GEM KMG Series Manual

90027360rev00

Technical service

INSTALLATION AND

MAINTENANCE MANUAL

COMBINATION OVEN

WITH DIRECT STEAM AND

WITH STEAM GENERATOR

EN

KMG .... / KME .... / FSC...

KVG .... / KVE ....

GGM .... / GEM ....

GGV .... / GEV ....

CVE .... / CVG ....

CEV .... / FCC ....

4 x GN 2/3 (042)

5 x GN 1/1 (051)

6 x GN 1/1 (061)

7 x GN 1/1 (071 - T07)

8 x GN 1/1 (081)

7 x GN 2/1 (072)

10 x GN 1/1 (101 - T10)

10 x GN 2/1 (102 - T20 - A20)

14 x GN 2/1 (142)

20 x GN 1/1 (201 - T21)

20 x GN 2/1 (202 - T40)

The reproduction or copying of any part of this manual by any means

whatsoever is strictly forbidden unless authorized previously in writing by

the manufacturer.

- ORIGINAL INSTRUCTIONS -

Page

1 •GENERALREMINDERS 3

2 •TECHNICALDATA 4

3 •SPECIALREQUIREMENTSFORTHEINSTALLATIONSITE 7

4 •STATUTORYREQUIREMENTS,TECHNICALREGULATIONSANDDIRECTIVES 8

5 •POSITIONING 8

6 •ELECTRICALCONNECTIONSANDEQUIPOTENTIALBONDING 10

7 •POINTSTOREMEMBERWHENMAKINGTHEELECTRICALCONNECTION 11

8 •WATERANDDRAINCONNECTIONS 12

9 •CALOUT 14

10•VENTS 16

11•GASCONNECTIONPROCEDURES 16

12•OPERATINGATTHERATEDHEATOUTPUT 18

13•COMMISSIONINGANDTESTING 25

14•IMPORTANTINFORMATIONFORTHEUSER 26

15•INSTALLATIONDIAGRAMS 27

2

CONTENTS

M - Standardelectromechanicaldeviceswithmanualcontrols,humidifierandlighting.

S-Programmableelectronicswithdirectaccesskeytotheprogramsandrecipes,automatichumidity

control and lighting.

X-Touch-screendisplay,scrollerwith“push”function,programmablewithautomatichumiditycontrol,

twinspeed,multipointcoreprobe,lightingandfittedshowerunit.

(Automatic washing system on request)

The manufacturer accepts no liability for any inaccuracies in this manual

attributabletoprintingorcopyingerrors.Wereservetherighttomodify

ourproductsaswedeemfit,withoutimpairingtheirbasicfeatures.

VERSIONS

90027360rev00

CAPACITY

MODELS

3

1.1 •Theovenmustbeinstalled,commissioned

and maintained only by an authorized

serviceagent.

1.2 •Carefully read the directions given in this

manual; they contain important information

on safety during installation, operation and

maintenance.

Keepthismanualinasafeplaceforfuture

consultation!

1.3 •This appliance must be put only to the

use for which it is specifically intended,

i.e. cooking foods; any other type of use is

improper and therefore dangerous.

1.4 •Havingremovedthepackingcheckthatthe

applianceisnotdamagedinanyway.

Ifindoubt,proceednofurtherwithinstallation

of the appliance and contact the Customer

Service or your dealer immediately.

1.5 •Packing materials arepotentiallydangerous

and must not be left where children can

play with them.

1.6 •Packing materials must be disposed of

in conformity with local regulations. This

normally means that the different materials

are sorted according to type and collected as

urban refuse.

1.7 •Before positioning and connecting the

appliance, check that the utilities (electrical

power, water and gas supplies) are as

indicatedonthedataplate.

The data plate is on the right-hand side, at

the bottom.

1.8 •Example of a data plate:

1.9 •The positions of the inlet and drain

connections are clearly labelled. For further

details,seetheinstallationdiagramattached

to this manual.

1.10 •Intheeventofbreakdownorfaultyoperation,

switchofftheovenimmediately!

1.11 •During installation and/or maintenance work it

is recommended you wear gloves to protect

your hands.

1.12 •Safety sticker

•Maximum height for inserting containers with

liquids.

ATTENTION:toavoidscalding,donotuse

thecontainersfilledwithliquidorfoodwhich,

throughcookingbecomefluid,atlevels

higher than those which can be observed.

1•GENERALREMINDERS

90027360rev00

0085

2008

EN 203/A1 AC 230V 50Hz

IT

IPX 5

G 25 / m3/h

Qn 40 kW

Cat.

