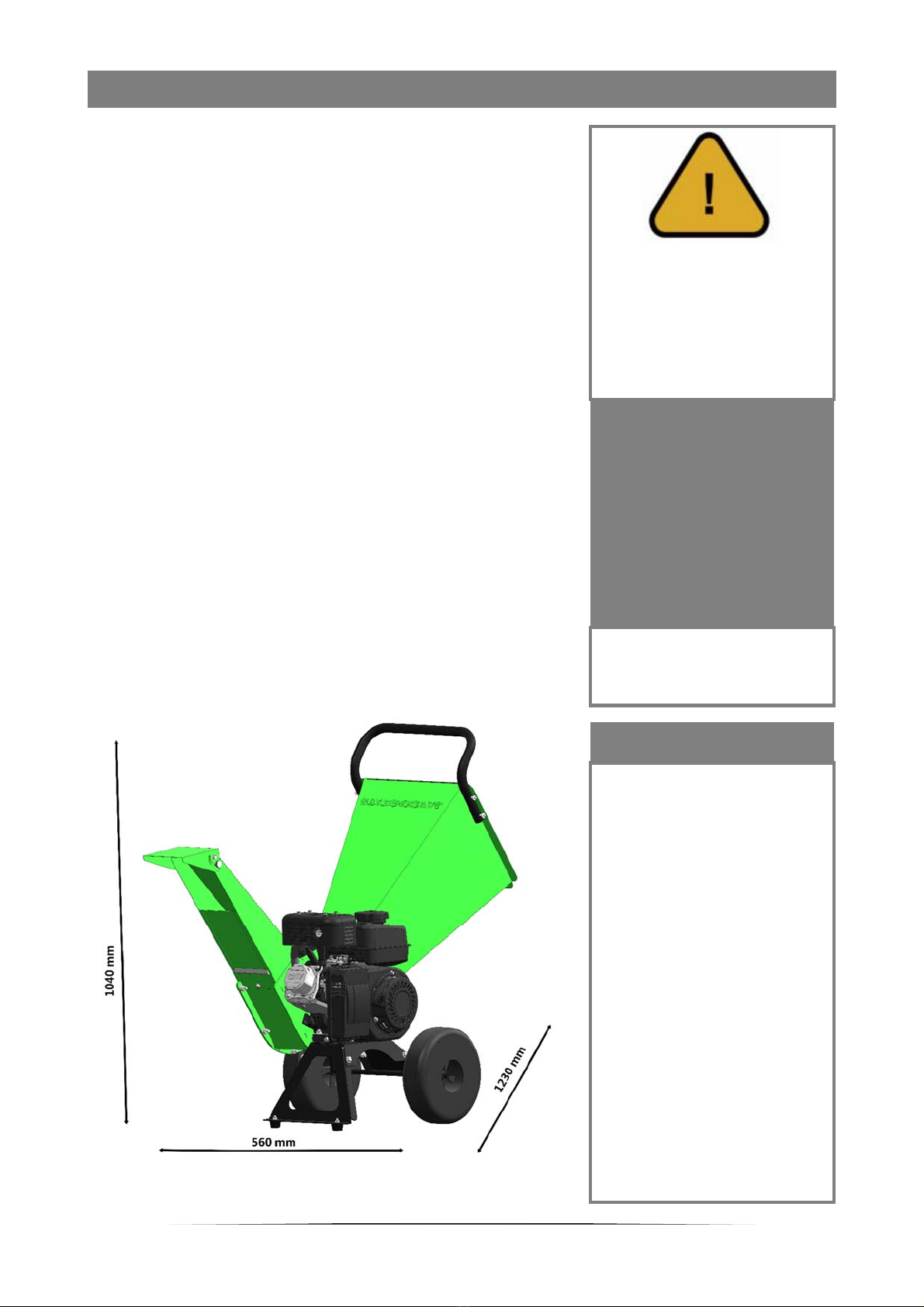

USER MANUAL FOR GB-R30 (GB-R0) WOOD CHIPPER

3

SAFE WORKING

OPERATOR'S PERSONAL PROTECTIVE EQUIPMENT (PPE)

Chainsaw safety helmet (EN 397) fitted with mesh visor (EN 1731) and

ear defenders (EN 352).

Work gloves with elasticated wrist.

Steel toe cap safety boots (EN 345-1).

Close fitting heavy-duty non-snag clothing. High-visibility clothing (EN.

471) if risk assessment identifies the need.

Face mask if appropriate.

DO NOT wear rings, bracelets, watches, jewelry or any other items that

could be caught in the material and draw you into the chipper.

WARNING

The chipper will feed material

through on its own. To do this, it

relies on sharp blades on the

chipper rotor. To keep the blades

sharp, only feed the machine

with

clean brushwood.DO NOT put

muddy / dirty wood, roots, potted

plants, bricks, stones or metal

into the chipper.

BASIC WOODCHIPPING SAFETY

The operator should be aware of the following points:

Maintain a safety exclusion zone around the chipper of at least 10 metres for the general public or employees without adequate

protection. Use hazard tape to identify this working area and keep it clear from debris build up. Chips should be ejected away

from any area the general public have access to.

Hazardous material-Some species of trees and bushes are poisonous. The chipping action can produce vapor, spray and dust

that can irritate the skin. This may lead to respiratory problems or even cause serious poisoning. Check the material to be

chipped before you start. Avoid confined spaces and use a face mask if necessary.

Be aware when the chipper is processing material that is an awkward shape. The material can move from side to side in the

hopper with great force. If the material extends beyond the hopper, the brash may push you to one side causing danger. Badly

twisted brash should be trimmed before being chipped to avoid thrashing in the feed hopper.

Be aware that the chipper can eject chips out of the feed hopper with considerable force. Always wear full head and face

protection.

Always work on the side of the machine furthest from any local danger, e g. not road side.

Never leave the chipper unattended when running. Machines must be supervised at all times when in use. ·

In the event of an accident, stop the machine and call the emergency services immediately.