© ATL Agricultural Technology Limited: July 2018

Innovation In and Out of Parlour

Index

Manual Version........................................................................................................... 4

About the Auto Wash Pro............................................................................................... 5

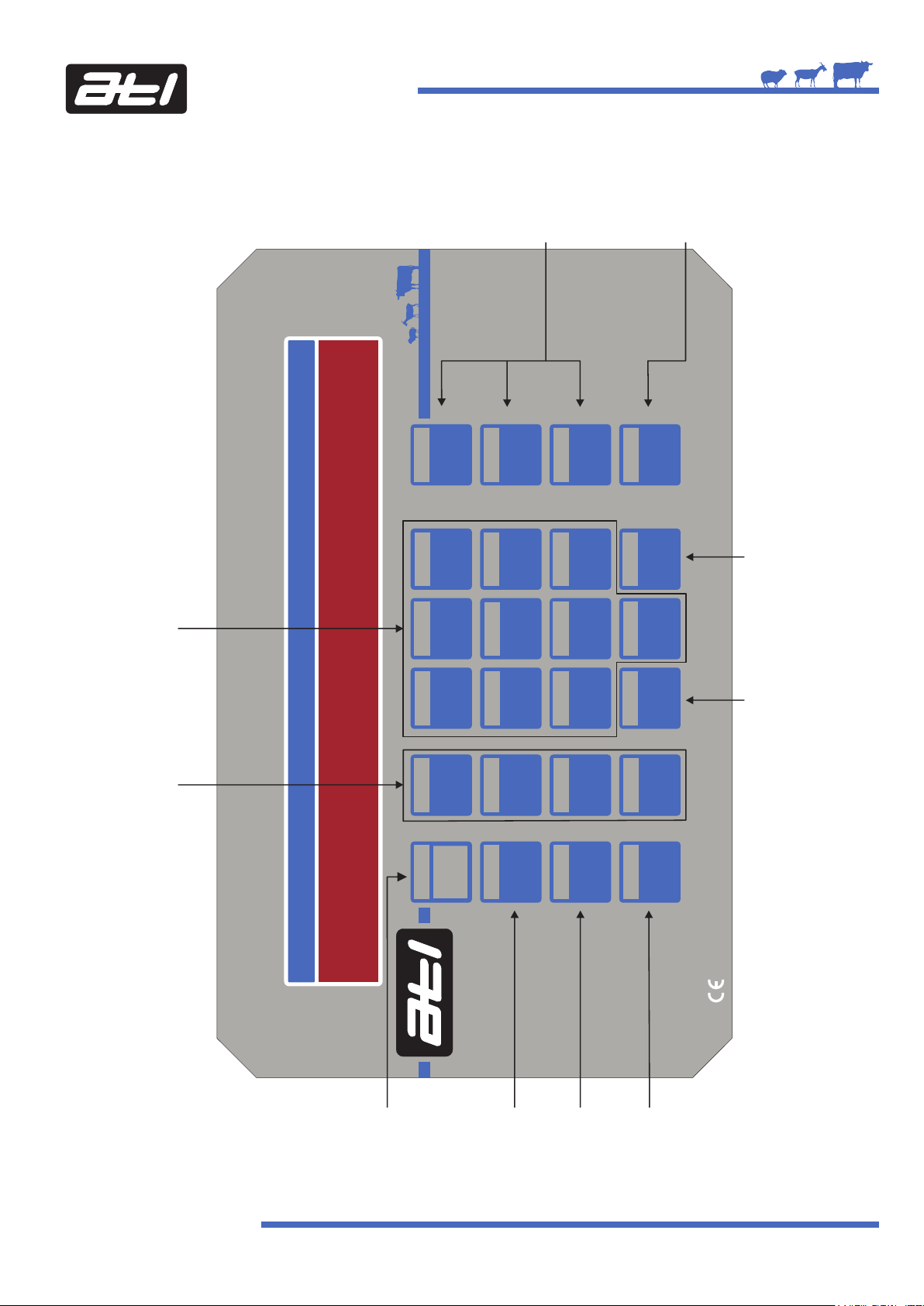

The Auto Wash Pro Front Panel........................................................................................ 6

Installing the Auto Wash Pro........................................................................................... 7

Good Practice During the Installation............................................................................... 8

