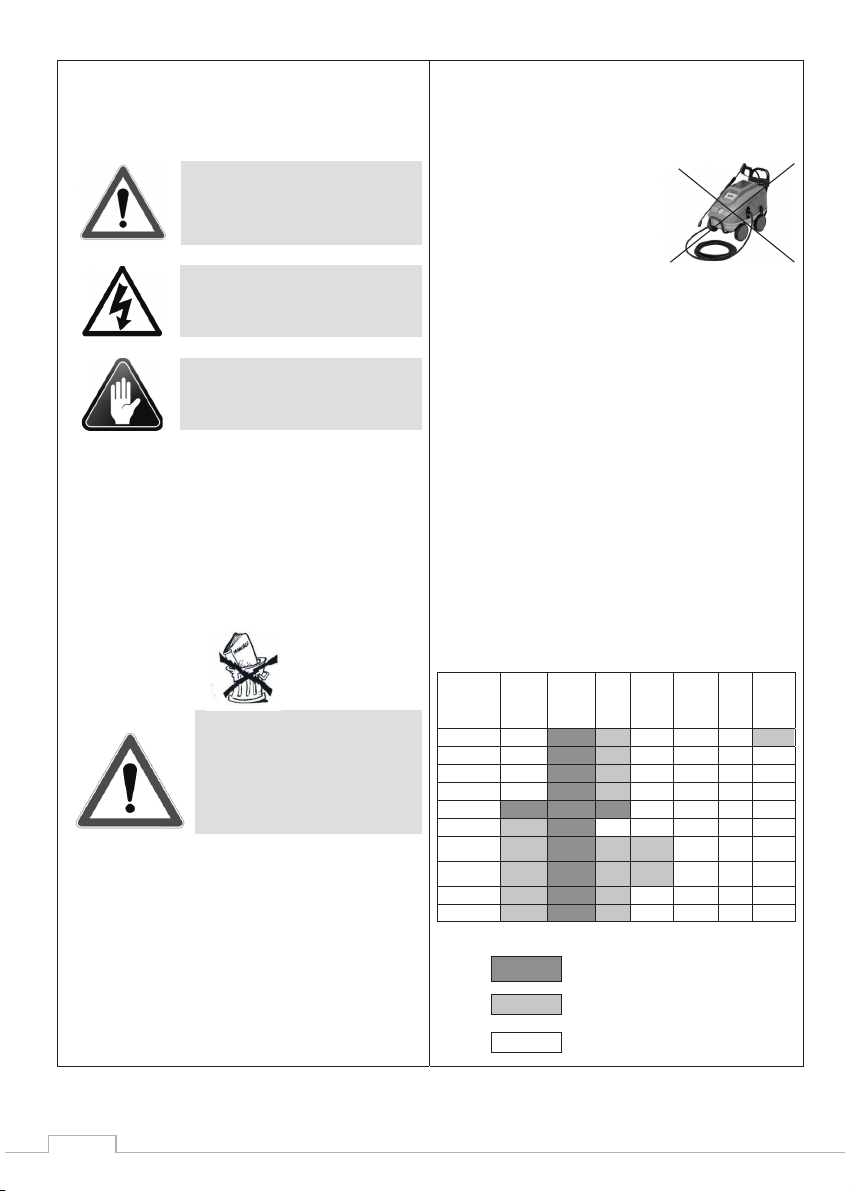

II. INSTRUCTIONS FOR USE

Before switching on the appliance, carefully read this

instructions manual which contains important information

about correct and optimum use of the appliance. For further

information about the

performance

characteristics and

washing

machine consult your local dealer.

Every six months the performance of a wash and rinse

parts of the line product is going to be mounted

by a

qualified technician

will ensure that there is no

.

Periodically (at least once a year) should be

device. For this purpose, we recommend

with the competent

The maximum water hardness 12°F and

conductivity value. Fail to comply with these values

may occur breakdowns when using tap water

. These

kind of breakdowns are

not covered by the

guarantee.

Consult your authorised water supplier to check your water

hardness. Use water softener system in case of need.

●

The machine will be placed into the plates using a

at intervals allowed by the

appropriate area.

●Do not place dishes

into the machine excessing

height of maximum 185 mm.

