Equipment Supplied by Contractor

Risers an Access covers per Site & Regulatory Requirements

Risers in 6” or 12” height increments and access covers are available from your distributor. If not already installed,

please refer to installation instructions in this Manual. Maximum riser height is 2 inches for No traffic load and H-

20, HS-20 with Support Columns. For H-20, HS-20 with No Support Columns, acceptable riser height is 12 inches to

set the depth 2 inches between ground level and adapter ring.

All Commercial Mo els: Two (2) 20-inch dia. Risers plus One (1) 2 -inch dia. Riser.

Insulation for Col Climate Installations

To maintain optimal treatment conditions, Fuji Clean recommends insulated risers and access covers as well as

foam board or insulating material (min. R-Value 8) over the upper half of the treatment tank. In H-20, HS-20 with

No Support Columns installation, insulate at depth of 2 inches between ground level and adapter ring.

Septic Tank an /or Pump Station.

For commercial system, structure use with high influent load cases, install a septic tank if necessary. Fuji Clean

systems are designed to accept straight wastewater. However, some treatment train designs call for pretreatment,

settling and/or trash tanks.

Fresh Water

Systems must be filled with fresh water to Low Water Level before backfill. Please refer to Approx. gallons required

per model is “Volume Total” on page 7.

Piping / Con uit

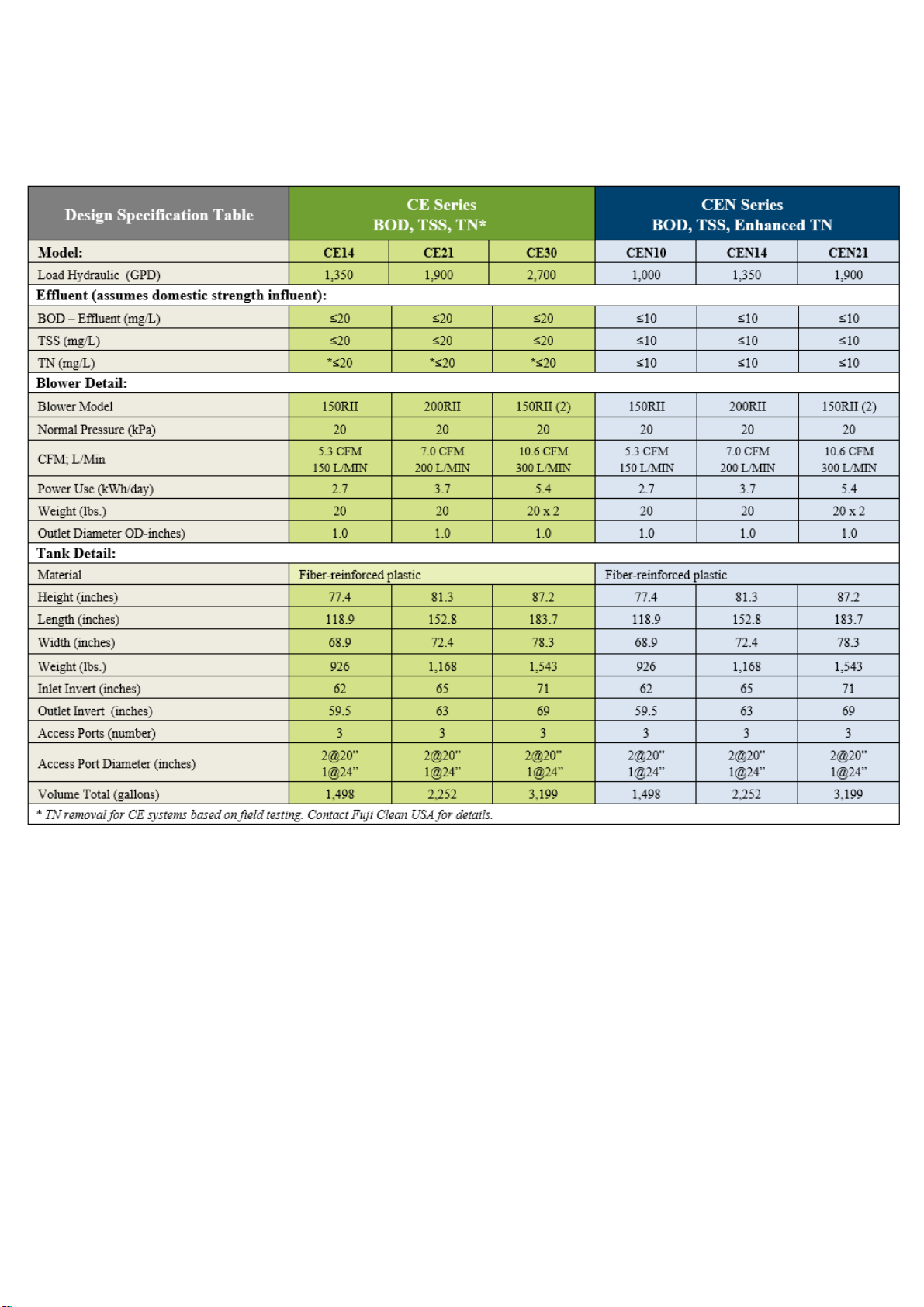

•Smaller models have inlet/outlet adapters for sched. 0 ” pipe. Models CE1 , CE21, CE30, CEN1 , CEN21

fittings are for 5” sched. 0 pipe and come with a 5”: ” eccentric adaptors, to accommodate sched. 0 ” pipe.