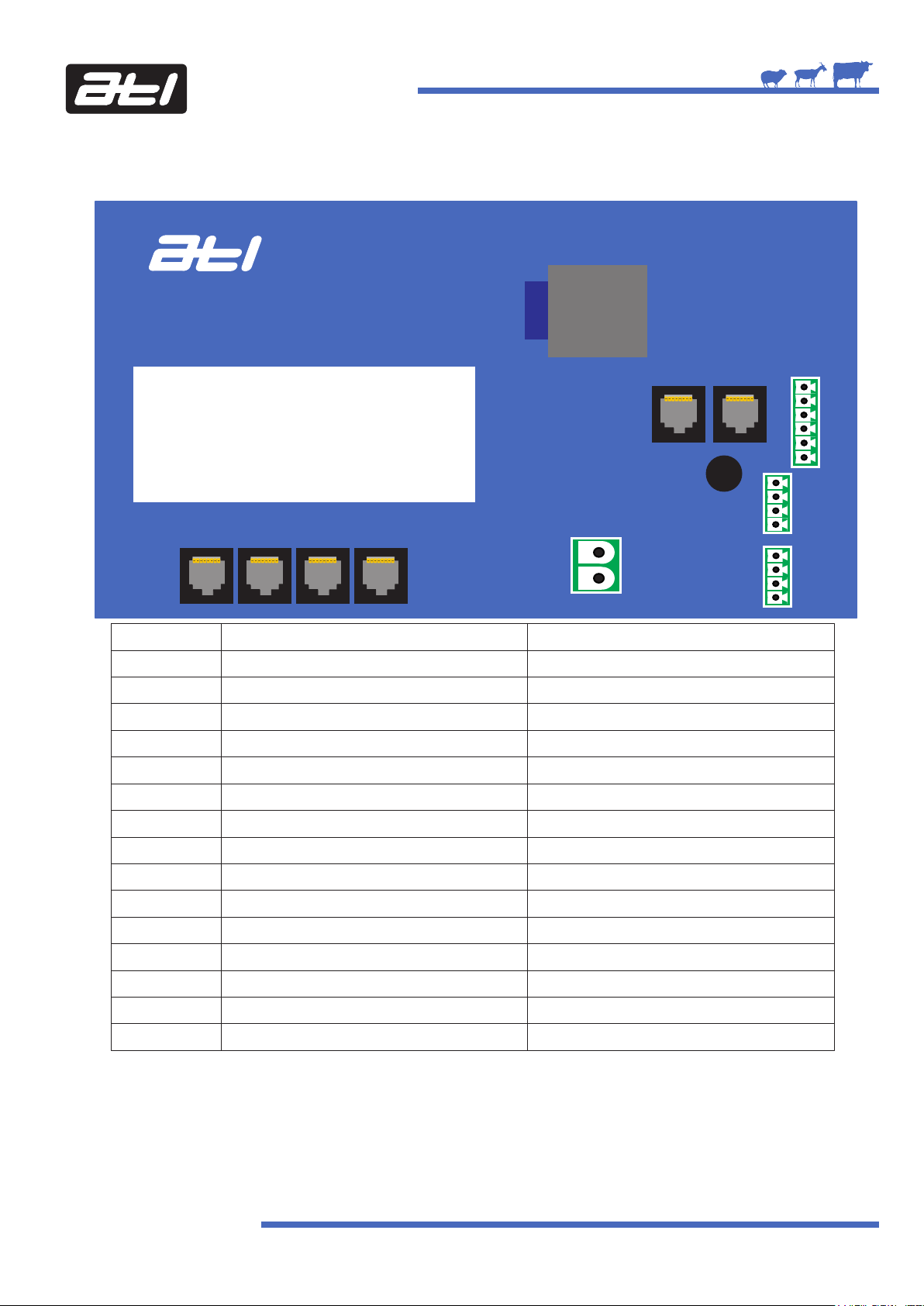

Auto Wash Pro Control PCB Wiring Connections................................................................. 9

Auto Wash Pro Input/Output PCB Wiring Connections......................................................... 10

Auto Wash Pump Box 2500 Connections ......................................................................... 14

Auto Wash Pump Box 2500 PCB Connections................................................................... 15

