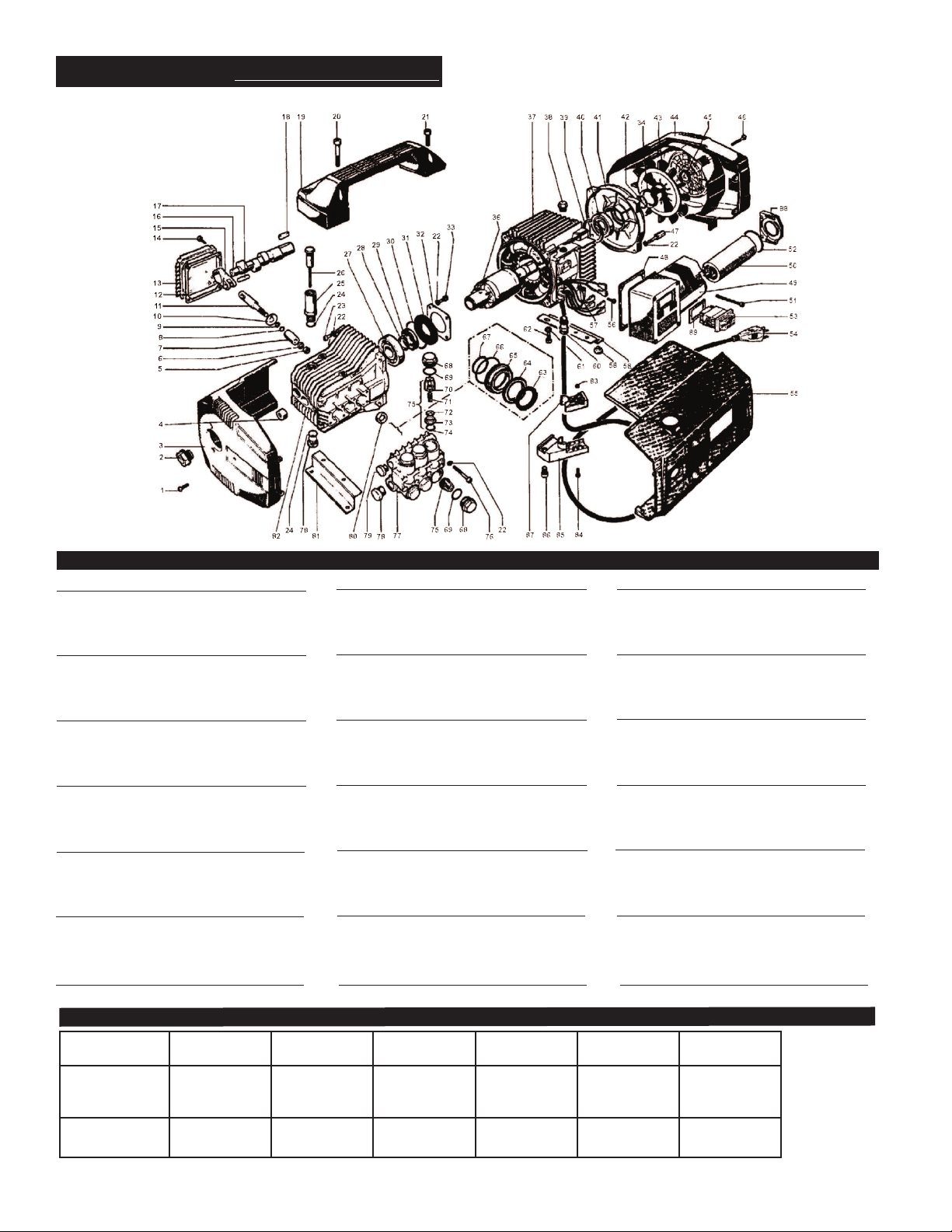

ITEM PART N . DESCRIPTI N QTY

1. 99157000 Screw, M5 x 16 6

2. 97596800 Indicator, Oil 1

3. 51230151 Cover 1

4. 91801400 Bearing, Needle 1

5. 92221600 Nut, M8, SS 3

6. 96700800 Washer, M8 3

7. 51040009 Piston, dia. 15mm 3

8. 90357200 O-ring,.208 x .070 3

9. 90502200 Ring, Back-up, 6.2x9x1.5 3

10. 96707000 Washer, M9 3

11. 51050056 Guide, Piston 3

12. 51210184 Cover, Gasket 1

13. 51160322 Cover, Crankcase 1

14. 99186700 Screw, M6 x 18 4

15. 51030022 Rod, Connecting 3

16. 51020435 Crankshaft 1

17. 97731000 Pin, Connecting Rod 3

18. 91487800 Key 1

19. 51240051 Handle 1

20. 99314400 Screw, M8 x 50 2

21. 99306900 Screw, M8 x 25 2

22. 96693800 Washer, M6, 4, Schnoor 20

23. 99189700 Screw, M6 x 25 4

24. 90383300 O-ring, .549 x .103 2

25. 51210051 Spacer, Oil Dipstick 1

26. 98209700 Oil Dipstick 1

27. 91832800 Bearing, Ball 1

28. 90063500 Circlip 1

29. 90163400 Ring, Oil Seal 1

30. 90409700 O-ring, 2.187 x .139 1

ITEM PART N . DESCRIPTI N QTY

31. 50211551 Spacer, Crankcase 1

32. 50150074 Cover, Crankcase 1

33. 99180700 Screw, M6 x 10 4

34. 90165200 Seal, Oil 1

36. 41340702 Rotor 1

37. 41328602 Housing 1

38. 98209300 Plug, 3/8-19 BSPP 1

