2.5 ELECTRICAL CONNECTION

The pellet stove is supplied with an approx. 2 m connecting lead with earth-

ing contact plug. The connection to the power network must only be carried

out on a earthing contact plug installed correctly and earthed according to

VDE guidelines. The mains connection line must be checked for damage at

regular intervals. A damaged connection line must be replaced immediately

by customer services or an authorised person (e.g., electrician).

Note: pull the plug out of the socket before carrying out any work where the

back wall of the device or the side cladding have to be opened.

3. COMMISSIONING AND OPERATION

Commissioning of the pellet stove must only be carried out in a completely

mounted state.

Wooden pellets with the quality specified must only be used as fuel. When

using other fuels, all claims for warranty and guarantee will be rendered

invalid.

Observe all maintenance and cleaning guidelines in order to enjoy an undis-

turbed heating experience.

Further information on commissioning, operating and maintaining the pellet

stove can be obtained in the „Operating instructions Mellino“.

Note: during the first commissioning, the paint of the stove will be burned-

in. This may lead to the development of smoke that is harmless to health,

but has an inconvenient odour. In this case, open the window and vent well.

4. SPECIAL FEATURES OF THE

CONTROL SYSTEM

The control system in the Mellino is characterised by several special

features.

4.1 DIFFERENTIAL PRESSURE CONTROL

The differential pressure control serves to provide constant conditions for

combustion and to compensate and control different chimney conditions at

the place of installation.

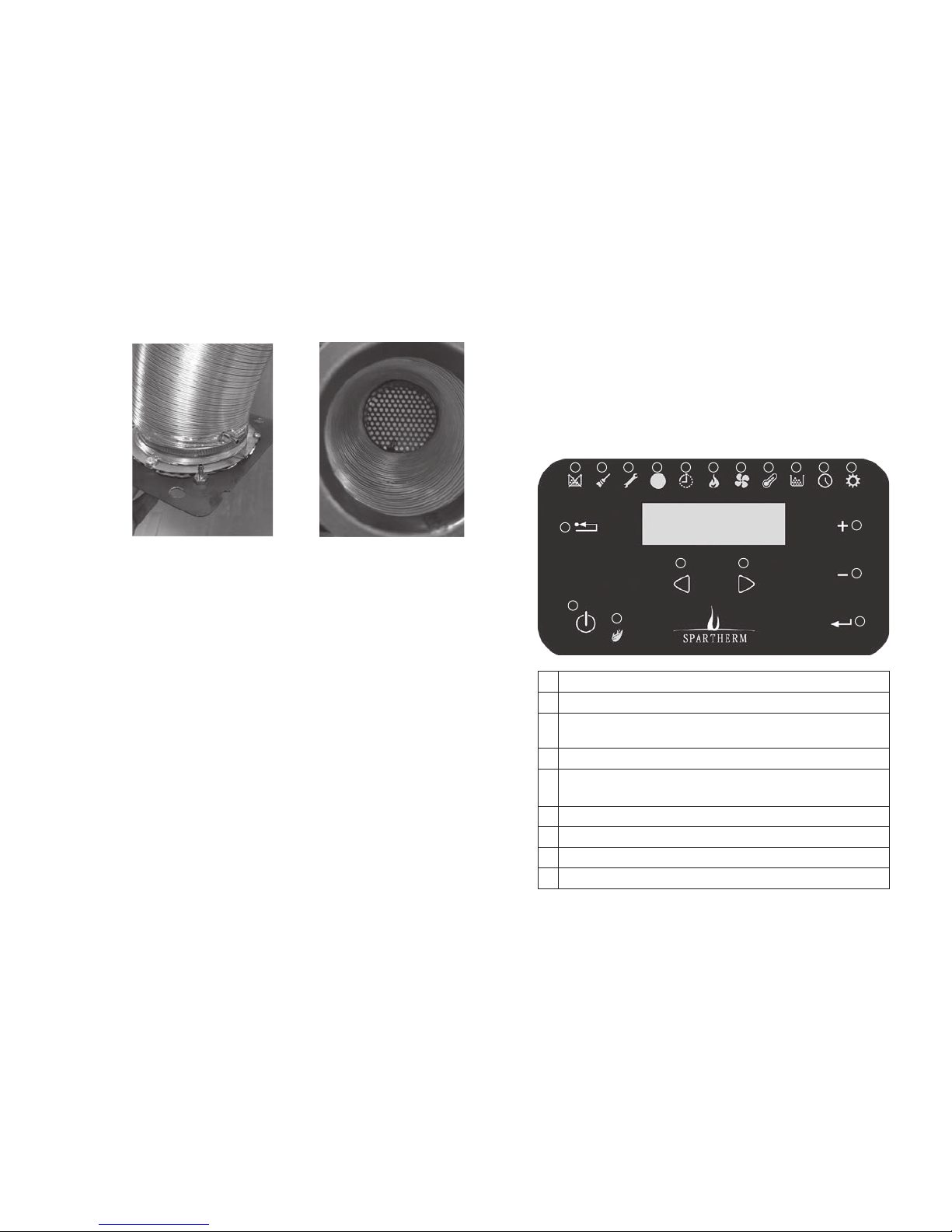

In the combustion air channel, a baffle plate made from perforated plate

is installed direct on the combustion air hood. A differential pressure is

measured in front of and behind this baffle plate. The control system is

connected direct to the measuring point using silicone hoses.

The flue gas fan is not given any rotational speeds as parameter, it is given

the value of a differential pressure. Depending on the draught in the chim-

ney, the flue gas fan is controlled so so that the differential pressure is

kept constant. This means that in event of a strong draught in the chimney,

the fan only rotates slowly whereas when the draught is weak, respec-

tively higher speeds are controlled. This creates constant conditions for the

combustion in the burner pot and the pellet stove is independent from the

draught in the chimney at the place if installation to a large extent as the

control system adapts to this.

The differential pressure also detects a complete chimney blockage and

then switches the device off. If the combustion chamber door is opened

during running operation, this is also detected as the differential pressure

now collapses. That is why this pellet stove does not have a door contact

switch. After a timer has elapsed, the extinguishing of the stove is initiated

when the door is opened: