1

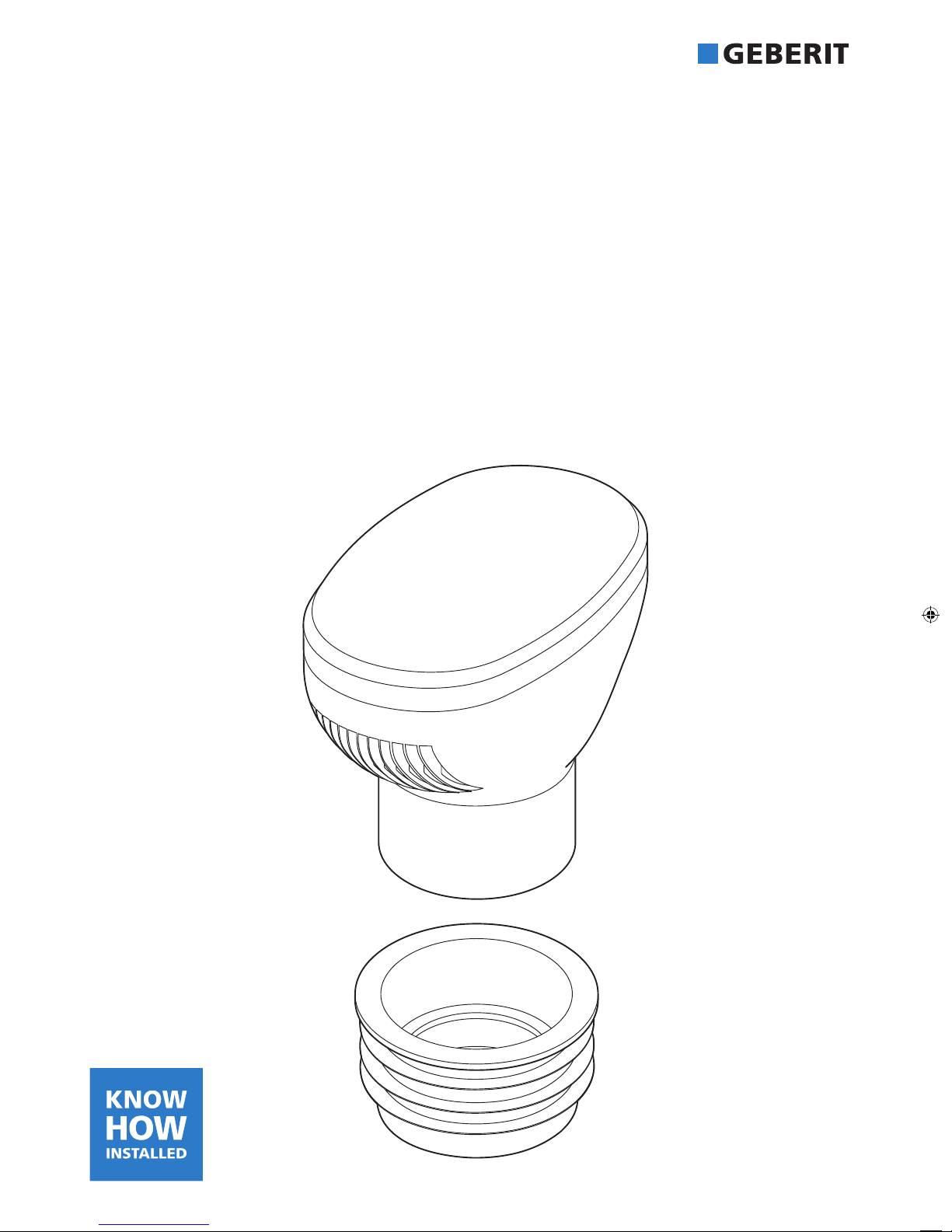

Geberit Drainage Systems

Introduction

BBA British Board of Agrément

Geberit HDPE pipes and fittings have been certified by

many European authorities and in 1976 also received

BBA certification.

European Quality Certificate IS0 9001.2000. For its

manufacturing plants in Europe Geberit has received the

highest quality system available, issued by theSwiss

EQ-Netmember SQS for compliance with the ISO 9000/

EN 29000 series. EQ-Net members are in all countries

throughout Europe, includingBSI QA United Kingdom.

DIN Standards Geberit conforms to:

•EN1519: Plastics piping systems for solid waste and

discharge (low and high temperature) within the building

structure. Polyethylene (PE)

•DIN 19535-10: High density polyethylene (PE-HD)

pipes and fittings for hot-water resistant waste and

soil discharge systems (HT) inside buildings-Part

10: Fire behaviour, quality control and installation

recommendations.

•DIN EN 12666-1: Plastic piping systems for

non-pressureunderground drainage and sewerage

systems. Polyethylene (PE).

Introduction

Geberit HDPE is the total solution for all types of drainage

including above ground, below ground and chemical waste.

It provides the appropriate solution for every requirement

whether it is conventionally installed or prefabricated.

Geberit Silent-db20 gives all the benefits of HDPE with

increased levels of sound proofing which is achieved by its

patented high density material. The ribbed fittings and

acoustic brackets further improve sound dampening near

impact zones.

This guide has been designed to assist you and provide

technical support for all your Geberit HDPE and Geberit

Silent-db20 installation needs. Geberit Silent-db20 has

specific requirements that should be considered when

planning and installing.

We hoped to haveincluded all your needs but should you

need further assistance please contact our Technical

Services department on 0800 077 8365.

Standards and Approvals