7

Before installation/maintenance, the vehicle and mower should be

stationary and the ignition key removed.

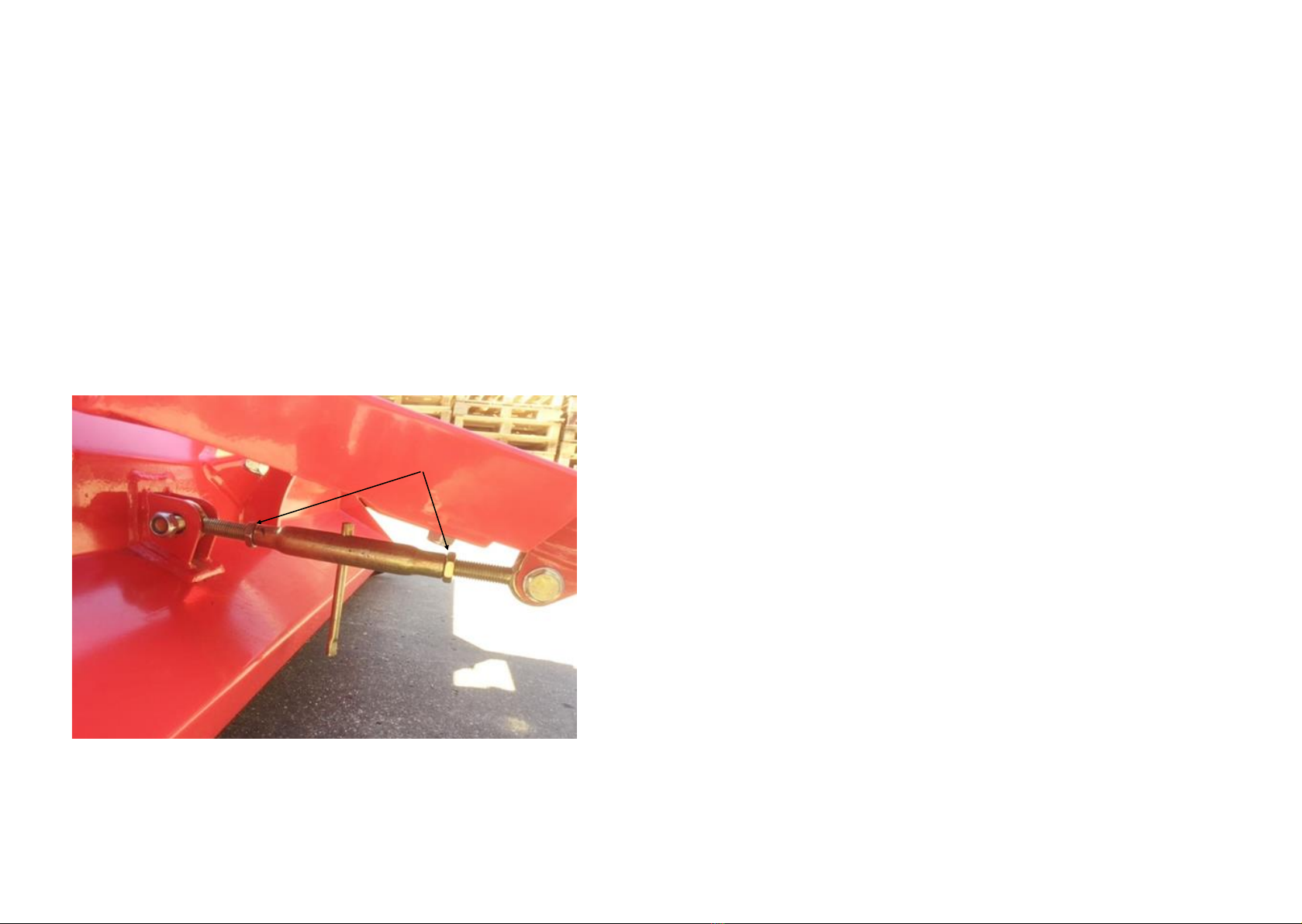

Adjust the mower drawbar to allow the mower to run directly behind the

towing vehicle.

The drawbar attachment height of the towing vehicle can vary. To

accommodate adjustment, an adjustment arm is located beneath the

drawbar. This should be lengthened or shortened so that the cutting deck

is horizontal to level ground. This ensures a better nish.

Unlock the locking nuts (A), spin the arm to lengthen the link to lower the

front of the deck, or shorten to raise the deck. Once the deck is level, re-

tighten locking nuts.

Drawbar Adjustment

A

8

Starting the Engine

Before installation/maintenance, the vehicle and mower should be

stationary and the ignition key removed.

Observe all safety precautions: Keep hands and feet away from rotor/

moving parts. Keep spectators at a safe distance. Ensure there is a gap

between the blades and the ground. Select an area clear of loose debris.

Set the engine choke and suitable idling speed with the throttle. Place one

foot on top of the deck body for a rm and balanced position. Pull the

starter cord rmly, allow the cord to return to the housing slowly (one or

two strong pulls should start the engine). After a few seconds warming up

at idling speed, move the throttle to the factory pre-set working position

(see the Engine Owner Manual for full operating instructions)

NOTE: If the throttle is altered to increase the engine rpm beyond the

recommended level, the guarantee may become invalid. This may

also cause cutting ineciency, excessive vibration and an increase in

fuel consumption.

Simply hitch up the mower and turn the ignition key to start the mower.

The amount of grass/weeds dictates the forward speed. In most cases,

slow forward speeds give better results; 1 mph = very heavy use, 6 mph =

very light use. Start o in the slowest speed possible, ensure the mower is

working eciently with the engine set at maximum rpm and not

labouring. If this is not possible due to very heavy cutting conditions, raise

cutting height of blades and be prepared to go over twice with the

machine set lower on the second pass. Leave 24 hours in-between rst

and second cut to allow grass to dry out. Always listen to the engine to

ensure both engine and mower are working eciently, slow down or stop

once the engine starts to labour.

Failure to do all of the above will result in clutch slip and ultimately

severe damage to the clutch and drive belts.