1

Contents

General............................................................................................................................................................ 3

Principle...................................................................................................................................................... 3

Machine concept ........................................................................................................................................ 3

Field of application ..................................................................................................................................... 3

Proper use.................................................................................................................................................. 3

Improper use .............................................................................................................................................. 4

Conversions or modications ..................................................................................................................... 4

Operating instructions ................................................................................................................................ 4

Instructions................................................................................................................................................. 4

Warning notices on the driving vehicle....................................................................................................... 5

Scope of supply.......................................................................................................................................... 6

Options....................................................................................................................................................... 7

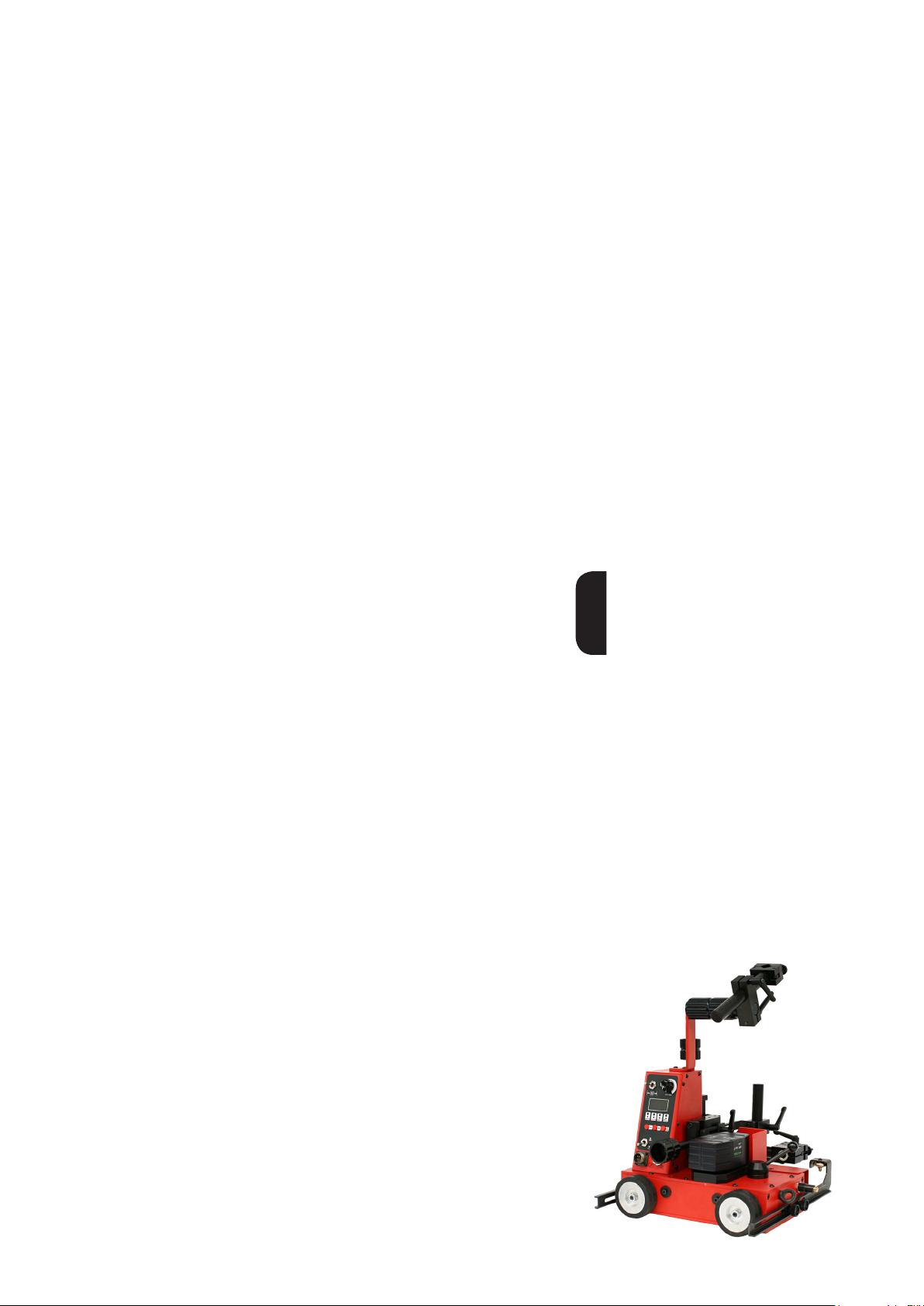

Driving vehicle components .......................................................................................................................... 10

Conguration FDV 22 MF with oscillation unit ........................................................................................ 10

Conguration FDV 22 MF without oscillation unit ................................................................................... 10

Controls, connections and add-ons............................................................................................................... 11

Driving vehicle control panel .................................................................................................................... 11

“Con” display ............................................................................................................................................ 12

“InF” display.............................................................................................................................................. 12

Total path active display ........................................................................................................................... 12

Display during program sequence ........................................................................................................... 12

“Bat” display ............................................................................................................................................. 12

“End“ display ............................................................................................................................................ 12

Control panel oscillation unit option ......................................................................................................... 13

Charger and battery pack......................................................................................................................... 14

AC-ACvoltage transformer ....................................................................................................................... 15

Welding position and seam tracking.............................................................................................................. 16

Possible welding positions ....................................................................................................................... 16

Guidance of the carriage.......................................................................................................................... 17

Second torch holder ................................................................................................................................. 20

Preparing the driving vehicle ......................................................................................................................... 21

Fitting the handle...................................................................................................................................... 21

Fitting the guide rails ................................................................................................................................ 21

Fitting the brushes (option) ...................................................................................................................... 22

Fitting lateral guides (Option) ................................................................................................................... 23

Fitting lateral guides with exible rail (Option).......................................................................................... 24

Fitting the additional torch holder (Option) ............................................................................................... 25

Connecting the charger to the mains supply............................................................................................ 26

Charge the battery pack........................................................................................................................... 26

Insert battery pack in driving vehicle docking station ............................................................................... 27

Adjusting the guide wheels ...................................................................................................................... 28

Check the surface of the workpiece and the driving vehicle to ensure they are clean............................. 28

Position the driving vehicle and activate the permanent magnet ............................................................. 28

Attach fall protection (vertical operation).................................................................................................. 29

Mounting and adjusting the welding torch................................................................................................ 29

Driving vehicle strain relief ....................................................................................................................... 30