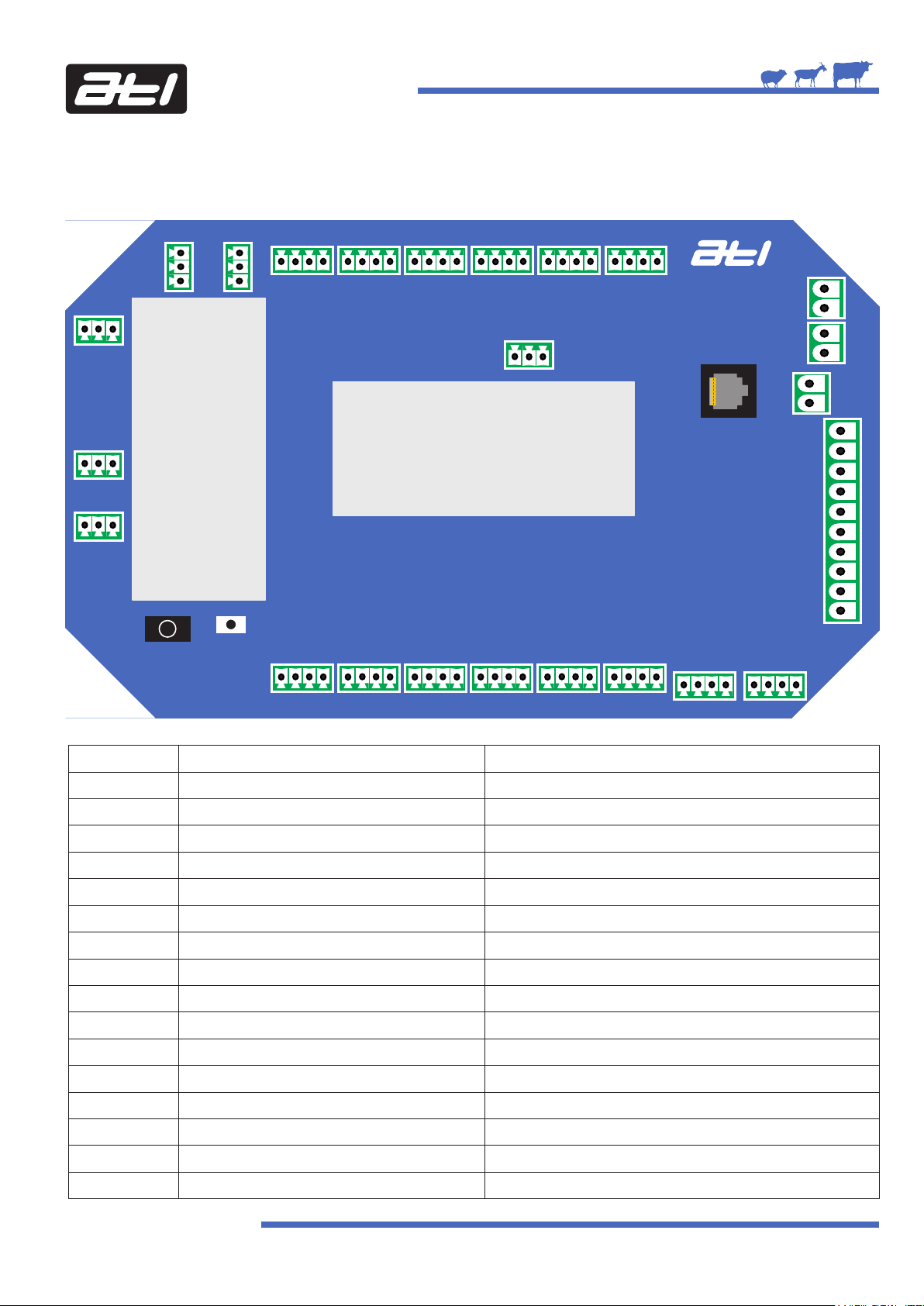

Auto Wash Pro Layout Diagram..................................................................................... 17

Connecting the Auto Wash Pro to Contactor Switched Vacuum Pumps.................................. 18

Connecting the Auto Wash Pro to Variable Speed Vacuum Pumps......................................... 20

Setting Up the Auto Wash Pro.......................................................................................... 21

The Keypad................................................................................................................. 21

The Display................................................................................................................. 22

Entering Setup............................................................................................................ 22

Entering the Access Code.............................................................................................. 22

Navigating Through Menu Items.................................................................................... 22

The Settings Menu Structure......................................................................................... 23

The Key Buzzer Setting................................................................................................. 25

Setting the Time.......................................................................................................... 26

Setting the Date.......................................................................................................... 27

Editing Programs - See Page 45...................................................................................... 29

Editing Tasks - See Page 49............................................................................................ 29

Setting the Conductivity Difference................................................................................. 29

Setting the Vacuum Low Warning Level............................................................................ 30

Setting the Milking Vacuum Level.................................................................................... 30

Setting the Washing Vacuum Level.................................................................................. 31

Setting the Vacuum High Warning Level........................................................................... 31

Setting the Vacuum Pump Type...................................................................................... 32

Setting the Wash Trough Lock Out................................................................................... 32

Setting the Milk Tank Lock Out........................................................................................ 32

Calibration the Peristaltic Pumps - See Page 53.................................................................. 33

2 | Auto Wash Pro Manual | v1.2