P0220613_en

Energy systems

General

2 3

Valued Froling Partner

Here at Froling we want to provide the environmentally friendly, economical and userfriendly energy

system solutions that people want.

This brochure presents our range and offers orientation for planning or implementation of heating

systems, and contains the most current variants.

We reserve the right to make technical changes without prior notice.

If you need more information or suggestions for hydraulic systems, our customer service department,

and of course our internal technical department, will always bei happy to assist.

Froling G.m.b.H

Contents

1) Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1) General sensors

1.2) Room sensor FRA

2) Bus system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

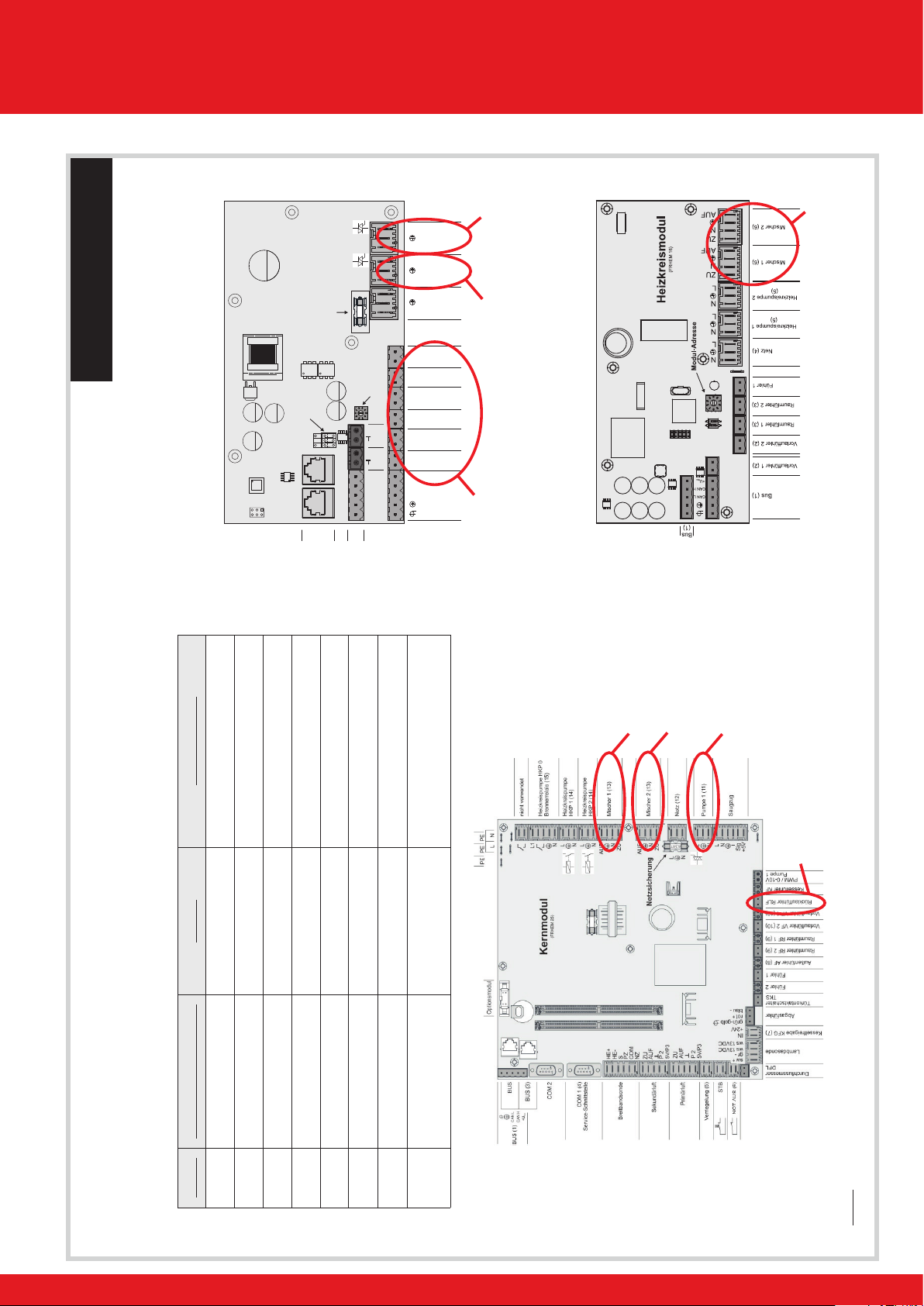

2.1) Heating circuit module

2.2) Hydraulic module

2.3) Room console RBG 3200 / RBG 3200 Touch

2.4) Bus cable

3) Sensor functions for standard systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1) Top store (sensor 0.1)

