INTRODUCTION

Thank you for purchasing a GENERAL PUMP Pressure

Washer Pump. With proper installation and maintenance

it will provide you with many years of dependable,

trouble-free service.

This manual was developed as a basic guide to

understanding the operation and requirements,

installation, and servicing of GENERAL PUMP positive

displacement pumps.

Pressure cleaning equipment is potentially hazardous

and could cause personal injury or property damage if

installed, repaired, or operated in an unsafe manner, or in

a manner which is not consistent with the manufacturer’s

recommendations or requirements.

There are many manufacturers of pressure washer

pumps and complementary components. Be sure that the

required components you choose to use are consistent

with the high quality standards of GENERAL PUMP

pumps.

GENERAL PUMP does not assume liability or

responsibility for the design of a customer’s high

pressure system.

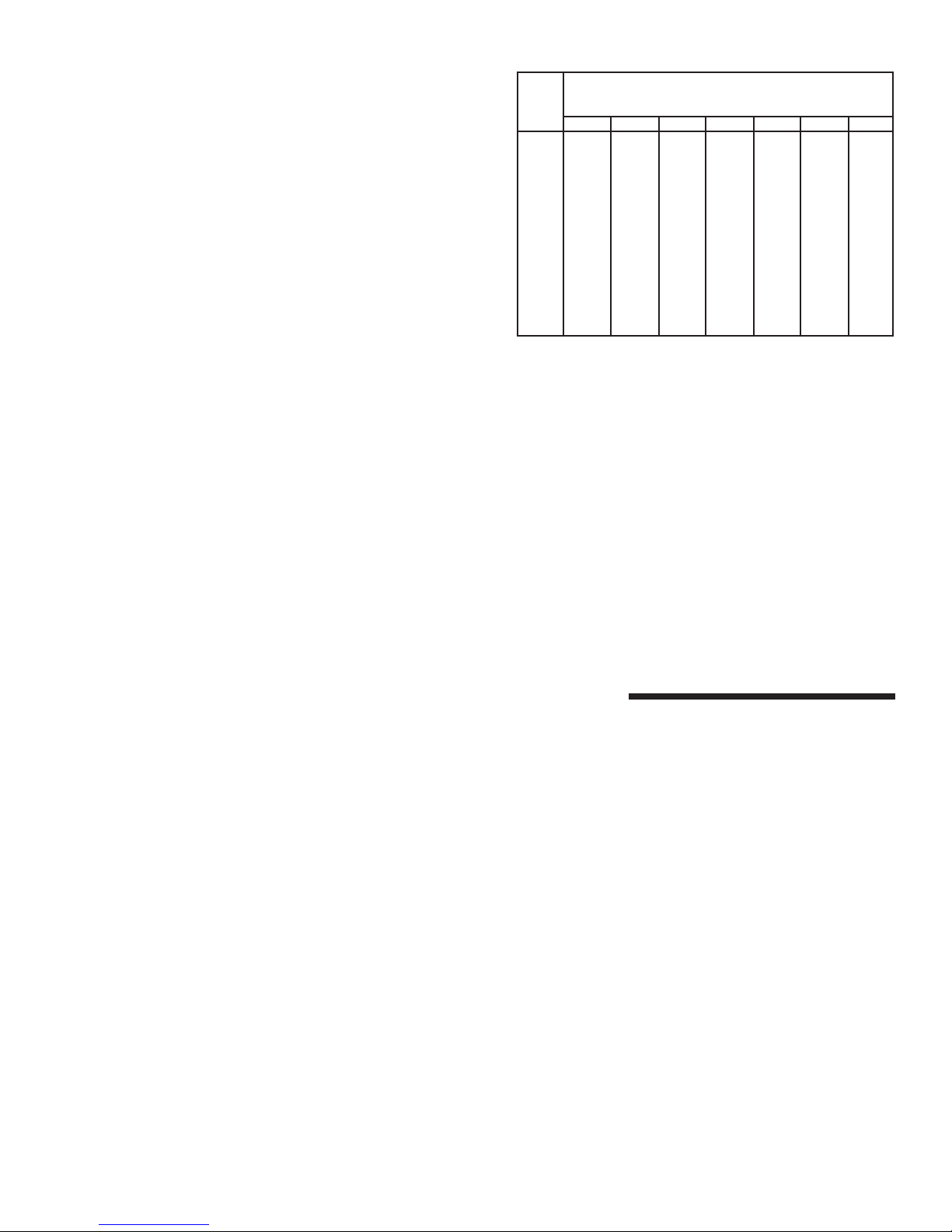

TYPICAL OPERATION AND

REQUIREMENTS

PRESSURE

The pressure produced in a pressure washer

system is the result of forcing a known volume

(or flow) of water through a known size orifice

(spray tip). Pressure is measured in pounds per

square inch (PSI).

FLOW

The flow or volume produced in a pressure washer

system is determined by the speed that the pump

shaft is rotated (RPM). The faster the shaft is

rotated, the higher the output volume. Flow or

volume is measured in gallons per minute (GPM).

