Gas-Tec GAS-TEC 500 User manual

GAS-TEC 500

HOT MELT APPLICATOR

OPERATING INSTRUCTIONS

PLEASE READ CAREFULLY BEFORE

ATTEMPTING OPERATION.

Product Description:- GAS-TEC 500 Hotmelt Applicator

Power Adhesives Ltd., Barking, England. (www.tecbond.com)

The Gas-Tec 500 is a Hotmelt Applicator specifically designed with the

professional user in mind. It is powered by butane gas, and can be simply

recharged using generally available cigarette lighter refill canisters.

Issue 1

GAS-TEC 500 Operating Manual

Page 1

SAFETY FEATURES

Stainless steel internal gas tank-

capable of withstanding great pressures

integral blow-out valve, preventing any explosive gas release

self-venting filling valve

Catalytic combustion -

flame-free heating system

reaction products are carbon dioxide and water

high efficiency (over 95% gas utilisation)

Patented „Magnetic Thermostat‟ for accurately controlling temperature

Safety cut-out –operates if the temperature exceeds 260ºC (500ºF),cutting

off the gas supply to the combustion chamber.

Exhaust gas manifold for cooling exhaust gas temperature

Integral piezo-electric ignition

Integral hinged tool stand

SAFETY INSTRUCTIONS

Do not touch the nozzle, the exhaust ports, or molten adhesive with

bare skin as they are hot - the operating temperature of the GAS-TEC

500 is approximately 200ºC. Protective gloves should always be worn.

Careless handling can cause skin burns. If molten adhesive comes into

contact with the skin immerse the affected area immediately in plenty of cold

water. Seek medical advice if necessary.

In addition to the safety instructions herein, any statutory regulations, local

fire insurance regulations, or other generally valid “regulations for accident

prevention” must be complied with when using this tool.

Never use the tool if it is damaged in any way.

Do not use this tool whilst under the influence of drugs or alcohol.

Do not use this tool in the vicinity of any heat-sensitive materials, or any

flammable materials, liquids, or gases.

When refilling, ensure that you switch off the tool before commencing, and

that you keep away from sources of ignition.

Ensure that the tool is held away from your face and body whilst igniting the

gas.

