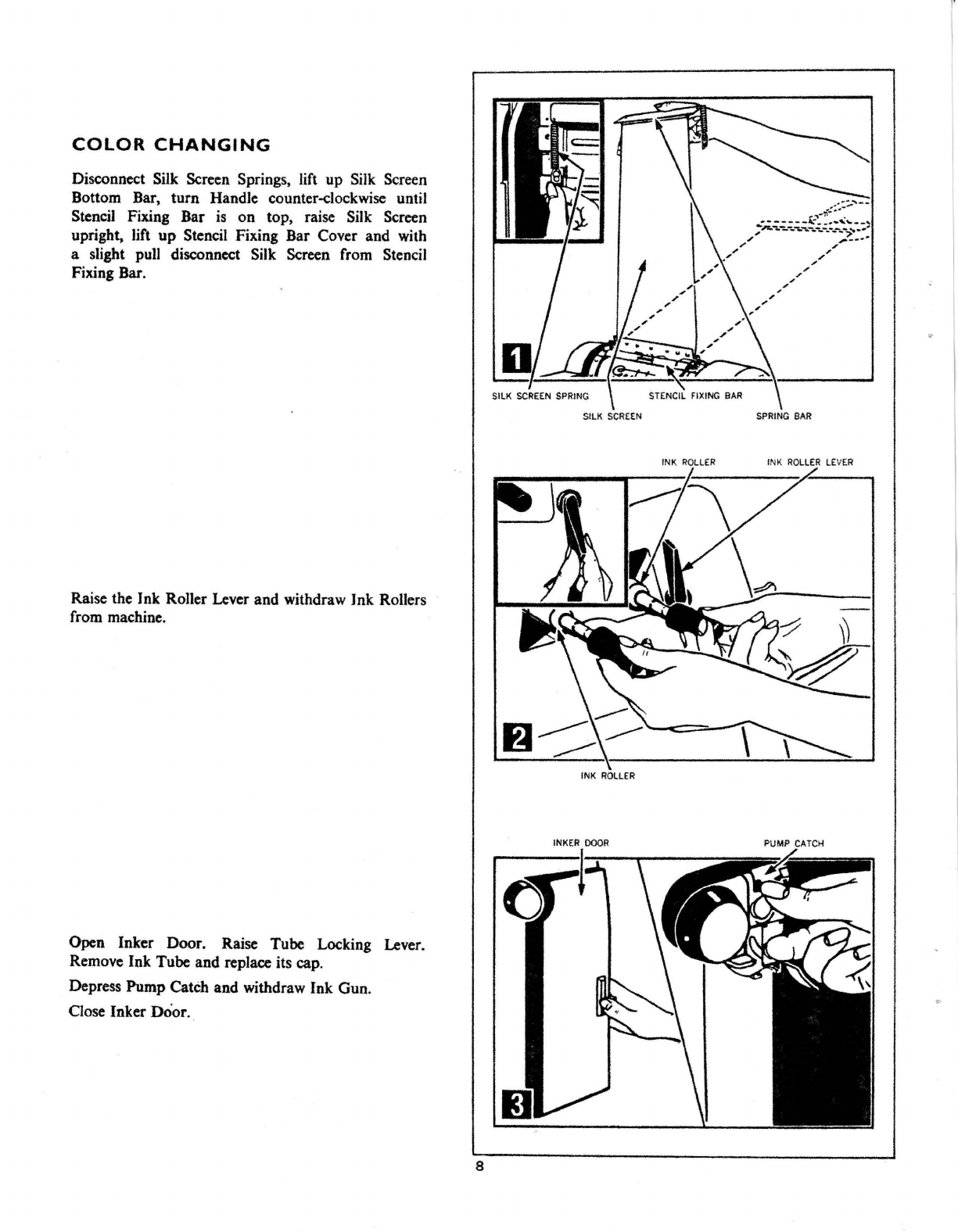

Depress

Proofing Button, turn Handle slowly one

complete revolution clockwise and release Proofing

Button.

Tum

Handle to its top position,

tum

back Backing

Sheet and check that the copy

is

uniformly inked.

If

necessary repeat the operation.

When the copy

is

uniformly inked, hold bottom

edge

of

Backing Sheet, raise it slightly outwards

and turn the Handle counter-clockwise to its bottom

position. Remove Backing Sheet

by

tearing it off

along

pcrf

orated line.

