GABRIEL KERAMIK AB

3

Foreword

General

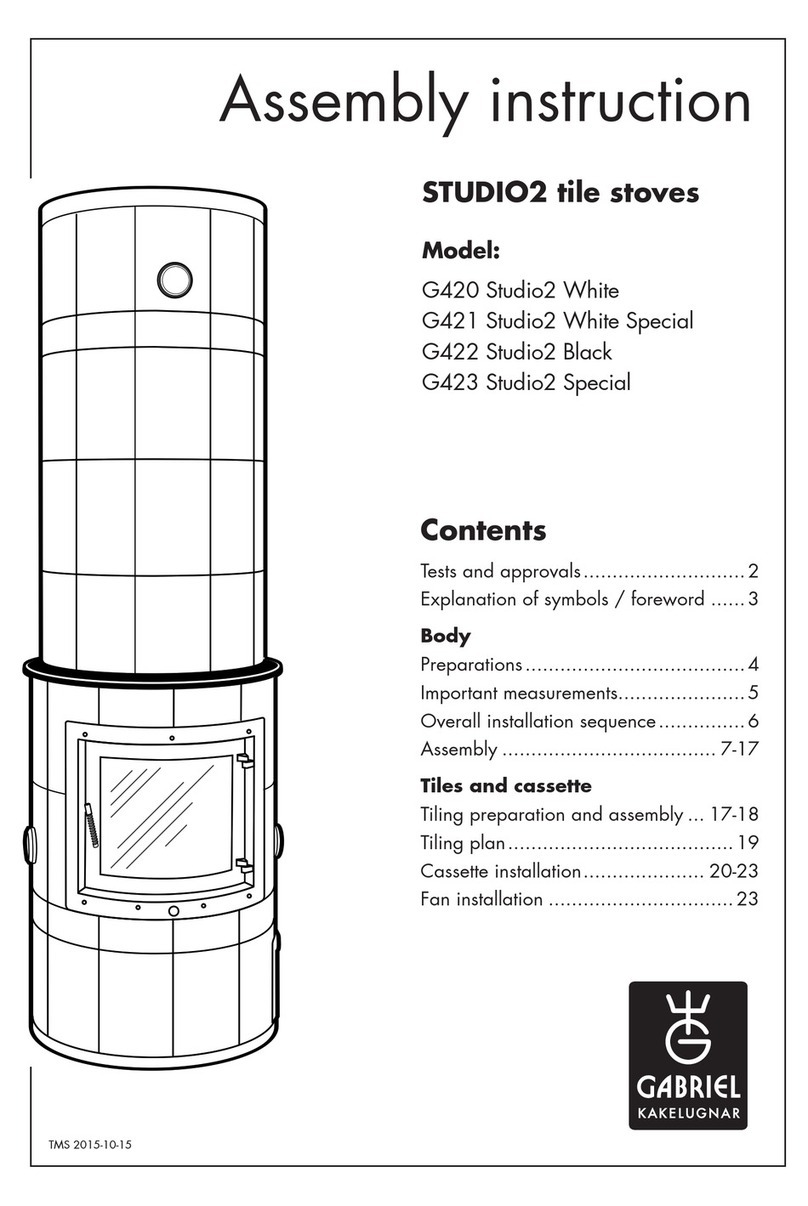

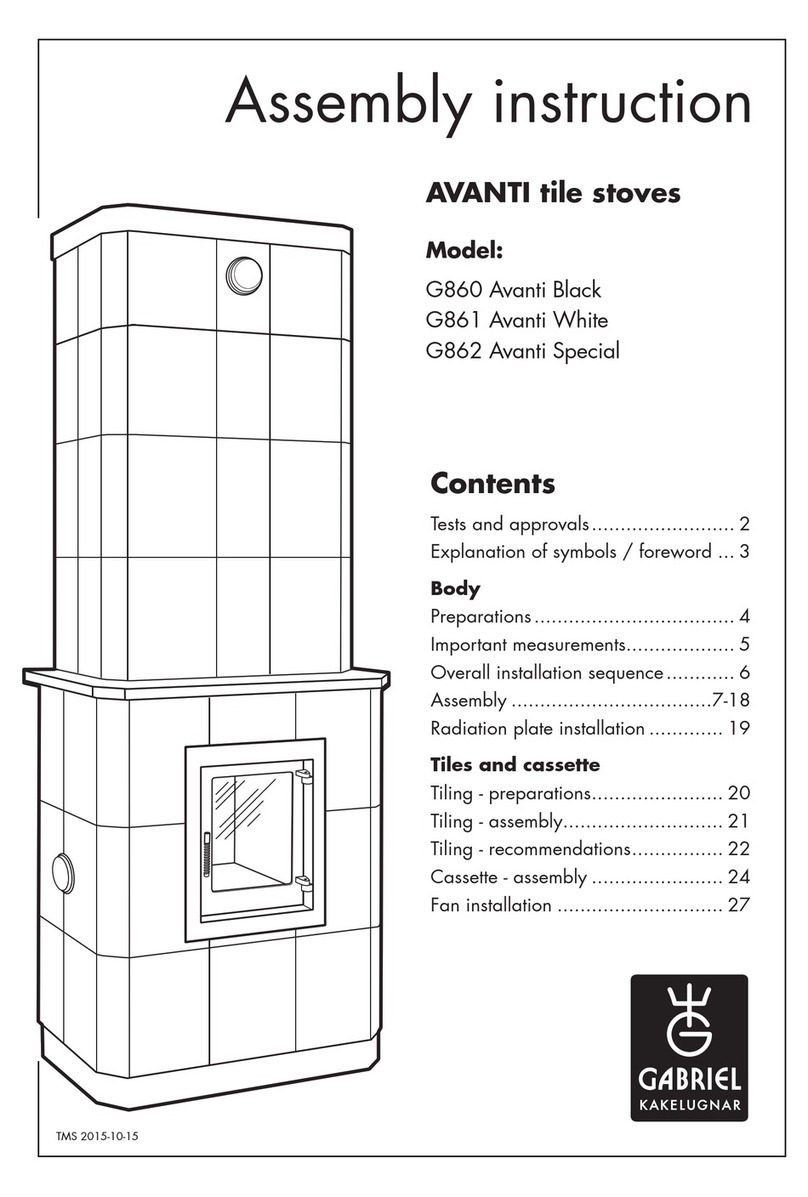

Gabriel tiled stoves consist of prefabricated modules,

cast from fireproof material. The stoves should be

built by an approved tradesman.

A building permit is needed when building a new

tiled stove. Before starting to fire, the tiled stove has

to be inspected by the Building Control Officer, (see

local and national regulations regarding installation

of fire places).

Distance and measurements

As to the following pictures in this manual you place

the first module 50 mm from a combustible wall. A

non-combustible hearth shall be placed on the floor

in front of the stove (for size, see local regulations).

A 300 mm free space is needed in front of the soot

holes on each side of the stove. The hole in the

base for inlet air to the convection heat must not be

blocked. The manual’s control measurements (page 5)

are very important, while the other measurements

should be seen as a guide during the assembly.

Support

The foundation and floor support of the stove has to

be approved before assembly.

The weight of the stove is between 1300-1800 kg

depending on the model and flue connection.

Therefore the foundation requires sufficient bearing

capacity and shall be checked and approved in

accordance with the building permit, (consult your

local building authorities).

Thickness of joints

The joints between the modules are approx.10 mm.

Use a suitable wet brush for neat, tight joints.

Explanation of symbols/foreword

Marking with a pen

Important positions, areas for sawing and

placing of mortar are marked with a pen.

Control measurement

Shows important measurements during