II 2H3+

NR XXXXXXXXXX

kPa

200 - 500

P mbar

20; 28-30/37

TOT 1 kW1 x 0.55 kW

G 20 / m3/h

G 30 3.16 Kg/h

Pmax / mbar Pmax / mbar

Pmin / mbar Pmin / mbar Pmin / mbar

A3 B13 B23

2008

3N AC 400V 50Hz

IPX 5

NR XXXXXXXXXX

kPa

200 - 500

TOT 8 kW1 x 0.25 kW

TYP. XXXXXXXX

TYP. XXXXXXXX

LOGO

LOGO

1600 mm (63 inch)

2•TECHNICALDATA

4

90027360rev00

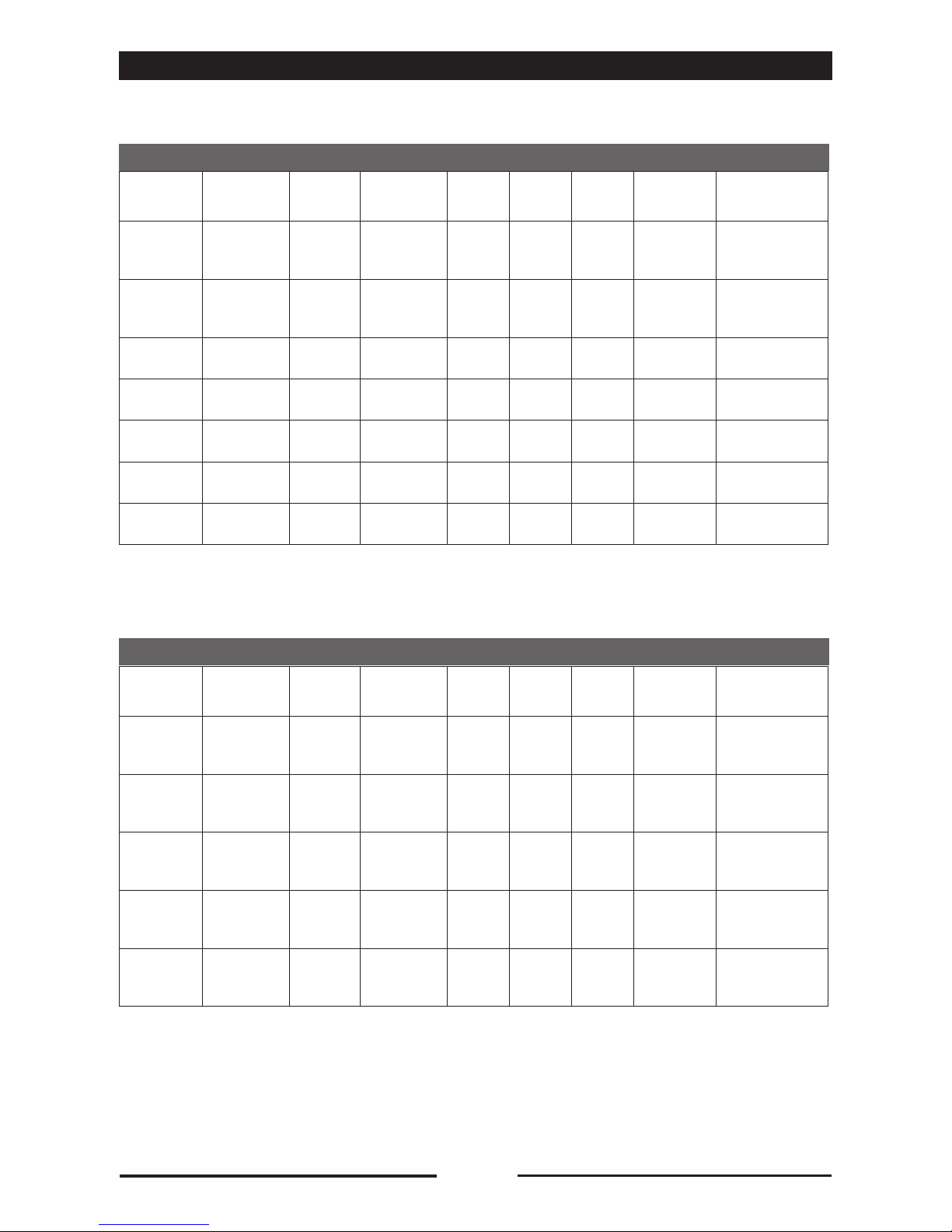

TABLE 1: GENERAL DATA - ELECTRIC OVENS

MODELS KME .... - KVE .... - GEM .... - GEV....

MODELS CVE .... - CEV ....

Model Supply

voltage Frequency Total power

imput Amps Chamber

power

Boiler

power Motor

Oil-proof connection

cable ( * )

6 x GN 1/1

3N AC 400 V

3 AC 230 V

AC 230 V

50 Hz 8,25 kW

12

20

36

8 kW 6 kW 1 x 0,2 kW

5 x 1,5 mm2

4 x 2,5 mm2

3 x 6 mm2

7 x GN 1/1

8 x GN 1/1

3N AC 400 V

3 AC 230 V

AC 230 V

50 Hz 10,5 kW

15

25

46

10 kW 7,5 kW 1 x 0,37 kW

5 x 1,5 mm2

4 x 2,5 mm2

3 x 10 mm2

10 x GN 1/1 3N AC 400 V

3 AC 230 V 50 Hz 16 kW 23

40 15 kW 15 kW 1 x 0,55 kW 5 x 2,5 mm2

4 x 6 mm2

7 x GN 2/1 3N AC 400 V

3 AC 230 V 50 Hz 19 kW 31

53 18 kW 15 kW 1 x 0,55 kW 5 x 4 mm2

4 x 10 mm2

10 x GN 2/1 3N AC 400 V

3 AC 230 V 50 Hz 31 kW 45

78 30 kW 30 kW 1 x 0,55 kW 5 x 10 mm2

4 x 25 mm2

20 x GN 1/1 3N AC 400 V

3 AC 230 V 50 Hz 31,8 kW 46

80 30 kW 30 kW 2 x 0,55 kW 5 x 10 mm2

4 x 25 mm2

20 x GN 2/1 3N AC 400 V

3 AC 230 V 50 Hz 61,8 kW 89

155 60 kW 60 kW 2 x 0,55 kW 5 x 25 mm2

2x (4 x 25 mm2)

Caution: The residual current device to be installed between the mains and the appliance

must be sized for a leakage of 1 mA x kW of power installed.

