DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT - RECONNECT ALL GRO NDING DEVICES

All parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, clips, nuts or washers used to

complete a path to ground are removed for service,

they must be returned to their original position and

properly fastened.

ELECTRICAL SPECIFICATIONS

Temperature Control (Position 5 ......................... 7-(-11 °F

Defrost Control .......................................... 60hrs @ 45 min

w/ no door openings

Overtemperature Thermostat .............................. 140-110°F

Defrost Thermistor ........................................................ 70°F

Electrical Rating: 115V AC 60 Hz ......................... 11.6 Amp

Maximum Current Leakage ................................... 0.75 mA

Maximum Ground Path Resistance .................. 0.14 Ohms

Energy Consumption . ..................................... 51 KWH/mo

NO LOAD PERFORMANCE

Control Position MID/MID

and Ambient of: ...............................................70°F90°F

Fresh Food, °F ................................................ 34-40 34-40

Frozen Food, °F .............................................. (-3 3 (-3 3

Run Time, % ...................................................... <80 <100

REFRIGERATION SYSTEM

Refrigerant Charge (R134a ............................... 6.0 ounces

Compressor ....................................................833 BTU/hr @

3000 RPM

Minimum Compressor Capacity ......................... 22 inches

Minimum Equalized Pressure

@ 70°F ....................................................................... 45 PSIG

@ 90°F ....................................................................... 57 PSIG

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation of

this information, nor can it assume any liability in

connection with its use.