assembly.

Trowel

Shows where the clay mortar is placed.

Rendered areas

Shows the areas that shall be rendered

with clay mortar.

Saw

Shows where the prefabricated modules

should be sawn.

Insulation

Shows where you place the insulation.

Flue connection

Gabriel stoves can be either rear or top connected.

A prefabricated flue can be directly connected on the

top of the stove. Check with your local dealer for the

best solution.

Step-by-step installation

Please follow the step-by-step assembly and pay

attention to the control measurements that are shown.

A certain tolerance is allowed but make sure the

control measurements are kept as it has a profound

impact on the tiling, which is to follow.

The thickness of joints should be approx.10 mm. For

good adherence, wipe the contact surfaces with a

squeezed sponge before jointing.

During the assembly the outer rings are always to be

one step ahead of the inner blocks.

Equipment

Trowels, brick layer, a long water level, radiator

brush, folding rule, chisel, buckets, sponge, rubber

mallet, covering plastic, angular grinder, hack saw, 2

ladders, joint sponge, wooden wedge.

Material included in the delivery

• Clay and sand - Clay mortar mix: 1:3½ (1 part

of clay to 3½ part of sand).

• Tile adhesive

• Grout

• Silicon - if during transport a module is broken it

can easily be fixed with the supplied heat-resistant

silicon or clay mortar by gluing the pieces together.

Safety instructions

Read these instructions carefully before

starting the assembly. Incorrect assembly

can cause serious damage and fire risk.

Make sure prior to the assembly that the

building permit is approved and that the

local chimney sweep has approved the

installation.