Model Supply

voltage Frequency Total power

imput Amps Chamber

power

Boiler

power Motor

Oil-proof connection

cable ( * )

4 x GN 2/3

3N AC 400 V

3 AC 230 V

AC 230 V

50 Hz 3,4 kW

5

8

14

3,15 kW - 1 x 0,2 kW

5 x 1 mm2

4 x 1 mm2

3 x 1,5 mm2

5 x GN 1/1

3N AC 400 V

3 AC 230 V

AC 230 V

50 Hz 6,25 kW

10

18

32

6 kW - 1 x 0,2 kW

5 x 1,5 mm2

4 x 2,5 mm2

3 x 4 mm2

6 x GN 2/3

3N AC 400 V

3 AC 230 V

AC 230 V

50 Hz 5,25 kW

8

13

23

5 kW - 1 x 0,2 kW

5 x 1 mm2

4 x 1,5 mm2

3 x 4 mm2

6 x GN 1/1

3N AC 400 V

3 AC 230 V

AC 230 V

50 Hz 7,75 kW

11

19

34

7,5 kW - 1 x 0,2 kW

5 x 1,5 mm2

4 x 2,5 mm2

3 x 6 mm2

10 x GN 1/1 3N AC 400 V

3 AC 230 V 50 Hz 15,5 kW 22

39 15 kW - 2 x 0,2 kW 5 x 2,5 mm2

4 x 6 mm2

Caution: The residual current device to be installed between the mains and the appliance

must be sized for a leakage of 1 mA x kW of power installed.

( * ) Flexible cable underneath sheath resistant to oil with designation 60245-IEC-57

5

2•TECHNICALDATA

90027360rev00

TABLE 2: GENERAL DATA GAS OVENS

Model Supply

voltage Frequency Imput Motor

Oil-proof

connection cable

( * )

Gas power

w/boiler

Gas power

w/o boiler

Gas

connection

5 x GN 1/1

6 x GN 1/1 AC 230 V 50 Hz 0,25 kW 1 x 0,2 kW 3 x 1 mm2- 8,5 kW 1 x R 1/2”

7 x GN 1/1

8 x GN 1/1 AC 230 V 50 Hz 0,5 kW 1 x 0,37 kW 3 x 1 mm215 kW 12 kW 1 x R 1/2”

10 x GN 1/1 AC 230 V 50 Hz 1 kW 1 x 0,55 kW 3 x 1 mm228 kW 18 kW 1 x R 1/2”

7 x GN 2/1 AC 230 V 50 Hz 1 kW 1 x 0,55 kW 3 x 1 mm230 kW 20 kW 1 x R 1/2”

10 x GN 2/1 AC 230 V 50 Hz 1 kW 1 x 0,55 kW 3 x 1 mm240 kW 27 kW 1 x R 1/2”

20 x GN 1/1 AC 230 V 50 Hz 1,8 kW 2 x 0,55 kW 3 x 1,5 mm248 kW 36 kW 1 x R 3/4”

20 x GN 2/1 AC 230 V 50 Hz 1,8 kW 2 x 0,55 kW 3 x 1,5 mm280 kW 54 kW 1 x R 3/4”

Caution: The residual current device to be installed between the mains and the appliance

must be sized for a leakage of 1 mA x kW of power installed.

( * ) Flexible cable underneath sheath resistant to oil with designation 60245-IEC-57

6

2•TECHNICALDATA

90027360rev00

TABLE 3: GENERAL WATER DATA

TABLE 4: FLUE GAS EXTRACTION DATA (TYPE B13)

(1) The ovens are equipped with two water inlets, one for non-softened cold water and the other for hot water (max. 50 C) or softened cold water.

WITH STEAM GENERATOR

Model

Water

pressure

kPa

Softened

water

consumption

max. l/h

Water

connection

ELECTRIC

6 x GN 1/1 200 - 500 7 2 x R 3/4 (1)

7 x GN 1/1

8 x GN 1/1 200 - 500 10 2 x R 3/4 (1)

7 x GN 2/1

10 x GN 1/1 200 - 500 19 2 x R 3/4 (1)

10 x GN 2/1 200 - 500 30 2 x R 3/4 (1)

20 x GN 1/1 200 - 500 37 2 x R 3/4 (1)

20 x GN 2/1 200 - 500 68 2 x R 3/4 (1)

GAS

7 x GN 1/1

8 x GN 1/1 200 - 500 8 2 x R 3/4 (1)

7 x GN 2/1

10 x GN 1/1 200 - 500 17 2 x R 3/4 (1)

10 x GN 2/1 200 - 500 24 2 x R 3/4 (1)

20 x GN 1/1 200 - 500 24 2 x R 3/4 (1)

20 x GN 2/1 200 - 500 48 2 x R 3/4 (1)

WITHOUT STEAM GENERATOR

Model

Water

pressure

kPa

Softened

water

consumption

max. l/h

Water

connection

ELECTRIC

4 x GN 2/3 200 - 500 4 2 x R 3/4 (1)

