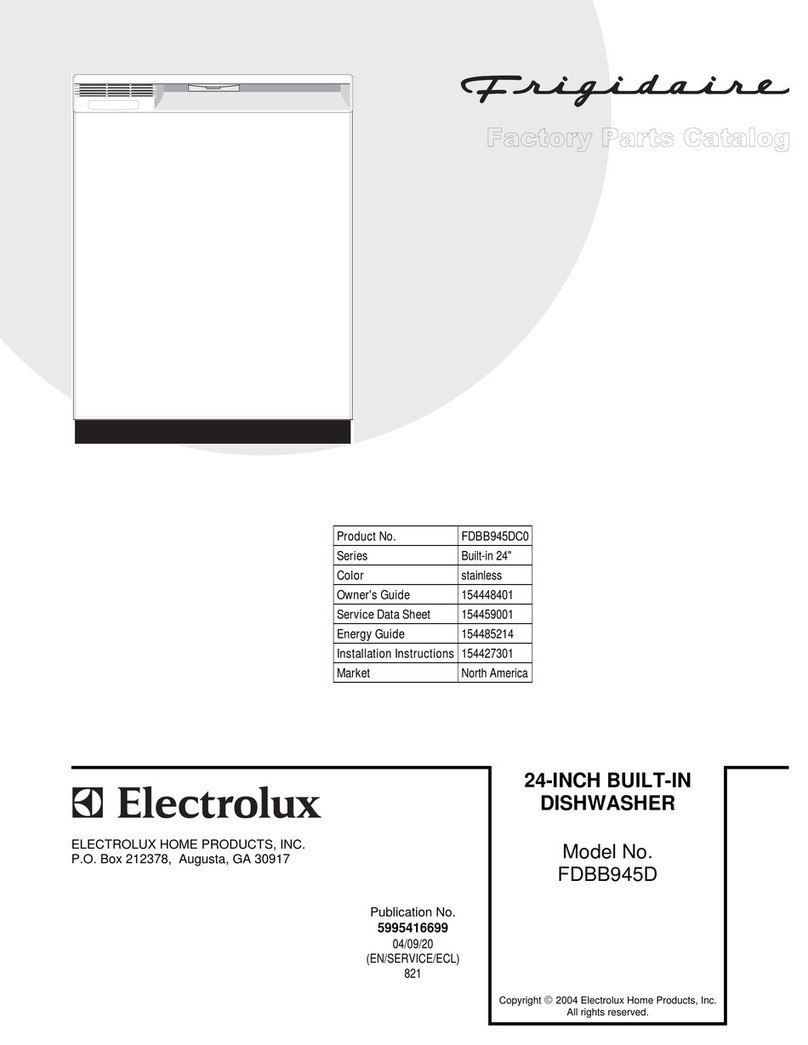

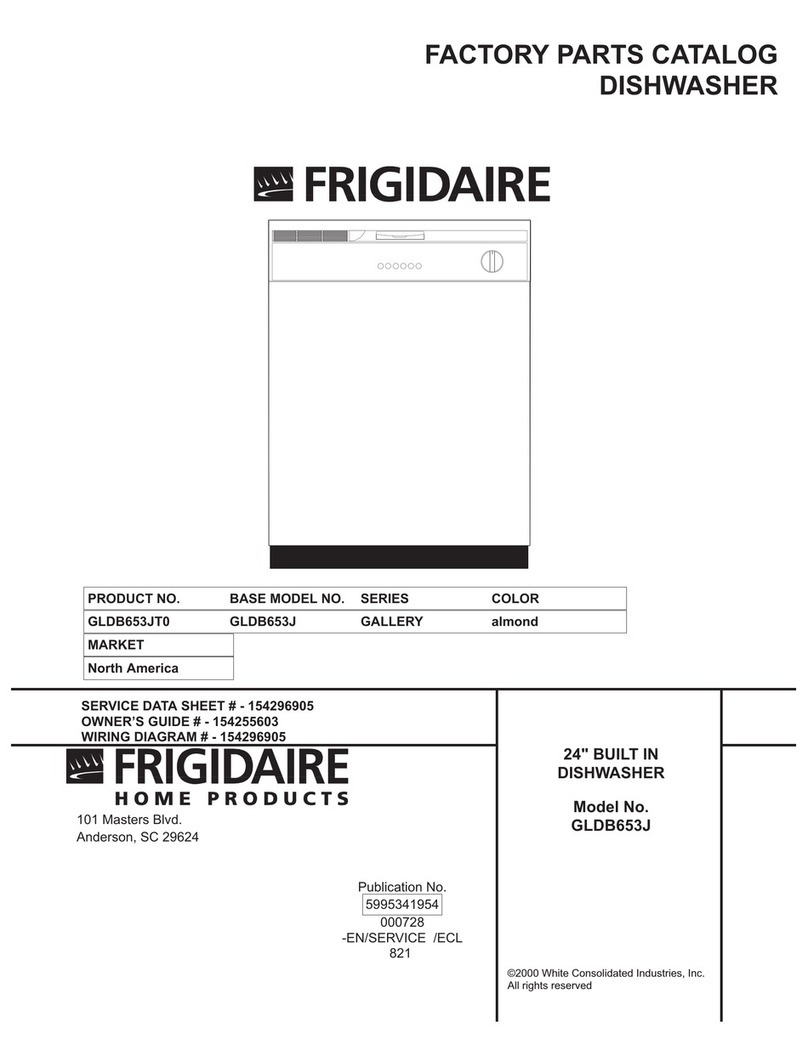

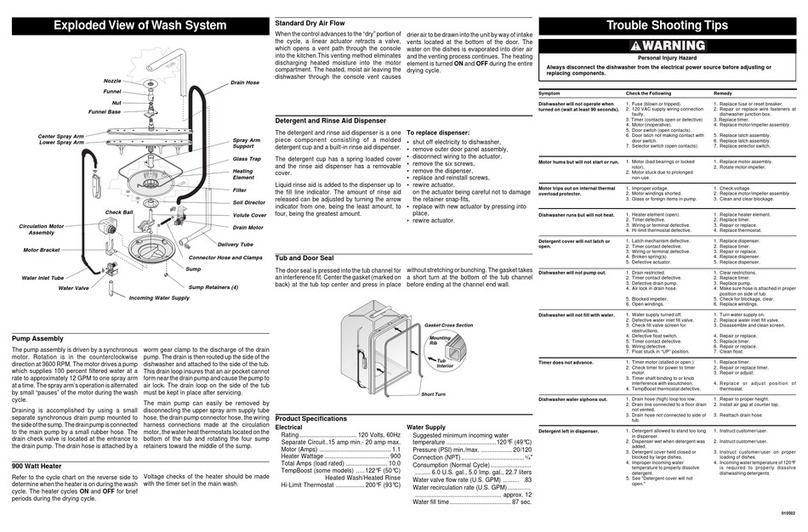

Exploded View of Wash System

011116(MECH)

worm gear clamp to the discharge end of

the drain pump.

The drain hose must have a loop at a

minimum height of 32 inches

in order to

insure proper drainage.

The main pump can easily be removed by

