Table of Contents

1. GETTING STARTED..............................................2

1.1 - Safety

1.2 - Equipment checklist

2. INSTALLATION ............................................... 3-7

2.1 - Selecting the appropriate cable size

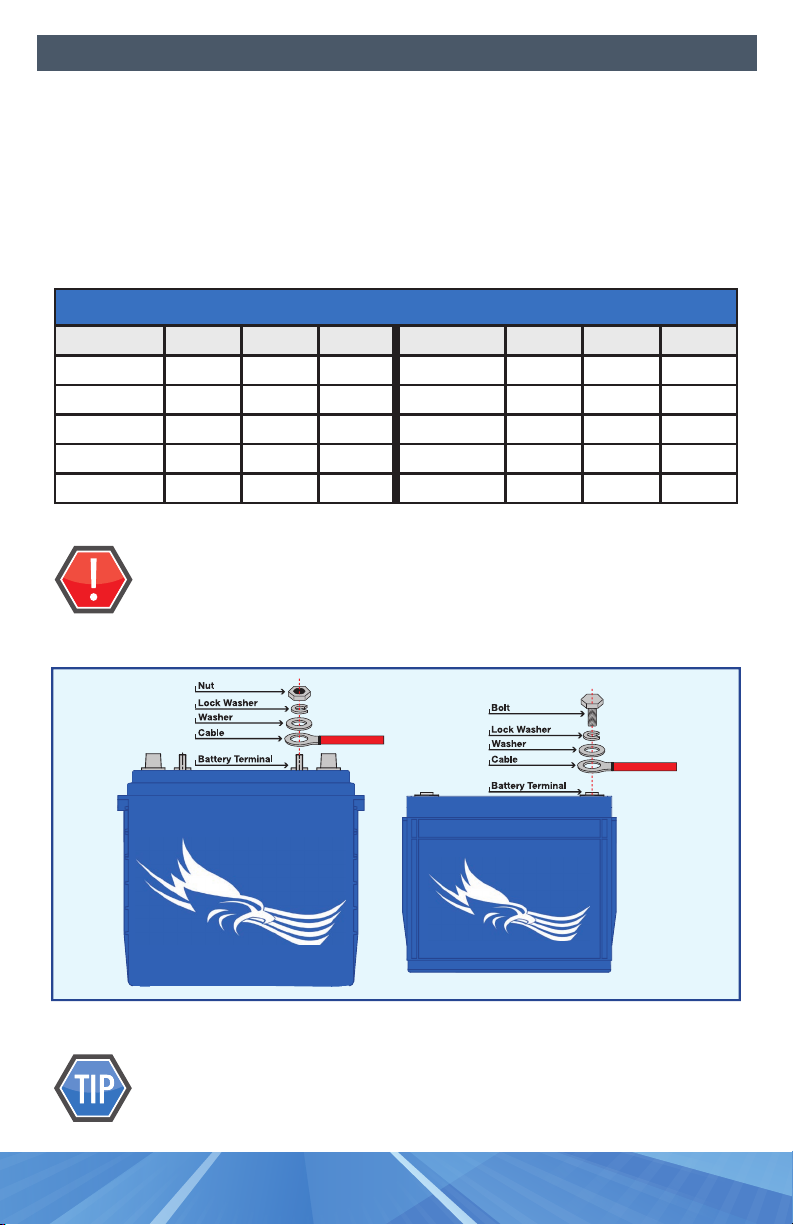

2.2 - Terminal connections

2.3 - Battery orientation

2.4 - Series connections

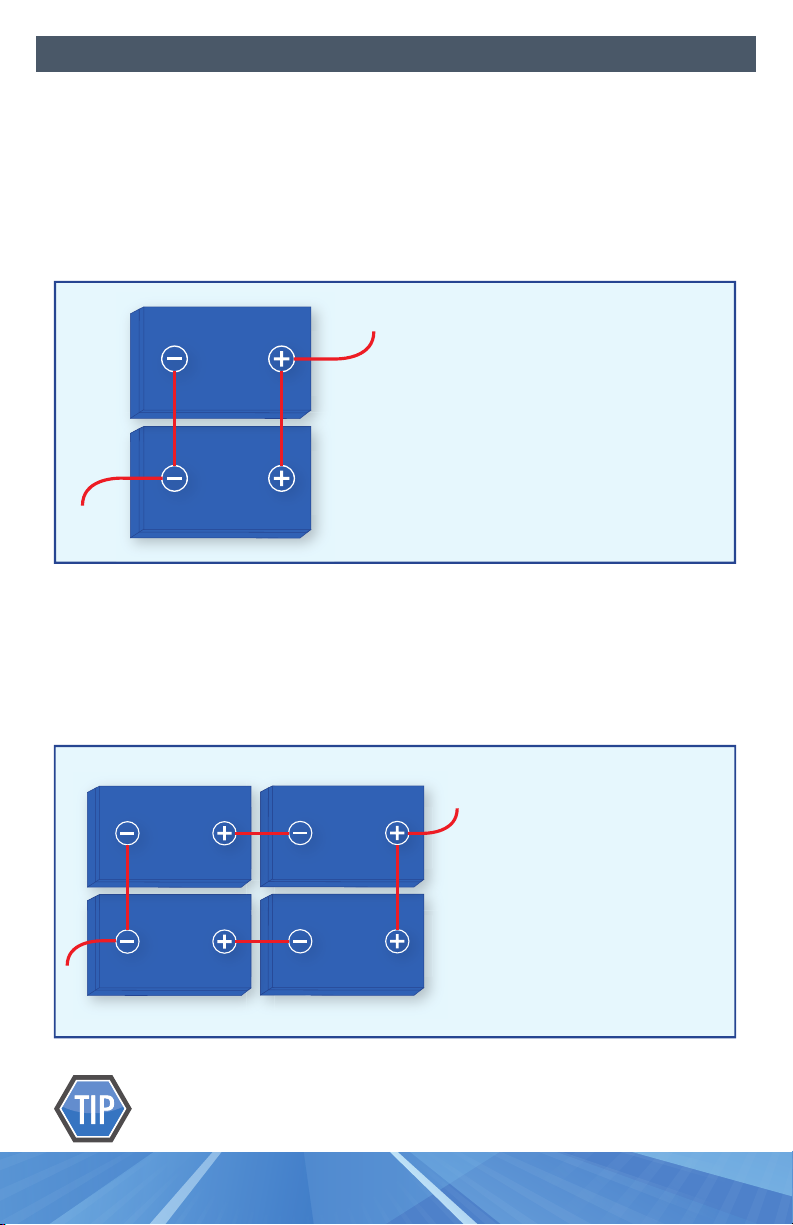

2.5 - Parallel connections

2.6 - Series / parallel connections

2.7 - Cross tying batteries in parallel packs

2.8 - Charging batteries before use

3. OPERATION ................................................. 8-9

3.1-Temperatureeectsonbatteryperformanceandlife

3.2 - Operating temperature range

3.3-Lowdischargerateeects

3.4 - Depth of Discharge (D.O.D.) vs. Battery Life

4. CHARGING ................................................10-11

4.1 - Charger inspection

4.2 - Charging your Fullriver batteries

4.3 - Charging temperature range

4.4 - Charging parameters

4.4.1 - Current

4.4.2 - Voltage settings

4.4.3 - Temperature compensation

5. STORAGE..................................................12-13

5.1-Batterystorageprocedure

5.2-Temperatureeectsonself-discharge

5.3 - Storage temperature range

6. TESTING ..................................................14-16

6.1 - Test preparation

6.2 - Open circuit voltage test

6.3 - Discharge test

6.4 - Optional test

6.5 - CCA test

6.6 - Battery replacement instructions

7. YOUR CLEAN-GREEN ENERGY SOLUTION ......................16-17

7.1-Fullriverproducts

7.2 - Fullriver manufacturing

7.3-Solarsettingrecommendations

8. TRANSPORTATION INFORMATION...............................18

A. APPENDIX ....................................................19

A.1 - Temperature ranges

A.2 - State of Charge (S.O.C.) vs. Open Circuit Voltage (O.C.V.)

A.3-Bolt/NutSpecications