8Safety

DM1160

Precautions to take before using the

machine

Do not wear loose clothing which could become caught

up in moving parts.

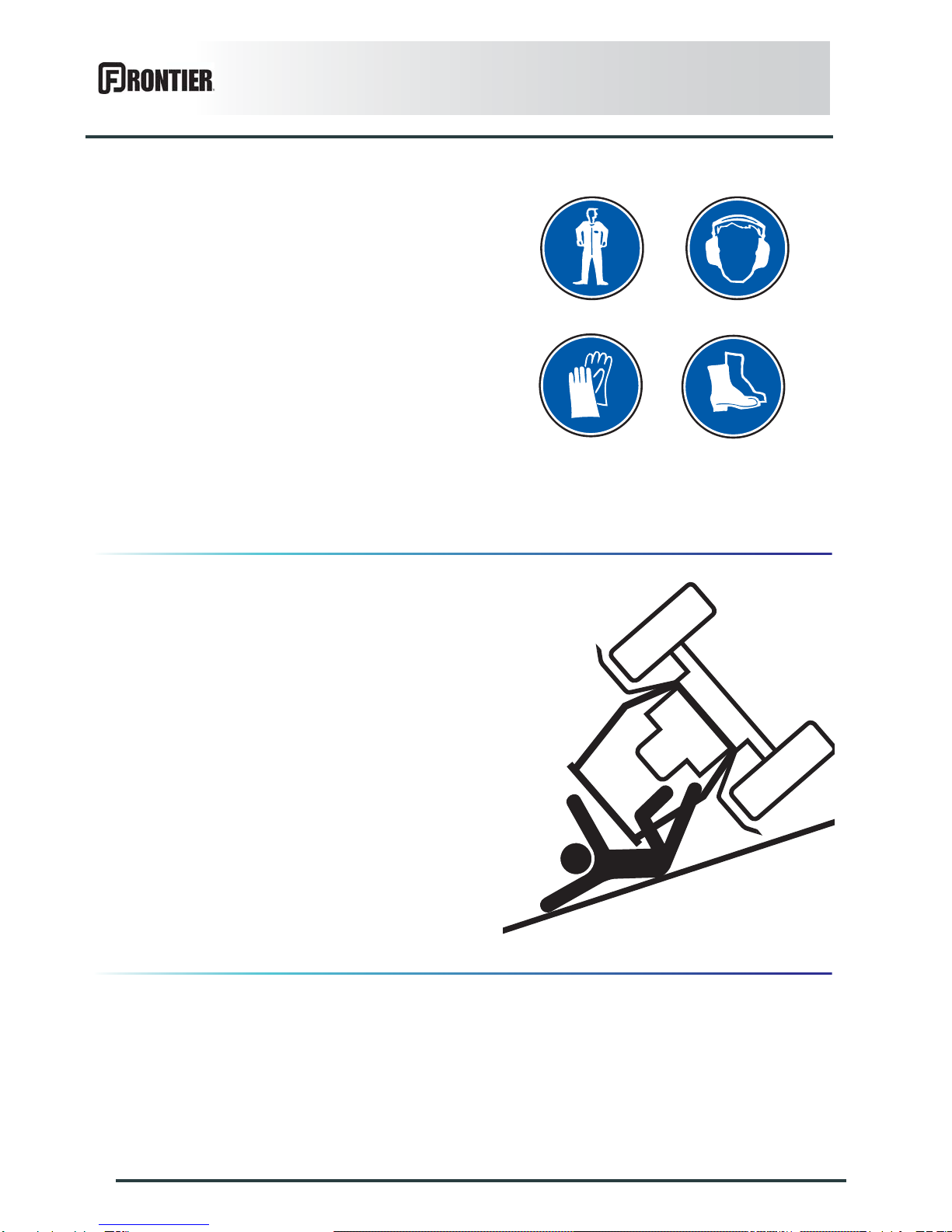

Wear appropriate protective clothing (gloves, shoes,

goggles, helmet, ear defenders, etc.).

Ensure that all operating controls (ropes, cables, rods,

etc) are placed so as they cannot be operated

unintentionally and cause damage or injury.

Before operating the machine, check tightness of nuts

and bolts, particularly on components that the machine

uses to process material (tines, forks, blades, knives,

etc). Retighten if necessary.

Before operating the machine, ensure that all the safety

guards are firmly in place and in good condition.

Immediately replace any worn or damaged guard.

Precautions when driving

Tractor handling, stability, performance and braking

efficiency are all affected by weight distribution, trailed or

mounted implements, additional ballast and driving

conditions. It is therefore of great importance that the

operator exercises caution in every given situation.

Drive speed must be adapted to ground conditions as

well as to roads and paths. Always avoid abrupt changes

of direction.

Be particularly cautious when turning corners, paying

attention to machine overhang, length, height and

weight.

Never use a narrow track tractor on very uneven or

steeply sloping ground.

Never leave the tractor seat while the machine is

operating.

Carrying people or animals on the machine when

working or in transport is strictly forbidden.