1

FAR-2807/2107 SERIES RADAR Console RCN-003/004

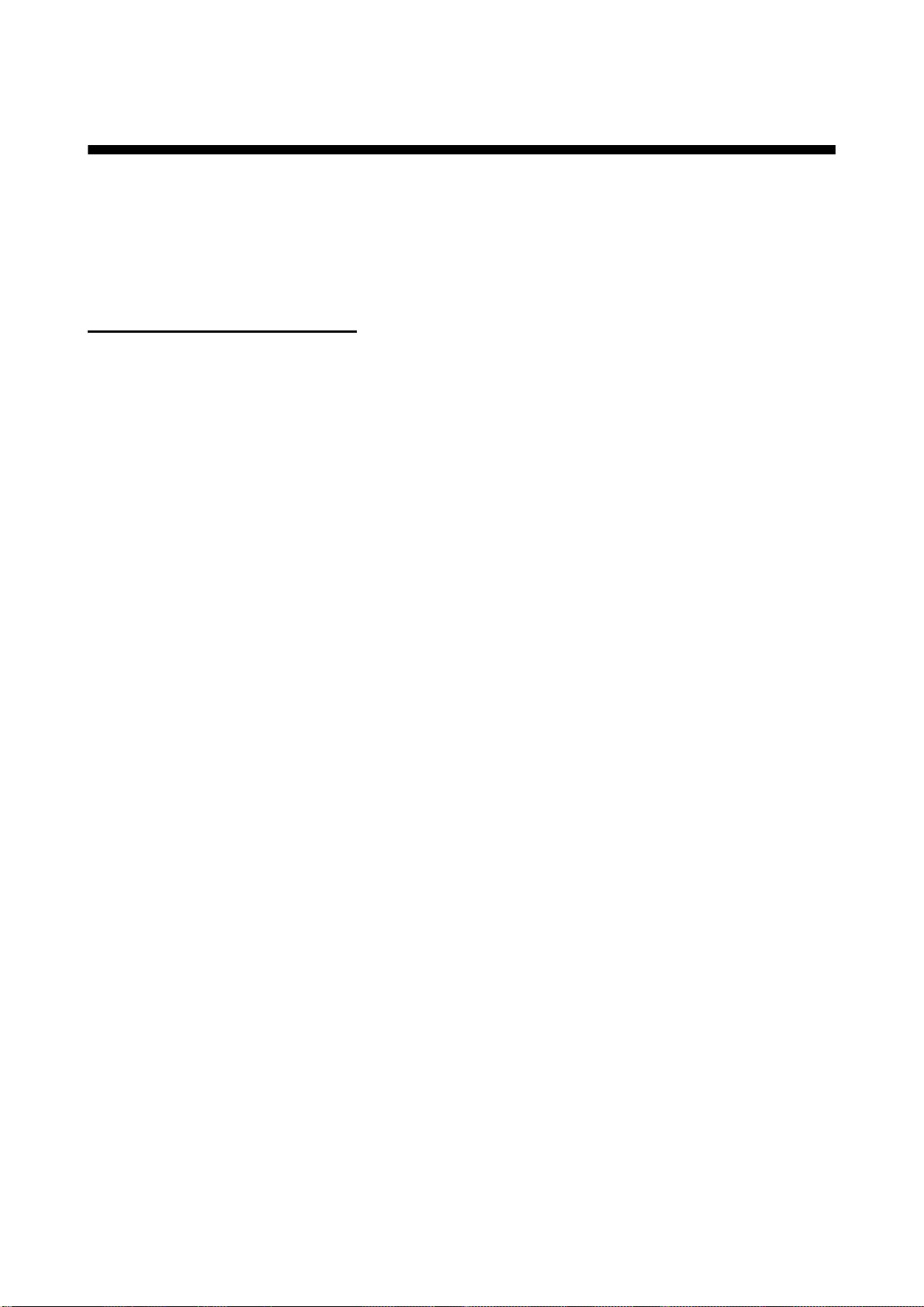

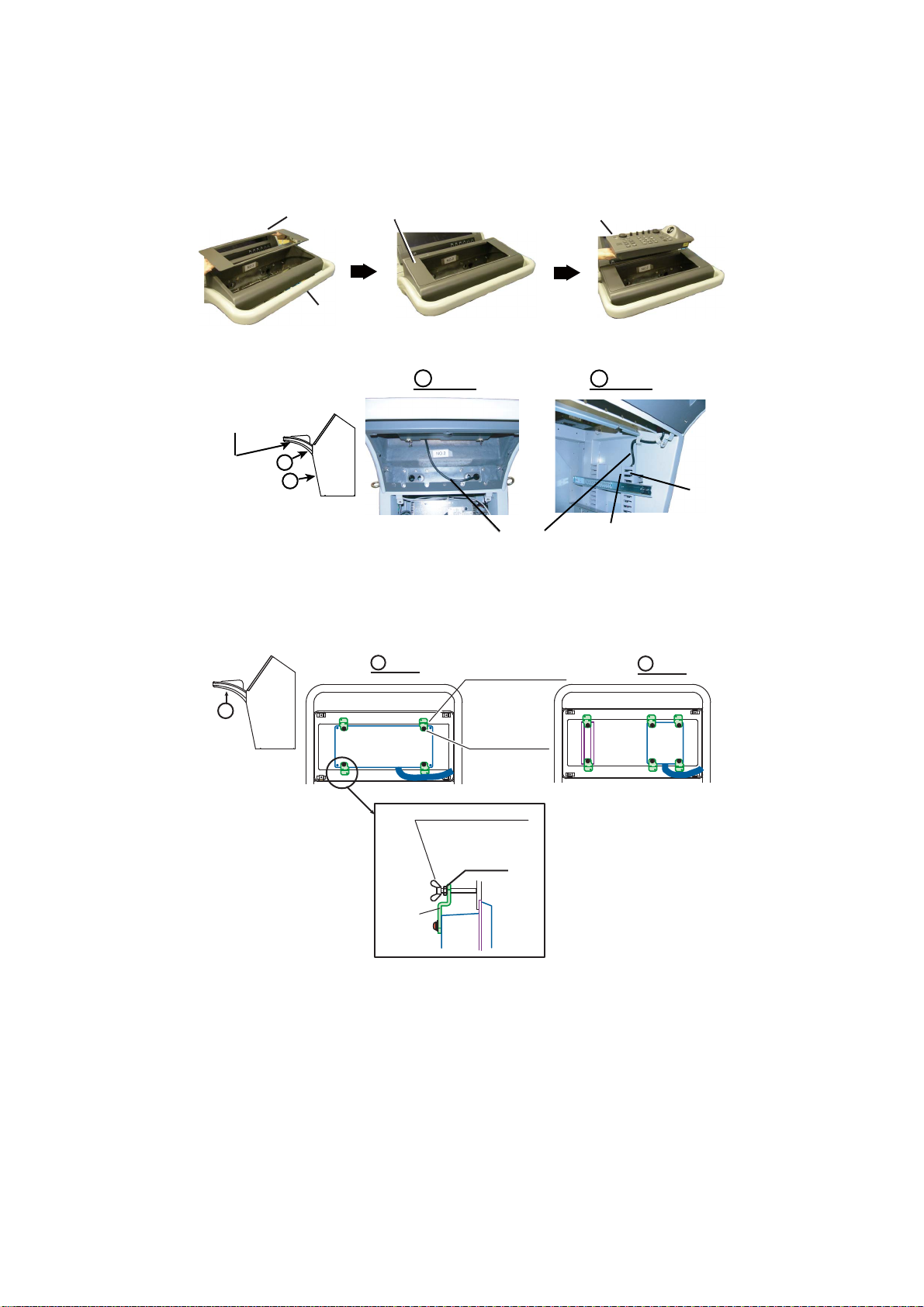

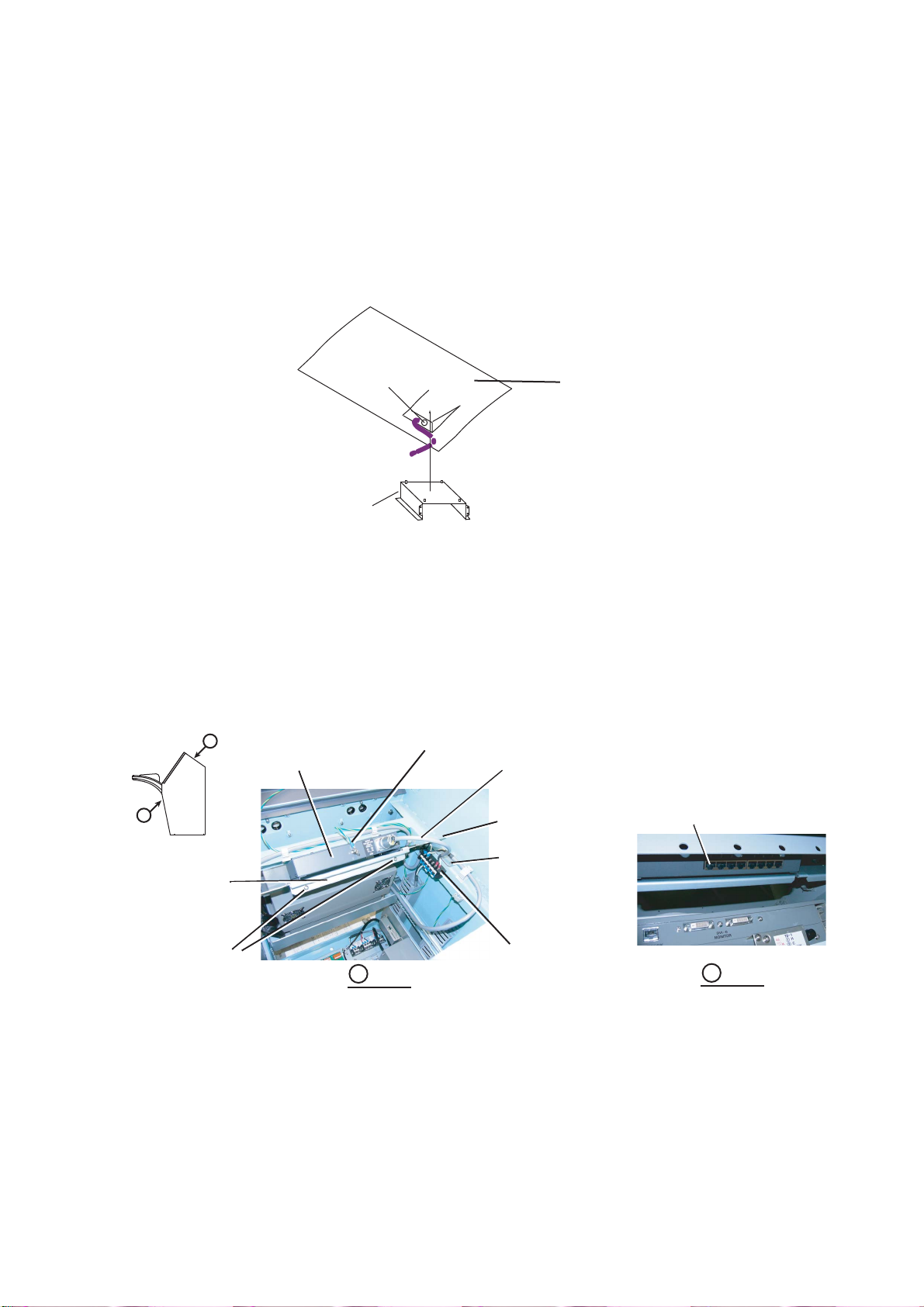

Installation Procedure

The components of the radar console are either assembled at the factory or require assembly in the

field. The purpose of this technical information is to provide the procedures for in-the-field installation

of the processor unit, monitor unit, control unit and optional equipment of the radar console.

There are eight types of radar console kits, as shown below. For further details, see the packing list

at the back of this manual.