6 x GN 2/3 200 - 500 8 2 x R 3/4 (1)

5 x GN 1/1

6 x GN 1/1 200 - 500 8 2 x R 3/4 (1)

2x

5 x GN 1/1 200 - 500 8 + 8 2 x R 3/4 (1)

7 x GN 1/1

8 x GN 1/1 200 - 500 8 2 x R 3/4 (1)

7 x GN 2/1

10 x GN 1/1 200 - 500 15 2 x R 3/4 (1)

10 x GN 2/1 200 - 500 15 2 x R 3/4 (1)

20 x GN 1/1 200 - 500 30 2 x R 3/4 (1)

20 x GN 2/1 200 - 500 30 2 x R 3/4 (1)

GAS

5 x GN 1/1

6 x GN 1/1 200 - 500 8 2 x R 3/4 (1)

7 x GN 1/1

8 x GN 1/1 200 - 500 15 2 x R 3/4 (1)

7 x GN 2/1

10 x GN 1/1 200 - 500 22 2 x R 3/4 (1)

10 x GN 2/1 200 - 500 22 2 x R 3/4 (1)

20 x GN 1/1 200 - 500 30 2 x R 3/4 (1)

20 x GN 2/1 200 - 500 44 2 x R 3/4 (1)

Models 7 x GN 1/1

8 x GN 1/1 10 x GN 1/1 10 x GN 2/1 20 x GN 1/1 20 x GN 2/1

Flue liner

pressure - 0,9 Pa - 1,8 Pa - 2,7 Pa - 2,2 Pa -

Volumetric

mass 18,6 g/sec. 28,4 g/sec. 34,5 g/sec. 39,9 g/sec. -

Flue gas

Temperature 145 °C 190 °C 250 °C 210 °C -

7

3.1 •The room where the oven is to be fitted has

to be well ventilated with all the openings

required for rooms with gas installations

(see specific regulations).

3.2 •In addition, it is good policy to locate the

appliance under an extractor hood so that

cooking vapours can be removed rapidly

and continuously.

3.3 •The room must have a flue gas extraction

stack (appliances with installation type

B13), or a suitable flue gas extraction

system fitted with all relevant safety

devices (appliances with installation type

B23). Further details are given under the

heading: “Gas connection procedures”.

Check with the appropriate agency whether

or not special authorization is required

for the emission of flue gases into the

atmosphere.

3.4 •Current CEI (Italian Electrotechnical

Committee) regulations require the

installation of a multiple pole switch

between the oven and the electrical power

supply; the switch must have a contact

gap of at least 3 mm on each pole.

3.5 •The oven needs two water supplies, one

of which need not be softened, but must

necessarily be cold (for condensing steam).

The other supply, serving the vaporizer,

must incorporate a softener with suitable

flow and pressure specifications (see

technical data and water connections

heading). A shutoff valve must be installed

on each of the water supply pipelines to

the appliance.

3.6 •The room must have a water drain in a

goodposition forthe ovento beinstalled,

its specifications are given under the

heading “Water and drain connections” in

this manual.

3.7 •The gas supply plumbing must be installed

in accordance with current regulations,

adopting pipe sections and pressures

suitable for the appliance (see technical

data and gas connections heading).

A fast acting shutoff valve must be installed

on the gas inlet line to the appliance. It is

absolutely essential that this valve should

be specified to current standards and type

test approved.

3.8 •The electrical isolating switch and the

water and gas shutoff valves must all be

located near to the appliance, within easy

reach for the user.

3•SPECIALREQUIREMENTSFORTHEINSTALLATIONSITE

90027360rev00

8

Throughout installation it is vital to observe

the following requirements:

4.1 •any health and hygiene standards

applicable to kitchens and eating places;

4.2 •local and/or territorial building regulations

and fire prevention standards;

4.3 •current accident prevention guidelines;

4.4 •CEI requirements relating to electrical

systems;

4.5 •UNI-CIG 8723 Standard “Gas systems for

appliances used in professional kitchens

andcommunalfacilities”;

4.5 •the regulations of the gas supply company

or agency;

4.7 •the regulations of the electrical power

supply company or agency;

4.8 •any other local regulations.

4•STATUTORYREQUIREMENTS,TECHNICALREGULATIONSANDDIRECTIVES

90027360rev00

5.1 •Topositiontheappliances,itisrecommended

to use the mount offered by the manufacturer;

shouldyouwanttodothingsdifferently,itis

necessary to take account of the weight of

the appliance.

5.2 •Before manoeuvring the oven into the

selectedposition,attachthewaterinlethoses

and waste pipe to the relative connection

points (refer to headings describing the water

and drain connections).

5.3 •The distances from other appliances or from

adjacent walls that must be left to allow

access for servicing operations will be found

on the installation diagram for the oven to

connect. In the event of the oven being

installeddirectlyagainstaninflammablewall,

suitable heat insulation must be provided.

Current fire regulations should be

meticulously observed and respected. Do not

obstruct the openings and slots in the casing

as they disperse the heat in the electric

component compartment.

Keep strictly to the installation diagrams.

5.4 •Oncetheapplianceisinstalled,theelectrical

power cable must be protected, and never

stretched or tugged.

5.5 •The appliance must be level: any difference

in level or sloping of the supporting surface

should be eliminated. Differences in level or

sloping negatively affect oven operation.