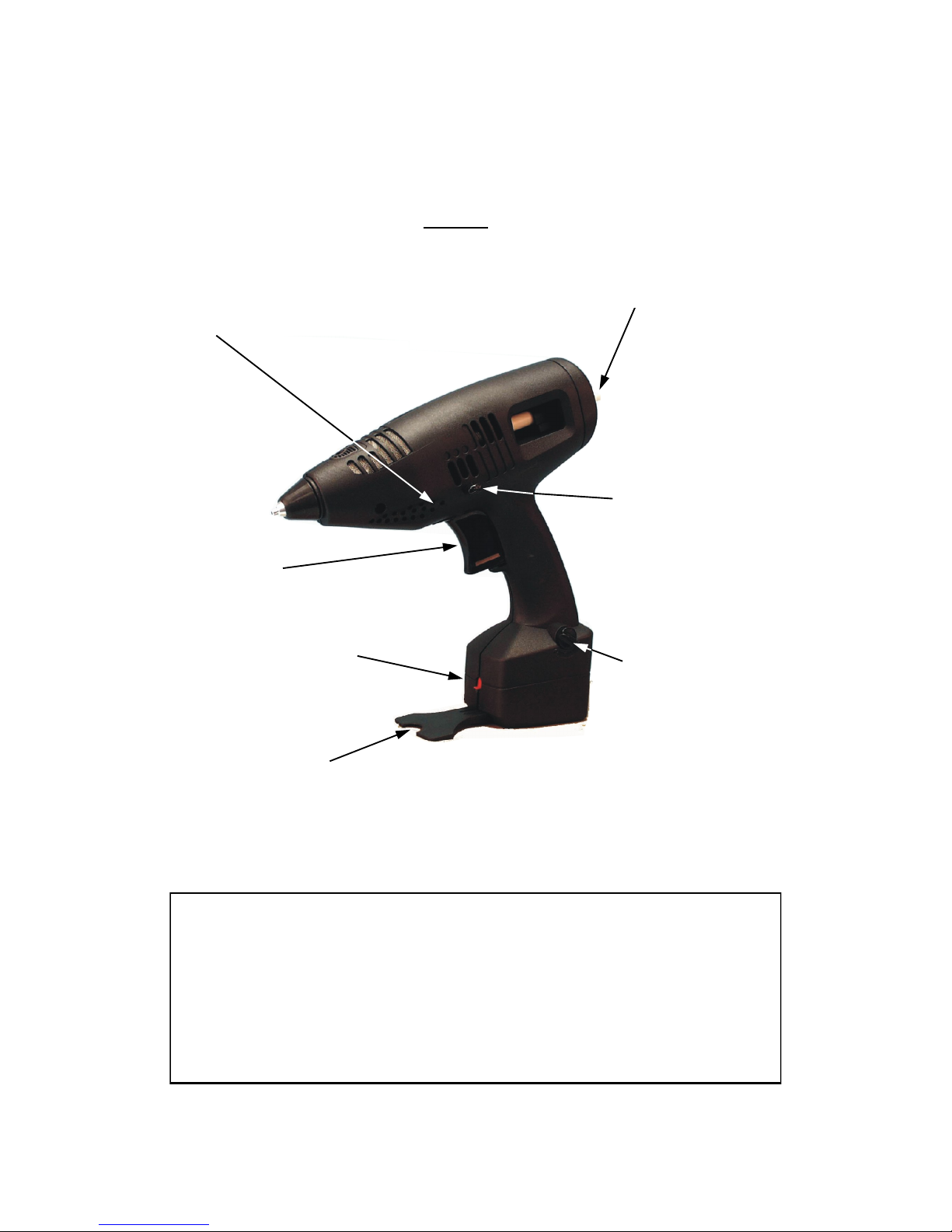

Always use the fold-away stand provided (see figure 1 ) when resting the

tool. Do not leave the tool on its side, as molten adhesive may flow back into

the melt chamber, clogging the feed system.

Do not leave the tool unattended whilst switched on.

Do not expose to heat above 50°C (120°F), and avoid prolonged exposure to

the sun.

Do not try to open, puncture, or incinerate the gas tank.

GAS-TEC 500 Operating Manual

Page 2

PREPARING THE GUN FOR USE

The Gas-Tec 500 is shipped without gas.

1. First fill the Gas-Tec 500 with butane gas (see figure 1 ). We recommend

the use of Braun, Calibri, Ronson, Rowenta, or other high-quality cigarette

lighter fuel.

When refilling, ensure that you switch off the tool before commencing,

and that you keep away from sources of ignition.

2.Load the tool with a high-performance Tec-Bond®12mm adhesive stick (see

figure 1 ).

3. Switch on the gas by rotating the „gas on/off‟ switch anticlockwise to position

„I‟ (see figure 1 ).

4. Press the ignition button (see figure 1 ) to ignite the gas. Gas ignition may

be confirmed by the sound of the gas flow changing (to a mild „roar‟), or by a

visible glow appearing in the „Ignition View‟ window (see figure 1 ) a few

moments later. You may need to repeat pressing the ignition button to

achieve ignition.

Ensure that the tool is held away from your face and body whilst

igniting the gas.

The glow in the ignition view window will disappear once the tool has

reached temperature (the thermostat valve will close, shutting off the

gas supply). It will only reappear once the tool has cooled sufficiently

for the thermostat gas valve to open.

5. Allow at least 4 minutes for the tool to reach operational temperature

(approx. 195°C/385°F).

Always use the fold-away stand provided (see figure 1 ) when resting

the tool. Do not leave the tool on its side, as molten adhesive may

flow back into the melt chamber, clogging the feed system. Do not

leave the tool unattended whilst switched on.

6. Adhesive may now be extruded through the tool by simply pulling the trigger

(see figure 1 ). Adhesive flow is controlled by regulating the pressure

applied to the trigger, and is stopped by simply releasing it.

