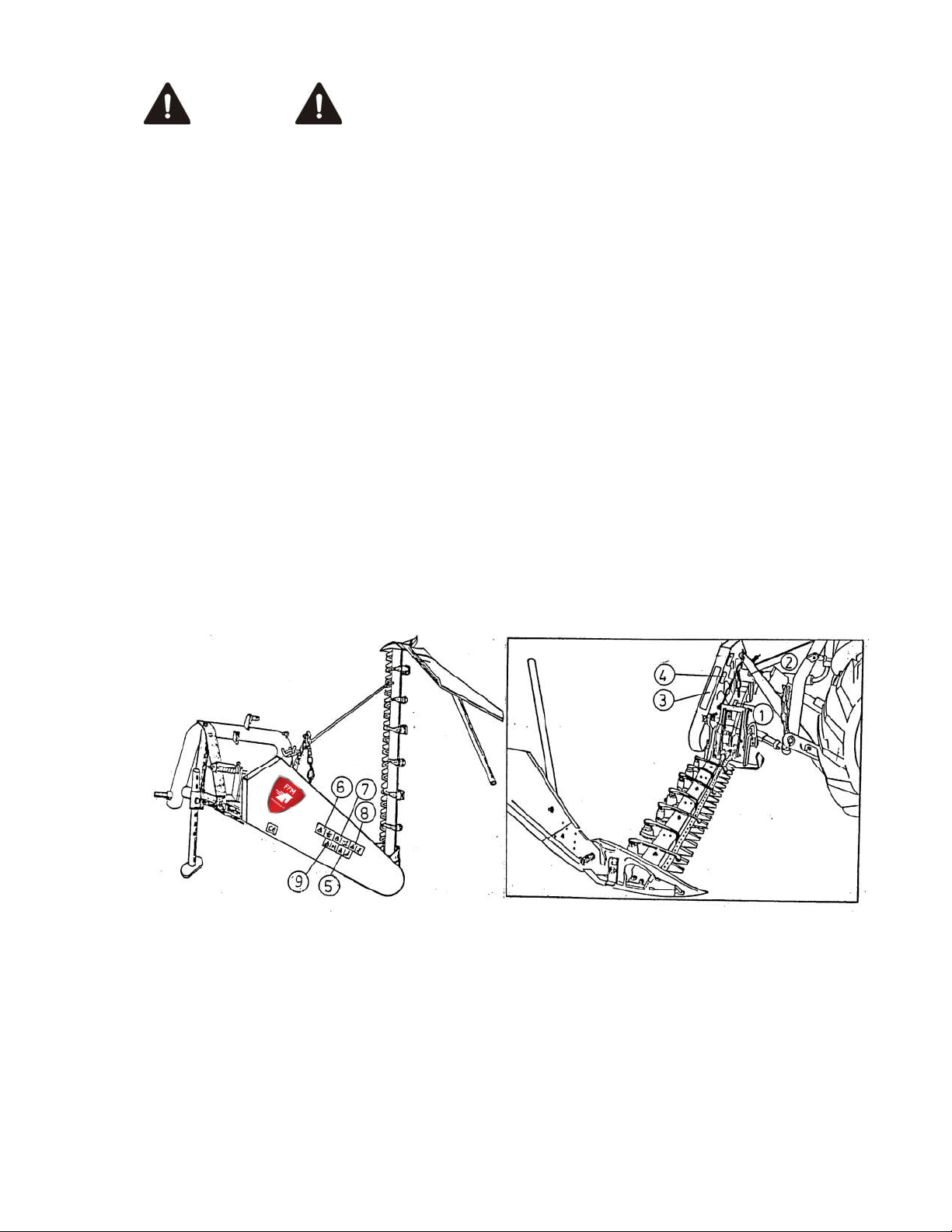

SAFETY

Most accidents occur during operation, maintenance, and transportation as a result of failure to comply

with basic safety requirements. For this reason, you are the most important person to work and

maintain your mower, whether you are working alone, with your family members or other people, be

sure to read and respect the basic procedures of working with the mower that others need to hear as

well. Additionally, warning labels are placed on the mower, which should draw attention to the

mandatory safety.

- Before the start of operation, the operator must be absolutely familiar with the functioning of all parts