Table of contents

1.

Certificate of conformity ............................................................................................................................................ 2

2.

Warranty.................................................................................................................................................................... 2

3.

General informations ................................................................................................................................................. 3

4.

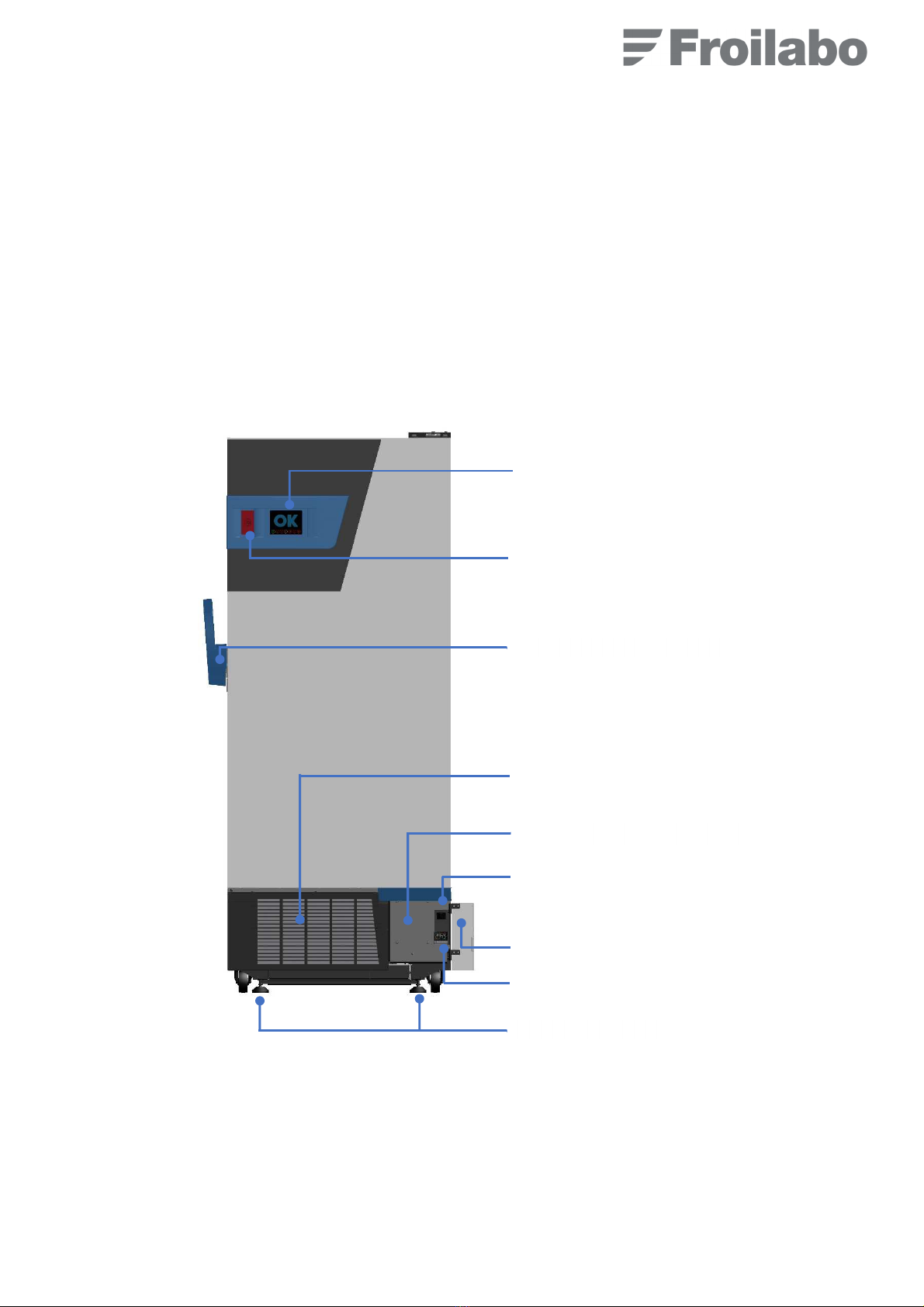

First contact with your freezer ................................................................................................................................... 3

4.1 Delivery and unpacking........................................................................................................................................... 3

4.2 Implantation and installation.................................................................................................................................... 4

4.3 Power supply........................................................................................................................................................... 4

4.4 Temperature range .................................................................................................................................................5

4.5 Construction and isolation....................................................................................................................................... 5

4.6 Technical characteristics and refrigeration system .................................................................................................7

4.7 Sample storage ....................................................................................................................................................... 8

4.8 Control panel........................................................................................................................................................... 8

4.9 Starting up............................................................................................................................................................... 9

5.

Using PXF4 regulator..............................................................................................................................................10

5.1 Ajusting setpoint temperature ............................................................................................................................... 10

5.2 Setting high and low temperature alarms ............................................................................................................. 10

5.3 Setting CO

2

/ LN

2

injection ....................................................................................................................................11

6.

Indicators et alarms LED.........................................................................................................................................11

6.1 Main power connected ..........................................................................................................................................11

6.2 Temperature alarm (high or low)...........................................................................................................................11

6.3 Overpressure CP1 ................................................................................................................................................12

6.4 Battery charge failure ............................................................................................................................................12

6.5 Open door alarm ...................................................................................................................................................12

6.6 Engine failure ........................................................................................................................................................12

6.7 CO

2

/LN

2

injection in progress ...............................................................................................................................12

7.

Maintenance and customer services.......................................................................................................................13

7.1 Security rules ........................................................................................................................................................13

7.2 Mainteance, cleaning and decontamination..........................................................................................................13

7.3 Long time stop....................................................................................................................................................... 14

7.4 Problems encountered and solutions....................................................................................................................15

8.

Security ...................................................................................................................................................................16

8.1 Liquid CO

2

backup ................................................................................................................................................ 16

8.2 LN

2

backup............................................................................................................................................................17

9.

Transportation et waste disposal ............................................................................................................................ 19

9.1 Transportation .......................................................................................................................................................19

9.2 Waste disposal...................................................................................................................................................... 19

10.

Customer services...............................................................................................................................................19

SERVICE CONTRACT ...................................................................................................................................................20