Table

ofContents

...........................................................................................................................................................................

Active Vent

28

.......................................................................................................................................

Circulation Pumpand Motor 30

Component LocatorViews

...........................................................................................................................................

10

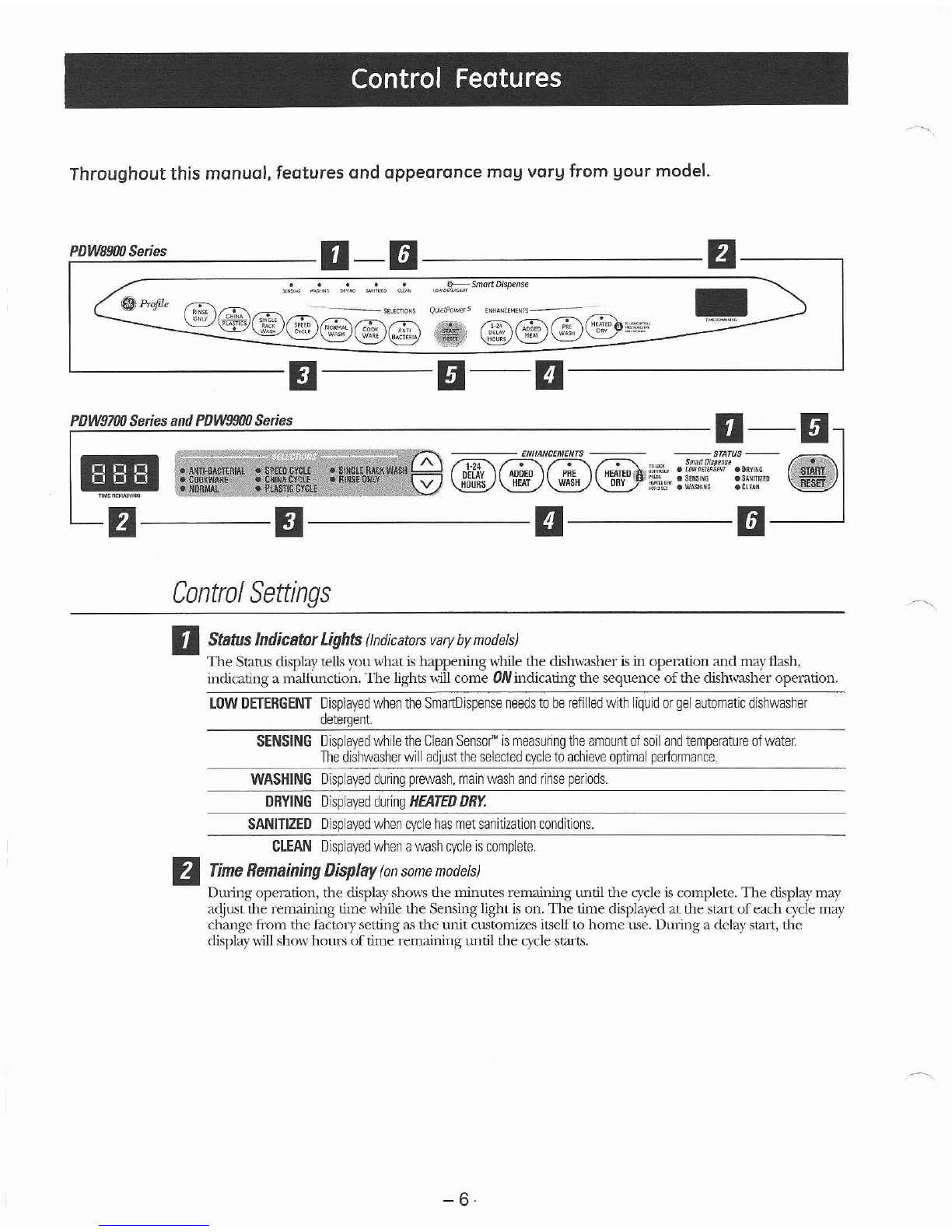

Control Features

................................................................................................................................................................

6

Control Module

..................................................................................................................................................................

27

..................................................................................................

Customer Purge ofthe Bulk DispenserTank

18

Demo Mode

......................................................................................................................................................................