3.2) Bottom store (sensor 0.2)

3.3) DHW tank (sensor 0.3)

3.4) Bottom DHW tank (sensor 0.4)

3.5) Oil/gas boiler (sensor 0.5)

3.6) Mid store (sensor 0.6)

4) Balancing valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1) Setting example

5) Connection instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1) HKP0 - output for oil/gas boiler connections

5.2) Isolating valve

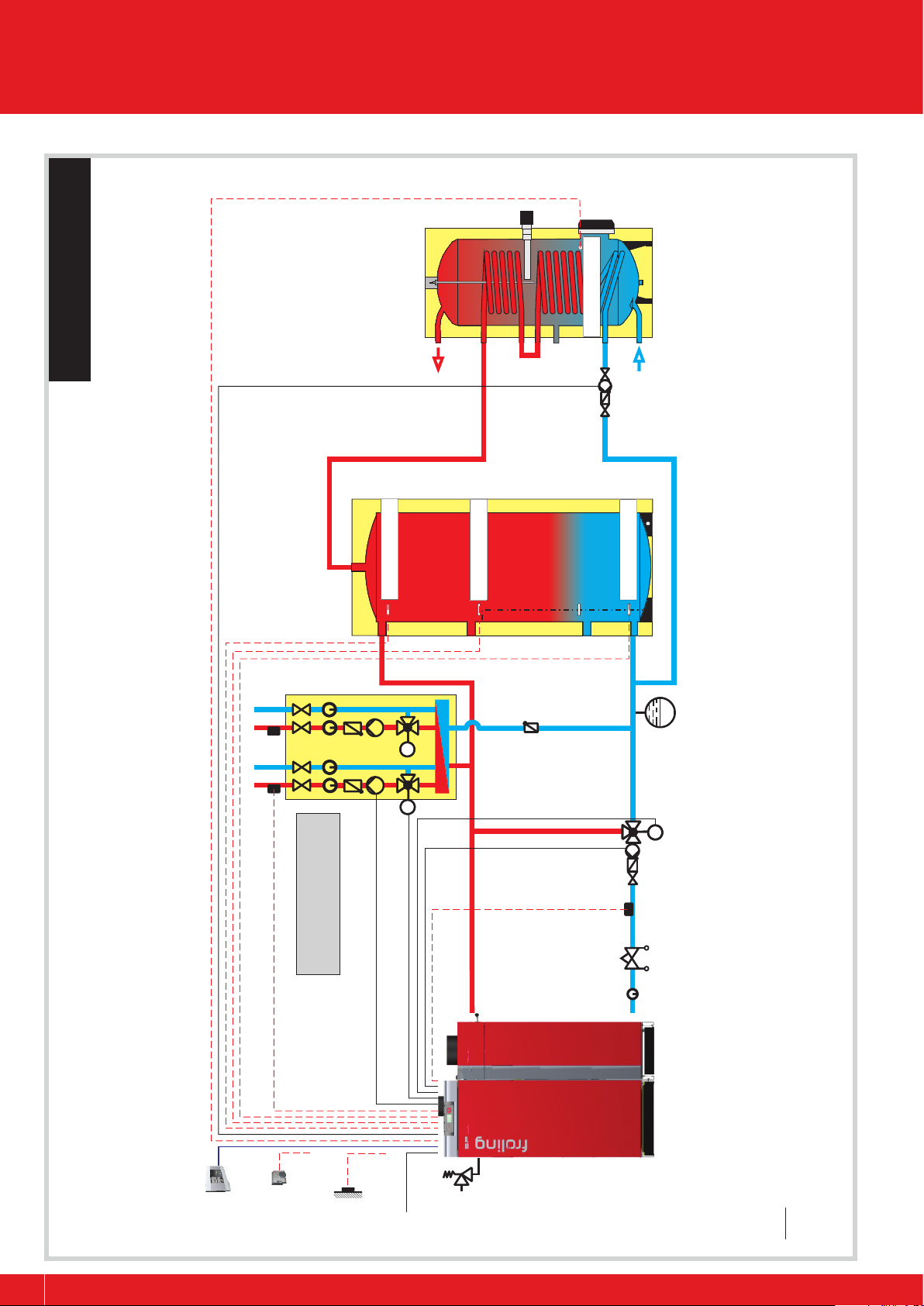

Layout proposals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RLA - S/SP 3200 / System 1.S013 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8/9

