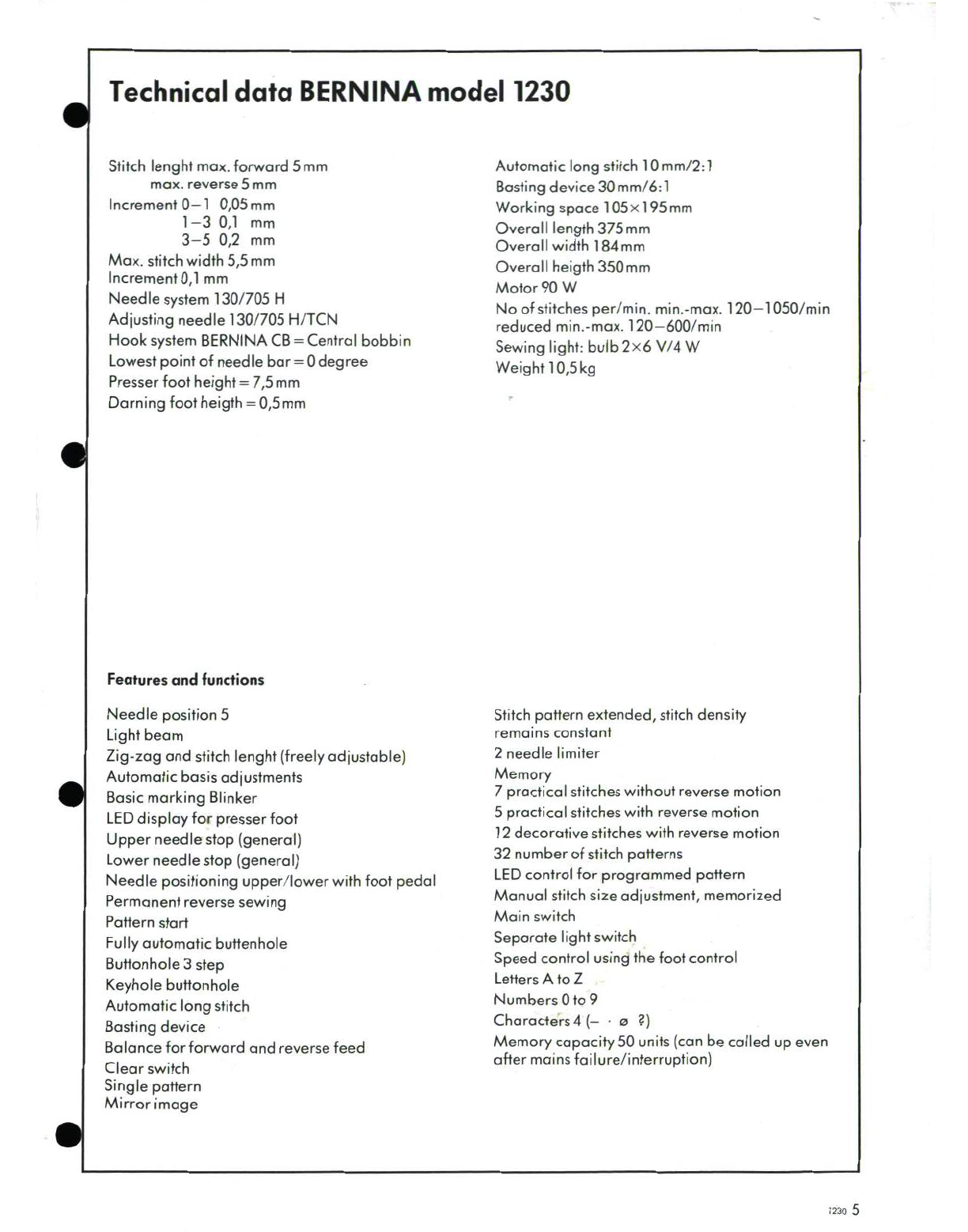

Technical

data

BERNINA

model

1230

Stitch

lenght

max.

forward

5 mm

Automatic

long

stitch

10

mm/2:1

max.

reverse

5 mm

Basting

device

30mm/6:1

Increment

0-1

0,05mm

Working

space

105x195mm

1-3

0,1

mm

Overall

length

375mm

3-5

0,2

mm

Overallwidth

184mm

Max.

stitch

width

5,5

mm

Overall

heigth

350

mm

Increment

0,1

mm

Motor

90

W

Needle

system

130/705

H

No

of

stitches

per/min.

min.-max.

120-1050/min

Adjusting

needle

130/705

H/TCN

reduced

min.-max.

120-600/min

Hook

system

BERNINA

CB

=

Central

bobbin

Sewing

light:

bulb

2x6

V/4

W

Lowest

point

of

needle

bar =

0

degree Weight

10,5kg

Presser

foot

height

=

7,5

mm

Darning

foot

heigth

=

0,5

mm

Features

and

functions

Needle position

5

Stitch

pattern

extended,

stitch

density

Light

beam

remains constant

Zig-zag

and

stitch

lenght

(freely

adjustable)

2

needle limiter

Automatic

basis

adjustments

Memory

Basic

marking

Blinker

7

practical

stitches

without

reverse

motion

LED

display

for

presser

foot

5

practical

stitches

with

reverse

motion

Upper

needle

stop

(general)

12

decorative

stitches

with

reverse

motion

Lower

needle

stop

(general)

32

number

of

stitch

patterns

Needle

positioning

upper/lower

with

foot

pedal

LED

control

for

programmed

pattern

Permanent reverse

sewing

Manual

stitch

sizeadjustment, memorized

Pattern

start

Main

switch

Fully

automatic

buttenhole Separate

light

switch

Buttonhole

3

step

Speed

control

using

the

foot

control

Keyhole

buttonhole

Letters

A

to

Z

Automatic long

stitch

Numbers

0

to

9

Basting

device

Characters

4

(- -

o

?)

Balance

for

forward

and

reverse

feed Memory

capacity

50

units (canbe

called

up

even

Clear

switch

after

mains

failure/interruption)

Single

pattern

Mirror

image

1230

5

Downloaded from www.Manualslib.com manuals search engine