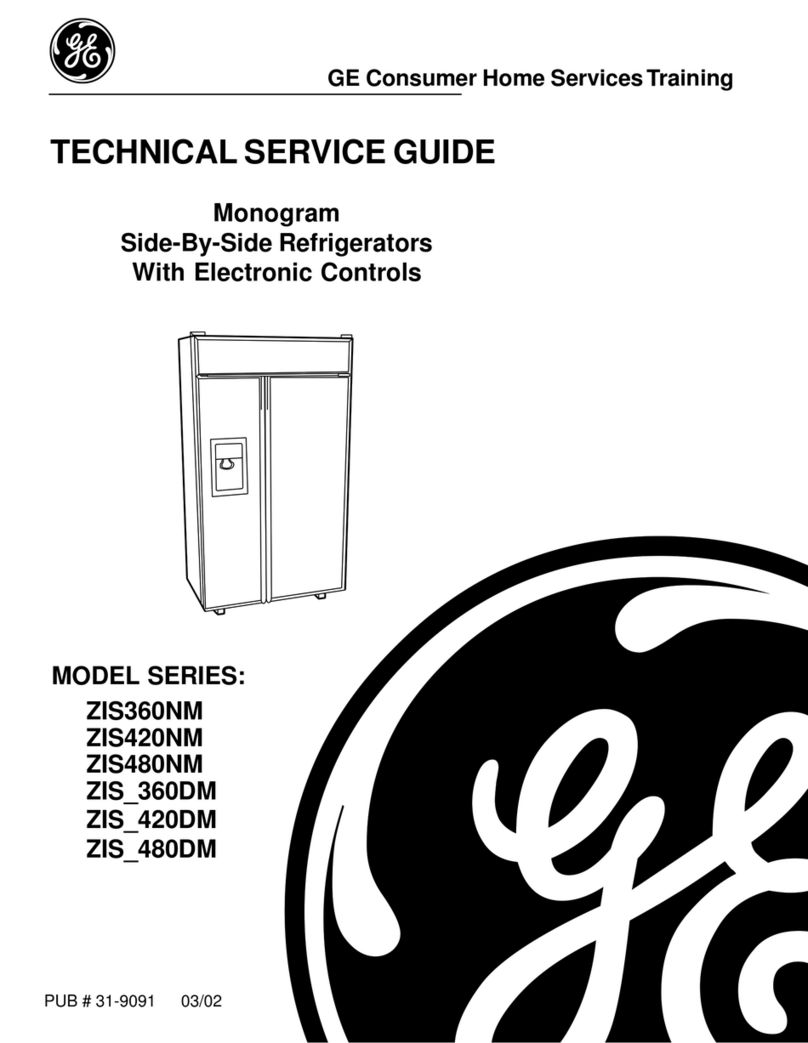

1997 REFRIGERATORS GLOBAL NEW GENERATION

SxS

© General Electric Company 1997 5

(CB): CODE BOARD

(V): VOLTAGE/THERMAL

RATING PLATE

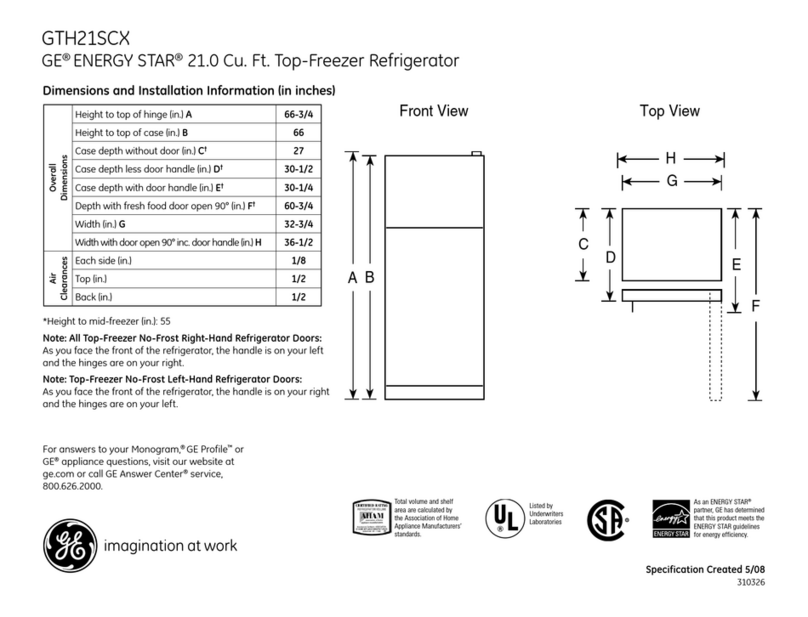

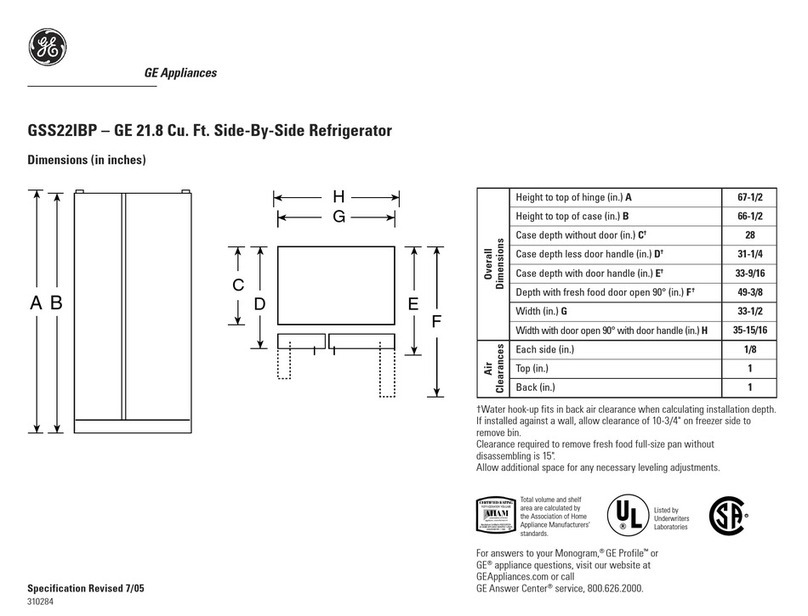

The rating plate is located at the top of the

fresh food liner, near the right front corner.

In addition to the refrigerator model and

serial numbers, the rating plate specifies the

minimum installation clearances; the electrical

voltage, frequency, and amperage ratings; and the

refrigerant type and charge quantity.

The model and serial numbers of the refrigerator

are also located on a bar-code label at the rear of

the cabinet.

KOREAN RATING PLATE (K-Line only)

The Korean rating plate is located on the right-

hand side of the outer cabinet. It shows KIAA

approval #, model #, total volume, fresh food

volume, freezer volume, motor input watts, defrost

heater watts and manufacture date (year/month).

ISO RATING PLATE

The ISO rating plate is located to the right of the traditional rating plate on the upper side of the fresh

food liner. Besides the model #, voltage, amperage, input watts, installation clearances, and refrigerant

charge, it contains unique information such as gross volume, freezing capacity, fresh food net volume,

freezer net volume, and frozen food storage area net volume. There is also a class designator which

identifies the ambient test condition range for its given ISO rating. On Korean models, the logos,

symbols or numbers for the international regulatory agencies/code boards that have approved the model

are shown.

KOREAN ENERGY LABEL (K-Line only)

The Korean energy label is located near the top of the outer fresh food door. It contains information

necessitated by two laws-- the Energy Consumption Control Law (upper half of label) and the Electric

Appliance Safety Control Law (lower half of label). The upper area has numbers ranging from 5 to 1,

where the lower the number, the better the energy rating. The lower half of the label specifies model

number, approval number, volume capacity, and monthly energy consumption.

MINI-MANUAL™

The Mini-Manual is located behind the base grille, at the left side, near the front of the machine

compartment. A plastic pin fastener is used to secure the Mini-Manual during shipping. Accordingly,