AFTER SALES SUPPORT

10

Important!

When using equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating manual with due

care. Keep this manual in a safe place, so that the

information is available at all times. If you give the

equipment to any other person, give them these

operating instructions as well.

We accept no liability for damage or accidents which

arise due to non-observance of these instructions

and the safety information.

Safety Information 1

CAUTION!

Read all safety regulations and instructions.

Any errors made in following the safety regulations

and instructions may result in an electric shock, fire

and/or serious injury.

Keep all safety regulations and instructions

in a safe place for future use.

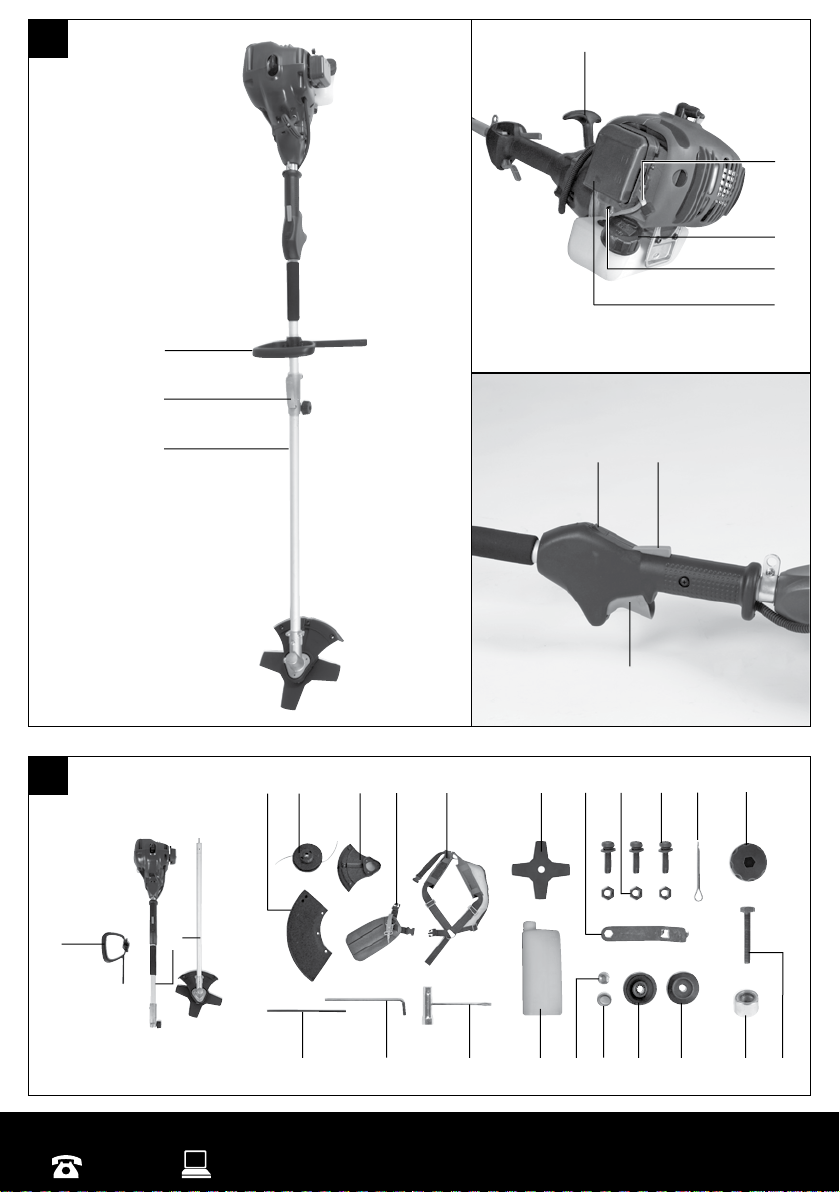

Safety Devices

When working with the equipment, the appropriate

plastic guard hood for cutting blade mode or cutting

line mode must be fitted to prevent objects being

thrown out by the equipment. The integrated blade

in the cutting line guard hood automatically cuts the

line to the optimum length.

Explanation of the information signs on the

equipment:

1. Warning:

2. Read the directions for use before operating the

equipment.

3. Wear safety goggles, a face guard and ear

protection.

4. Wear sturdy, non-slip footwear.

5. Wear safety gloves.

6. Protect the equipment from rain and damp.

7. Be careful of objects being thrown out!

8. Always switch off the equipment and pull out

the spark boot plug before carrying out any

maintenance work.

9. All bystanders must be kept at least 15m from

the equipment.

10. The tool continues to rotate!

11. Caution: Hot equipment parts. Keep your

distance.

Safety Information

1. Read the directions with due care. Familiarise

yourself with the settings and proper operation

of the machine.

2. Never allow children or other persons who are

not familiar with the operating instructions to

use the petrol power scythe. Contact your local

governmental agency for information regarding

minimum age requirements for operating the

petrol power scythe.

3. Never mow in the direct vicinity of persons -

especially children - or animals.

Warning:

Maintain a safety distance of 15m. If

approached, switch off the appliance

immediately.

Always keep in mind that the machine operator

or user is responsible for accidents involving

other persons and/or their property.

Preliminary measures

1. Always wear sturdy, non-slip footwear and long

trousers when mowing.

2. Check the grounds on which the machine will

be used and remove all objects that could be

caught up and violently flung out.

3. Warning:Petrol is highly flammable! Therefore:

- Only store petrol in containers designed to

hold petroleum-based liquids.

- Only refuel out in the open and do not smoke

during the refueling process.

- Always refuel before starting the engine. Do

not open fuel tank cap and do not refuel when

the engine is running or when the scythe is hot.

- If petrol has overflowed, do not under any

circumstances attempt to start the engine.

Instead, remove the machine from the affected

area. Avoid starting the engine until the petrol

fumes have completely evaporated.

For safety reasons, the petrol tank and other

tank closures must be replaced if they are

damaged.

4. Replace defective mufflers.

5. Before using the scythe, visually inspect it to

ensure that the blade, mounting bolts and the

entire cutting apparatus are in good working

order (i.e. not worn out or damaged). To prevent

any imbalance, replace worn out or damaged

blades and mounting bolts as a set only (if

applicable).

6. The powered equipment will create toxic

exhaust fumes as soon as the engine is started.

Never work in enclosed rooms or in rooms with

poor ventilation.

Handling

1. Wear close fitting, tough work clothing

that will provide protection, such as long slacks

or trousers, safety work shoes, heavy duty work

gloves, hard hat, a safety face shield, or safety

glasses for eye protection and a good grade of

ear plugs or other sound barriers for hearing

protection.