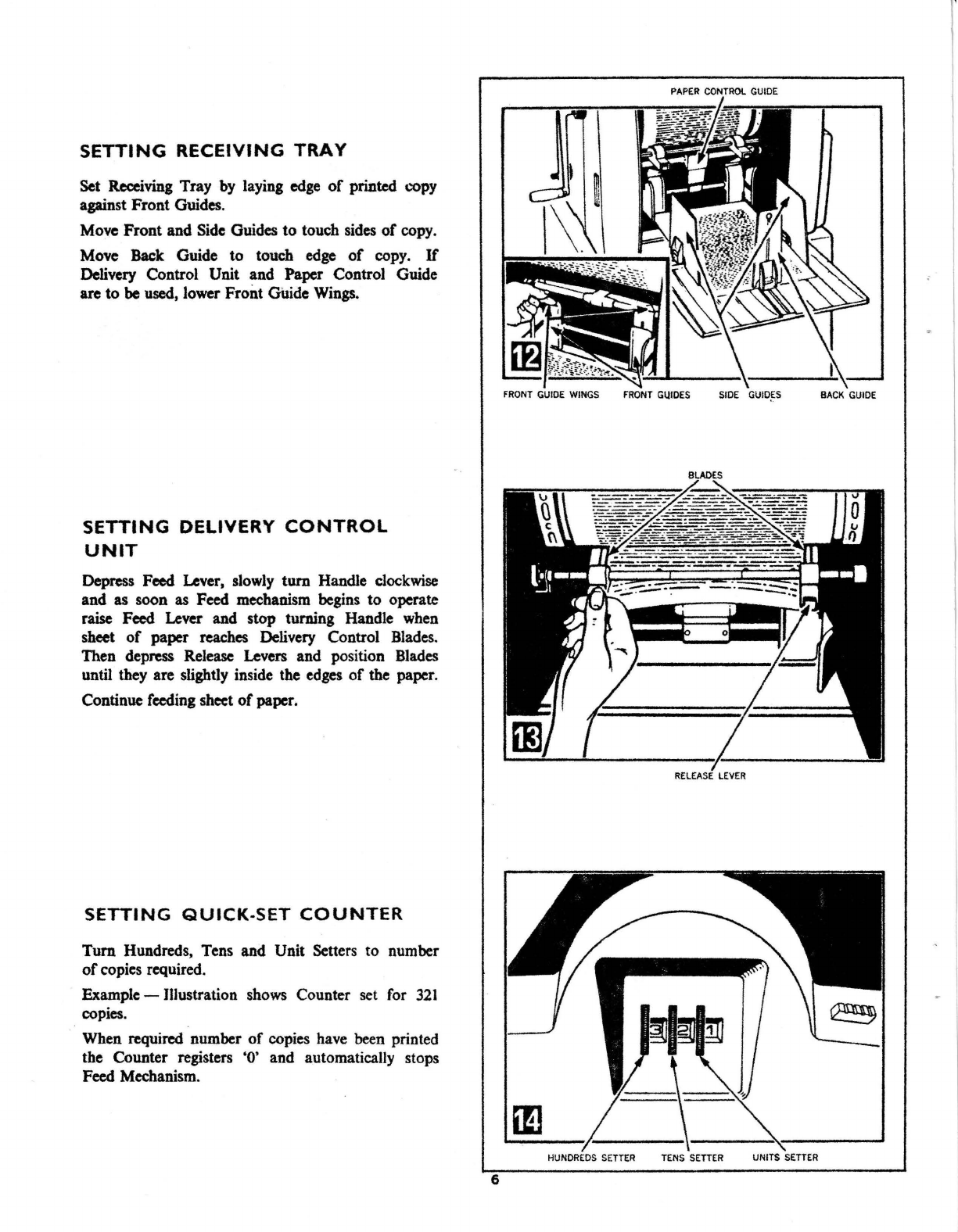

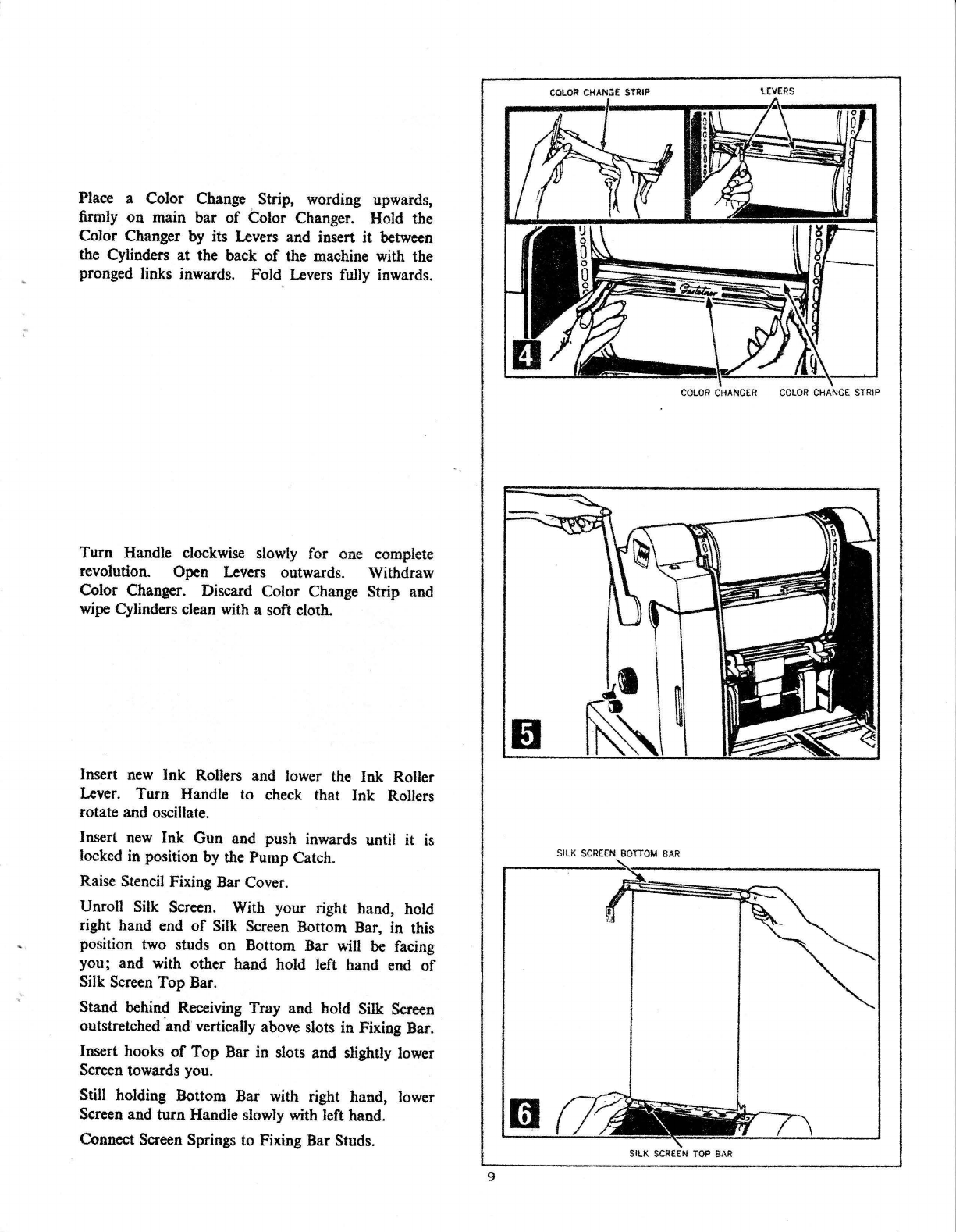

PREPARING

RECEIVING

TRAY

AND

FEEDBOARD

Raise Back and Side Guides

of

Receiving Tray and

move them fully outwards.

Slacken Side Fence Knobs and move Side Fences

fully

outwards. Pull Back Fence fully to rear

of

Feedboard.

Fan out paper and square it up to original state.

Then place on Fecdboard fully forward;

use

Feed-

board Scales to position stack in relation to subject

matter on stencil.

NOTE: Never place more paper on Feedboard

than

will

fit

easily under Paper Height Stop.

Move Side Fences to rest lightly against paper stack.

Tighten Side Fence Knobs.

Raise Back Fence and slide it towards paper stack

until it almost touches stack and rest Paper Weight

on paper.