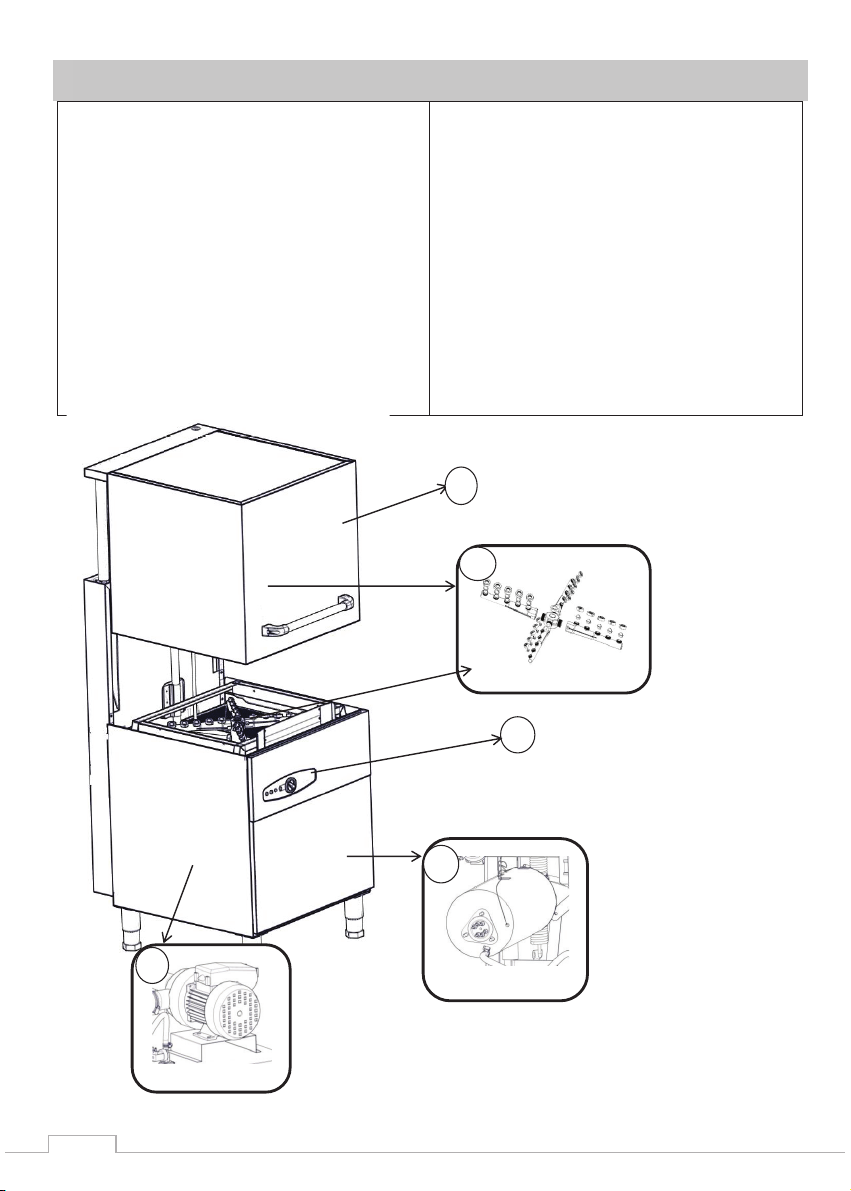

DESCRIPTION OF THE CONTROL PANEL

INTRODUCTION

To facilitate familiarisation with the dishwashers functions,

refer to the fold

-

out page at the end of this booklet,

illustrating the control panel.

The different functions available on the various models are

described below.

Some functions are common to all models while others are

only available on certain models.

CONTROL PANEL

refer to figure at the end of booklet)

- On-Off And Program Switch

- Power Lamp

- Heat Lamp

- Washing Lamp

- Rinsing Lamp

- Drain Button

COMMISSIONING

(Please refer to the shape of the control panel

the booklet)

Information

Before opening the device

, make sure the device

ground line and power source. Water on / off, turn the

must open.

TURNING ON THE APPLIANCE

● Turn right "A" On-Off switch. “B” power

illuminate. Make sure the machine's hood is closed.

machine will begin the process of obtaining water.

of the water obtain process automatically, the water

process will start. After heating process is completed "C"

heat lamp will be

on. This is the time when the dishwasher is

ready for loading. In this case, place the basket

machine with soiled dishes to be washed. After placing

baskets, close the hood of dishwasher. To

washing turn right the switch “A” to 1st, 2nd, 3rd or 4

programs (1, 2, 3 or 4 minutes washing) according to

desired washing time. The machine will begin

washing. During this process, "D"

indicator light will illuminate

to indicate washing continues. When the light

washing is finished. But after waiting for 5 seconds

dishwasher will start the rinsing process

between 15-20 seconds. During this process “E”

illuminate to indicate rinsing continues. After this process,

light E will be off and all washing cycle will be completed.

the machine’s hood and remove the basket with clean dishes

● Try to put the dishes into the machine free of rough

This will significantly affect washing performance.

● At the very first washing cycle, using the machine

water temperature is not heated enough will create

situation. Cleaning chemicals will action with unheated

in the machine which will create a foamy water.

make sure that t

he heating indicator lamp lit before starting

the washing process.

● The built-in automatic rinse aid dosing pump

the built-

in automatic detergent dosing pump (optional) takes

place through the process itself.

Make sure that the button on

the pumps are switched on. Plunge the mouths of the pumps

hoses directly into the detergent and rinse aid liquid bo

xes.

Always use high quality detergent and rinse aid liquids to reach

perfect washing results. You can get more information

significant subject from the authorized dealer

service.