2

Table of Contents

920-075-08

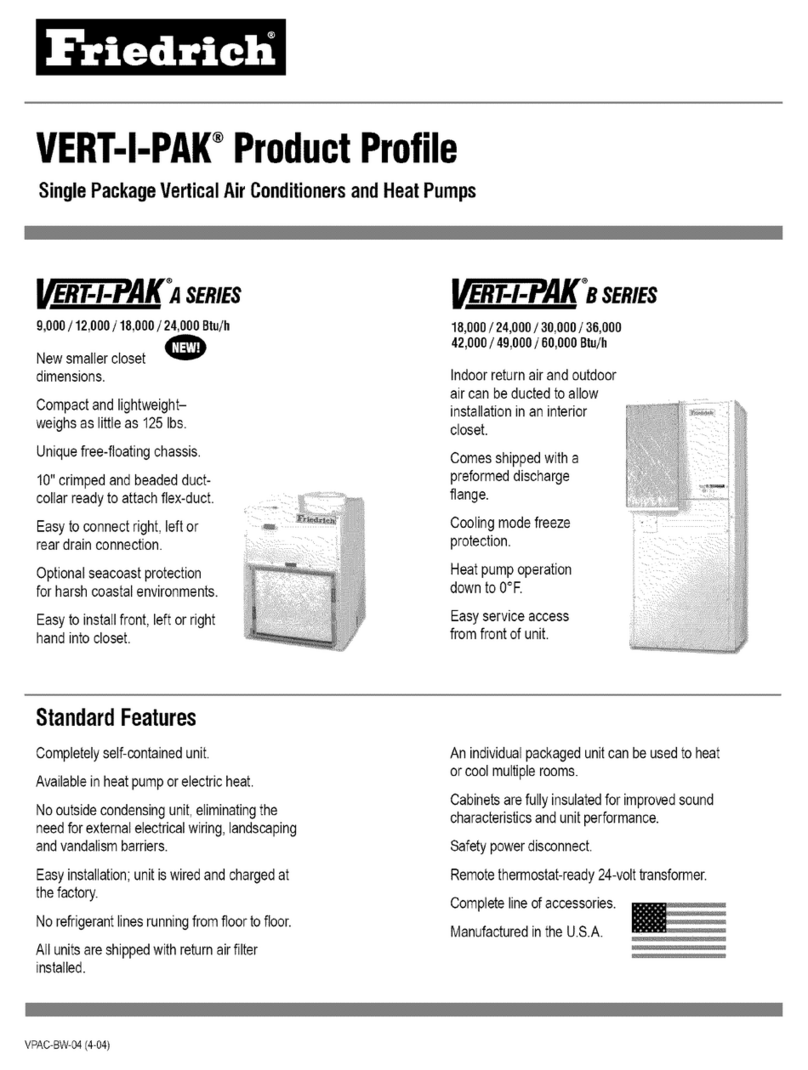

I. General Specifications

Installation Recommendations .......................................................................................................................................... 3

Model Number Identification Guide ................................................................................................................................... 4

VERT-I-PAK Chassis Specifications .................................................................................................................................... 4

II. Installation

1. Utility Closet Dimensions ................................................................................................................................................... 5

2. Wall Plenum & Architectural Louver Installation ................................................................................................................ 6

3. Electrical Information...................................................................................................................................................... 7-9

4. Indoor Return Air Grille Installation .................................................................................................................................. 10

5. Ductwork Preparation and CFM ....................................................................................................................................... 11

6. Chassis Installation.......................................................................................................................................................... 11

7. Chassis Final Connections (Electrical, Duct, Drain & Wall Thermostat)............................................................................ 12

8. Final Installation Checklist............................................................................................................................................... 12

III. Chassis Operation

9. Thermostat Control .......................................................................................................................................................... 13

10. Low Ambient Protection for Compressor & Fan ................................................................................................................ 13

11. Heating Defrost (Heat Pump Models only)........................................................................................................................ 13

12. Fresh Air Door...................................................................................................................................................................13

13. Condensate Disposal System .......................................................................................................................................... 13

IV. Service & Warranty

14. Servicing / Chassis Quick Changeouts............................................................................................................................. 13

15. Warranty........................................................................................................................................................................... 14

V. Vert-I-Pak Accessories .................................................................................................................................................... 15

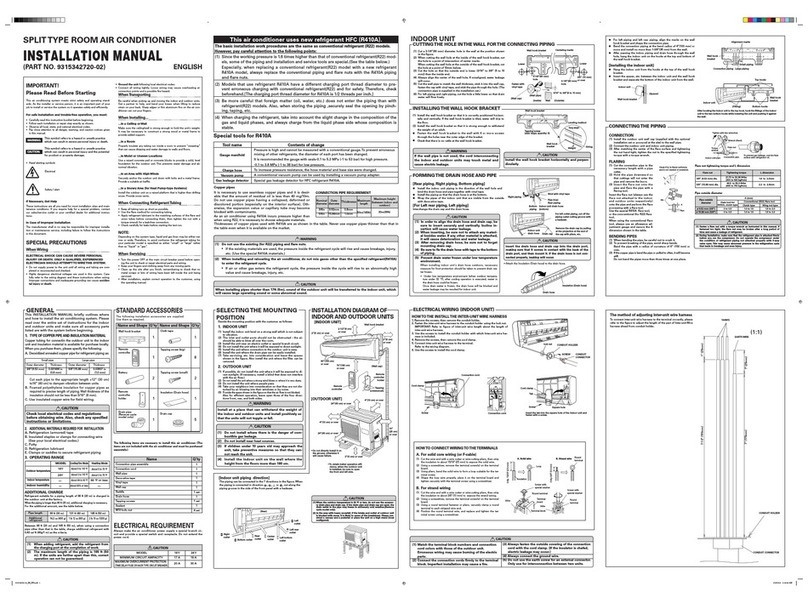

Please read this manual thoroughly prior to equipment installation or operation. It is the installer’s

responsibility to properly apply and install the equipment. Installation must be in conformance

with the NFPA 70-2002 National Electric Code or current edition and Universal Mechanical Code

current edition and applicable local or national codes.

Proper installation is not difficult but it is essential.