•¾” or 1” PVC conduit for air line. Flexible irrigation line, 100 PSI Max, (or equivalent) is also acceptable.

•Electrical conduit for float switch line (direct burial line is also acceptable if allowed by code).

Electrical

•Please use licensed electrician and adhere to applicable national/local electrical code(s).

•Two (2) standard 115V, 15A circuits for control/alarm panel connection.

•Float Switch Wire: #18 AWG, comes with standard 30’ length. (Longer lengths are available on request).

•Float Switch: May come pre-installed in treatment system. For electrical hookup, please refer to SJE Rhombus

installation instructions.

•Miscellaneous fittings and connectors to assure watertight connections.

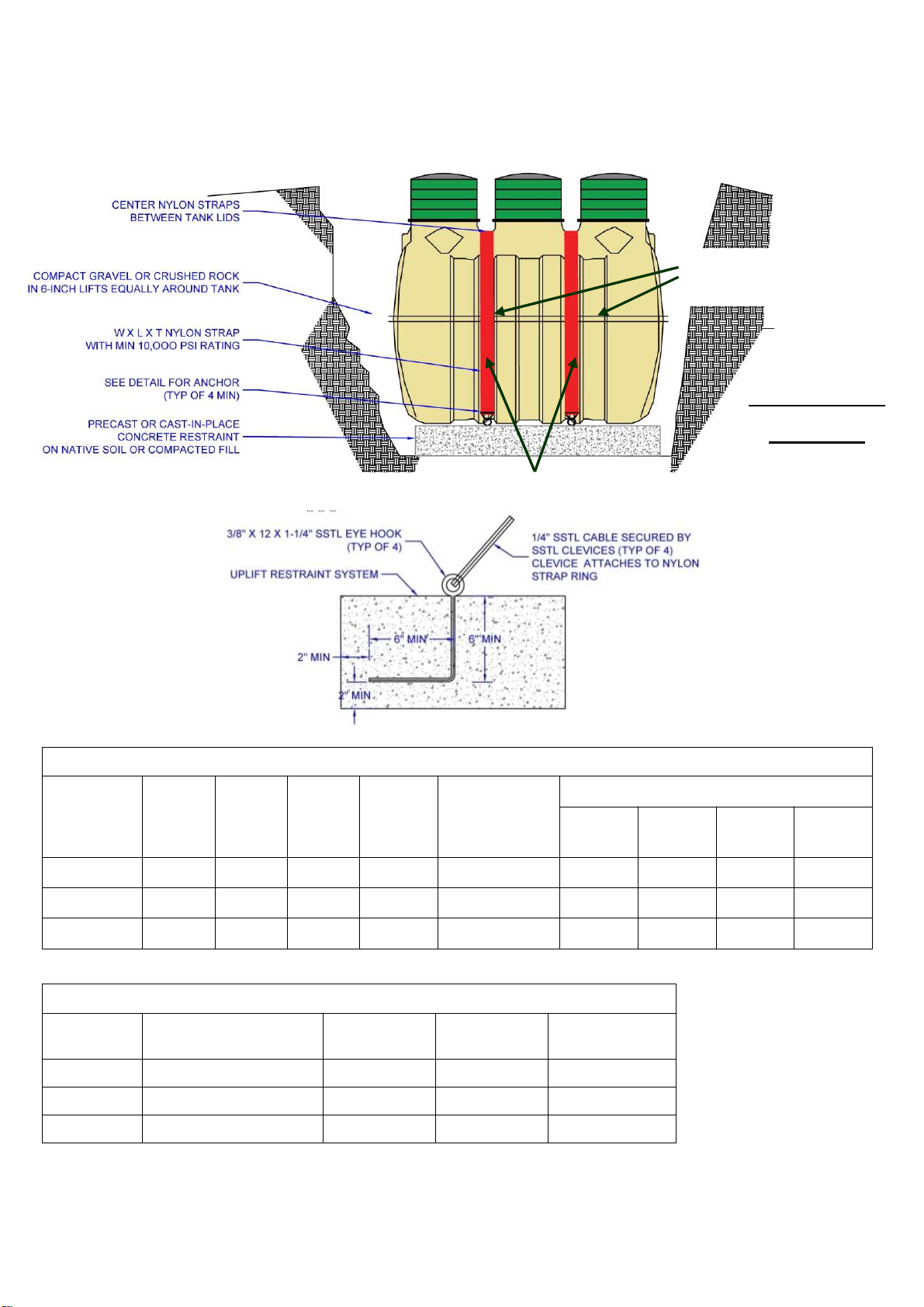

Anti-Float Devices, if necessary

•Please refer to high water, uplift restraint recommendations in this Manual.

Materials for Air Blower / Controller Installation

•Concrete base (or equivalent) on which to set air blower.

•Protective cover for air blower (recommended) vented and able to achieve free air flow in all conditions.

•Materials or location on which to mount control panel and protect from elements.

Crushe Stone, Fill, Loam etc.

•H-20 and HS-20 load needs concrete base.

•Fuji Clean USA is not responsible for design, installation or materials associated with leach field or treated

wastewater disposal area.

Please note: Proper installation permitting is the responsibility of the installing contractor.

Contractor Installation Manual – Commercial Systems

3