1

Table of Contents Page

Introduction............................................................................ 2

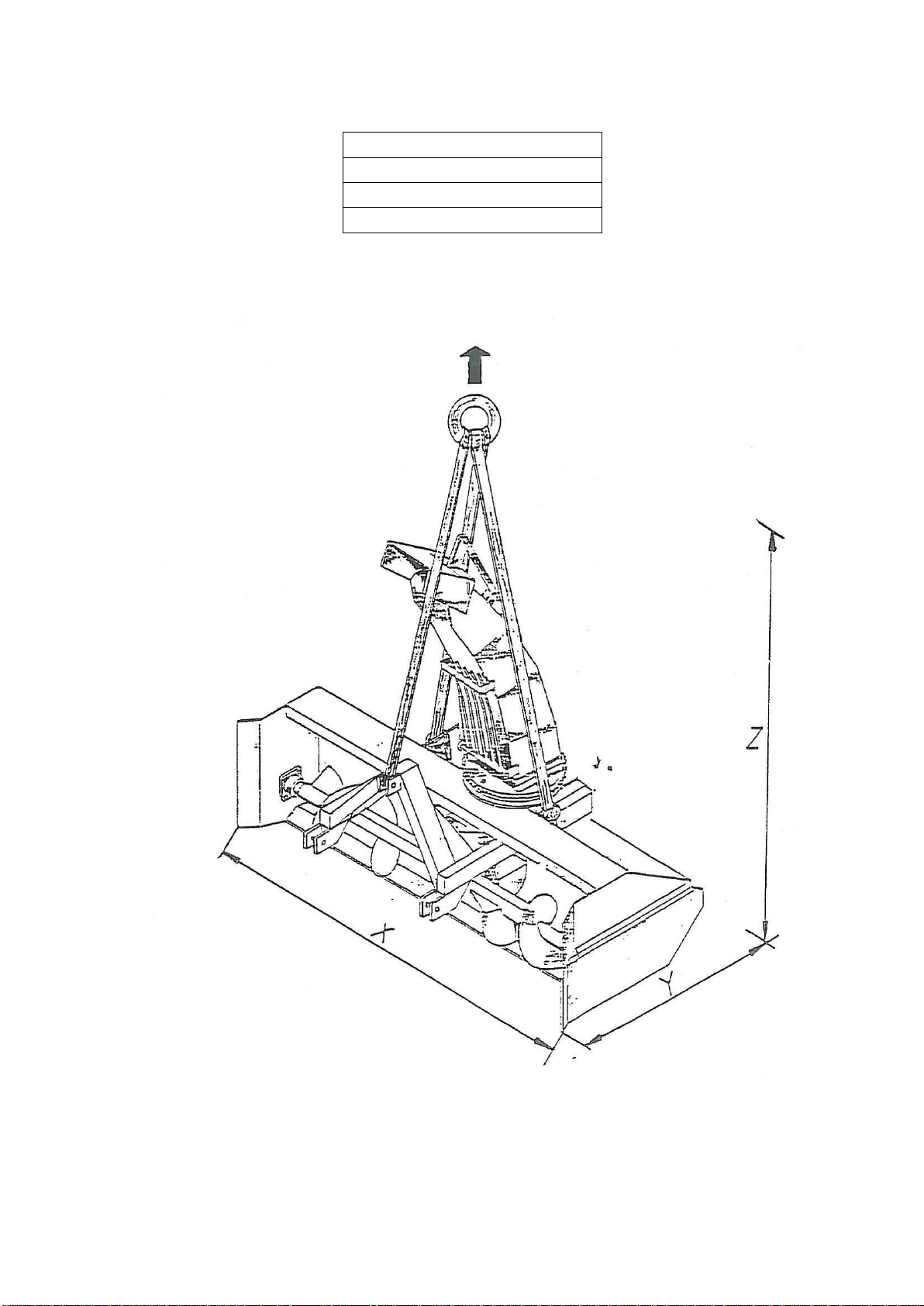

General information about the machine................................. 3

Tractor requirements .............................................................. 4

Transport ................................................................................ 5