5•POSITIONING

9

90027360rev00

5•POSITIONING

5.6 •Removeallpackingmaterialsandpeelaway

the protective plastic film from all external

surfaces of the oven.

5.7 •

For free-standing models, the appliance needs

to be levelled: small differences in level of the

supporting surface can be eliminated with the

adjustable feet (by screwing or unscrewing

them). A significantly uneven or sloping stance

can affect the operation of the oven adversely.

For models equipped with a pan trolley,

it is necessary to pay special attention when

levelling.

5.8 •Liningupthepantrolleys20x1/1GNand

20x2/1GN.Ifthefloorisnotlevel,aremedy

must be found using an access rampwith a

maximum gradient of 4° (not included inthe

supply).

If there is an outlet grate in front of

theappliance,it isnecessary tofitrunners in

thepan trolley entry area.

OK

OK

201 - 202

X = 200 mm

Y = 300 mm

OK

OK

10

90027360rev00

6•ELECTRICALCONNECTIONSANDEQUIPOTENTIALBONDING

6.1 •

As this oven is a type X appliance (oven

without power cable and plug), the cable

and other hardware needed to make the

connection to the electrical power supply

must be provided by the installer. The cable

must satisfy the requirements indicated in

table 1 “General data”.Asalreadymentioned,

the oven must be connected to the power

supply by way of a multiple pole main isolating

switch ensuring a gap between open contacts

of at least 3 mm on each pole.

6.2 •

To gain access to the AC mains connection

terminal board, the right hand panel of the

casing must be removed by undoing the fixing

screws (all models).

6.3 •

The cable must be fed in from beneath the

clamp. The individual wires are then fastened

to the corresponding terminals of the terminal

board. The earth wire must be longer than the

otherwires,so that in theeventof the cable

being jerked or the clamp broken, the live

wires will disconnect first.

Check the efficiency of the isolating switch.

6.4 •

The oven must be kept in an equipotential

system. This connection is made by wiring a

conductor of nominal cross section 10 mm

2

to

the corresponding terminal at the back of the

oven,whichismarkedwiththeinternationally

recognized symbol.

All appliances in the room are bonded in this

way and connected to the earth system of the

building.

6.5 •

The electrical safety of this appliance can

be guaranteed only when it is connected

correctly to an efficient earth system, in

compliance with current standards.

11

90027360rev00

7.1 •As all ovens of the series are fitted with

an alternating fan motor (clockwise and

anticlockwise rotation), there is no need

for the fan to rotate in any particular

direction. Simply verify, when

commissioning the appliance, that

the fan is balanced and rotates freely.

Warning: the

20 x GN 1/1 and 20 x GN 2/1

models are equipped with two motors.

7.2 •When making the electrical connection

you need to take care that the neutral

pin of the terminal block corresponds to

the neutral wire of the supply line. If this

connection is not made correctly, the

burners will not be able to operate.

7.3 •This trouble is indicated:

On gasmodels mechanicalversion by the

burnerignitionresetbutton,whichislitup.

On gas models electronic version via the

electronic card.

7.4 •Check also that the neutral registers

zero potential when tested. If not, the

fault already described in point three of

this section will occur. In this eventuality,

consult the installer of the building’s

electrical system.

7•POINTSTOREMEMBERWHENMAKINGTHEELECTRICALCONNECTION

12

90027360rev00

8•WATERANDDRAINCONNECTIONS

8.1•WATERPRESSURE

The pressure of the water in the network

must be between 200 and 500 kPa,

as already stated under the heading

“Technical Data”. If the supply pressure is

higherthanthis,apressurereductionvalve

must be installed between the oven and

the main.

8.2• WATERCONNECTIONSTOTHE

BOILER (IF APPLICABLE) AND

VAPORIZER

The water supplied to the vaporizer must

be either cold and softened or hot (max

50 °C), as described below. The water

connection is R 3/4”. The hose for

connection to the water supply must be

provided by the installer. Do not re-use

pre-existing or already used connection

tubes. A shutoff valve must be installed on

the line between the oven and the supply.

8.3• WATERSPECIFICATIONS

The characteristics of the water must come

within the limits given below, in order to

preventbothcorrosion,whichisextremely

damaging for the appliance, due to

supplying water that is too softened or too

aggressive,andscalingin theovenandin

the water system in the case of supplying

water that is too hard.

Hardness: between6°and9°TH

PH: greaterthan7.5

Chlorides: lessthan30ppm

These values are important for ensuring that

the water used by the appliance is suitably

treated!

8.4•WATERCONNECTIONSFOR

CONDENSING STEAM

The water used for condensing steam need

not be softened, but must necessarily be

cold. The water connection is R 3/4”. The

hose for connection to the water supply

must be provided by the installer. Do

not re-use pre-existing or already used

connection tubes. A shutoff valve must be

installed on the line between the oven and

the supply.