26

DetergentfRinseModule

...............................................................................................................................................

19

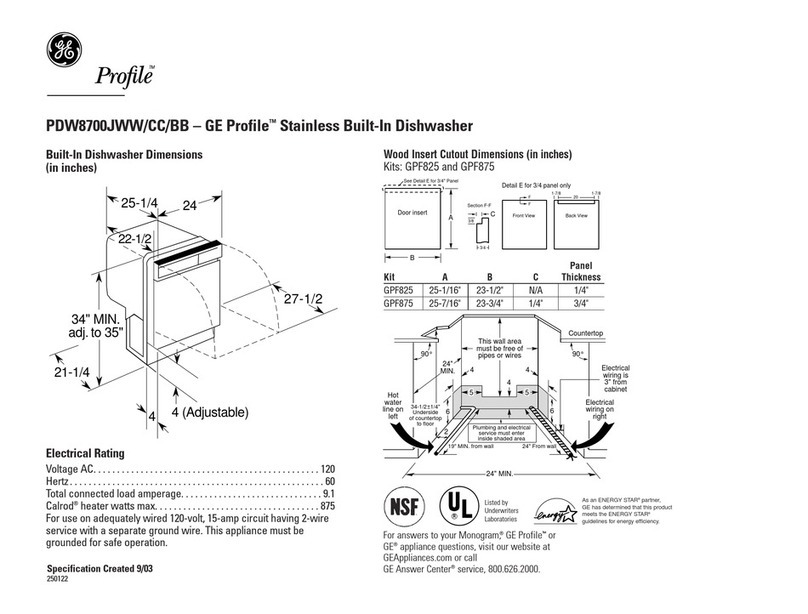

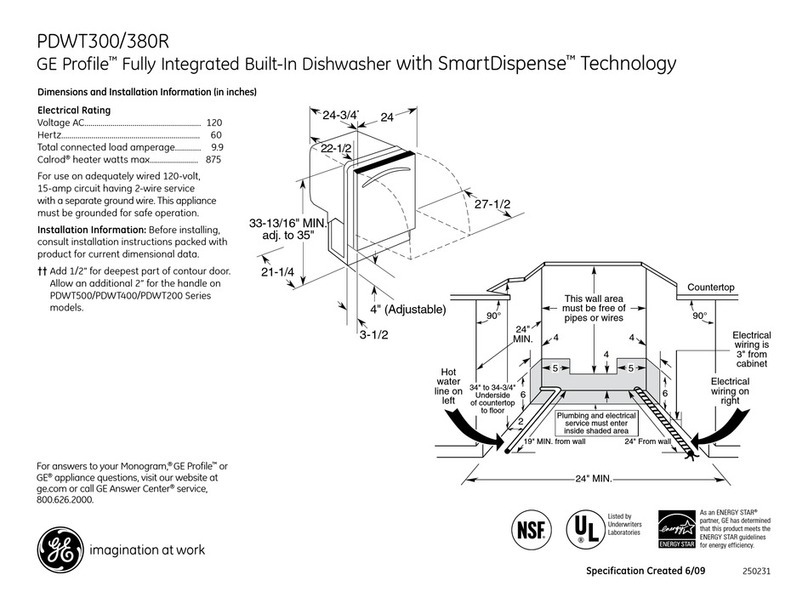

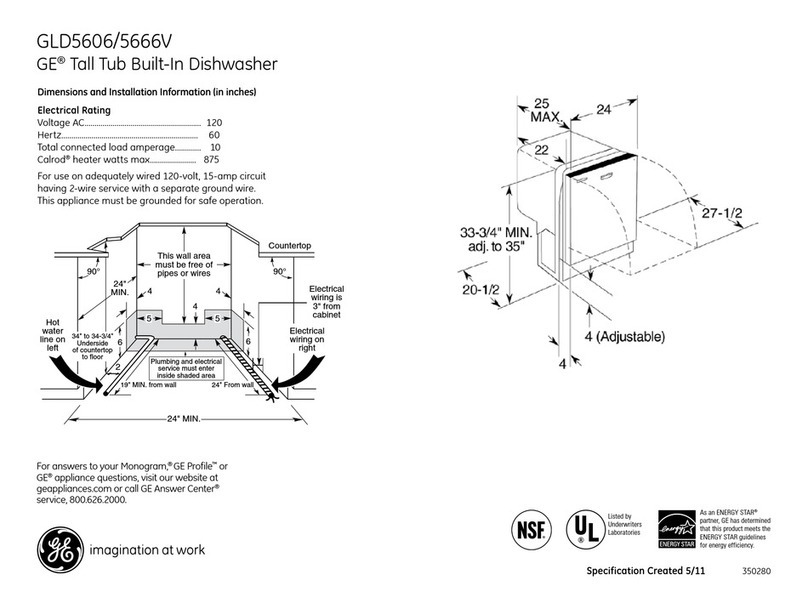

DishwasherComponents

.........................................................................................................................................

12

Door Interlock Switch

......................................................................................................................................................

19

Door Panel

....................

...............

.........................................................................................................................................

12

Door Spring Installation

............................................................................................................................................

31

DrainSystem

......................................................................................................................................................................

24

Factory Test Mode

............................................................................................................................................................

33

Fan (PDW9700and PDW9900Series)

.....................................................................................................................

28

Fill Funnel

..............................................................................................................................................................................

21

Heating Element

................................................................................................................................................................

22

Introduction

.........................................................................................................................................................................

5

KeypadAssembly

.............................................................................................................................................................

13

Lower Spray Arm. Fine Filter.and InletCover

......................................................................................................

21

MainConduit

.......................................................................................................................................................................

21

MiddleSpray Arm

.............................................................................................................................................................

20

Nomenclature