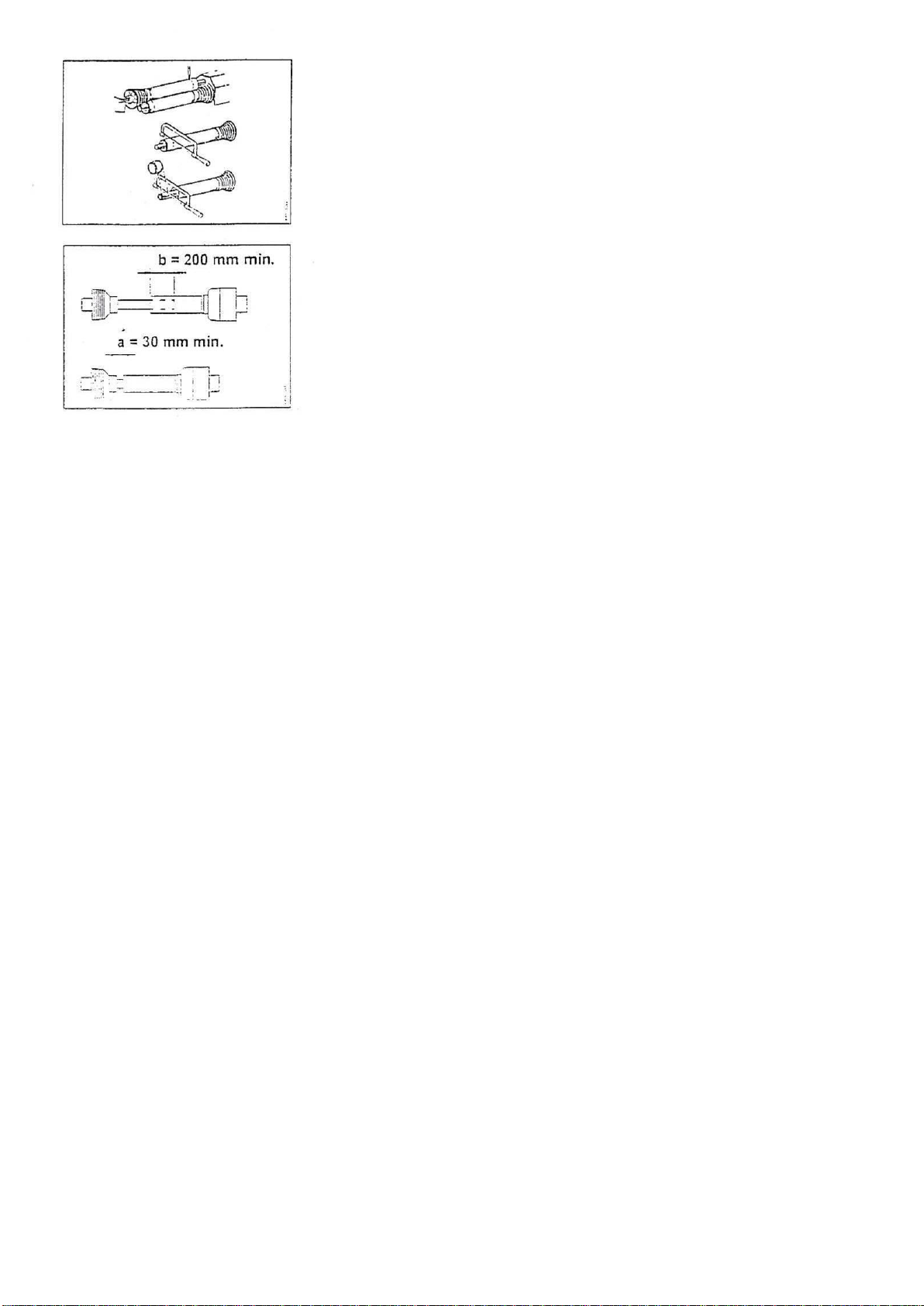

Assembly................................................................................ 6

Hitching up the machine......................................................... 5

Fitting additional equipment .................................................. 7

Starting up the machine.......................................................... 9

Unhitching............................................................................ 10

Maintenance ......................................................................... 10

Lubrication ........................................................................... 11

Storage.................................................................................. 11

Safety.................................................................................... 12

Operating hazards................................................................. 13

Dismantling.......................................................................... 13

Ordering spare parts ............................................................. 13

Technical data

Width...........................................................approx. 2200 mm.

Length..........................................................approx. 1250 mm.

Impeller diameter .......................................................650 mm.

Number of blades on impeller................................................ 4

Auger diameter...........................................................350 mm.

Throw length...................................................... 10-30 metres.

Angle of rotation for chute................................... 360 degrees.

Weight............................................................. approx. 560 kg.

Power requirement ...........................................approx. 50 HP.

Capacity.................................................................8/10 m/min.

PTO revolutions ................................................max. 540 rpm.

Three-point hitch............................................................Cat. 2.