– 3 –

3. Conrm consumer is using the correct amount

of HE detergent. Refer to HE detergent package

label for correct detergent amounts for partial

and full loads. Less HE detergent is required

for soft/softened water and/or partial loads.

Conrm clothes loads of similar fabrics and

reasonable size. A reasonable load size is up

to one full laundry basket (about 16 lb of dry

clothes). Some loads cause more vibration (rugs,

towels, jeans, etc.) than others. For example,

washing only a few towels alone can cause an

unbalanced load because they soak up water

and concentrate weight in only one part of the

basket.

Note: The following diagnosis steps apply

to all units (both pedestal and nonpedestal

installations).

4. Four on the oor - ensure the unit is level and

all four leveling legs are properly adjusted and

securely on the oor. The objective is for each

of the four legs to carry equal weight; four on

the oor. As little as 1/4 or 1/2 turn on a single

leveling leg can be signicant. A helpful quick

check is to place your left hand on the top left

front corner and your right hand on the top

right rear corner. Then, push the washer in the

direction of your hands and note force required

to remove the weight from the front leg. Now,

reverse hands, i.e., right in top right front corner

and left in top left rear corner, and note the force

required to remove weight from the front leg.

The two forces should be equal.

5. With basket empty of clothes and water, run the

T14 test and check for acceptable vibration or

movement. To run T14, press the Power button

to clear any current cycles. (The display must be

blank to proceed.) Press the Extra Rinse button,

press the Delay Start button, press the Extra

Rinse button again, then press the Delay Start

button again. When congure UI comes up on

the display, rotate the Cycle Select knob until

T14 is displayed, then press the Start button.

Note the test does not rebalance the load. Press

Power to quickly end the test for an extreme

out-of-balance condition. Once the unit reaches

410 rpm, press the Start button again, the

washer will then ramp up to 1050 rpm. Pressing

Start again ramps up to 1150. Press Start again

and the washer ramps to 1300 rpm.

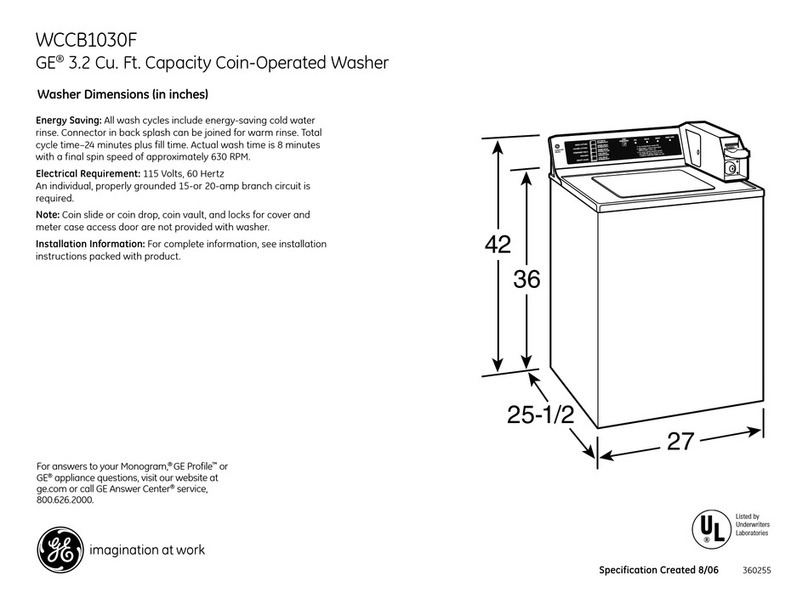

4. Ensure rear legs are level and rear jam nuts

are wrench tight against washer or pedestal

bottom (see picture below). Next, run T14 Spin

Test and adjust front legs for minimum vibration

or movement at ~ 400 rpm. Secure the front

jam nuts wrench-tight and run Spin Test again

to conrm legs are set properly for minimum

vibration or

movement while washer is spinning

at 400 rpm.

Press on the washer top left front

corner toward the top right rear corner with

your hands and note if there is any increased

vibration. Then, press on top right front corner

toward the top left rear corner with your hands

and note if there is any increased vibration.

If pressing either corner decreases/lessens

vibration or movement, the legs are still out of

adjustment and must be corrected. If pressing

either corner increases/worsens

vibration or

movement, the legs are properly set.

6. Exit Diagnostic Mode, open door, and place 1

or 2 dry, tightly rolled up, bath towels in basket

and tape in place to a bafe inside against the

basket, centered front to back (see picture). The

weight of the towel(s) should be about 1-1.5 lb;

do not exceed 2 lb. This test simulates an out of

balance load to make checks and adjustments

minimizing vibration and movement.

Note: Up to 1/4-inch movement is normal

operation. If okay, proceed to step B. If not okay,

adjust legs and/or check for a machine structural or

mechanical fault (see next Section).