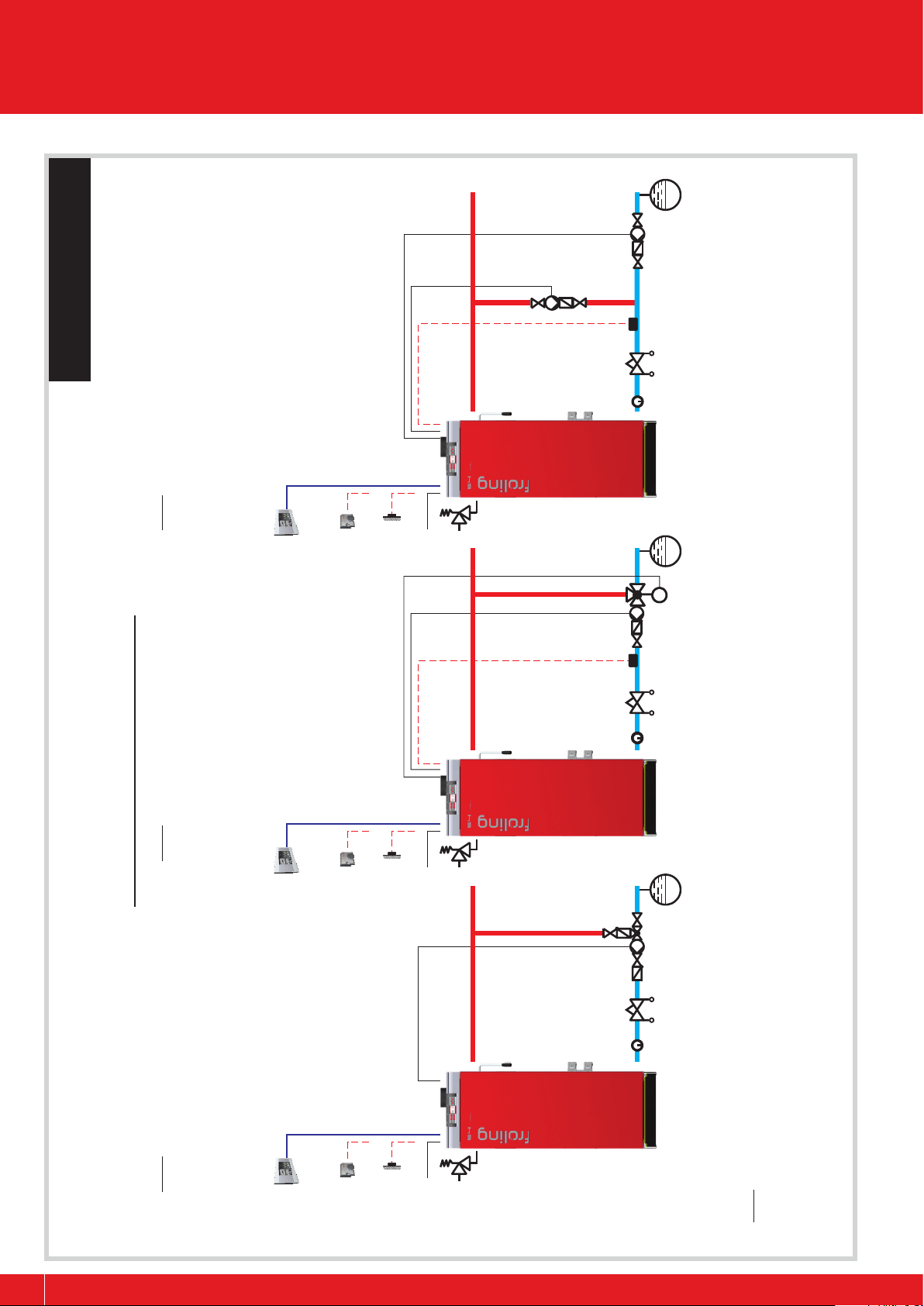

System 1.SP003 / System 1.S002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10/11