disconnecting the drain pump connector

hose and the wiring harness connections

made at the circulation motor and rotating

the four sump retainers toward the middle

of the sump.

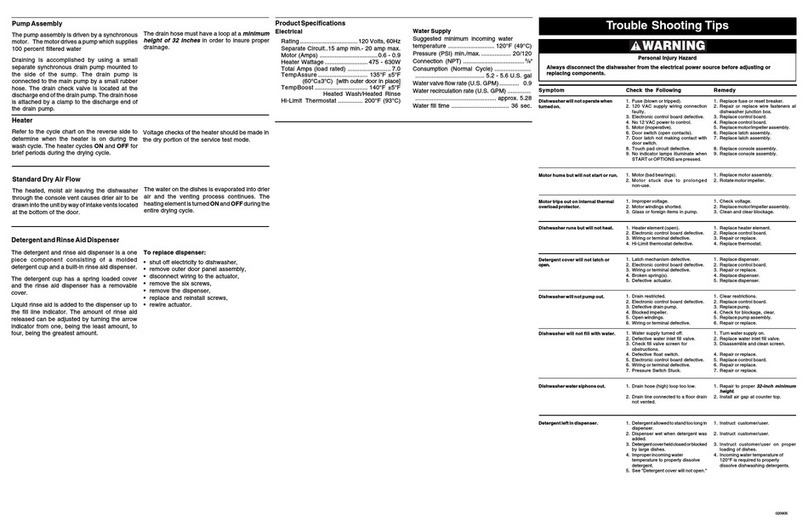

Pump Assembly

The pump assembly is driven by a

synchronous motor. Rotation is in the

counterclockwise direction at 3600 RPM.