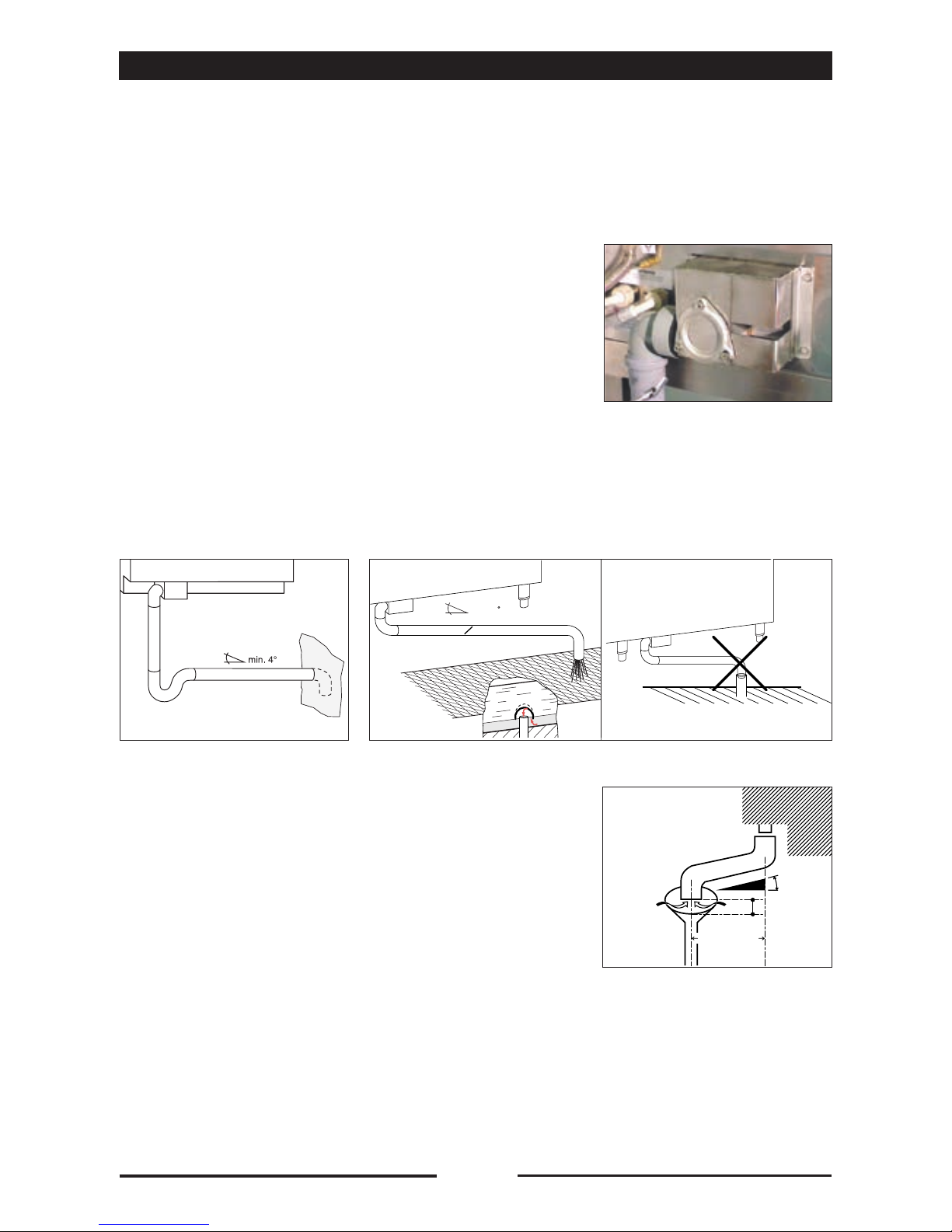

Fig.2 Fig.3

13

90027360rev00

8•WATERANDDRAINCONNECTIONS

Forthe range withthe drain asper fig.1 it is

possible to make a direct connection with an air

trap, without fitting a drain cup, as the drainage

manifoldsystemhasaninternalairdrop(Fig.2).

With a drain on the floor without an air trap it is

necessary to have an outlet clearance of 2 cm

(Fig.3).

For the remaining models it is imperative to

fit a drain cup to ensure a minimum air drop of

25 mm. between the appliance’s plastic drain

elbow and drain line. A direct connection is not

permissible.

8.5•DRAINING

The water is drained off by gravity through

a heat-resistant pipe DN 50 (not flexible),

maximumlength2m,installedatanangle

of no less than 4°.

Mean temperature of the drain water: 65 °C.

Fig.1

WARNING:

Thedrainlinemustbeoutsidetheperimeteroftheoven.

Itisprohibitedtoreducethedraindiameter.

Max. 200 cm

Min. 4

25 mm.

min. 4

O 50 mm / 1,9 inch

14

90027360rev00

9.1•THECALOUT

The CALOUTisacleaningsystem,which

keeps the steam generator free from

limescale and prevents the latter from

building up.

The CALOUT system is available AS

STANDARD for ovens equipped with

steam generator included in the HEART

range both Xand S versions.

The ovens equipped with CALOUT can be

directly connected to the water supply

withoutanyneedforawatersoftener,only

if water hardnessdoesnotexceed25°fH.

Forhardnessvaluesgreaterthan25°fH

itisrequiredtheinstallationof a water

softenerabletobringthembelow25°

fH.

Waterhardnessparameters

conversiontable

The CALOUT system efficiency is

guaranteed only if the anti-limescale and

non toxic“Calfree” product provided by

the producer is used.

WARNING: No other anti-limescale product

can be used to replace the“Calfree”

provided by the producer.

The CALOUT system allows for periodic

cleaning of the steam generator through

a specific program to be initiated by

the user when signalled by the oven

warning (see the oven user manual).

