FROMM

CH12-TI-FS250.EN10

MASKED PARAMETERS FS 250 – FS 270 – FS 270+

As we have tried to make the machine as friendly a possibele, for maintenance purposes. We decided

to develop only one control board. All programms possibele in the FS 2XX series are already installed

on the board. We only have to change the different setting for some parameters to swich On or Off

these different functions.

To enter the parameter section:

Press the STOP button for five seconds

The indication of the parameter (F0, F1, F2, F3, F4, F5, F6 etc. ), which may be changed by means of

the «+» or «–», is shown on the left-hand side of the display.

The value of the parameter, which may be changed by means of the «+» or «–» is shown on the right-

hand side of the display.

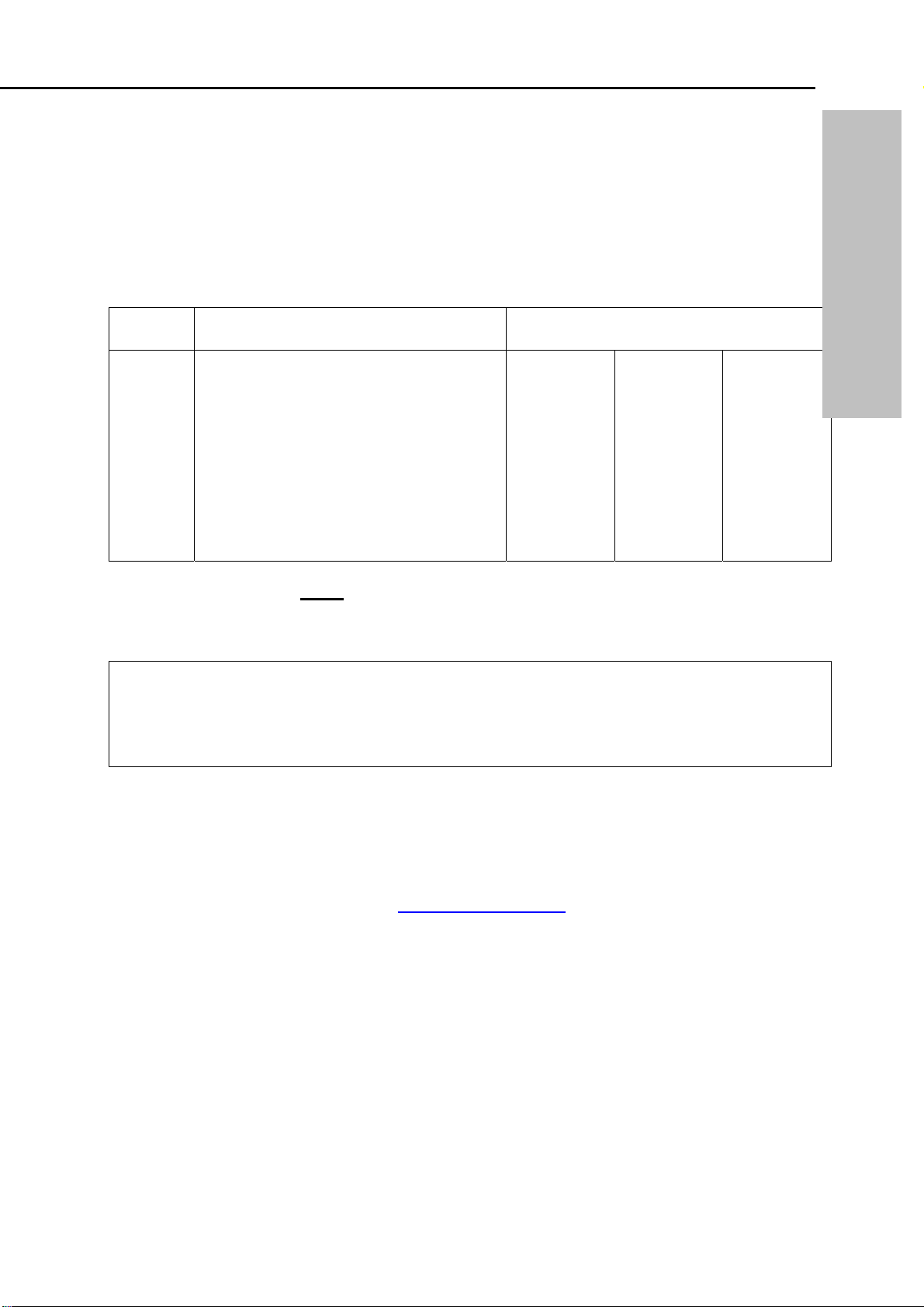

These parameters are associated with:

F0 = Pallet overlap ( 7 ) (Settings between 0 – 100)

F1 = Friction delay ( 0 – 11 )

F2 = Friction voltage (motor pre stretch 100 )

F3 = Film cutting system ( 0 = OFF, 1 = ON )

F4 = Friction voltage before cutting (Settings between 0 – 255)

F5 = Cutting time ( 10 = 0,1 sec ) (Settings between 0 – 255)

F6 = Slow time (10 = 0,1 sec ) (Settings between 0 – 255)

We also have the possibility to regulate some parameters. This regulation can also be done on the

inverter itself. In any case it is advisebel the cheque the standard settings before any adjustment is be

done.