....................................................................................................................................................................

4

...................................................................................................................................

SchematicsandStripCircuits

34

Service Mode

......................................................................................................................................................................

32

Single Rack WashTM

..........................................................................................................................................................

29

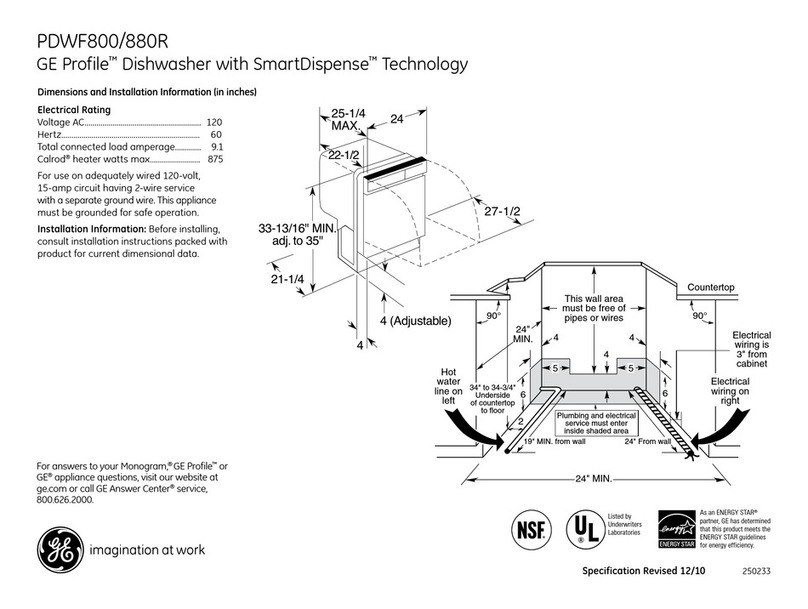

SmartDispenseTM

...............................................................................................................................................................

15

Smart FillSystem

..............................................................................................................................................................

24

.

.

Turb~d~tySensor

................................................................................................................................................................

23

Upper Spray Arm

..............................................................................................................................................................

21

..................................................................................

Usingthe Dishwasherwith the Upper Rack Removed 20

Warranty for 2005 Product

.........................................................................................................................................

36

....................................................................................................................

Warranty for 2006 and Later Product

37

Wash Cycles

........................................................................................................................................................................

26

....................................................................................................................

Water HardnessTest and Calibration

14

Water Valve and FloodSwitch

....................................................................................................................................

25

Water Valve Test

...............................................................................................................................................................

25

................................................................................................................................................

Wax Motor and Magnet 30