39. 90079500 Ring, Dia. 52mm 1

40. 91832300 Bearing, Ball 1

41. 41070022 Cover, Rear Motor 1

42. 90385700 O-ring, .937 x .103 1

43. 41030051 Fan, Motor 1

44. 51230051 Cover, Motor 1

45. 90062800 Clip, Retainer 1

46. 99165800 Screw, M5 x 45 4

47. 41210465 Screw 4

48. 41210147 Gasket 1

49. 41212451 Cover, Switchplate 1

50. 93568800 Capacitor 1

51. 99170600 Screw 4

52. 90388600 O-ring, 1.799 x .103 1

53. 93503100 Switch 1

54. 10710801 Cable 1

55. 51230751 Caver 1

56. 99151500 Screw, M5 x 12 1

57. 96691300 Washer, M5.3x9x.6 1

58. 51200374 Rail, Mounting 1

59. 98192400 Plug 4

60. 93521000 Nut, Cable Fitting 1

ITEM PART N . DESCRIPTI N QTY

61. 96701400 Washer, M8.4, Schnorr 4

62. 99303700 Screw, M8 x 16 4

63. 51100051 Ring, Head 3

64. 90261800 Packing 3

65. 51080070 Retainer, Packing 3

66. 90360400 O-ring, .989 x .070 3

67. 90383500 O-ring, .593 x .103 3

68. 96221800 Plug, Valve, M24 6

69. 90384700 O-ring 6

70. 36200251 Guide, Valve 6

71. 94737600 Spring 6

72. 36200176 Plate, Valve 6

73. 36200366 Seat, Valve 6

74. 90384100 O-ring, .674 x .103 6

75. 36703201 Unit, Valve 6

76. 99194300 Screw, M6 x 40 6

77. 51120022 Manifold, Aluminum 1

51120041 Manifold, Brass 1

78. 98210000 Cap, 3/8-19 BSPP 2 .

