TABLE OF CONTENTS

1. General Warnings ................................................................................................................................................................... 5

1.1. Positioning and reading the data plate ....................................................................................................................... 6

2. Company History .................................................................................................................................................................... 7

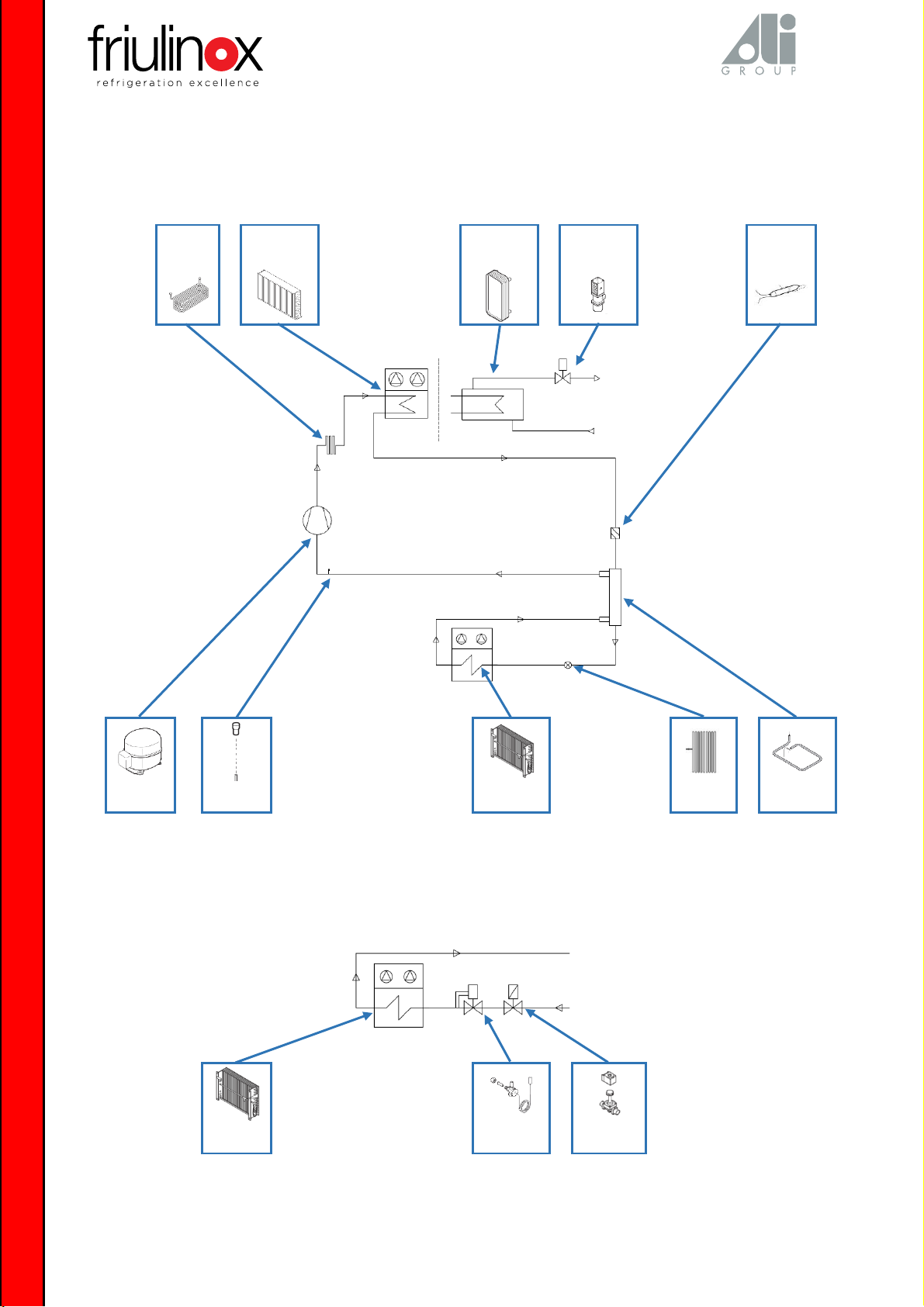

3. Explanation of the refrigeration system................................................................................................................................... 8

3.1. Unit on board............................................................................................................................................................ 8

3.2. Set-up for remote unit ............................................................................................................................................... 8

