M11517;9/57

- 9 -

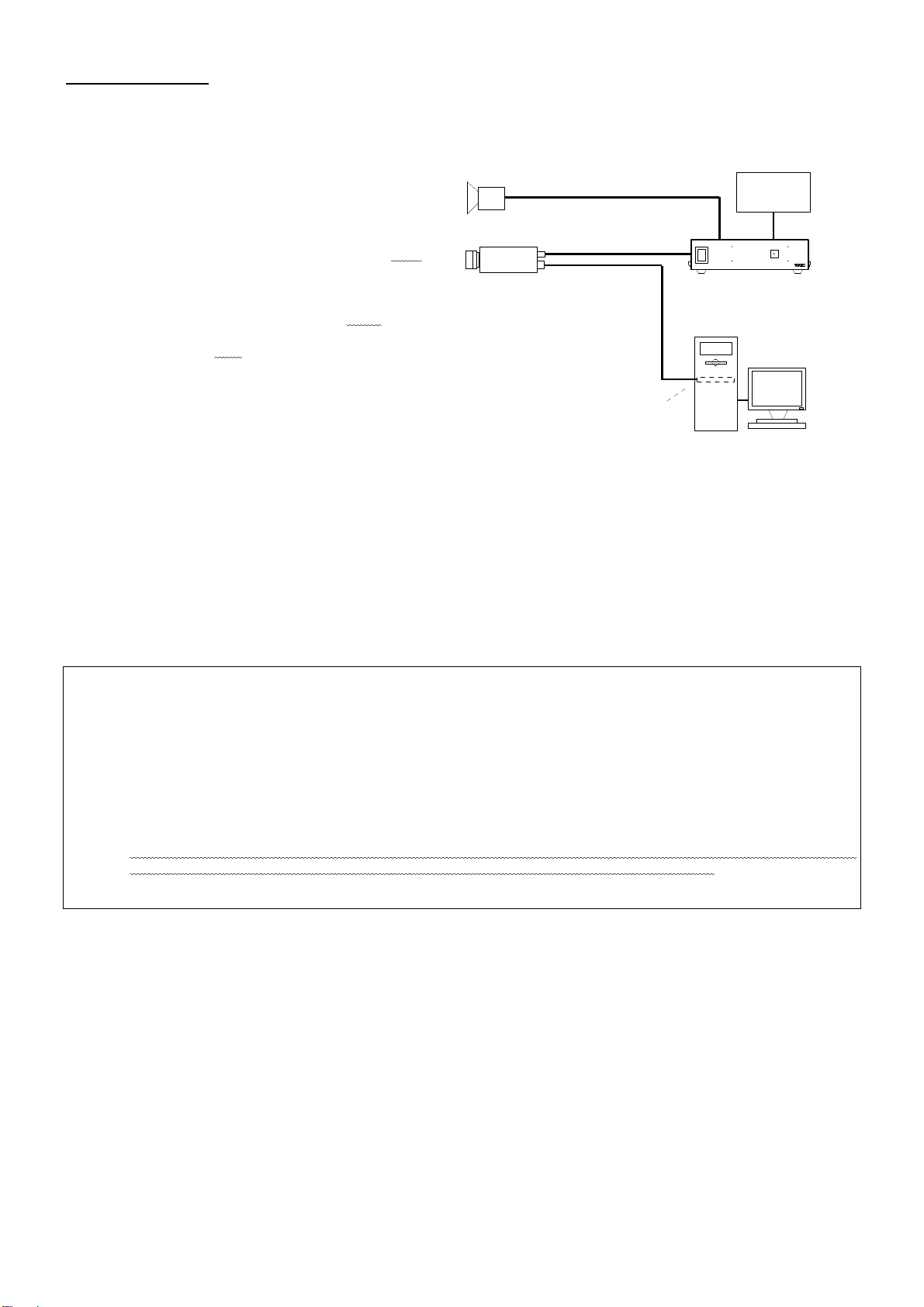

●Recommended timing of asynchronous shutter trigger signal (Vinit signal) for preset shutter/pulse width control

For the case of preset shutter mode

, the negative logic pulse is

applied within the width range from 1 H (1 horizontal synchronous

interval) to 1ms as described below.