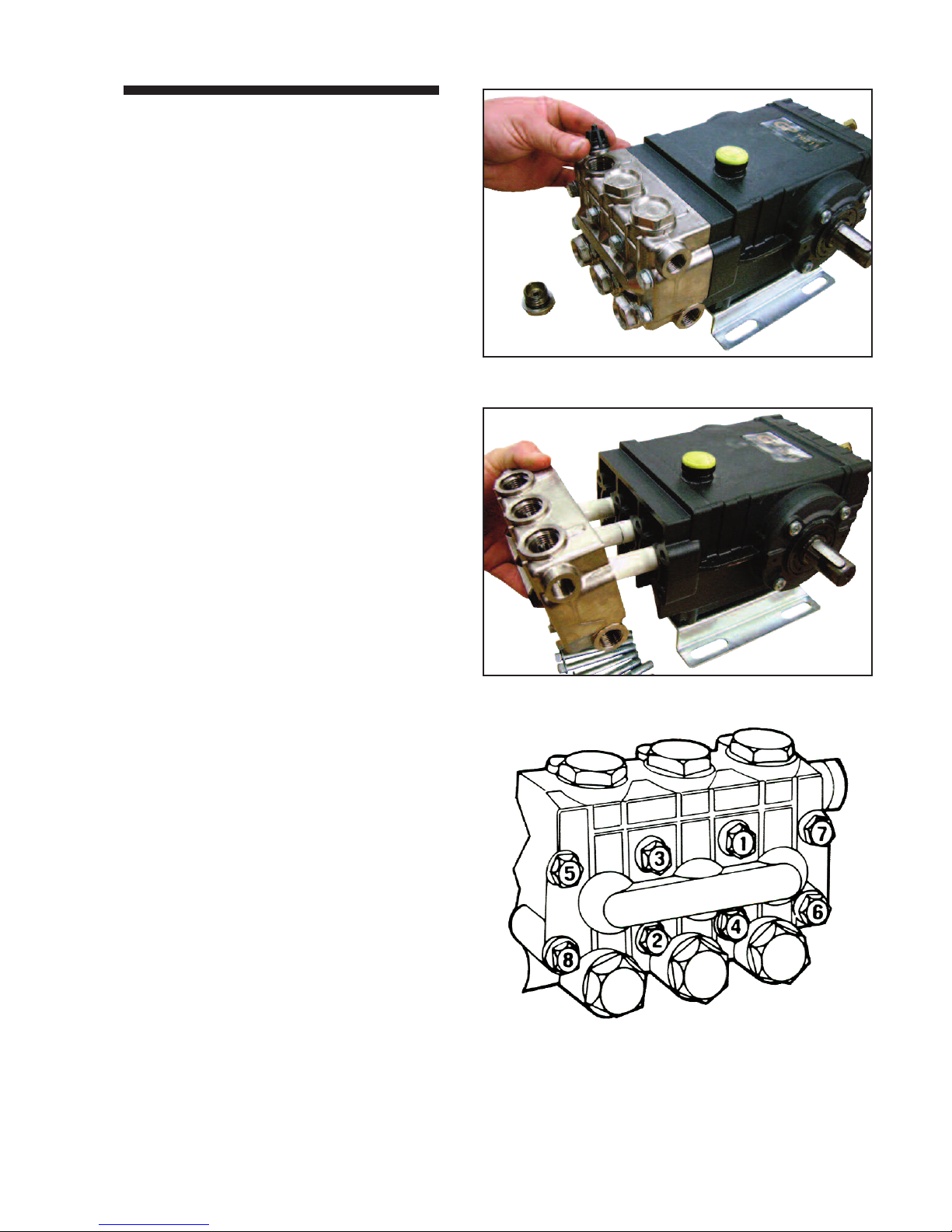

The pump, which is driven by an electric motor or a gas

engine, draws or accepts filtered water in through a se-

ries of inlet check valves as the plungers move back. As

the plungers move forward, the inlet valves close, forcing

the water to travel through a series of outlet check valves,

and to the outbound side of the pump.

After the water exits the pump, its flow direction must be

controlled with an unloading or regulating valve. A

positive displacement pump is always delivering a

certain volume of water whether the spray gun is open

or closed, therefore a device is needed to control the di-

rection of flow, either allowing the flow to go through the

open spray gun, or redirecting (by-passing) the flow back to

the inbound side of the pump when the spray gun is closed.

Without an unloading or regulating valve, dangerously high

pressures will be produced when the spray gun is closed

because the water being forced out of the pump has no

place to go. Serious bodily injury or property damage could

be caused by failure to properly utilize an appropriate un-

loader or regulator valve in your pressure washer system.

As a safety device, at least one pressure relief valve should

be installed in the outbound side of the pump to guard

against failure of component parts, and the development of

dangerously high pressures.

Cleaning chemicals or detergents may be introduced into

the flow of water either inbound or outbound of the pump.

An inbound or upstream type of chemical injector simply

uses the pump’s ability to draw or suck fluid in to introduce

a chemical into the stream of water. Care must be taken to

avoid introducing any chemicals which are not compatible

with the materials in the pump and downstream compo-

nents. An upstream injector does allow chemicals to be ap-

plied to the work surface at the normal high working

pressure of the system. An outbound or downstream type of

chemical injector uses a venturi (very similar to that used in

an automotive carburetor) to draw a chemical into the water

stream. A downstream injector requires low pressure to ac-

tivate chemical flow. Low pressure is achieved by chang-

ing to a large sized spray tip, or opening up a large orifice

at the outlet end of the spray gun using an adjustable noz-

zle or a double lance. There are several advantages to

using a downstream injector over using an upstream type.

1. Fewer component parts are exposed to the cleaning

chemicals, extending system life.

2. The operator can control the flow of chemical (on and

off) by changing the system pressure at the nozzle.

3. Applying chemical at low pressure is more

economical because less chemical bounces off the

work surface.

eated pressure washers and steam cleaners increase

the ability of a high pressure flow of water to break down

dirt and grease. They also increase the action of most

cleaning chemicals. These systems are very comples,

and add more potential personal injury and property

damage hazards. Design of these systems requires many

more additional components as well as experienced de-

sign personnel with knowledge of fuels, heat transfers,

electronics, etc.

2