NOTE:

For

quick reloading raise Paper Weight to

top position and lay Back Fence horizontal to

Feedboard.

4

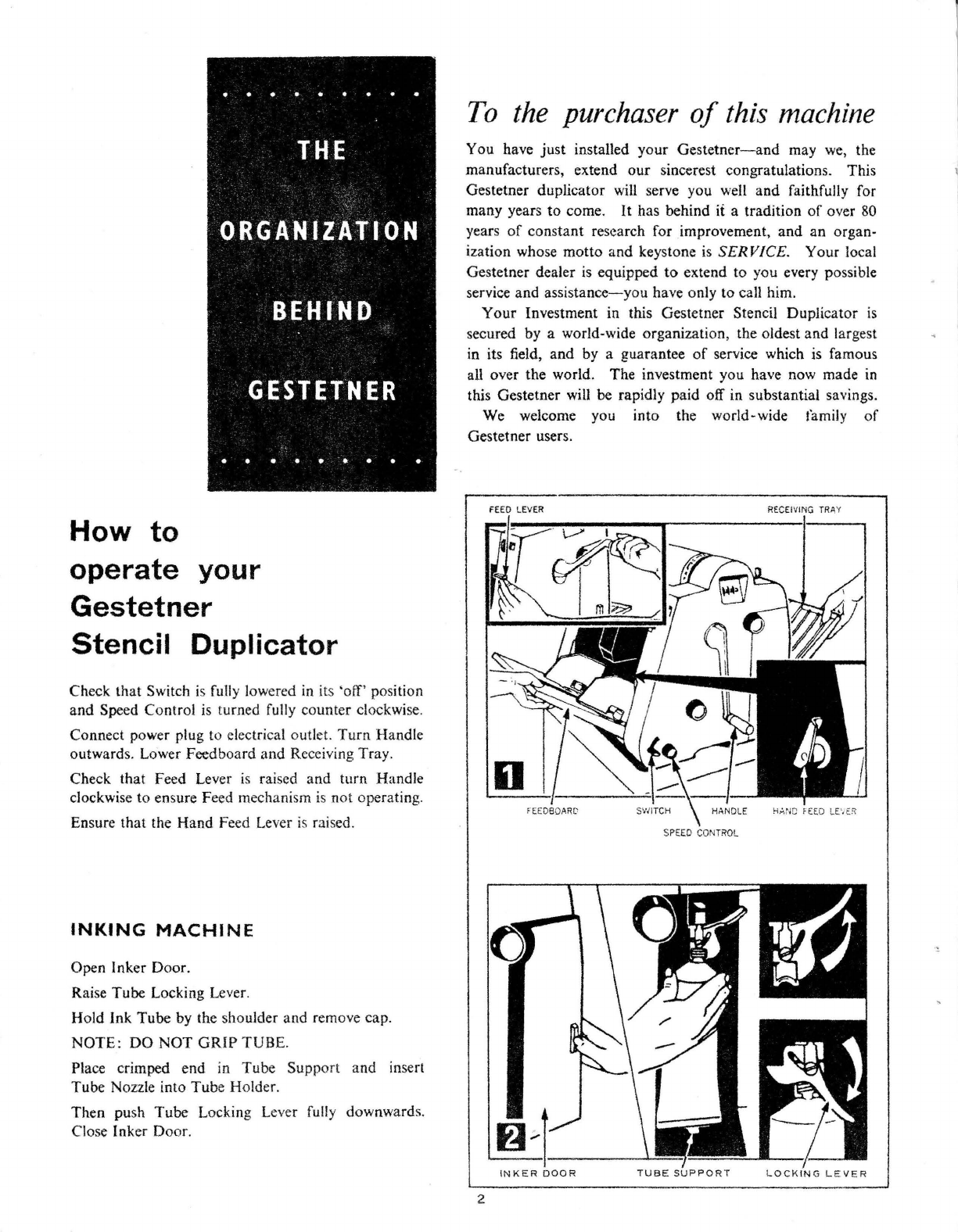

PROOFING

BUTTON

fJ--

S

IDE

GUIDES REC

EI

V

IN

G TRAY

BA

CK G

UIDE

PAP

ER

WEIGHT

BACK FE

NCE

~

.

_·

1-====illi

.......

~

,,,

-L_

//;';o-;;;;

~

(:]

SIDE

FENCE

S KNOB