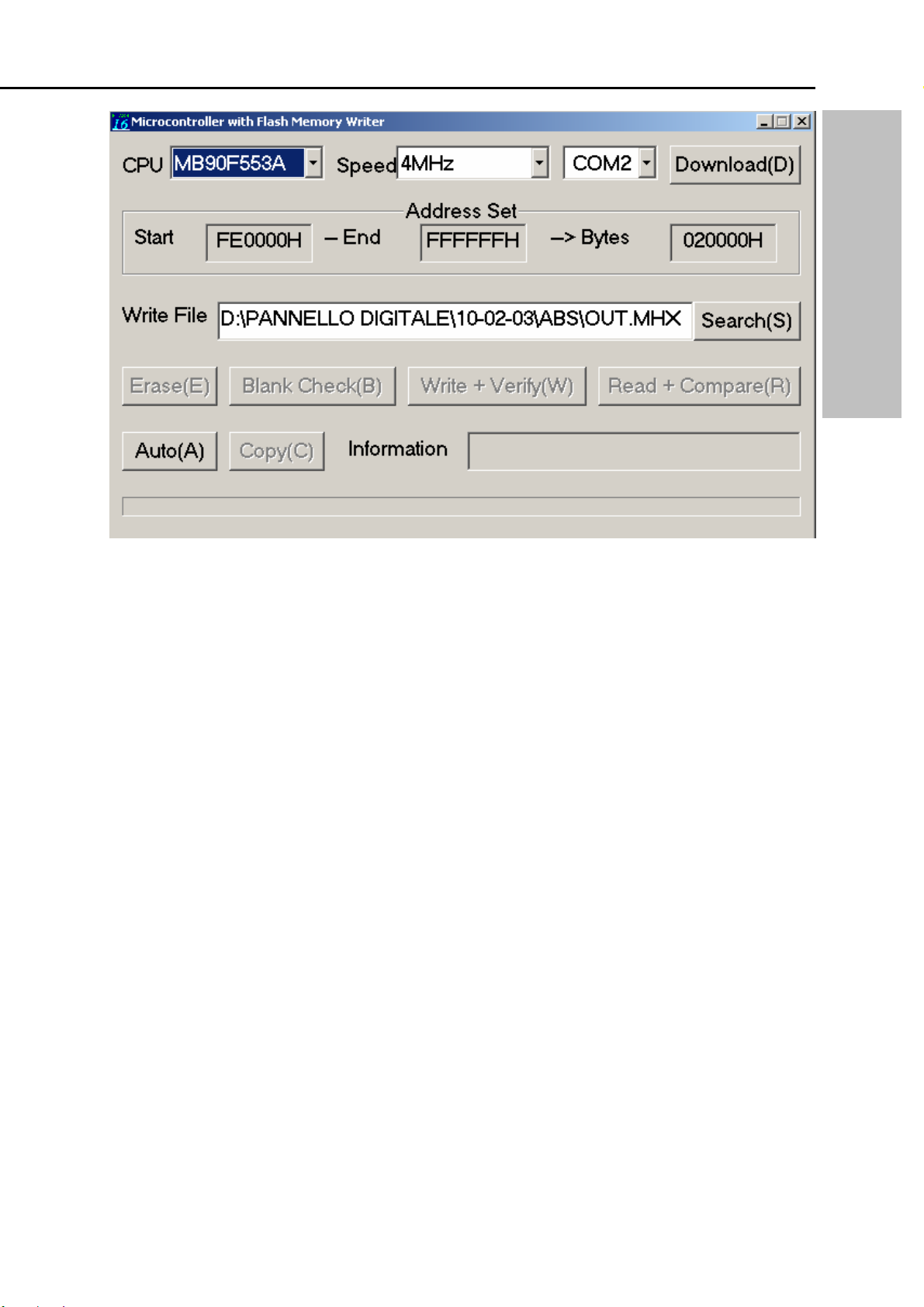

Regulation of the parameters

Push the button Stop + Manual toppress for 5 seconds

Insert password 16-07 than press stop again

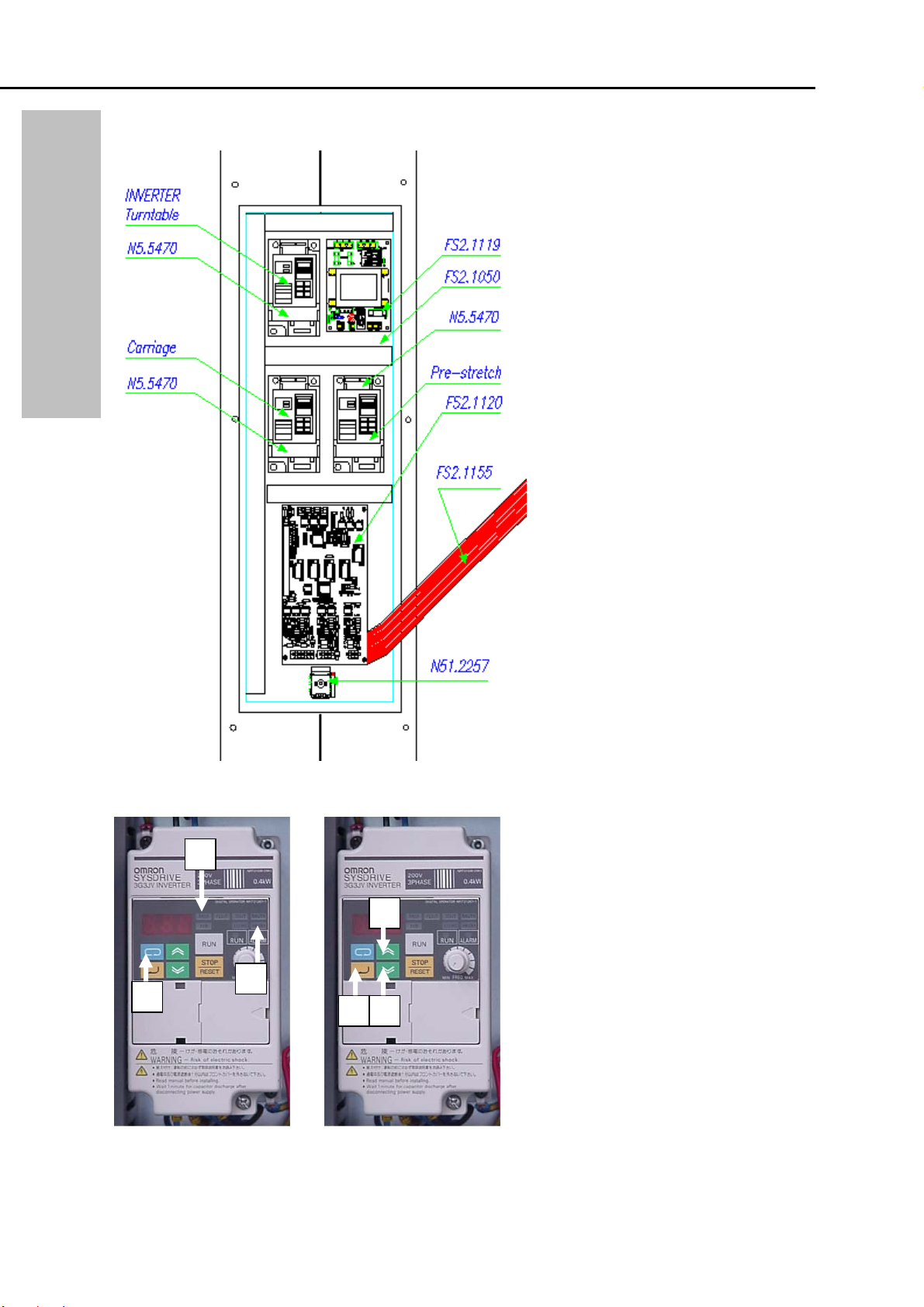

T0 = Analog output 1 Inverter turntable (55Hz = 100 = 10V )

T1 = Analog output 2 Inverter carriage (60Hz = 100 = 10V )

T2 = Analog output 3 Inverter Pré – Stretch (60 Hz = 100 = 10V )

T3 = Analog signal offset = 10 Inverter

T4 = Gain signal offset = 10 Inverter

T5 = Pré stretch ( 0 = No, 1 = Yes )

T6 = Top press ( 0 = No, 1 = Yes )

T7 = Film broken ( 0 = OFF, 1 = ON )

T8 = Block parameters possible ( 0 = No, 1 = Yes ) (Standard 1)

T9 = Horse shoe turntable ( 0 = No, 1 = Yes )

T10 = Pre stretch indepentedly adjutabele

during carriage movement up and down ( 0 = No, 1 = Yes )

T11 = Sound of the alarm during the cycle ( 0 = No, 1 = Yes ) (Standard 0)

T12 = Different parameters for every cycle ( 0 = No, 1 = Yes ) (Standard 0)

T13 = Left side PW for un-blocking parameters ( 22 )

T14 = Right side PW un-blocking parameters ( 3 )

After changing or regulation of the parameters always switch of the machine. Wait for approx.

10 seconds and switch on the machine again.

MASKED PARAMETERS