System 1.S040 / System 1.S007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12/13

System 1.SP001 / System 1.S008 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14/15

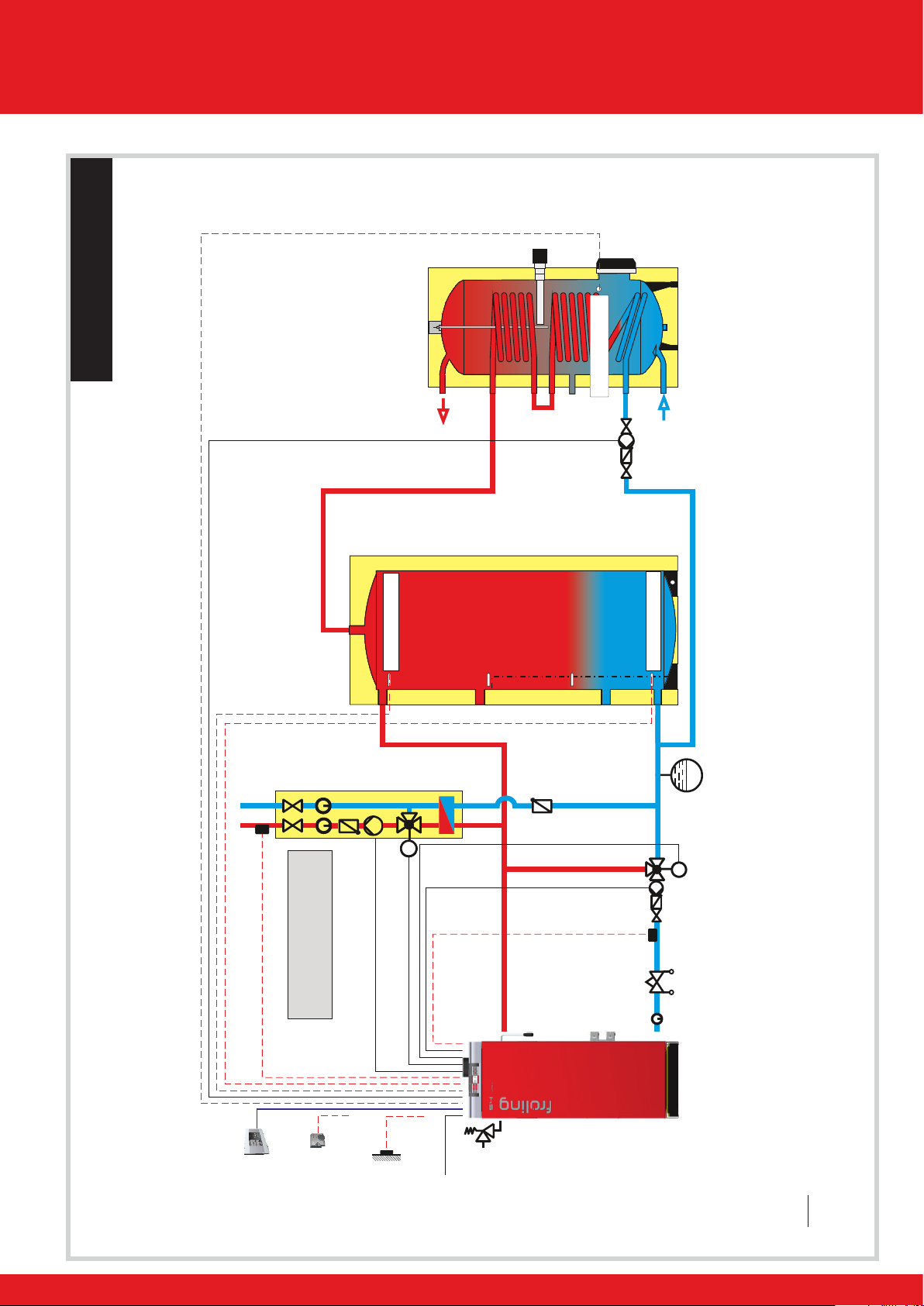

System 1.S035 / System 2.S001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16/17

System 2.S021 / System 2.S034 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18/19

System 2.S003 / System 2.S011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20/21

System 12.S001 / Coupled tank systems . . . . . . . . . . . . . . . . . . . . . . . . . 22/23