SWITCHING THE GUN OFF

When work with the tool has been completed, switch off the gas by rotating

the „gas on/off‟ switch clockwise to position „O‟ (see figure 1 ).

Allow the tool to stand for a few minutes before packing away, as it

may operate one last time (even though the switch is in the ‘off’

position); this is due to the tool consuming any gas retained between

the switch and the thermostat valve.

GAS-TEC 500 Operating Manual

Page 3

TECHNICAL DATA

Dimensions (L x H x W): approx. 350 x 270 x 75 mm

Total weight: approx. 750 g

Heating up time: 4 - 7 min.

Operating temperature: approx. 200° C

Diameter of adhesive inlet: 11 - 12 mm

(use only genuine TEC-BOND®adhesive sticks)

Figure 1

Ignition View Window

Load Glue Stick

Gas Ignition Button

Gas On/Off Switch

Fold-away Stand

Gas Filler

Trigger

GAS-TEC 500 Operating Manual

Page 4

APPLICATIONS

BOND SEAL ASSEMBLE INSULATE REINFORCE ENCAPSULATE

REPAIR FILL - INSTANTLY

Suitable for use with most materials. Just apply TEC-BOND®hotmelt to one

surface then press parts together and the bond is made. Can be used for

bonding: Wood, Paper, Cardboard, Foam, Chipboard, Hardboard, some

Plastics, Rubber, Glass, thin Metals, Ceramics, Leather, Fabrics and many

more.

The GAS-TEC 500 is simplicity itself. To operate just turn on the gas, press the

ignition switch, and the gun will be ready for use in approximately 5 minutes.

Glue sticks can be fed continuously through the back of the gun. Use only

genuine TEC-BOND®high performance glue sticks.

APPLICATION NOTES

As with all adhesives, performance depends on conditions of use. Suggestions

or recommendations contained herein are for guidance only, since actual

conditions of use are outside the supplier‟s control.

Ensure that the surfaces to be bonded are dry, free from dust, grease, and

loose particles.

Apply adhesive to one surface only. Bring the two surfaces together

immediately, quickly making any further adjustments. Hold the joint for 20 - 30

seconds to complete the bond.

When gluing dissimilar materials, apply the adhesive to the least heat

conductive of the two.

On materials that are cold to the touch, a better bond can be made by pre-

warming them before applying adhesive.

Surplus adhesive can be trimmed using a sharp knife once it has cooled.

Should molten adhesive drip onto a smooth or polished surface, allow it to cool

completely before removal.

Spots or blobs of adhesive are recommended for workpieces having a large

surface area, or which are particularly long.

Applying the adhesive in wavy lines is recommended for gluing textiles or

similar materials.

Foam materials, like polystyrene, can be easily bonded to other surfaces.

However the adhesive must be applied to the other surfaces, not to the foam.

Use only genuine TEC-BOND® adhesive sticks to ensure reliable performance.

TEC-BOND®adhesive sticks are non-toxic and non-flammable.

GAS-TEC 500 Operating Manual

Page 5

GUARANTEE AND REPAIRS

There are no user serviceable parts within this tool. If you

experience any problems with the tool please return it to your

Distributor for inspection and / or repair.

This GAS-TEC 500 is guaranteed against faulty workmanship and

materials for a period of 12 months from the date of purchase. Within

this warranty period the manufacturers undertake, at their discretion, to

either repair or replace any tool proved to be defective (proof of

purchase will be required for verification). This guarantee is invalidated

if the tool is opened, or modified in any way, or if adhesive formulations

other than those supplied by the tool‟s manufacturer are used.

Warranty claims attributable to improper, or careless, use or handling,

and to normal wear, are excluded from this guarantee.

The supplier‟s and manufacturer‟s only obligation shall be to replace

such tools that are proved to be defective. Neither supplier nor

manufacturer shall be liable for any injury, loss or damage, direct or

consequential, arising out of the use, or the inability to use, this tool.

The user shall determine the suitability of this product for its intended

use, and the user assumes all risks and liability whatsoever in

connection therewith.

The manufacturer reserves the right to improve or modify this

product without prior notice.

Sold and serviced by:

Table of contents