For this

operation starts in synchronization with the trailing edge

the internal HD pulse

(the leading edge of pixel clock in the

case of H-reset mode)

after and closest to the trailing edge

timing of the applied pulse.

For the case of the pulse width control exposure mode,

value of

the L level interval of the input Vinit pulse (shown as Tvinit

in the figure) is retrieved in synchronization with the trailing edge

of the internal HD pulse (the leading

edge of pixel clock in the

case of H-reset mode)

, and the integer multiple number of H (1

horizontal synchronous interval) that is closest to the retrieved

Vinit pulse duration is transmitted as nH

number of pixel clock in the case of H-reset mode)

the camera. Then the shutter speed

is determined in response to

the time nH.

Vinit

Tvinit

[For the case of preset shutter mode]

1H ≤Tvinit ≤1ms

(The exposure time is independent of the Vinit width.)

[For the case of pulse width control mode]

(Where PWC=ENABLED, shutter switch = 9)

nH ≤Tvinit <(n+1)H (n is 1 or larger integer.)

(This is the pulse width where shutter exposure time =nH)

Recommended Vinit signal timing waveform

(Note) In the pulse width control, the shutter exposure time is almost equal to the integral multiple number of the

horizontal synchronous time (H) that is closest to the Vinit pulse duration. More specifically, however, the

shutter exposure time is indefinite for the time period corresponding to 1H width in the case of normal external

trigger input (or the case where the Vinit signal is not in synchronization with the horizontal synchronous

timing of the camera). It is improved by being employed in “with H-reset” mode

→Refer to the timing chart described in another section for the details.

(Note) When the shutter exposure time is too long in the pulse width control mode, the S/N ratio of the image will

be degraded due to the reduction of dynamic range of CCD, accumulation of thermal noise components of

CCD image sensor in proportion to the shutter speed and other factors. Therefore, if a long exposure time is

employed, it is recommended to conduct experiments using realistic exposure times in actual conditions to

check for the appropriateness.