WARNING: FAILURE TO COMPLY

WITH THE CALOUT USAGE TIMES

MAY AFFECT THE OPERATION

AND INTEGRITY OF THE STEAM

GENERATOR (inthiscasethesteam

generatorrepairorreplacementwillnot

behonouredaswarranty).

9•CALOUT

°fH

(°tH)

°dH °eH

(Clark°)

ppm

(mg/lt)

gr/gal

(US)

1°fH

(°tH) 10,56 0,7 10 0,6

1°dH 1,79 11,25 17,9 1,07

1°eH

(Clark°) 1,43 0,8 114,28 0,86

1ppm

(mg/lt) 0,1 0,06 0,07 10,06

1gr/gal

(US) 1,71 0,96 1,2 17,15 1

15

90027360rev00

9.2•INSTALLINGOVENSWITHCALOUT

DEVICE

•Placethetankoftheanti-limescale

“Calfree” with the GREEN cap (supplied

with the oven) on the right side of the oven.

•InsertthelittlehosewiththeGREEN

cap that comes with the oven and is

marked with the CALOUT label(seethe

connectionontherightsideoftheoven)

until it touches the bottom of the tank and

close the cap tightly.

ONLYUSETHE“CF010-CALFREE”

PRODUCT SUPPLIED BY THE

PRODUCER.

NEVER USE GENERIC ANTI-LIMESCALE

OR DESCALING PRODUCTS.

USING ANY OTHER PRODUCTS

VOIDS THE WARRANTY ON CALOUT

SYSTEM COMPONENTS AND STEAM

GENERATOR.

IMPORTANT:

The manufacturer to avoid connection

errors and tank exchange or confusion has

provided the following features:

•Thecapofthetankcontainingtheanti-

limescale product “Calfree” for the oven

CALOUT system is GREEN coloured.

•Thecapofthetankcontainingthealkaline

detergent “Combiclean” (intended for the

washing system) for the oven is YELLOW

coloured.

Inanycase,thetankscontainingthe

anti-limescale“Calfree”andthe

“Combiclean”detergentaremarked

withlabelsbearingproductsname,

specificationsandinstructionsforuse.

9•CALOUT

CALFREE

Anti-limescale,non-

toxic product for the

prevention of limescale

deposits in the steam

generator tank

CF 010

10 lt.

CALFREE

11.1 • GAS CONNECTION

The section of the gas supply pipe must be

chosen according to the type of gas and

the consumption of the appliance to be

connected. The system must be designed

and installed in accordance with current

regulations. The gas connection on

the oven is R 1/2” or R 3/4”, and this

sectionmustneverbereduced.

A fast acting shutoff valve must be installed

on the gas inlet line to the oven. The valve

must be type test approved in accordance

with current regulations.

The connection to the gas main can be

permanent or detachable; if flexible metal

tube is used, this should be made of a

stainless and corrosion resistant material

(rubber hose is not recommended).

If when making the connection you use any

sealing materials, they must be type test

approved for this purpose.

11.2•LEAKTEST

All connections between the mains and

the appliance must be tested for leakage.

The recommended method is to use a

proprietaryleakdetectionspray;alternatively,

a non-corrosive foamy liquid of any general

description can simply be brushed onto

the fittings: whichever method is used, no

bubbles should appear.

Never under any circumstances test for

gasleakswithanakedflame!

11.3•EXHAUSTINGFLUEGASES

Modelwith5,6and7pansGN1/1

Since this appliance due to its capacity has

installation type A3, it is not necessary to

connect it to a stack for extracting the flue

gases. The flue gases can be exhausted into

the installation room. It is especially important

tohavegood,continuousventilation!

Remainingmodels

As these ovens have a power rating of

>14 kW, type B installation is required. The

installer must select one of the methods

described below, according to the design

of the building and of the room where the

appliance is sited. The diameter of the flue

pipes must be as indicated in the installation

diagrams.

Warning:

fluegasesmayreachtemperaturesof400

°C!

Fumesmustneverbeductedawayutilizing

anextractionsystem!

Clear the gas supply system of any

machining debris before connecting the

oven!

11•GASCONNECTIONPROCEDURES

16

90027360rev00

10.1 •Under no circumstances must vents A

and B be shut, blocked or ducted into

otherpipes.

A - Vent to extract vapours from the oven

B - Safety vent

10•VENTS

AB

17

90027360rev00

11•GASCONNECTIONPROCEDURES

Afterinstallation,theinstallermustupdatethedataplatebytickingthebox,correspondingtothe

typeofinstallationmade,withanindeliblemarkerpen.

The manufacturer accepts no liability for any damage or malfunctioning of the appliance

attributable to the absence or inadequacy of earthing systems, to the incorrect arrangement or

installation of auxiliary systems, also to incorrectly made connections or to non-compliance of

thebuilding’selectricalsystemwithcurrentregulations.

InstallationtypeB23

Flue gases are exhausted mechanically through a

suction hood with a heat-resistant filter or a ducted

ceiling, without a damper being fitted, and

eitherconveyed into a stack or released directly to

the atmosphere together with other fumes extracted

from the room. Leave a suitable distance between

the oven’s smoke outlet and the hood filter or the top

intake.

Where extraction systems are selected for type

B23installations,thesemustbeproperlysizedand

specified with at least one interlock device that will

shut off the gas supply to the oven automatically

in the event of the extractor system failing to

operate.