The motor drives a pump which supplies

100 percent filtered water at a rate to

approximately 12 GPM.

Draining is accomplished by using a small

separate synchronous drain pump mounted

to the side of the sump. The drain pump is

connected to the main pump by a small

rubber hose.The drain check valve is

located at the discharge end of the drain

pump.The drain hose is attached by a

900 Watt Heater

Refer to the cycle chart on the reverse side

to determine when the heater is on during

the wash cycle.

Voltage checks of the heater should be

made with the timer set in the main wash.

Drain Hose

(32" minimum

height)

HeatingElement

Filter

SoilDirector

VoluteCover

DrainMotor

Connector Hose and Clamps

Sump

IncomingWaterSupply

Water Valve

Water Inlet

Tube

Circulation

Motor Assembly

Nut

LowerSprayArm/Tower Assembly

Tub and Door Seal

The door seal is pressed into the tub

channel for an interference fit. Center the

gasket (marked on back) at the tub top

center and press in place without stretching

or bunching.The gasket takes a short turn

at the bottom of the tub channel before

ending at the channel end wall.

Mounting

Rib

Tub

Interior

Gasket Cross Section

ShortTurn

Product Specifications WaterSupply

Minimumincomingwatertemperature ..............

................................................... 120°F(49°C)

Pressure (PSI) min./max. ..................... 20/120

Connection(NPT) ........................................ 3/8”

Consumption(NormalCycle) ...........................

........................................... 7.2gal.,27.3liters

Electrical

Rating ..................................... 120Volts, 60Hz

SeparateCircuit ......15 amp min.-20 amp max.

Motor(Amps).............................................. 1.1

HeaterWattage .......................................... 900

TotalAmps (load rated) ............................. 10.0

Trouble Shooting Tips

ElectricShock Hazard

Check the list below each symptom. Repair or replace defective components as encountered.

Symptom. . .Dishwasher will not operate

when turned on (wait at least 90 seconds).

1. Fuse(blown or tripped).

2. 120 VAC supply wiring connection faulty.

3. Timer (contacts open or defective)

4. Motor (inoperative).

5. Door switch (open contacts).

6. Door latch not making contact with door switch.

7. Selector switch (open contacts).

Symptom. . .Motor hums but will not start or

run.

1. Motor (bad bearings or locked rotor).

2. Motor stuck due to prolonged

non-use.

Symptom. . .Motor trips out on internal thermal

overloadprotector.

1. Improper voltage.

2. Motor shaft binding.

3. Motor windings shorted.

4. Glass or foreign items in pump.

Symptom. . .Dishwasher runs but will not heat.

1. Heaterelement(open).

2. Timerdefective.

3. Wiringorterminaldefective.

Symptom. . .Dishwasher will not pump out.

1. Drain restricted.

2. Timercontactdefective.

3. Defectivedrainpump.

4. Air lock in drain hose.

5. Blocked impeller.

6. Open windings.

Symptom. . .Dishwasher will not fill with water.

1. Watersupply turnedoff.

2. Defective water inlet fill valve.

3. Check fill valve screen for obstructions.

4. Defectivefloat switch.

5. Timercontactdefective.

6. Wiringdefective.

7. Float stuck in “UP” position.

Symptom. . .Timer does not advance.

1. Timermotor (stalledoropen.)

2. Check timer for power to timer motor.

3. Timer shaft binding to or knob interference with

escutcheon.

Symptom. . .Dishwasher water siphons out.

1. Drain hose (high) loop too low--must be a

minimum height of 32 inches.

2. Drain line connected to a floor drain not vented.

(Install air gap at counter top.)

Disconnect electrical power at the fuse box or circuit breaker box before

adjusting or replacing components. Failure to follow this warning could

result in death or serious injury.

Motor

Bracket

Sump Retainers (4)