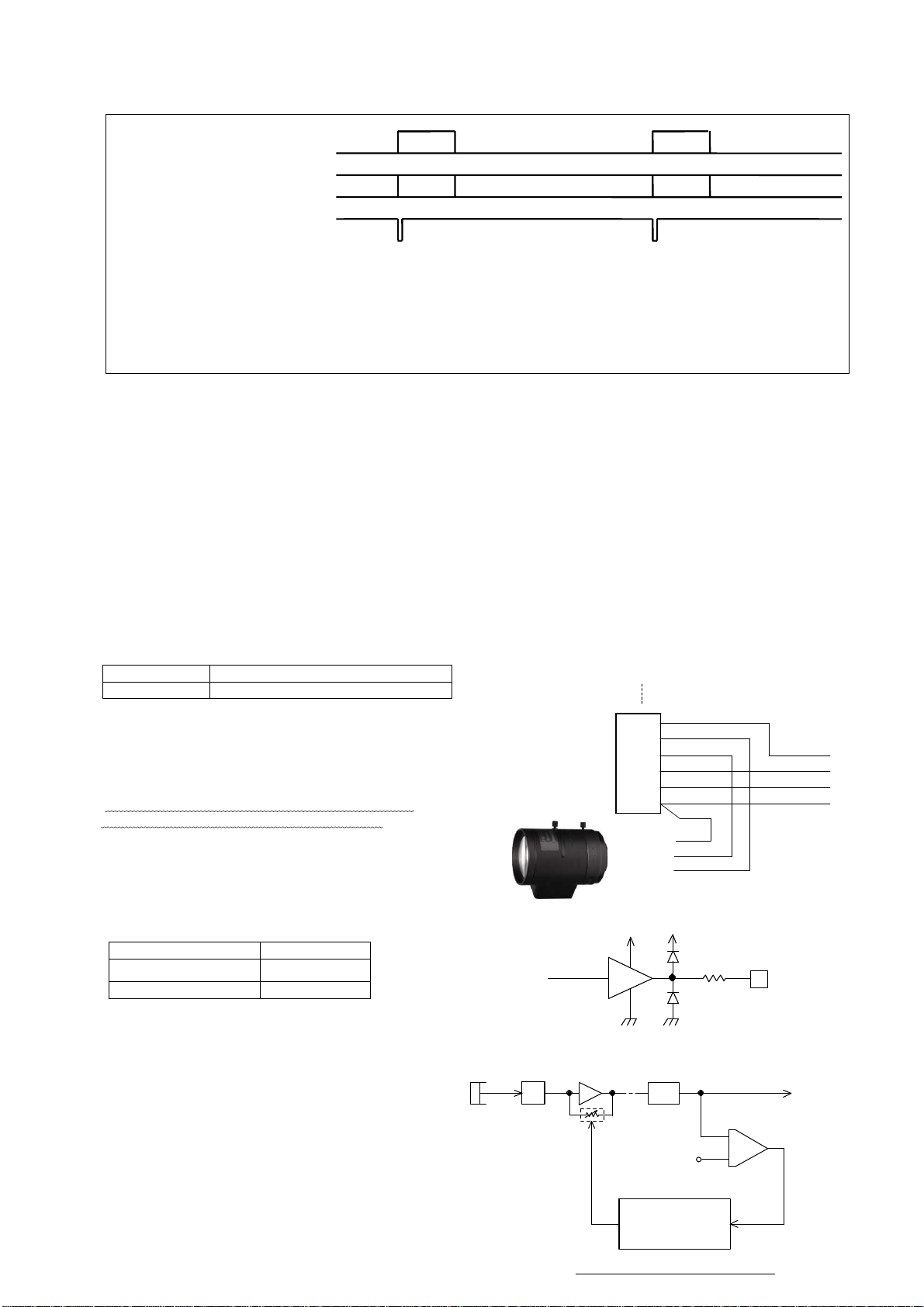

●Example of drive circuit for Vinit input circuit

* The Vinit signal should not include unnecessary noise components such as chattering.

[Input voltage range]

H level 2.5 to 5.5 V

L level -0.5 to 0.5 V

*

T

he voltage of the terminal end on camera side is required to be within the above voltage range with the camera being connected.

(4-5) Strobe signal (STRB)

It is able to adjust the light emitting timing of external strobe light to the exposure time of the camera.

This signal can be output in the continuous shutter mode as well as in the asynchronous shutter mode.

●Strobe signal output circuit

The signal output terminal is used both for strobe signal (STRB)

and busy (BUSY) signal.

Select any of OFF (Default: H level fixed), STRB and BUSY in

configuration setting.

→Refer to (7-5) Internal flag register and configuration register

The internal output circuit is shown in the right figure.

[output voltage range]

H level 3.0V (at 0mA) to 2.0 V (at 10mA)

L level 0.2V (at 0mA) to 0.5 V (at 10mA)

(!) The factory default is set to OFF for this camera.

It is required to set STRBC0 flag and STRBC1 flag when outputting STRB or BUSY signal,

●Output signal switching at strobe signal terminal

The signal from this terminal is set to OFF

as a factory default value.

This can be changed to STRB (Strobe timing

signal) or BUSY state by way of rewriting the

configuration register(CR) with serial

communication commands.

(CR5) and (CR6) correspond to STRBC0 and STRBC1, respectively.

(STRBC1,STRBC0)

Signal name Remarks

(0,0) OFF Always H level(Default)

(0,1) STRB Strobe timing

(1,0) BUSY Asynchronous shutter busy

100

5

STRB signal

or equivalent

internal circuit

Camera

connector

4

Vi ni t1 IN

VCC

4 7p

3.3 V

1 0k

T C7SH 14 FU o r equ ivalen t

To in te rn al c irc ui t

6.8V Z D

Trig ge r sign al v ia s eria l c o m m unic ation

Trig ger signal of inte rnal CPU origin

V C C is + 3.3V to +5 V

others

[Ex am p le of us e r circ u it]

Ins id e o f c am e ra