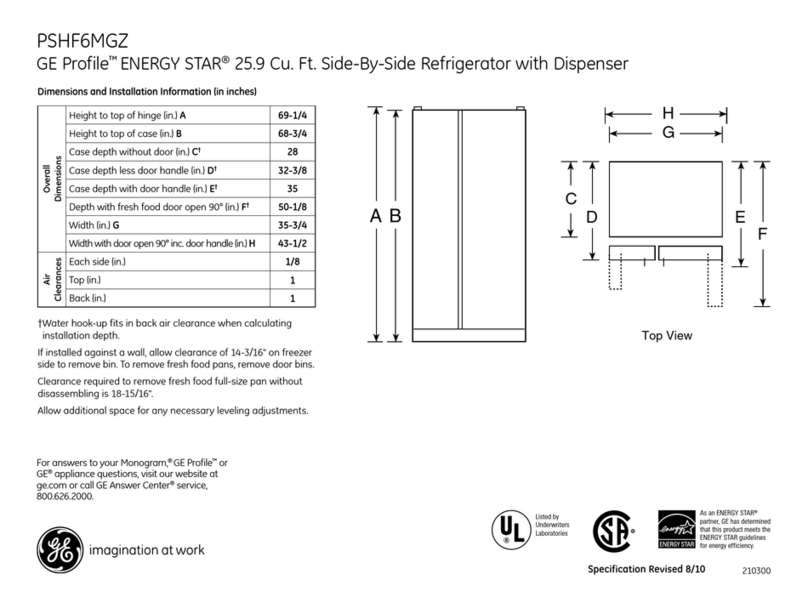

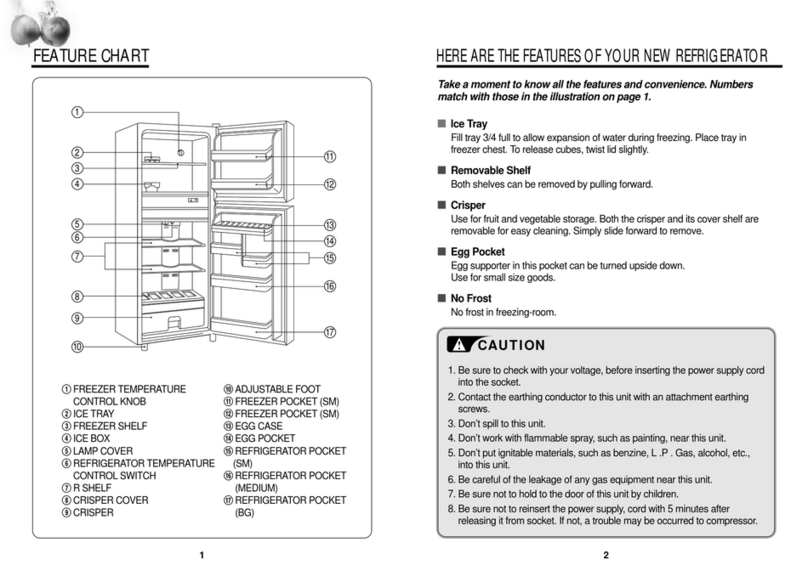

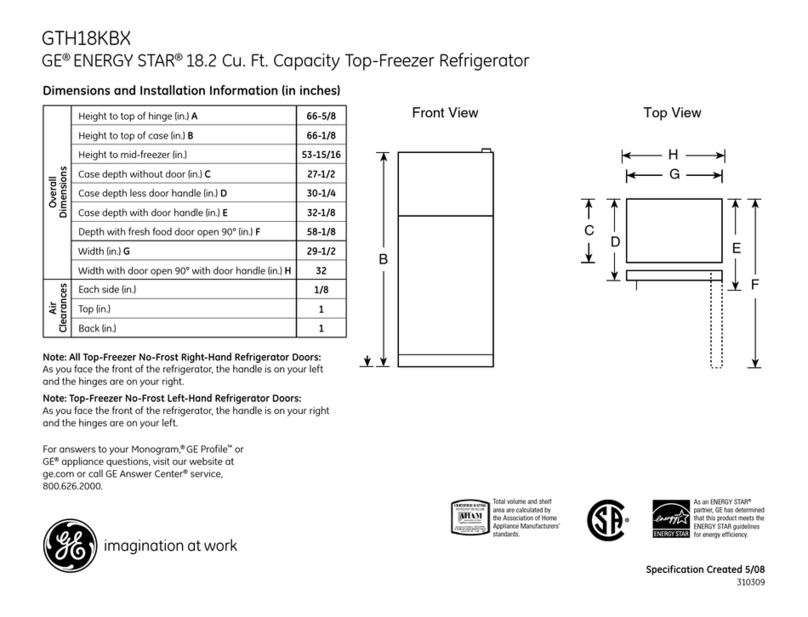

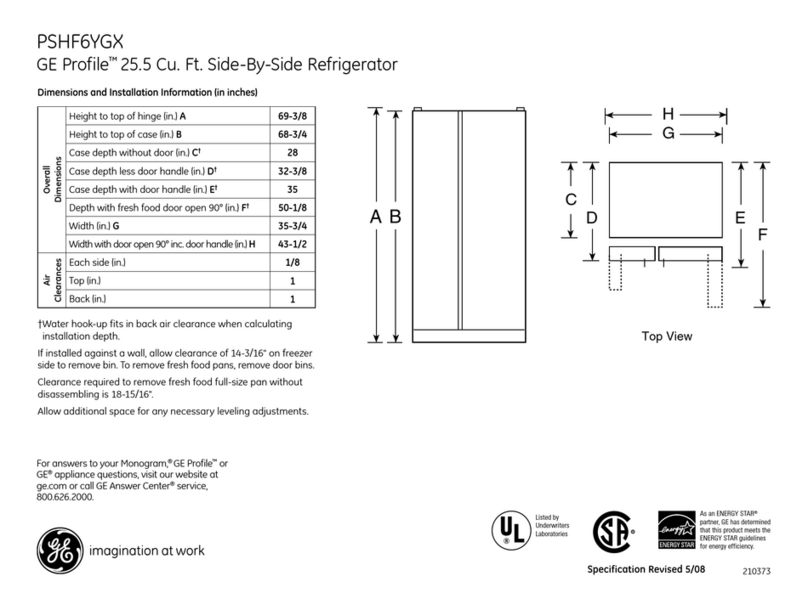

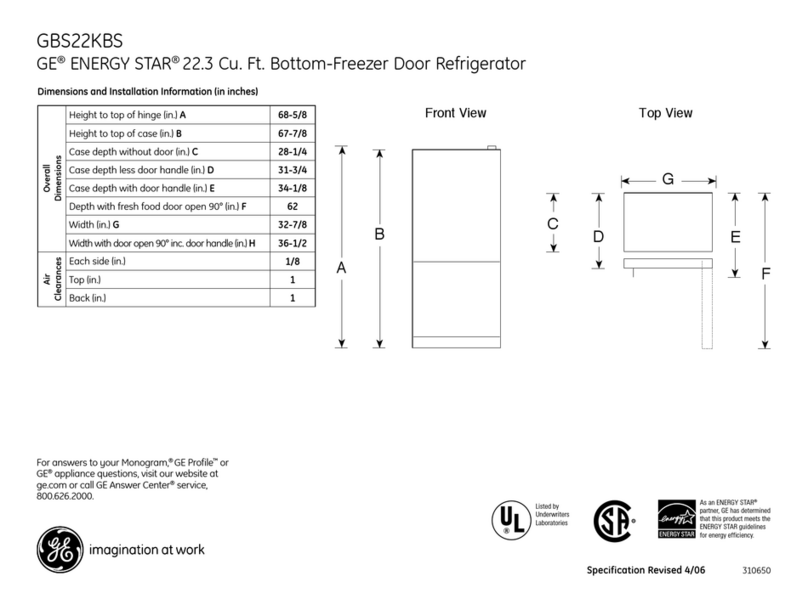

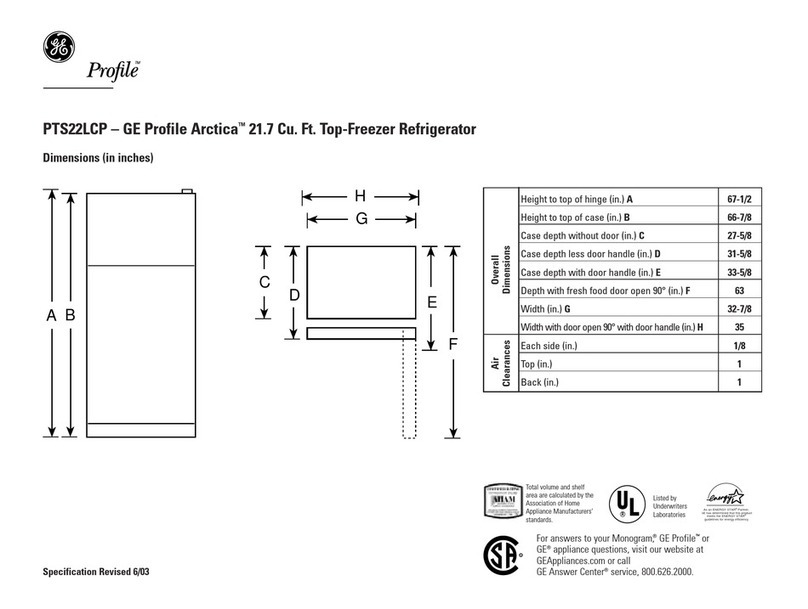

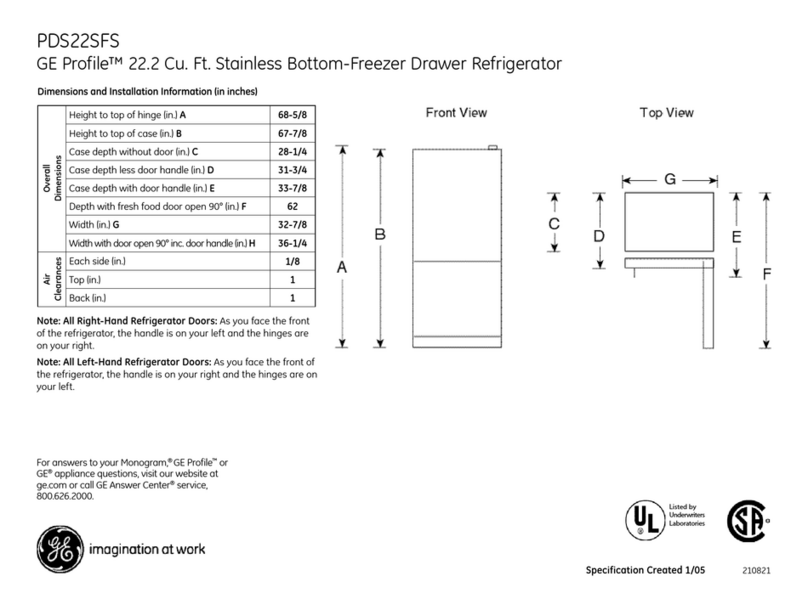

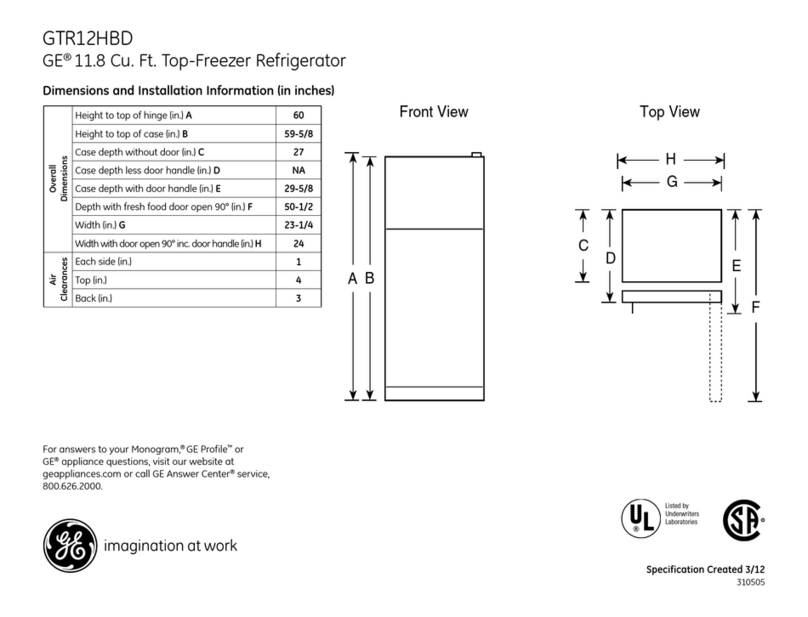

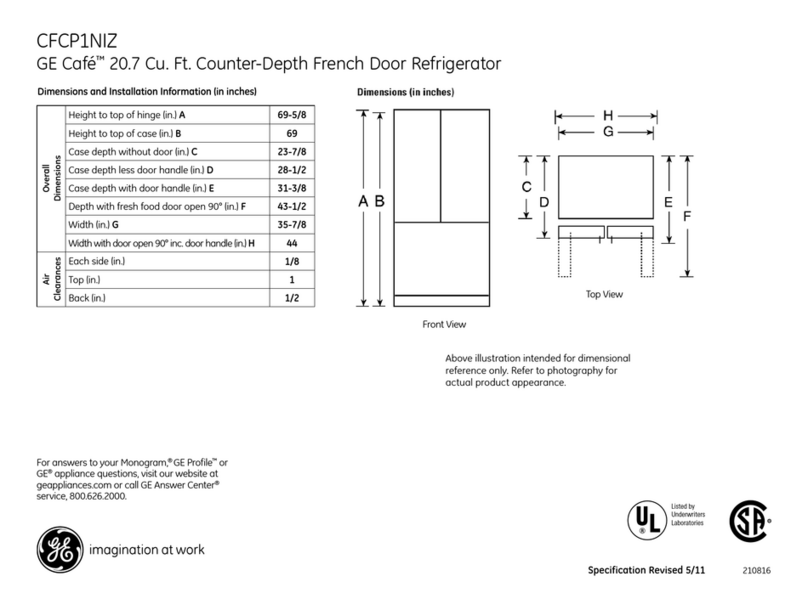

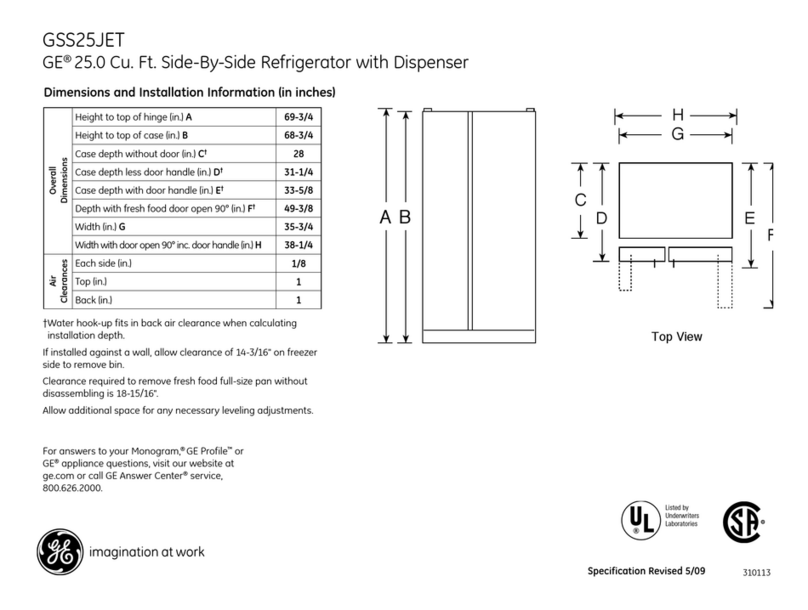

INSTALLATION

Minimum clearance required for air circulation:

TOP ............................................................................................. 1"

SIDES ................................................................................... 0.125"

REAR ........................................................................................ 0.5"

REPLACEMENT PARTS

Temperature Control ...................................... WR55x10023

Inverter ............................................................. WR55x10155

Overtemperature Thermostat ........................ WR50x10015

Defrost Heater Harness & Thermostat ......... WR23x10142

Defrost Heater & Bracket ............................... WR51x10030

Condenser Fan Motor ..................................... WR60x10042

Evaporator Fan Motor .................................... WR60x10043

Main Board ...................................................... WR55x10156

Dispenser Board.............................................. WR55x10029

Thermistor (EV ............................................... WR55x10025

Thermistor (FZ ............................................... WR55x10026

Thermistor (FF ................................................ WR55x10027

Thermistor (FF ................................................ WR55x10028

Thermistor (CC ............................................... WR55x10030

Compressor ..................................................... WR87x10064

FF Fan Motor ................................................... WR60x10051

Damper ............................................................ WR60x10052

AIR FLOW