79. 98204100 Cap, 1/4-14 BSPP 1

80. 90156500 Seal, Oil 3

81. 51200274 Rail, Mounting 1

82. 51010322 Crankcase 1

83 92192600 Nut, M4 2

84. 99130600 Screw, M4 x 16 2

85. 41211851 Holder, Cable 1

86. 99303900 Screw, M8 x 16 1

87. 41211951 Clamp 1

88. 41212051 Cover, Swichbox 1

89. 41212684 Gasket 1

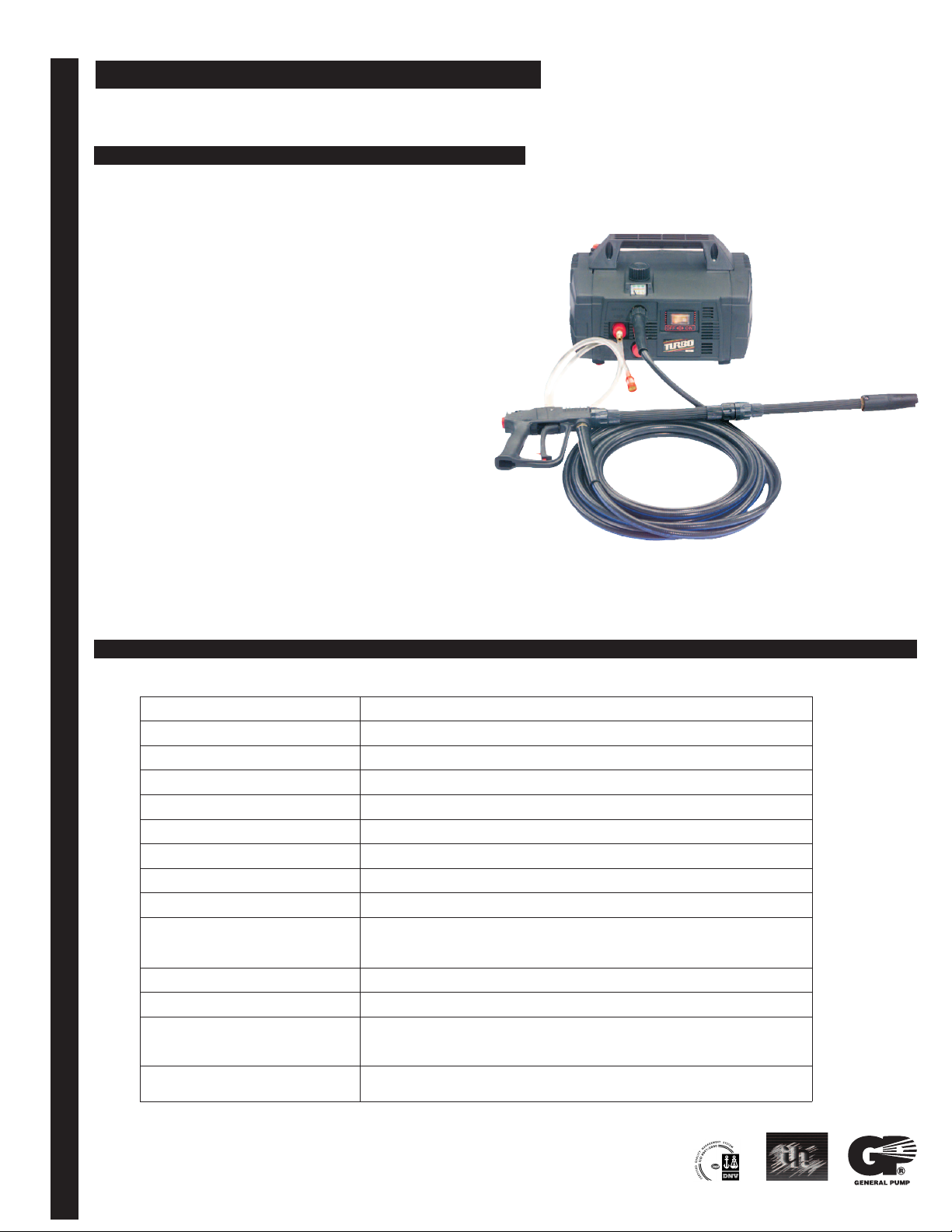

Turbo 21 Boxjet

GENERAL PUMPA member of the Interpump Group

PARTS LIST

Electric Pressure Washer

REPAIR KITS

KIT NO. 1 83 84 85 86 87

ITEM NO’S

INC UDED

IN KIT

70, 71, 72,

73, 74, (75) 80 68, 69 63, 64, 65,

66, 67 65, 66, 67 63, 64,

66, 67

NUMBER OF

ASSY’S

IN KIT

6 3 6 1 3 3