InstallationtypeB13

Extraction with natural draught fitted with a

damper and a heat-resistant pipe (see “Flue

gas temperatures” in Table 4 under the heading

“Technical Data”) connected to the stack. Selecting

this type of installation the oven must be fitted with

a damper that is specific for each oven (as shown in

the drawing). If the oven is equipped with an adaptor

collarforstandardsizefluepipes,fittheadaptor.

Never under any circumstances must flue gases be

ducted away directly utilizing a mechanical extraction

system.

Stack connection

pipe

Adaptor

Damper

Hood filter

Suction hood

Ducted

ceiling

18

12.1 •All appliances, during final testing in the

factory, are fitted for the type of gas shown

on the sticker next to the data plate. Should

the appliance fitting not correspond to the

family of gases available on location, the

appliance must be converted to adapt to

the type of gas available. If conversion is

necessary, then you must inform Customer

Service and refer to the technical manual.

12.2 •Commissioning of the appliance to operate

at the rated heat output is dependent on the

inlet pressure and calorific value of the gas

and the correct amount of primary air.

12.3• The inlet pressure required for the appliance

to operate with the various types of gas

typically available will be within the limits

indicated in table 6 of the “Tecnical gas data”

booklet.

Theappliancemust notbecommissioned

if inlet pressure values are outside these

limits. If pressures differ from those indicated

in Table 6, the gas supply company or

agency should be contacted, or alternatively

the contractor by which the system was

installed in the building.

12.4•The lower calorific value of the gas can be

checkedwiththesupplycompanyoragency,

and should comply with the information given

in table 5 of the “Tecnical gas data” booklet.

12.5•MEASURINGTHEINLETPRESSURE

The inlet pressure is measured using a

manometer connected to the pressure tap (3)

of the gas adjustment valve. To gain access

tothevalve,theright-handsidecasingpanel

has to be removed.

Before connecting the manometer it is

necessary to loosen the screw sealing the

pressure tap (3). You then measure the

pressure with the burner in operation. The

value shown on the manometer must come

within the limits given in table 6 “of the

“Tecnical gas data” booklet.

Afterchecking,carefullyclosethescrew(3).

The sealed screws you can see on the valves

must never be tampered with under any

circumstances.

Tampering immediately invalidates

warranty!

12•OPERATINGATTHERATEDHEATOUTPUT

90027360rev00

Warning!

Thegassystemcomponentsarefittedforamaximumpressureof

65mbar.Higherworkingpressuresarenotpermissible.

12•OPERATINGATTHERATEDHEATOUTPUT

CHECKING NOMINAL HEAT CAPACITY

M VERSION

-ChamberBurner

Check the depth of the screw “A” in

accordance with table 5

of the “Tecnical gas

data” booklet,

using a gauge.

Shift the J3 jumper in TEST position - see

picture

Checkthattheburnerfanspeed,corresponds

to the data given in table 5 of the “Technical

gasdata”booklet.

Set 180 °C convection cooking at low speed

(whereapplicable),otherwiseatnormalspeed.

Checkthespeedatposition“IGN”,withtheJ3

jumper in TEST position.

After testing, shift the J3 jumper in the initial

NORM position.

Check the speed on position “MIN”.

Set the normal speed and check the speed at

position “MAX”.

Check the combustion, CO (ppm) and CO2

(%)values,withanappropriateinstrument:

Start the oven working, 180 °C convection

mode, open the door and activate the micro-

door with a magnet fixed with tape, the oven

restarts and wait for approximately 5 minutes.

Position the flue gas collection probe in the

flue gas outlet pipe (chamber and boiler).

The CO2must be for:

Naturalgas between9%and10.5%

L.P.G. between9%and13%

The CO must be no greater than 300 ppm

(measured).

Carry out the test in both convection and

steam mode.

If these readings are outside the ranges,

proceed as stated in the technical manual.

For the conversion from natural gas to LPG,

or vice versa, proceed as described in the

technical manual.

Readingin:

D-E=Hz(0-200Hz)

D-F=VDC (0-6 VDC)

-BoilerBurner

Repeattheseoperations,setting100°Csteam

cooking.

19

90027360rev00

Conversion:Asmentionedabove,everyapplianceisfactorysettoburnthetypeofgasspecified,

itmaybecomenecessarynonethelesstoconverttheappliancefromonetypeofgastoanother.

Therefore,onlypersonnelauthorizedbythecompanyandbelongingtothetechnicalservicewho

havethecorrespondingtechnicalhandbookcandothiswork.

A

3

MAX

IGN

MIN

J3

EFD

20

90027360rev00

CHECKING NOMINAL HEAT CAPACITY

S VERSION

- ChamberBurner

Check the depth of the screw “A” in

accordance with table 5

of the “Tecnical gas

data” booklet,

using a gauge.

Checkthattheburnerfanspeed,corresponds

to the data given in table5ofthe“Technical

gasdata”booklet.

To enter the management screen of the burner to

check:

Withtheapplianceliveanddisplayoff,press

button 1, thedisplay2shows [USb], turnknob3

until [rEL]isdisplayed,presstheknobtoconfirm

the selection

Turn knob 3to set the password for parameter

modification and confirm by pressing knob 3.

12•OPERATINGATTHERATEDHEATOUTPUT

1

2

3

5

4

A

3

This manual suits for next models

12

Table of contents