Radar console installation kits

Type: RCN-003-14, Code No.: 000-083-519 (for MU-231CR/MU-231, RCU-014)

Type: RCN-003-15, Code No.: 000-083-520 (for MU-231CR/MU-231, RCU-015)

Type: RCN-003-S-14, Code No.: 000-083-521 (for MU-231CR/MU-231, S-band; RCU-014)

Type: RCN-003-S-15, Code No.: 000-083-522 (for MU-231CR/MU-231, S-band; RCU-015)

Type: RCN-004-14, Code No.: 000-083-523 (for MU-201CR/MU-190, RCU-014)

Type: RCN-004-15, Code No.: 000-083-524 (for MU-201CR/MU-190, RCU-015)

Type: RCN-004-S-14, Code No.: 000-083-525 (for MU-201CR/MU-190, S-band; RCU-014)

Type: RCN-004-S-15, Code No.: 000-083-526 (for MU-201CR/MU-190, S-band; RCU-015)

Optional equipment of the radar console are as below.

• Gyro converter kit GC-10-4, Code No.: 000-083-528

• DVI-RGB conversion kit OP03-180-4*, Code No.: 008-545-600

• BNC connector converter DSUB-BNC-1-RCN3/4*, Code No.: 008-545-850

• Switching Hub HUB-100-RCN3/4, Code No.: 000-084-322

• Memory Card Interface Unit CU-200-FAR, Code No.: 000-081-568

• Video LAN converter IF-7100, Code No.: 000-026-912

• AC/DC power supply unit PR-240, Code: 000-013-632

*: When Video LAN converter IF-7100 is installed, DVI-RGB conversion kit and BNC connector

cannot be installed together.

If you are installing a factory-assembled console, follow step 1, step 24 and step 31.