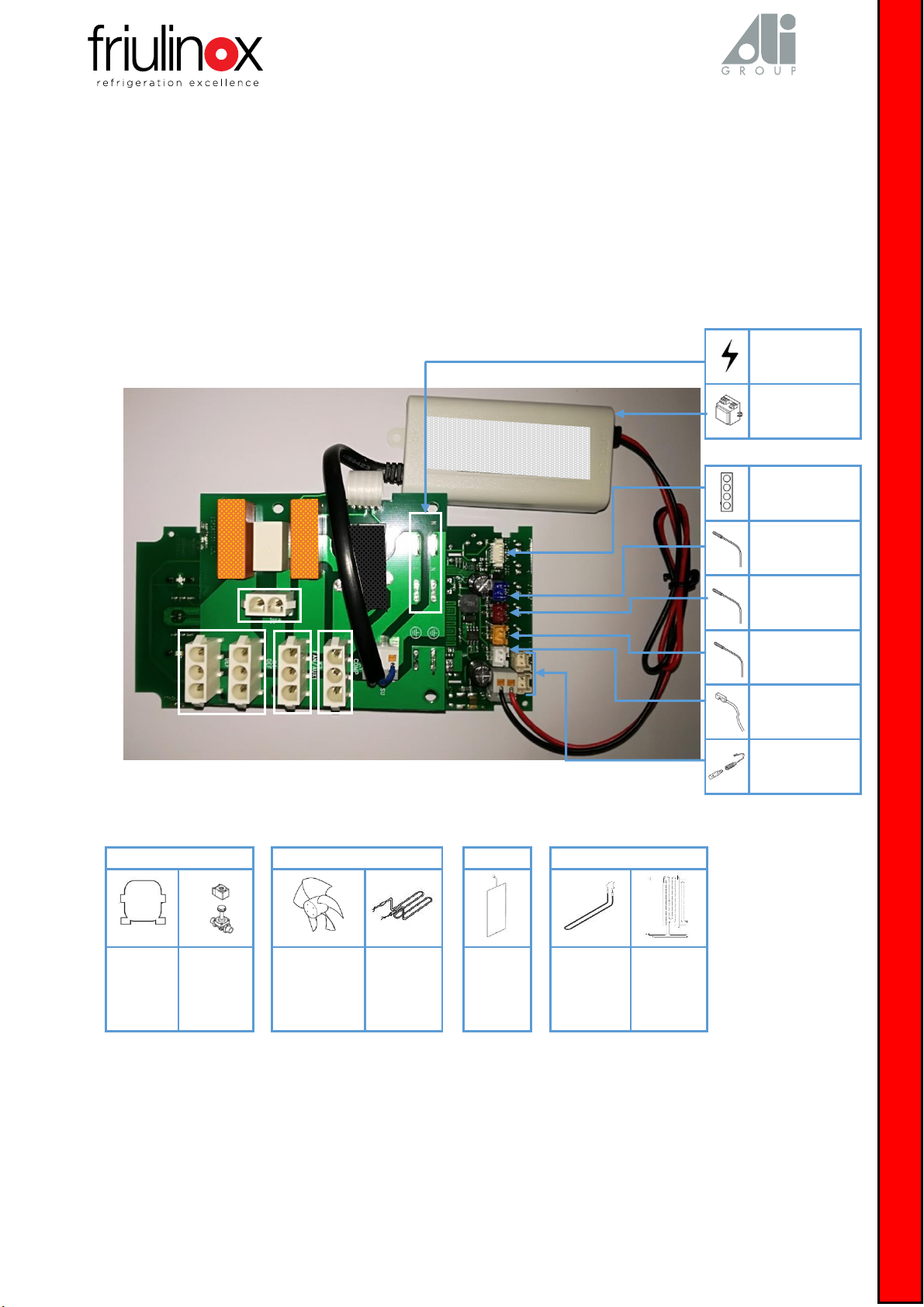

4. Explanation of the electronic board......................................................................................................................................... 9

4.1. 700lt Haccp Basic cabinet board................................................................................................................................. 9

4.2. 700-1400lt Haccp Basic cabinet board...................................................................................................................... 10

4.3. 700-1400lt Haccp cabinet board + “rtc” clock module............................................................................................... 11

4.4. Specific electronic board connections ...................................................................................................................... 12

4.5. Temperature probes tables...................................................................................................................................... 15

5. Installation checklist ............................................................................................................................................................. 16

6. Routine maintenance............................................................................................................................................................ 18

7. Electronic board operation.................................................................................................................................................... 20

7.1. Board functions ....................................................................................................................................................... 20

7.2. Access to the service menu...................................................................................................................................... 21

7.2.1. Parameter access .................................................................................................................................... 21

7.2.2. Access to internal values.......................................................................................................................... 24

7.2.3. Access to alarms...................................................................................................................................... 24

7.2.4. Reset data memories (HACCP) ................................................................................................................. 26

7.2.5. Reset factory values ................................................................................................................................ 26

7.2.6. HACCP..................................................................................................................................................... 26

8. Interventions on the equipment............................................................................................................................................ 27

8.1. Electronic board replacement .................................................................................................................................. 27

8.2. Door opening inversion...........................................................................................Errore. Il segnalibro non è definito.

8.3. Door gasket replacement......................................................................................................................................... 33

8.4. Frame heater replacement ...................................................................................................................................... 34

8.5. Condenser filter panel removal and cleaning............................................................................................................ 36

8.6. Monoblock unit components replacement ............................................................................................................... 37

8.6.1. evaporator fan ........................................................................................................................................ 37

8.6.2. defrosting heater..................................................................................................................................... 39

8.6.3. KLIXSON thermostat ................................................................................................................................ 42

8.6.4. drain heater ............................................................................................................................................ 45

8.6.5. air probe ................................................................................................................................................. 48

8.6.6. evaporator probe .................................................................................................................................... 51

8.6.7. condenser probe ..................................................................................................................................... 53

8.6.8. compressor ............................................................................................................................................. 55

8.6.9. condenser fan ......................................................................................................................................... 56

8.7. Door microswitch replacement ................................................................................................................................ 57

8.8. Lock replacement .................................................................................................................................................... 58

8.9. Cell light replacement.............................................................................................................................................. 59